Patents

Literature

48results about How to "Simple production operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

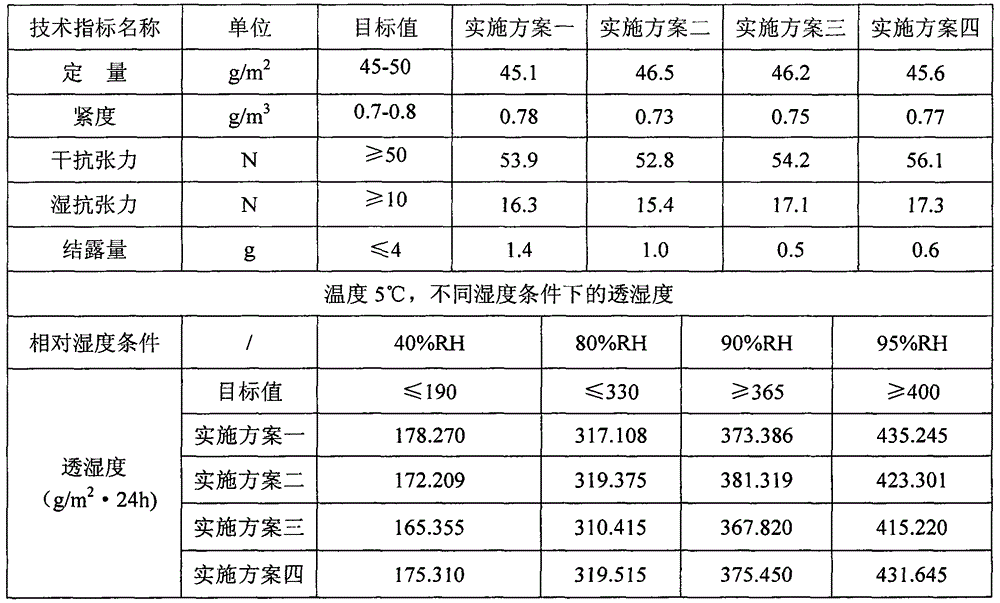

Method for manufacturing fruit and vegetable humidity-adjusting fresh-keeping film

ActiveCN105986511AReduce dosageSimple production operationWater-repelling agents additionReinforcing agents additionRefrigerated temperatureFruits and vegetables

The invention discloses a method for manufacturing a fruit and vegetable humidity-adjusting fresh-keeping film. Body paper is prepared through papermaking by means of plant fiber as the raw material and by adding a proper wet strength agent and a proper dry strength agent. The body paper is prepared into the humidity-adjusting fresh-keeping film by coating a mixed glue solution composed of a hydrophilic water-retention natural high-molecular polymer and a water-insoluble, safe and environment-friendly mildew-proof antibacterial agent. The manufacturing method is environmentally friendly and simple, and the special humidity-adjusting fresh-keeping film is used for a fruit and vegetable box with a fresh-keeping function and a refrigerator with the fresh-keeping fruit and vegetable box. The fruit and vegetable humidity-adjusting fresh-keeping film can make fruits and vegetables in the fruit and vegetable box hold moisture and kept fresh when relative humidity is small, moisture permeability is remarkably increased when relative humidity is large, and condensation and rotting are prevented. The humidity-adjusting fresh-keeping film can be completely and naturally degraded.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

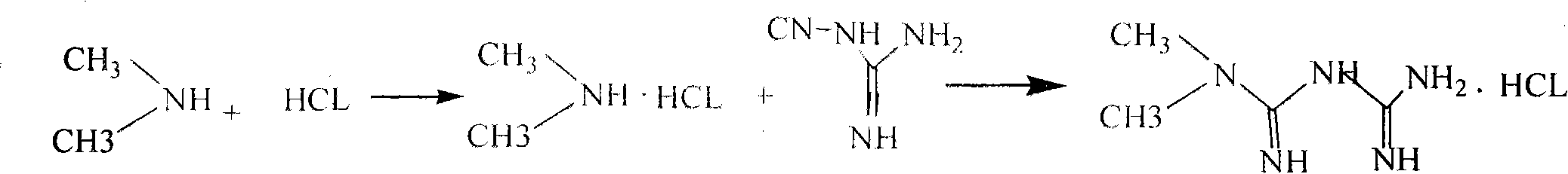

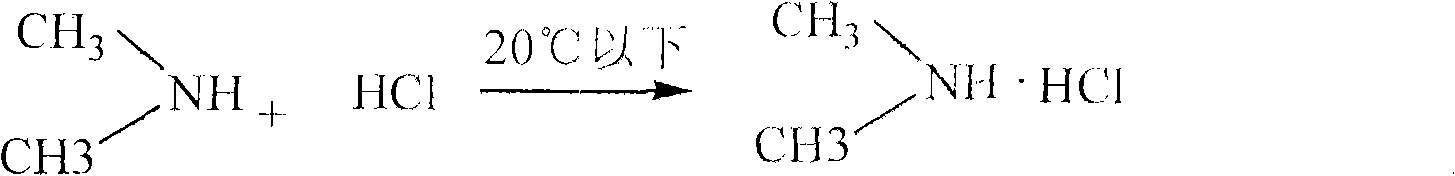

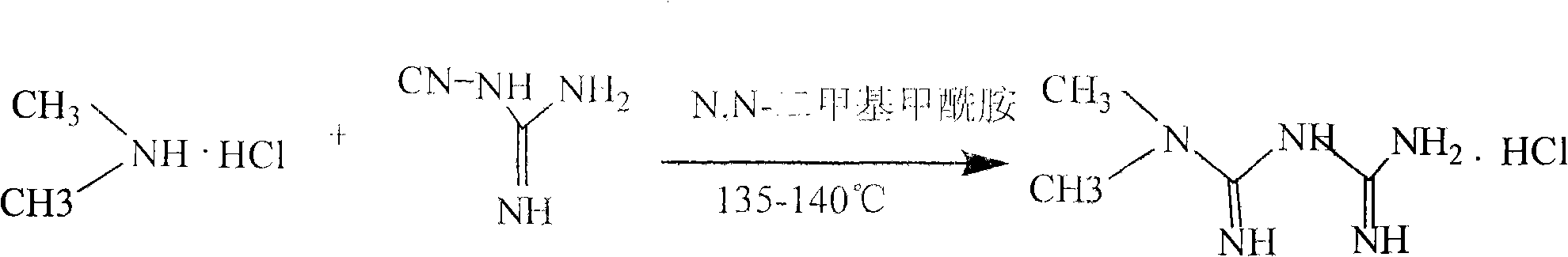

Preparation method of metformin hydrochloride

InactiveCN102516130ASimple production operationHigh purityOrganic chemistryOrganic compound preparationDimethyl formamideMetformin Hydrochloride

The invention discloses a preparation method of metformin hydrochloride. The method comprises: taking 40% dimethylamine as a starting material, which is subjected to a salification reaction with hydrochloric acid salt forming reaction of dimethylamine hydrochloride, subjecting the dimethylamine hydrochloride and dicyandiamide to an addition reaction in solvent N, N-dimethylformamide so as to generate a metformin hydrochloride crude product, then conducting refining, thus obtaining metformin hydrochloride. The solvent of the invention has viscosity insusceptible to temperature, and is easy to be separated from the product. Besides, the solvent can dissolve the reactant dicyandiamide, and even if dicyandiamide is not fully reacted, it cannot be separated out during separation of the product and the solvent, so that the production operation can be easier, and the purity of the final product can be very high. The method of the invention has the advantages of simple and easy production operation, high raw materialutilization rate, and cheap as well as easily available solvent, the market price of which is 2-3 times lower than prices of solvents in prior, and the synthesis cost is reduced by about 30%, so that the preparation method of the invention is very suitable for industrial production of metformin hydrochloride.

