High-strength vanadium-containing high-manganese non-magnetic steel and production method thereof

A production method and high-strength technology, applied in the field of iron and steel smelting, can solve problems such as increasing production costs, and achieve the effects of high production efficiency, significant economic and social benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

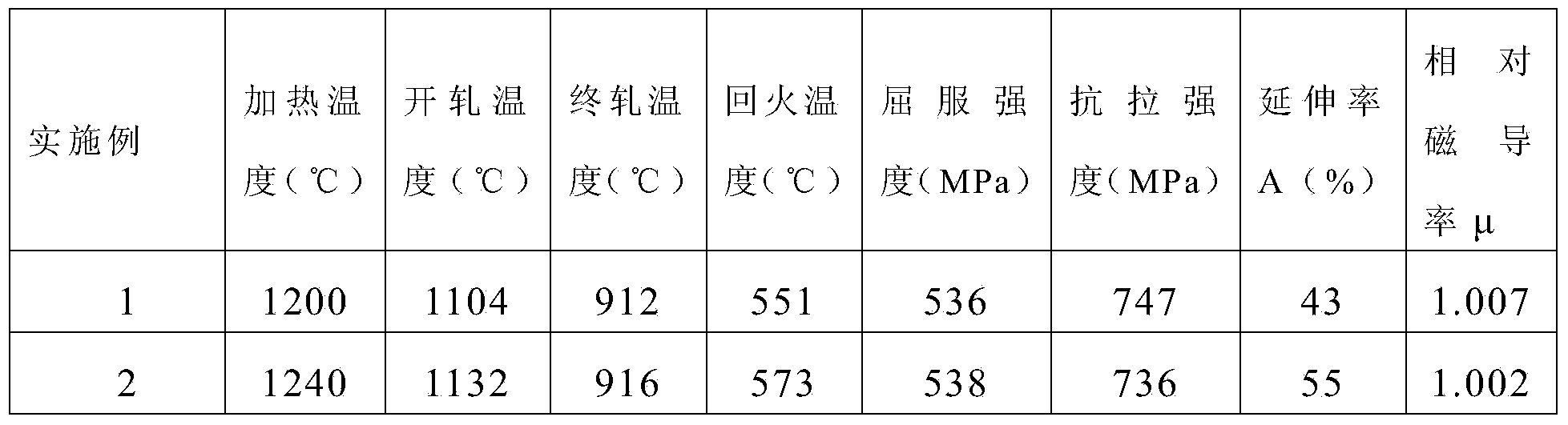

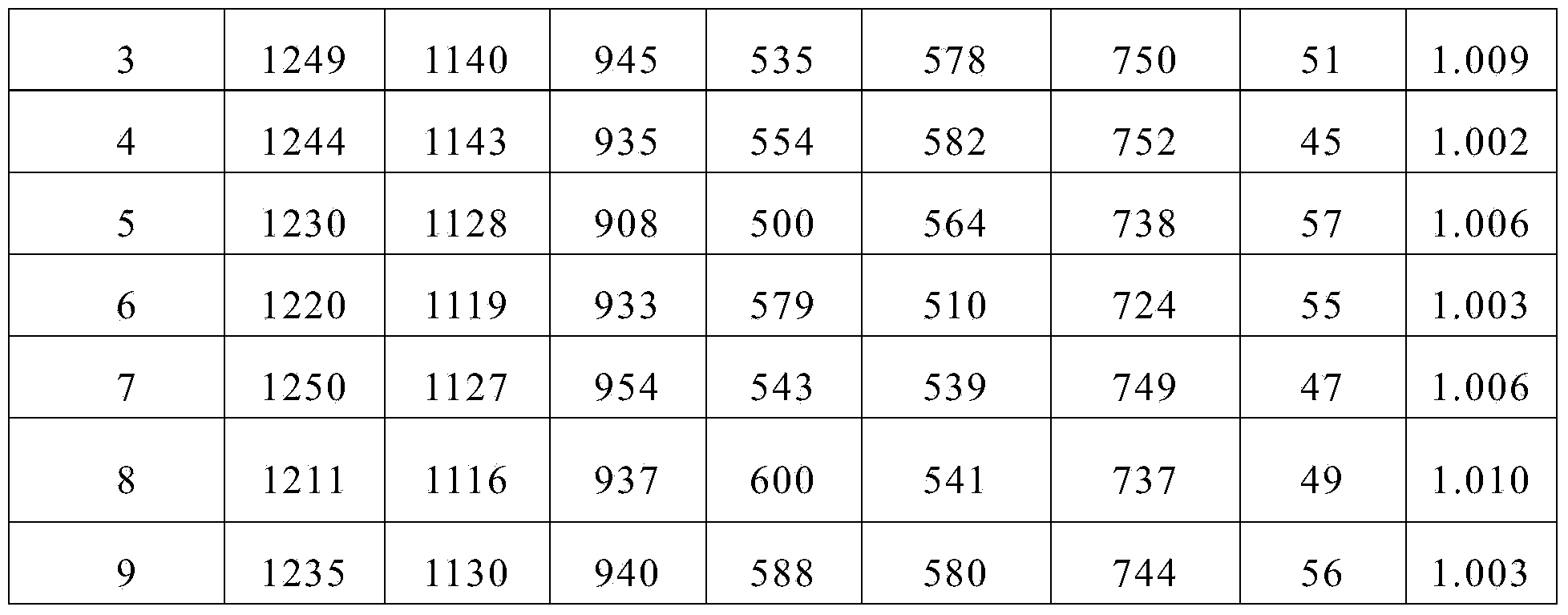

[0021] The high-strength vanadium-containing high-manganese non-magnetic steel of the present invention and its production method are described in further detail below in conjunction with specific examples:

[0022] The chemical composition of the high-strength vanadium-containing high-manganese non-magnetic steel selected in Examples 1-9 is shown in Table 1 by weight percentage (the balance is Fe and unavoidable impurities).

[0023] Table 1 Chemical composition (wt%) of each embodiment steel of the present invention

[0024] Example

[0025] Table 1 has listed 9 groups of the present invention and can be used for the concrete chemical composition of the required high-strength non-magnetic steel of projects such as transformer, generator, nuclear power, the production method of above-mentioned high-strength vanadium-containing high-manganese non-magnetic steel comprises the following steps: Carry out according to the usual pure steel process, including the steps of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com