Owner:赤峰万泽药业股份有限公司

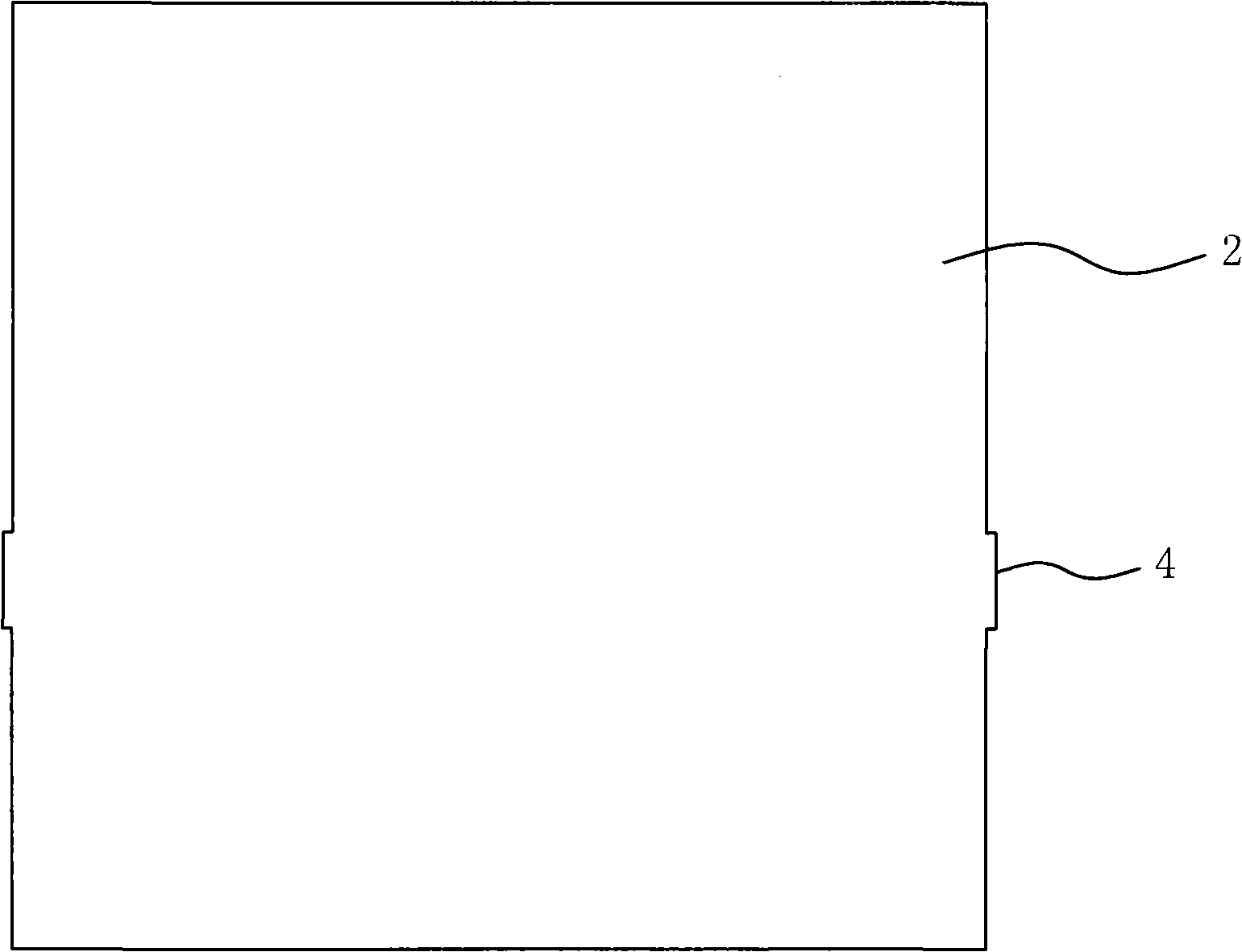

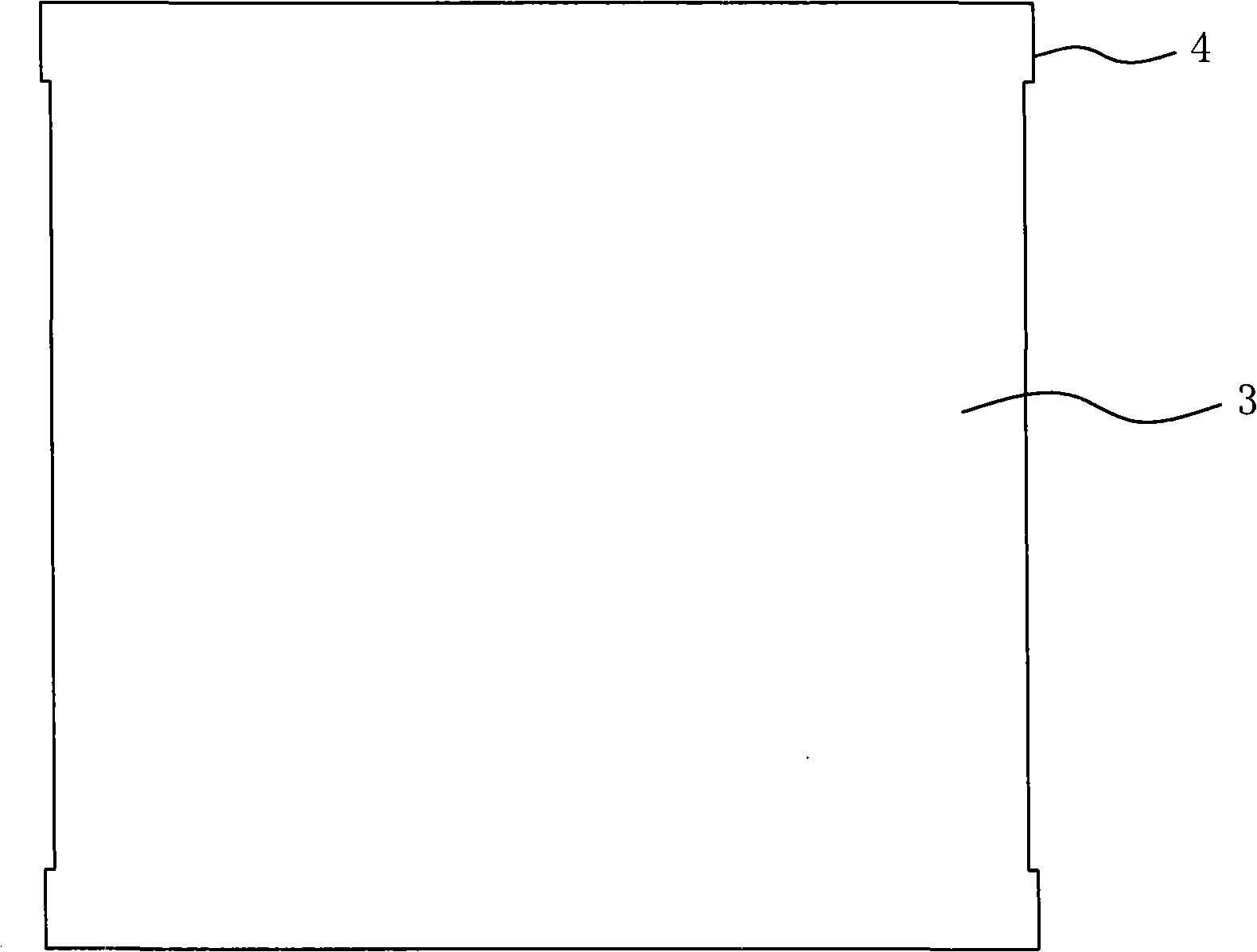

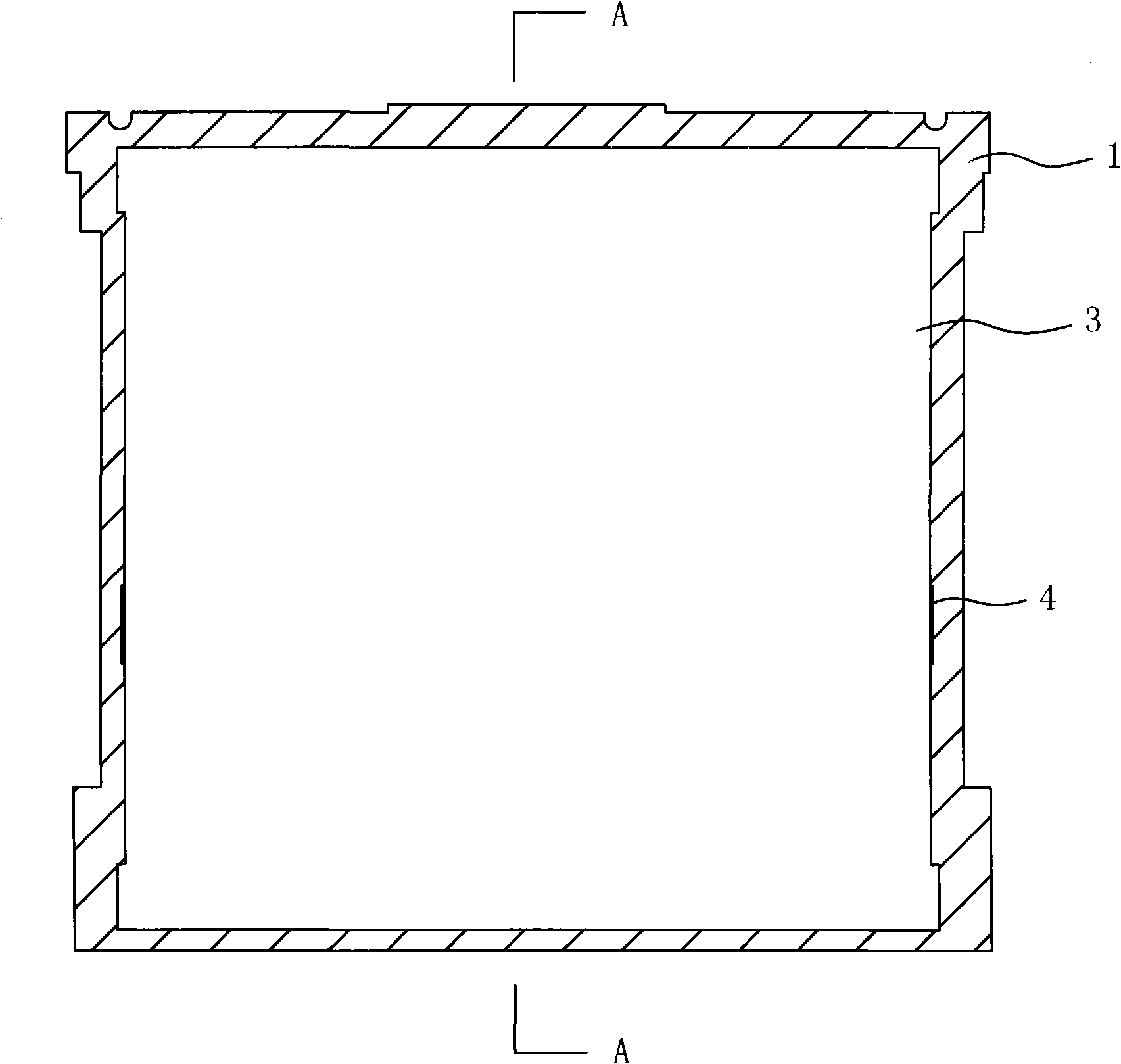

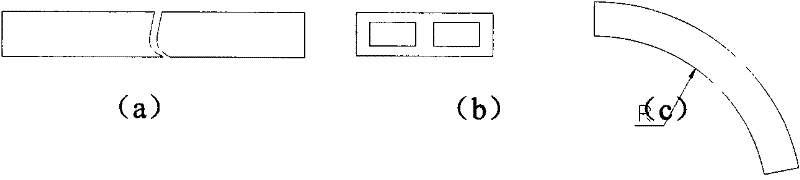

Three-layer combined optical film piece

InactiveCN101271222ASimple production operationReduce defective rateLayered productsNon-linear opticsAutomatic processingOptoelectronics

The invention discloses a composite optical membrane which comprises protecting films, optical membrane layers and a shading double-side adhesive tape layer, and the surrounding of the shading double-side adhesive tape layer is an annular stickiness part with the middle forming a transparent part. The invention is characterized in that: the hierarchical structure of the composite optical membrane consists of a first protecting film, the shading double-side adhesive tape layer, a first optical membrane layer, a second optical membrane layer and a second protecting film which are orderly overlapped. The first optical membrane layer is larger than the transparent part but less than the second optical membrane layer; and the surrounding is jointed with the stickiness part. The second optical membrane layer is less than the shading double-side adhesive tape layer, and the surrounding part of the second optical membrane layer exceeding the first optical membrane layer is jointed with the stickiness part of the shading double-side adhesive tape layer. The invention uses the stickiness of the shading double-side adhesive tape layer to directly compound each layer of membrane together by an automatic processing device, which is different from prior complex production process, ensures the more reliable performance of a backlight module and improves the production efficiency.

Owner:普胜科技电子(昆山)有限公司

Method for producing wax with co-cracking of multiple plastics and resins

InactiveCN101402697AGood overall performanceSimple production operationPlastic recyclingDistortionWax

The invention discloses a method for preparing wax from multiple plastic resins by copyrolysis. Raw material of polyolefin is put into a reaction kettle; the reaction kettle is vacuumized and then filled with nitrogen until the pressure reaches 100kPa; raw material in the kettle is heated by a method of oil-bath or infrared ray until the raw material comes to a total fusion; the temperature is controlled between 300 DEG C to 450 DEG C and maintained constant for 0.5 hour to 10 hours; heating is stopped, the temperature is reduced below 200 DEG C and the raw material which is the wax is discharged; and the performance of the product is tested. The method has the advantages of high heat distortion point, high rigidity, high tenacity, lubricating property, wet fastness and the like; and the method also has simple production operation and wide application.

Owner:上海五将化工科技有限公司

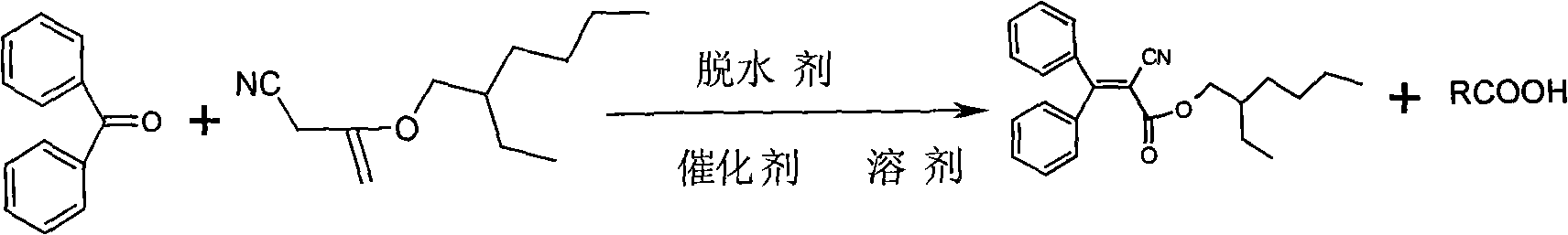

Method of preparing Octocrilene

InactiveCN101492394ASimple production operationLow manufacturing costCosmetic preparationsCarboxylic acid nitrile preparationSolventChemistry

The invention relates to a preparation method of Octocrilene. Iso-octyl cyanoacetate and benzophenone are used as raw materials. And under the function of catalysts, dehydrating agent is used in solvent for the reflux dehydration to obtain the Octocrilene. The molar ratio of iso-octyl cyanoacetate to benzophenone is 1-2 to 1-5. The molar ratio of iso-octyl cyanoacetate to the dehydrating agent is 1-5 to 1-5. A practical Octocrilene preparation method is provided. The product yield is 95 percent and the purity is 99.5 percent.

Owner:南京寒武纪科技有限公司

Production method of hydrolysis resistance regenerating resin synthetic leather

ActiveCN103031737ASimple processSimple production operationSynthetic resin layered productsTextile/flexible product manufactureChemistryToluene

The present invention discloses a production method of hydrolysis resistance regenerating resin synthetic leather, including: stirring uniformly and filtering dimethylformamide and wet hydrolysis resistance paste; adding a mixture of dimethylformamide, a wet hydrolysis resistance additive and a surfactant and stirring uniformly, adding wet high hydrolysis resistance regeneration polyurethane resin to mix uniformly, filtering and defoaming to get a coating; stirring the dimethylformamide and the high hydrolysis resistance regeneration polyurethane resin uniformly and then adding the mixture of the surfactant, dimethylformamide and the wet hydrolysis resistance paste to stir uniformly to get an immersion liquid, feeding non-woven fabrics in the immersion liquid and then feeding into a quantitative roll, scraping the coating, solidifying to be film, extruding and washing, drying and fixing the shape, processing the color to get the wet base, uniformly scraping the high hydrolysis resistance dry polyurethane resin, dimethylformamide, toluene, butanone, dry hydrolysis resistance paste and the surfactant on release paper, and adhering the wet base to get the product. The synthetic leather of the present invention is soft in hand feel, good in flexibility, good in touch sense, and high in peel strength.

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

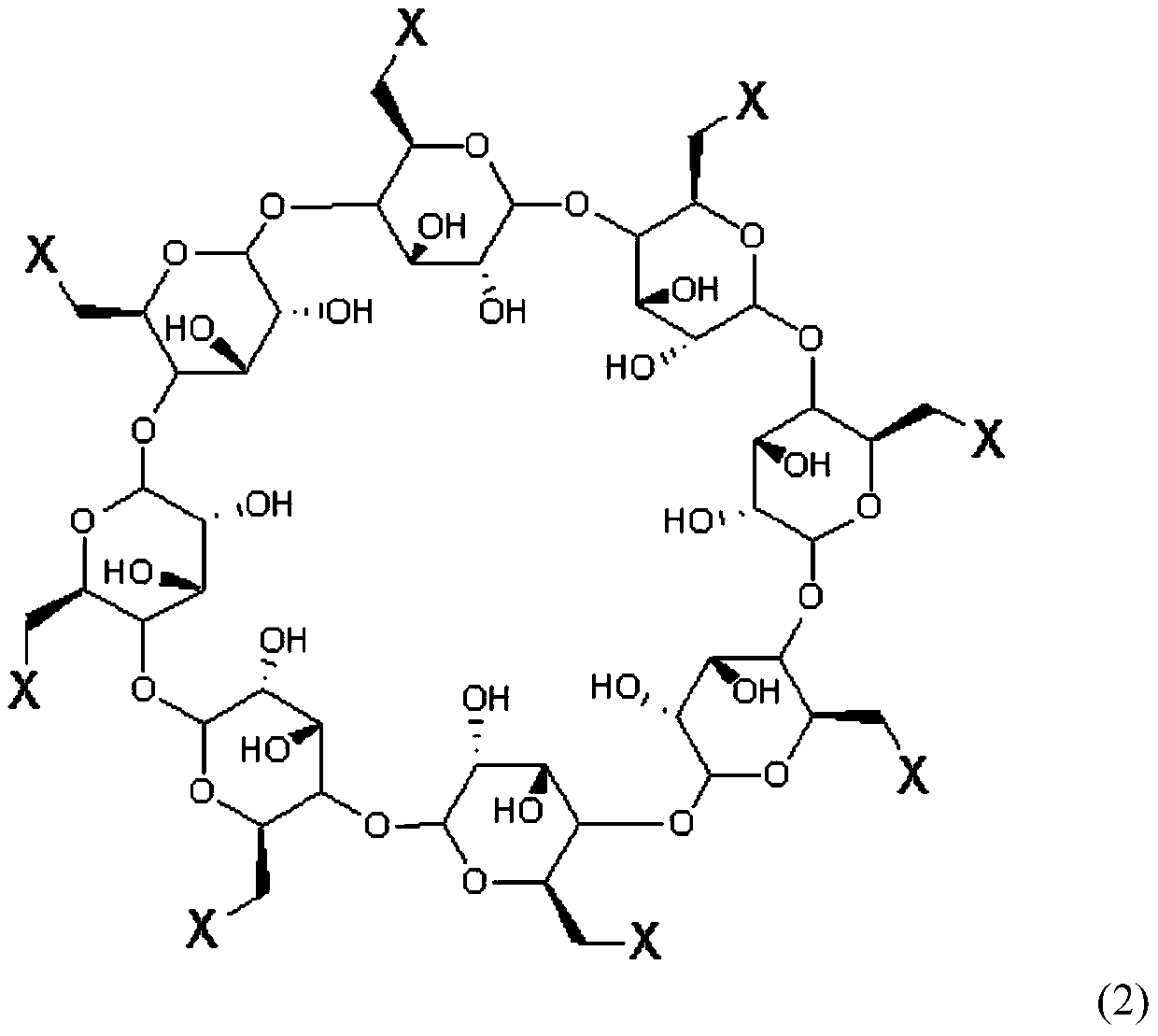

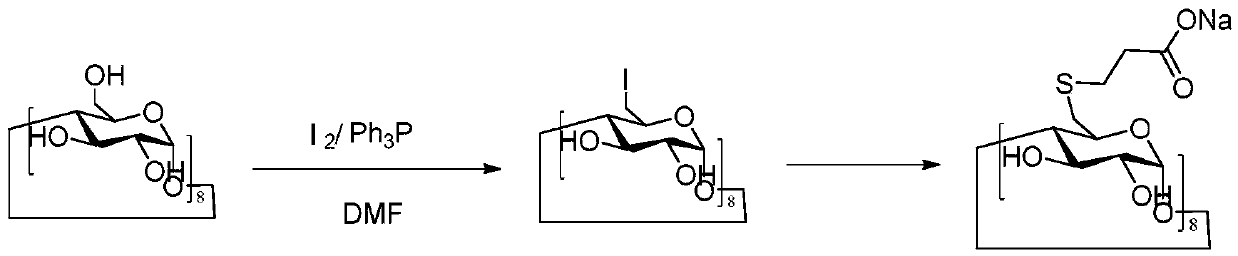

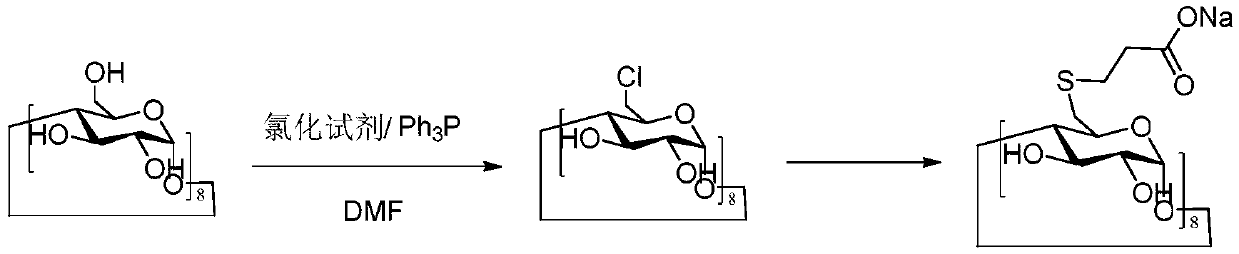

Method for preparing sugammadex sodium and sugammadex sodium intermediate

InactiveCN109879986AThe synthesis method is environmentally friendlySimple production operationGamma-cyclodextrinNeutral state

The invention relates to a method for preparing sugammadex sodium and a sugammadex sodium intermediate. The method comprises the following steps that a, gamma-cyclodextrin, a halogenating agent and triphenylphosphine react in N,N-dimethylformamide; after the reaction is completed, alkali is added into reaction liquid for regulating the pH value of the reaction liquid to reach a neutral state and then reach an alkaline state; then, water is added for separating out solid; filtering is performed; through pulping and washing, an intermediate of 6-deoxy-6-perhalogeno-gamma-cyclodextrin (2) is obtained; b, in an organic solvent, the formula (2) and 3-mercaptopropionic acid react under the alkaline condition to generate sugammadex sodium; c, the sugammadex sodium crude product is refined to obtain the sugammadex sodium.

Owner:陈文辉

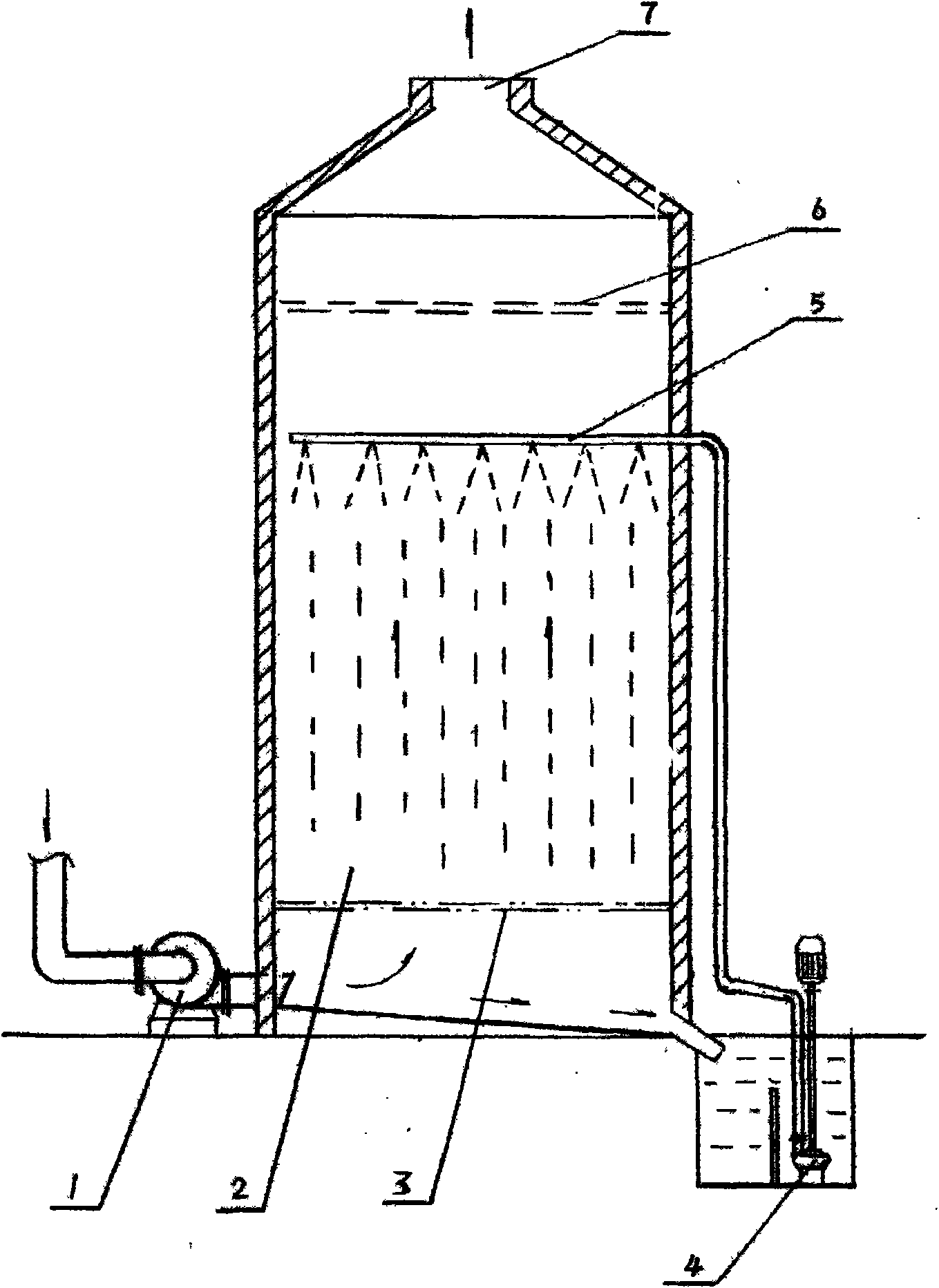

Continuous clean deodorizing method for activated sludge fermentation gas

InactiveCN101664635ASimple equipmentSimple production operationDispersed particle separationDeodrantsChemistryActivated sludge

The invention discloses a continuous clean deodorizing method for activated sludge fermentation gas, which pumps gas generated by the fermentation of the activated sludge into a liquid medicine washing tower by an exhaust fan, by using the liquid medicine for spray washing, emptying is realized after fermentation smell is removed, and the liquid medicine is circularly used by a pump, thus solvingthe problem that the activated sludge fermentation gas needs the continuous clean deodorizing, having the advantages of simple equipment, easy operation, and continuous, fast and clean removing odor generated by the fermentation of the activated sludge and the like, and being widely applied to deodorizing of the activated sludge.

Owner:罗健泉

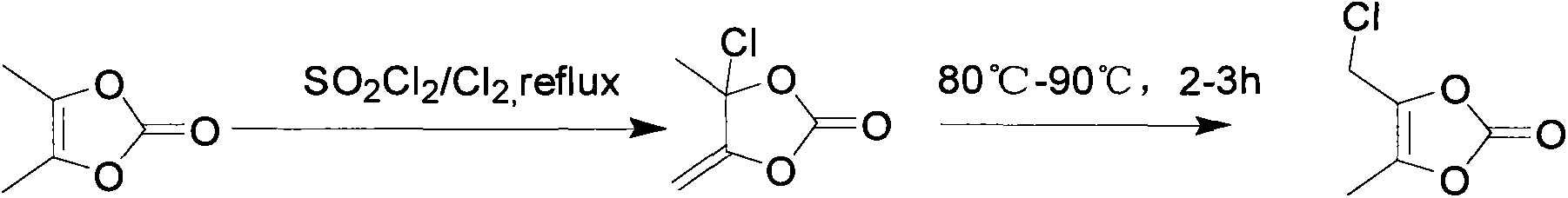

Purification method of 4-chloromethyl-5-methyl-1,3-dioxole-2-ketone

ActiveCN103864748ASimple production operationShorten the production cycleOrganic chemistrySolventButanol

The invention discloses a purification method of 4-chloromethyl-5-methyl-1,3-dioxole-2-ketone. The purification method comprises the following steps of dissolving a crude product of 4-chloromethyl group-5-methyl-1,3-dioxole-2-ketone into a mixed solvent of methyl alcohol, ethyl alcohol, isopropyl alcohol and tertiary butanol for crystallizing for 0-24 hours at a temperature of -10-0 DEG C, and filtering to acquire the 4-chloromethyl-5-methyl-1,3-dioxole-2-ketone. The purification method has the characteristics of low cost, good refining effect, high yield, low requirement on equipment and simplicity and convenience in operation and is suitable for industrial production.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

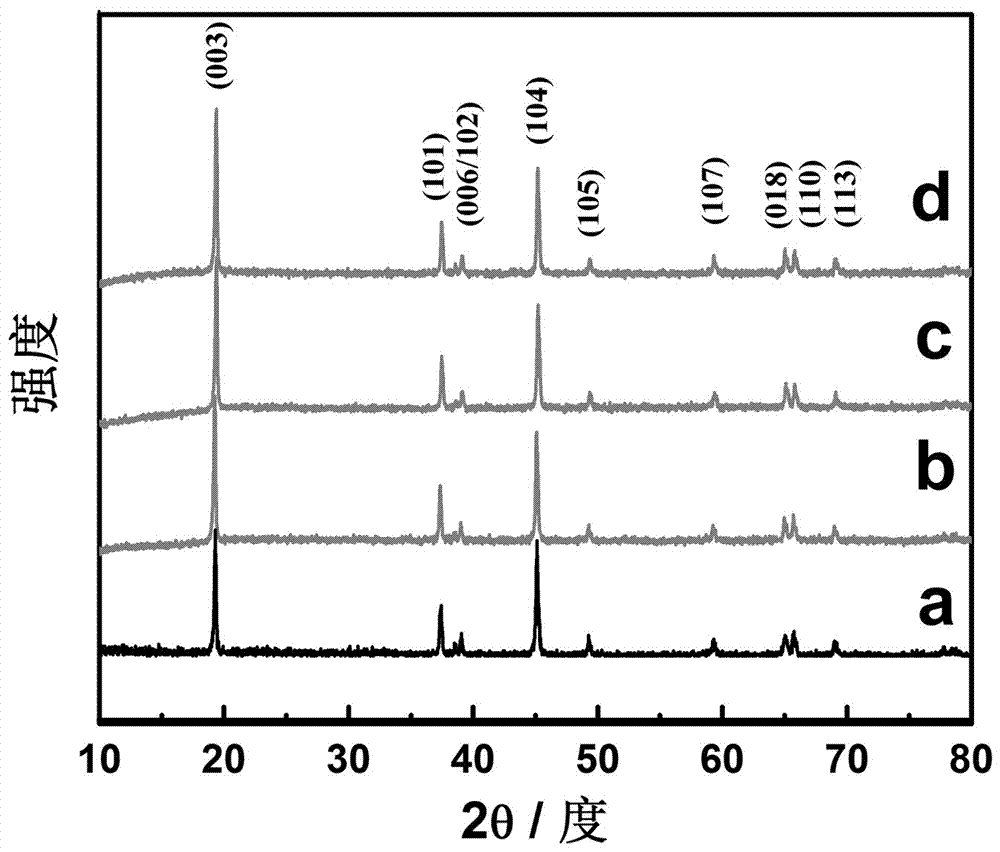

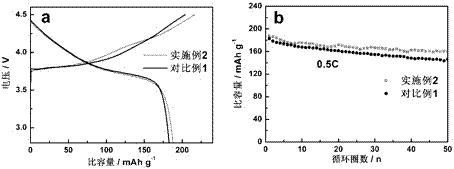

Method for preparing LiNi<1/3>Co<1/3>Mn<1/3>O<2> ternary cathode material

ActiveCN107342402ASimple production operationReduce manufacturing costCell electrodesSecondary cellsChemistryNitrogen gas

The invention provides a method for preparing a LiNi<1 / 3>Co<1 / 3>Mn<1 / 3>O<2> ternary cathode material. Specifically, the method comprises the steps of dropwise adding mixed solution of nickel salt, cobalt salt and manganese salt to NaOH solution, adding ammonia water as complex agent, carrying out stirring, and carrying out heat preserved reaction for 10-12 hours, thereby obtaining black suspension, and carrying out still standing, filtering, washing and drying to obtain precursor; carrying out ball-milling on the precursor and Li<2>CO<3> for 4-6 hours by taking anhydrous ethanol as medium, carrying out drying, carrying out sintering for 3-6 hours at the temperature of 400-500 degrees centigrade, and then carrying out sintering for 10-14 hours at the temperature of 850-950 degrees centigrade, and carrying out sieving to obtain the LiNi<1 / 3>Co<1 / 3>Mn<1 / 3>O<2> ternary cathode material. Compared with a traditional coprecipitation method, the preparation method provided by the invention has the advantage that nitrogen does not need to be imported, so the production cost is greatly reduced. According to the preparation method provided by the invention, in the process of synthesizing the precursor, a pH value of a reaction system does not need to be controlled strictly, namely, the pH value does not need to be adjusted by adding the ammonia water continuously in the process of synthesizing the precursor.

Owner:CHINA THREE GORGES UNIV +1

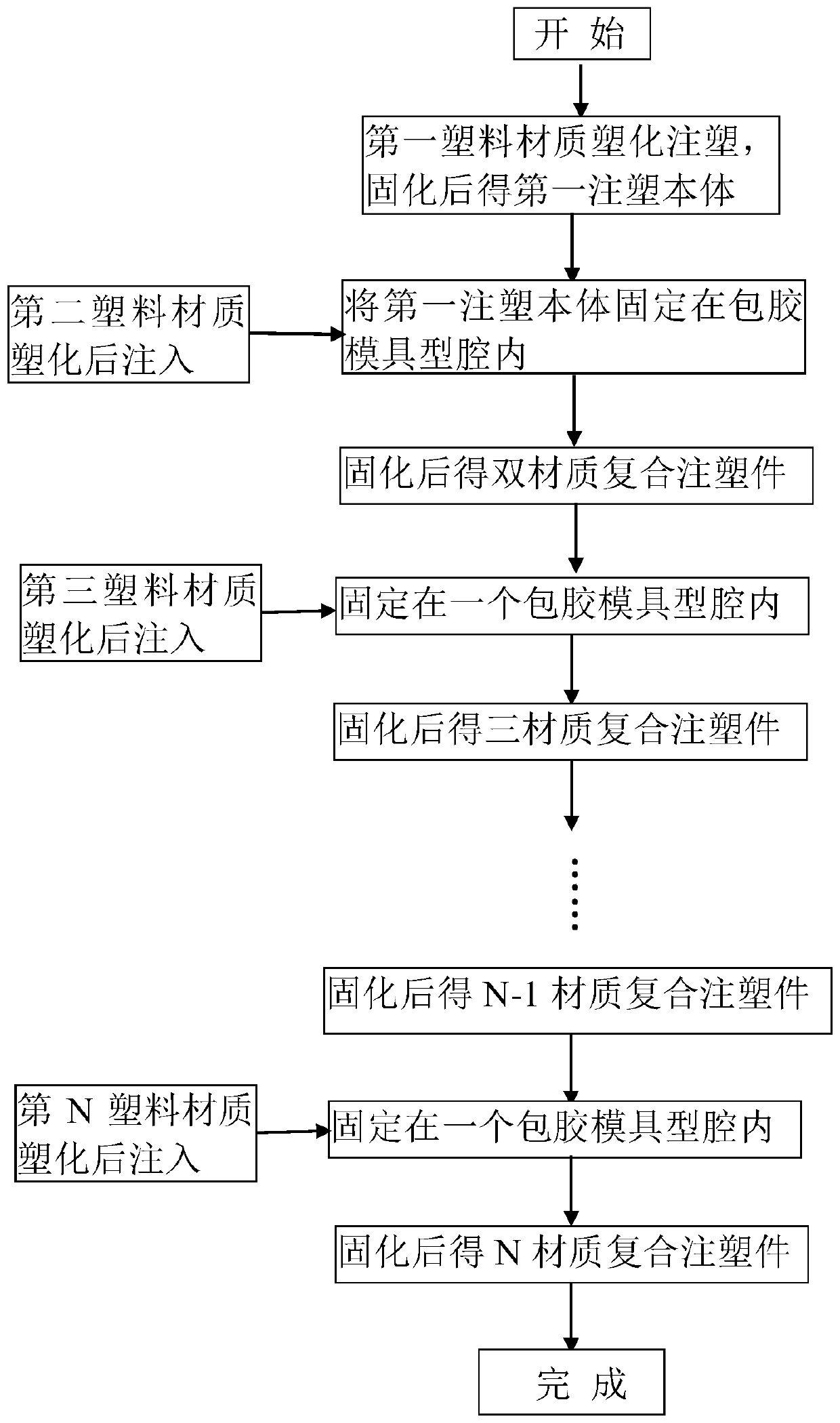

Multi-color multi-material injection molding method

InactiveCN110216838ASimple production operationReduce manufacturing costDomestic articlesMulti materialPlastic materials

The invention relates to a multi-color multi-material injection molding method. The method comprises the following steps of S1, selecting at least a first plastic material and a second plastic material as injection molding materials; S2, heating and plasticizing the first plastic material, injecting the first plastic material into a first mold cavity, and taking out the molded first plastic material to obtain a first injection molding body; S3, placing the first injection molding body into a second mold cavity and fixing the position of the first injection molding body; and S4, heating and plasticizing the second plastic material and then injecting the second plastic material into the second mold cavity, so that the melt of the second plastic material covers the local surface of the firstinjection molding body, and after cooling and curing molding are completed, taking out an obtained double-material composite injection molded part taking the first plastic material as a main body andthe second plastic material as a coating glue; and so on. According to the method, each time the injection molded part molded in the previous step is placed in a novel coating mold cavity for fixing,and the Nth plastic material is plasticized and injected into the mold cavity, so that a novel layer of coating glue is formed on the surface of the injection molded part molded in the previous step until products are completed. According to the method, the production process is simple; and the product is safer and healthier, is more stable in quality and higher in grade.

Owner:湖南桑尼森迪玩具制造有限公司

Method for preparing D, L-pantolactone through normal-pressure reduction

PendingCN111440133ASimple processSimple production operationOrganic compound preparationCarboxylic compound preparationOrganic basePantoic acid

The invention discloses a method for preparing D, L-pantolactone through normal-pressure reduction, and belongs to the technical field of vitamin production. The method comprises the following steps:(1) adding organic alkali into glyoxylic acid at 15-35 DEG C; (2) adding isobutyraldehyde, and performing heating until aldehyde condensation reaction to generate 2-hydroxy-3-methyl-3-formylbutyric acid; (3) adding a reduction catalyst into the aldehyde condensation reaction solution, and carrying out reduction reaction to generate pantoic acid; (4) adding acid to carry out intermolecular dehydration cyclization to generate D, L-pantolactone; and (5) neutralizing, extracting, concentrating and distilling the feed liquid of D, L-pantolactone to obtain a D, L-pantolactone product. The method comprises the following steps: after 2-hydroxy-3-methyl-3-formylbutyric acid is generated through an aldehyde condensation reaction, carrying out a normal-temperature and normal-pressure reduction reaction by using a reduction catalyst to generate pantoic acid, so that high-risk processes such as highly toxic raw materials and high-pressure hydrogenolysis are avoided, heavy metal impurities are prevented from being introduced by using a hydrogenolysis catalyst, and operation is safe.

Owner:内蒙古精晶生物科技有限公司 +1

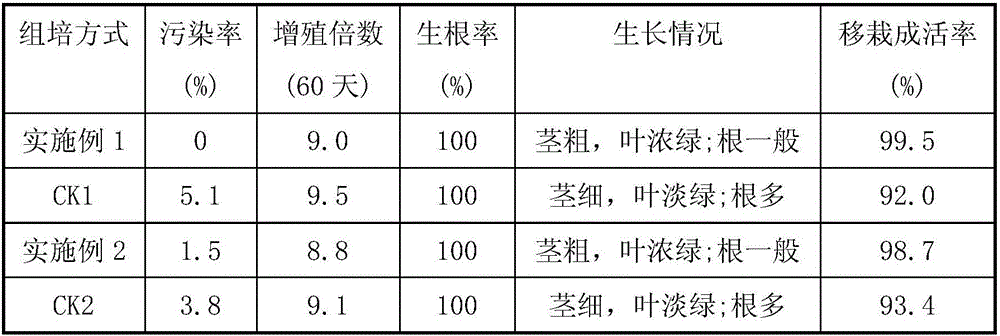

Open cultivation method of sugarcane tissue culture seedling

ActiveCN106305419ASimple production operationImprove work efficiencyPlant tissue cultureHorticulture methodsCulture mediumsMetabolite

The invention relates to a plant seedling cultivation method, in particular to an open cultivation method of a sugarcane tissue culture seedling and belongs to the technical field of biology. The open cultivation method of the sugarcane tissue culture seedling comprises: selecting and sterilizing a cultivation apparatus, preparing an antibacterial agent, carrying out induced cultivation of a tissue culture seedling, carrying out proliferation culture, and carrying out rooting culture; tissue culture seedling production is simplified, the antibacterial agent is added only to a culture medium, and inoculation and cultivation can be carried out under bacterial environmental conditions; working efficiency is greatly improved, production cost is reduced, and popularization and application of tissue culture seedlings is facilitated; the breeding process of the tissue culture seedling is open, photosynthetic and respiratory abilities of the tissue culture seedling are enhanced, and the quality of the tissue culture seedling is good; a culture medium nutrient solution is attached to the surface of a tissue culture plant in a sprayed manner, sufficient oxygen is provided for the growth of the tissue culture seedling, and harm of phenolic metabolites to the tissue culture seedling is reduced.

Owner:SUGARCANE RES INST GUANGXI ACADEMY OF AGRI SCI

Degerming deodorization non-woven fabric and preparation method thereof

ActiveCN103753918AImprove wear resistanceSimple production operationSynthetic resin layered productsNon-woven fabricsPolypropyleneWoven fabric

The invention discloses a degerming deodorization non-woven fabric and a preparation method thereof. The degerming deodorization non-woven fabric comprises a top surface layer, a back surface layer and a cellucotton layer sandwiched between the top surface layer and the back surface layer. The top surface layer and the back surface layer are made from a non-woven fabric material. Through a melt blowing method, the degerming deodorization non-woven fabric is prepared from 100 parts by weight of isotatic polypropylene, 1-2 parts by weight of an anti-oxidant 1010, 6-8 parts by weight of bamboo powder, 2-3 parts by weight of 2,2,4-trimethyl-1,3-pentanediol isobutyrate, 1-2 parts by weight of sodium tripolyphosphate, 2-3 parts by weight of nanometer mica powder, 12-15 parts by weight of dioctyl terephthalate, 1-2 parts by weight of fumed silica, 1-2 parts by weight of an antiager MB, 3-4 parts by weight of stearic acid, 1-2 parts by weight of malic acid, 1-2 parts by weight of peach gum powder, 3-4 parts by weight of pseudo-ginseng, 1-2 parts by weight of root of Indian abutilon, 1-2 parts by weight of herb or rhizome of Calystegia hederacea Wall., 2-3 parts by weight of rust-colored crotalaria herb and 4-5 parts by weight of an assistant. The degerming deodorization non-woven fabric has good wear resistance, a fragrance and antibacterial effects, can adsorb harmful gas and a peculiar smell and has effects of flame retardation and oxidation resistance.

Owner:MAANSHAN HUBIN NONWOVEN CLOTH TECH

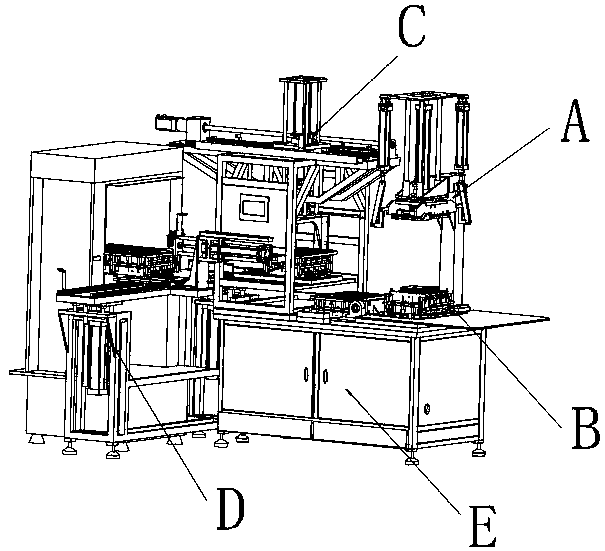

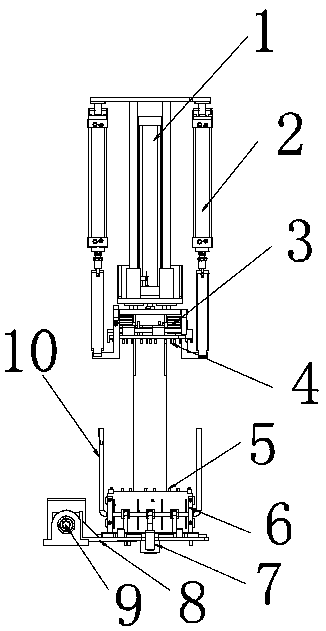

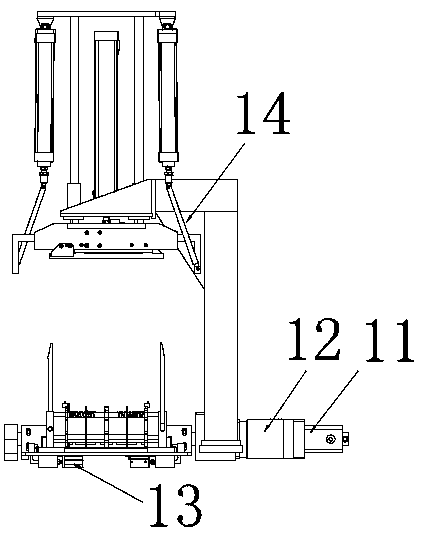

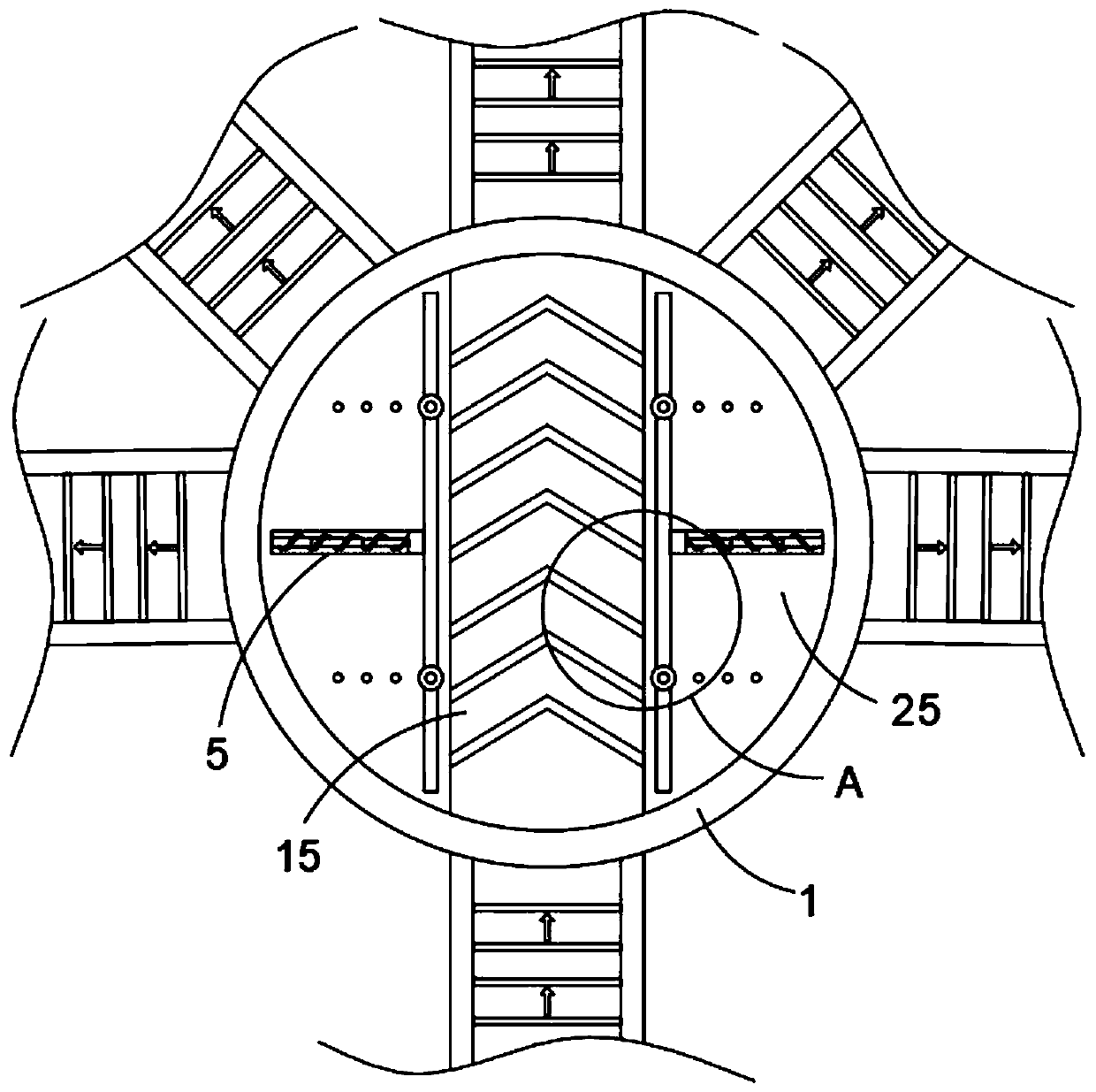

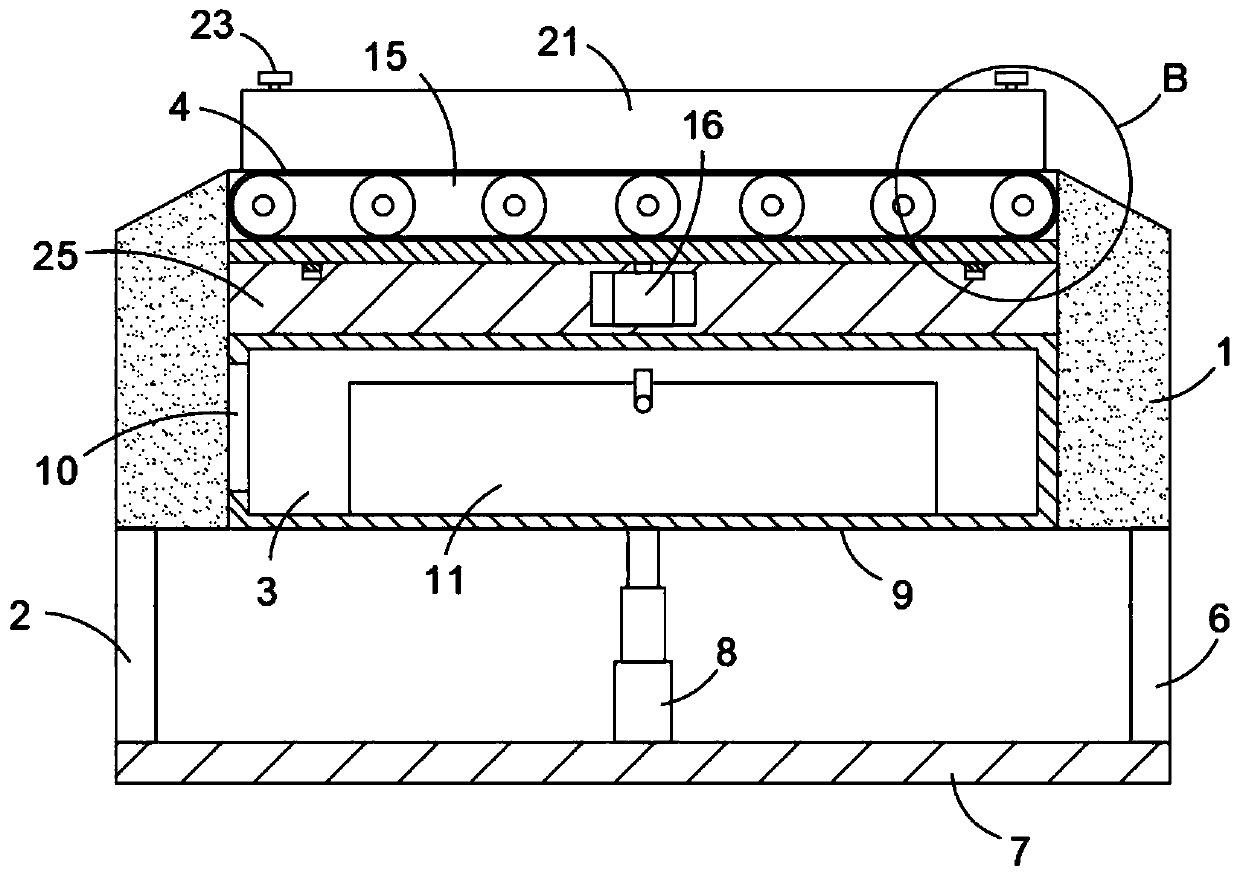

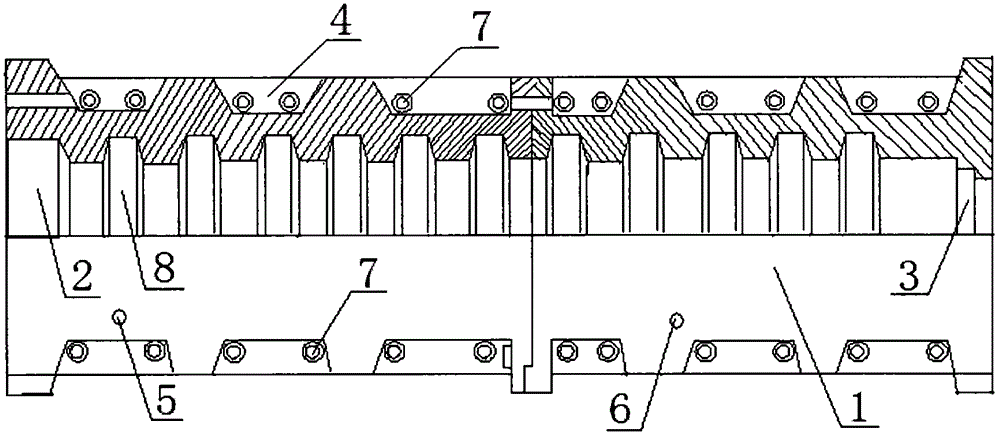

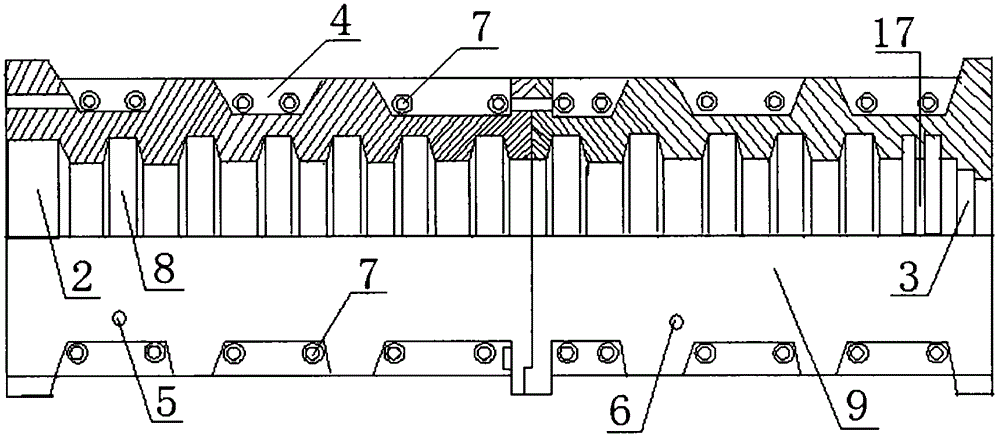

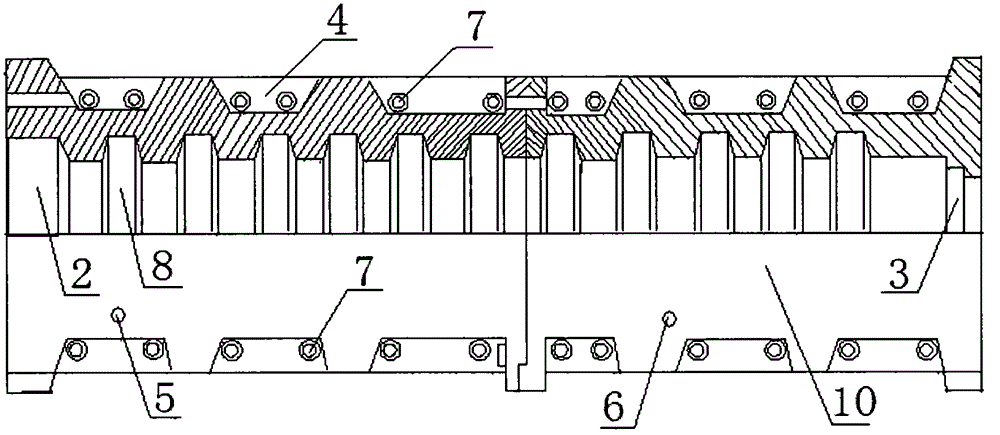

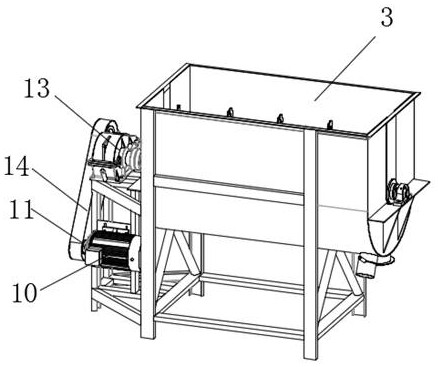

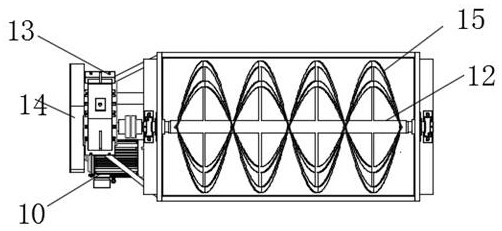

Cast-weld conveyor for lead-acid storage battery

PendingCN110797588AReasonable structural designSimple production operationFinal product manufactureLead-acid accumulators constructionElectric machineryManufacturing engineering

The invention relates to a cast-weld conveyor for a lead-acid storage battery. The conveyor comprises a lug arranging and overturning module, a cutting and brushing module, a liquid dipping and conveying module and a cast-weld butt joint module, wherein the lug arranging and overturning module and the liquid dipping and conveying module are arranged on a rack, the cutting and brushing module is arranged on an inner side of the rack below a cutting and brushing panel between the lug arranging and overturning module and the liquid dipping and conveying module, and the cast-weld butt joint moduleis arranged on an outer side of the rack beside the liquid dipping and conveying module. The conveyor is advantaged in that the structural design is reasonable, a cylinder and a motor are adopted fordriving, a series of actions such as lug trimming, cutting and brushing, liquid dipping and feeding and discharging of a cast-weld machine are automatically conducted, production operation is simplified, and production efficiency is greatly improved.

Owner:WUXI JIALIANG PRECISION MACHINERY MFG

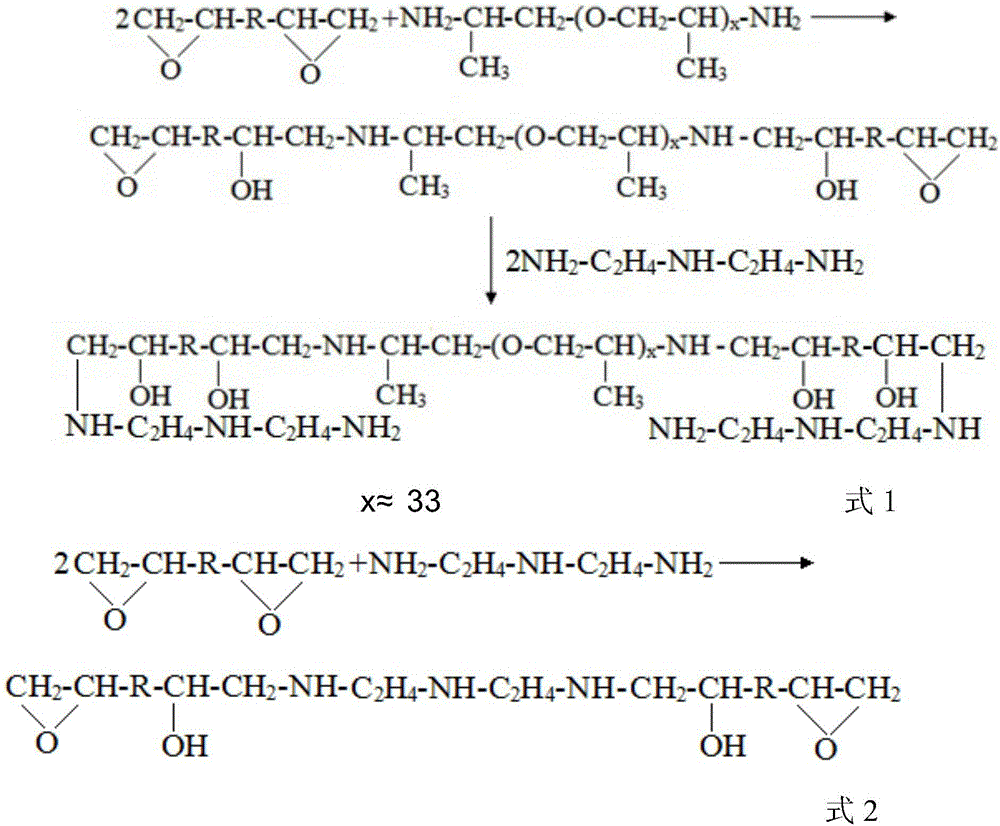

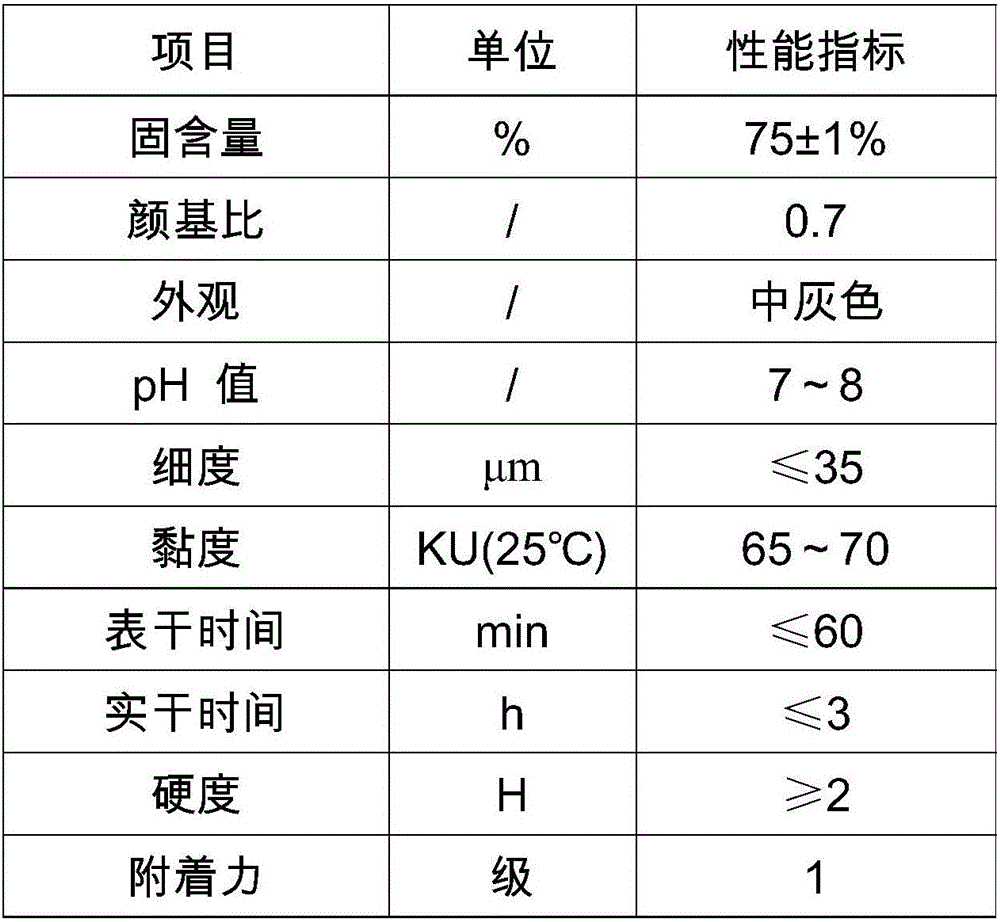

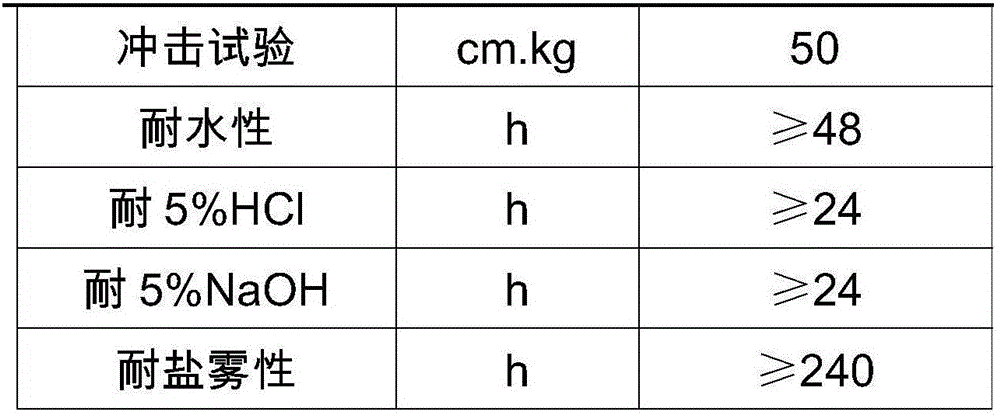

Waterborne epoxy modified polyamine curing agent and waterborne epoxy anti-corrosion primer coating

ActiveCN105949958ASimple production operationGood storage and mechanical stabilityAnti-corrosive paintsEpoxy resin coatingsChemistryDiethylenetriamine

The invention discloses a waterborne epoxy modified polyamine curing agent and a waterborne epoxy anti-corrosion primer coating. The curing agent is prepared through the following steps that a first part of E51 epoxy resin and a first part of butyl cellosolve are added into a three-mouth flask with a stirrer, a condenser pipe and a thermometer, the temperature is increased to 60 DEG C, polyether amine is dropwise added, the temperature is kept at 60 DEG C to 75 DEG C in the dropwise adding process, polyether amine is completely added within one hour, and then stirring is conducted for one hour; the temperature is decreased to 70 DEG C, diethylenetriamine is dropwise added and completely added within two hours, then a second part of E51 epoxy resin and a second part of butyl cellosolve are added, the temperature is kept at 70 DEG C to 75 DEG C, reacting is conducted for 3 h, the temperature is decreased to room temperature after it is detected that no primary amino exists, deionized water is added to dilute the mixture until the solid content is 60%, and then the waterborne epoxy modified polyamine curing agent is obtained. The prepared curing agent can directly emulsify epoxy resin, is good in storage stability and mechanical stability and has good application in a waterborne epoxy resin coating.

Owner:青岛乐化科技有限公司 +3

Preparation method of dipropylene glycol methyl propyl ether

ActiveCN101921179ASimple production operationShort reaction timeEther preparation by ester reactionsDipropylene glycolInorganic salts

The invention discloses a preparation method of dipropylene glycol methyl propyl ethers. The preparation method comprises the following steps of: dissolving an organic alkali in dipropylene glycol monomethyl ether, adding chloropropane or bromopropane at the temperature of 60-90 DEG C, completing the addition and reacting for 2-10 h at 60-120 DEG C; standing and layering after completion of the reaction to obtain an organic matter of an upper layer, adding inorganic salt water solution with the concentration of 1-30% to extract the unreacted dipropylene glycol monomethyl ether, and carrying out reduced pressure distillation on a crude product of the upper layer to obtain a dipropylene glycol methyl propyl ether geometric isomer with the purity more than 99%. The invention has simple production process, short reaction time, low production cost and high product purity.

Owner:ANHUI LIXING CHEM

Process of high purity pyrethrins

InactiveCN1500390ASimple production operationShort production timeBiocideAnimal repellantsSolventChemistry

The production process of high-purity pyrethrin includes adding into the coarse pyrethrin extractive antioxidant BHT in the amount of 2-3 % weight of coarse pyrethrin extractive; dissolving in ethanol or methanol solvent in 5-7 times weight of coarse pyrethrin extractive at 25-30 deg.c for 1-1.5 hr before filtering to eliminate insoluble matter; freezing the solution at temperature below -20 deg.c; decolorizing the frozen liquid and concentrating to obtain ethanol or methanol concentrate while recovering ethanol or methanol; dissolving in petroleum ether solvent in 7-8 times weight of ethanol or methanol concentrate at 30-40 deg.c for 1-1.5 hr before filtering to eliminate insoluble matter; and concentrating to obtain high-purity pyrethrin while recovering petroleum ether solvent. The said process raises the content of pyrethrin in the product, reduces pollution and raises the safety of using the product.

Owner:中植生物科技开发有限责任公司

Sorting machine for warehouse logistics

PendingCN110052415AIncrease flexibilitySimple production operationSortingEngineeringLogistics management

The invention discloses a sorting machine for warehouse logistics. The sorting machine comprises a machine body, wherein a support mechanism is fixedly connected with the lower end of the machine body; a mounting hole penetrating through the upper and lower parts is coaxially formed in the center of the machine body; a recycling mechanism is arranged in the mounting hole; the lower end of the recycling mechanism is fixedly connected with the upper end of the support mechanism; a deflection mechanism is fixedly connected with the upper end of the recycling mechanism; the upper end face of the deflection mechanism is parallel and level with the upper end face of the machine body; and a pair of protecting mechanisms is fixedly connected with the upper end of the deflection mechanism. According to the sorting machine, according to the traditional sensor identifying manner, the transported and classified categories can be freely added or deleted, so that the using flexibility is improved, and the defective goods can be better recycled to effectively lower the labor intensity of a worker at the phase.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

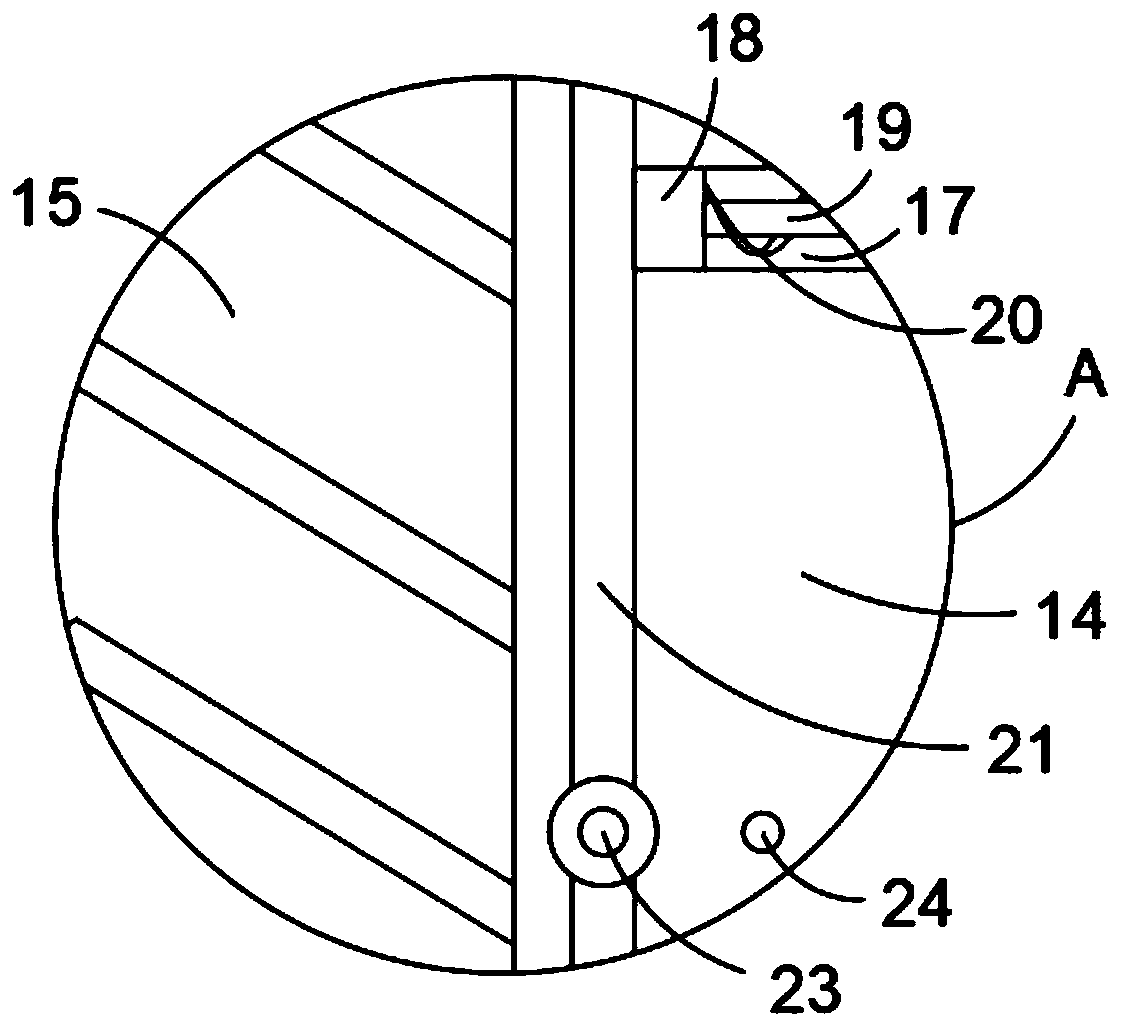

Multi-pipe connecting die for die pressing pipes

InactiveCN105365076ASimple and reasonable structural designSimple production operationMechanical engineeringBuilding construction

The invention discloses a multi-pipe connecting die for die pressing pipes. The die comprises a die body A and a die body B. The die body A is composed of a female die A and a male die A. The die body B is composed of a female die B and a male die B. An inner muzzle bell cavity is formed in one end of the female die A and an annular spigot is arranged at the other end of the female die A. An inner muzzle bell cavity is formed in one end of the female die B and the other end of the female die B is provided with an annular spigot and a sealing ring groove. The male die A and the male die B each comprise a pipe body and an inner cavity. The multi-pipe connecting die for the die pressing pipes further comprises die bodies C and the number of the die bodies C can be increased according to actual requirements; and each die body C comprises a female die C and a male die C, an inner muzzle bell cavity is formed in one end of each female die C, an annular spigot is arranged at the other end of each female die C, and each male die C comprises a pipe and an inner cavity. By the adoption of the multi-pipe connecting die for the die pressing pipes, the die bodies C are additionally arranged and the number of the die bodies C can be increased according to the actual requirements, the defect that only die pressing pipes with the length of 2 m can be produced in the prior art is overcome, and therefore the die pressing pipes can be more widely applied to drainage facility construction of municipal engineering and the like.

Owner:荆州洪湖科技有限公司

Production method for natural bamboo juice rich in selenium

ActiveCN104305444ASimple production operationEasy to promoteFood preservationFood preparationSucroseAntioxidant

The invention relates to a production method for natural bamboo juice rich in selenium. The production method comprises the steps of adding organic acid and saccharose into a sodium selenite water solution for normal temperature reaction, so as to obtain an organic acid saccharose solution rich in selenium, wherein the concentration of the organic acid is 5-10g / kg, and the concentration of the saccharose is 20-50g / kg; adding pure water into the organic acid saccharose solution rich in selenium to dilute, so as to obtain organic acid saccharose injection rich in selenium; slantly injecting 20ml-40ml of amino acid injection rich in selenium above a bamboo joint at the lower part of the bamboo with an injector, then sealing the injection hole; and 3-7 days later, drilling at the lower part of the other bamboo joint, inserting a bamboo juice tube into the hole, sealing the exterior with beewax, connecting the bamboo juice tube with a bamboo juice container, so as to obtain the bamboo juice rich in selenium, after finishing taking the juice, sealing the hole with beewax. According to the production method, the bamboo juice is rich in microelement selenium, has high nutritive value, is slightly sweet, and can be used as the raw material of antioxidants or health drink.

Owner:广西竹黄金生态科技股份有限公司

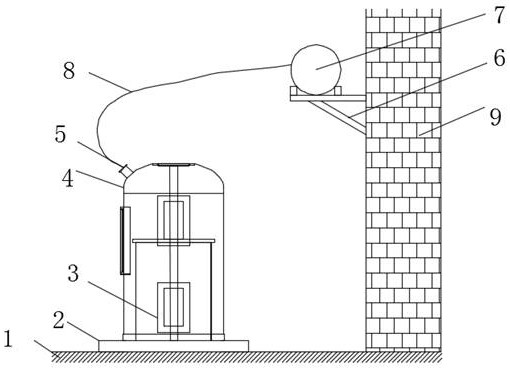

Refrigerator with heat preservation function

InactiveCN102419064ASimple to make and installSimple production operationDomestic cooling apparatusLighting and heating apparatusFreezing chamberEngineering

The invention relates to a refrigerator, in particular to a refrigerator with a heat preservation function. The refrigerator comprises a freezing chamber, a refrigerating chamber, a heat preservation box, a compressor, a freezing chamber evaporator, a condensation heater, a condenser, a refrigerating chamber evaporator, a drying filter and a capillary, wherein the heat preservation box is arranged above the refrigerating chamber; and the compressor, the condensation heater, the condenser, the drying filter, the capillary, the refrigerating chamber evaporator and the freezing chamber evaporator are sequentially connected in a closed loop mode. The invention has the advantages that: after the refrigerator with the heat preservation function is used, the condensation heat of the refrigerator is recycled, so that energy conservation is realized; and the refrigerator with the heat preservation function can be simply manufactured and mount and is easy to produce and operate.

Owner:林勇

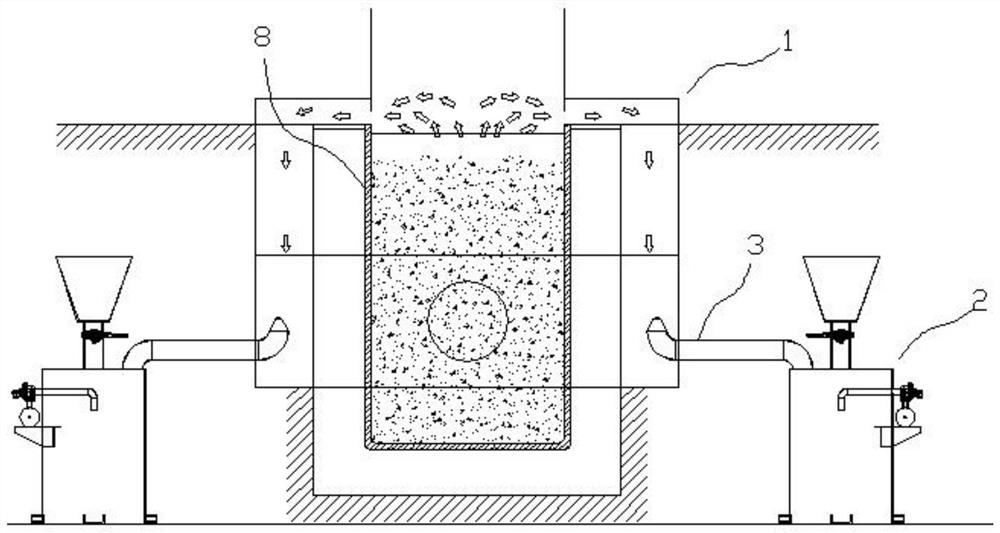

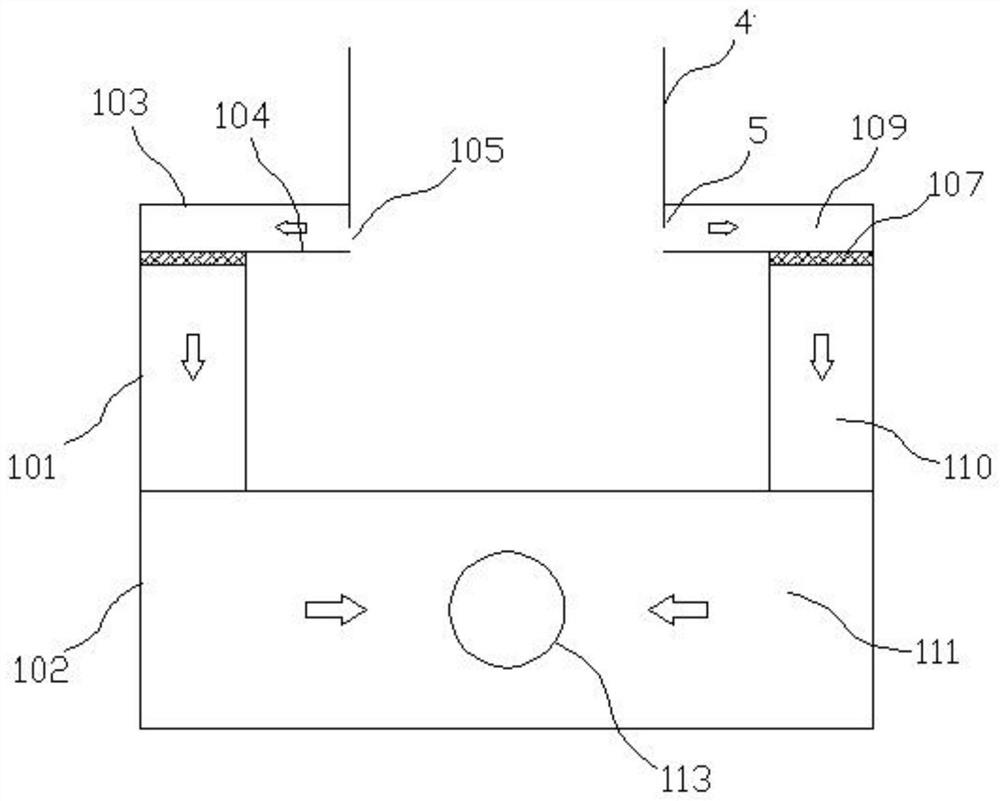

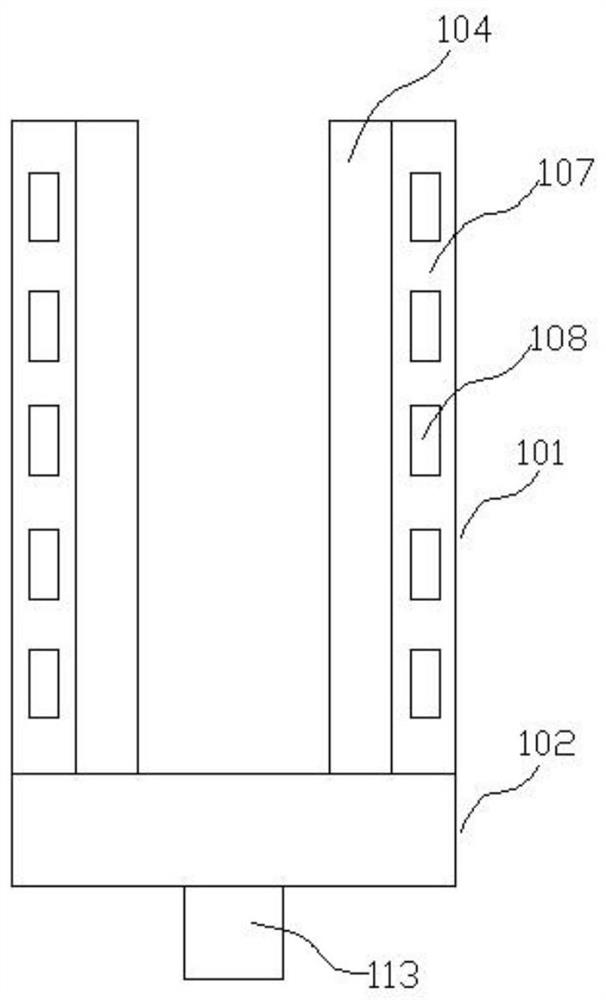

Hot galvanizing pot smoke exhaust gas collecting device

ActiveCN112011751ASave space for production operationsSimple production operationHot-dipping/immersion processesDirt cleaningExhaust gasExhaust fumes

The invention discloses a hot galvanizing pot smoke exhaust gas collecting device, and relates to the technical field of zinc pot smoke exhaust gas treatment. The hot galvanizing pot smoke exhaust gascollecting device comprises a gas collecting hood and powder spraying equipment, the gas collecting hood comprises gas collecting boxes and an air mixing box, and a conveying pipeline is connected between the powder spraying equipment and each gas collecting box; each gas collecting box comprises a gas collecting strip opening, and an air outlet is formed in each gas collecting box; and an innerspace of each gas collecting box is divided into an air equalizing chamber and a smoke dust channel from top to bottom, each smoke dust channel is communicated with the corresponding air outlet, the air mixing box comprises an air mixing channel arranged inside and a pair of air inlets communicated with the air mixing channel, the air inlets are communicated with the air outlets in the corresponding gas collecting boxes, and an air exhaust pipeline communicated with the air mixing channel is arranged on the air mixing box. The hot galvanizing pot smoke exhaust gas collecting device is constructed around a zinc pot heat preservation layer, the influence on production operation is reduced to the maximum extent, meanwhile, the viscosity of smoke particles of a hot galvanizing pot can be greatly reduced, the dust removal efficiency of a dust remover is improved, the service life of a filter material is prolonged, and the maintenance period is prolonged.

Owner:安徽徽柏环保科技有限公司

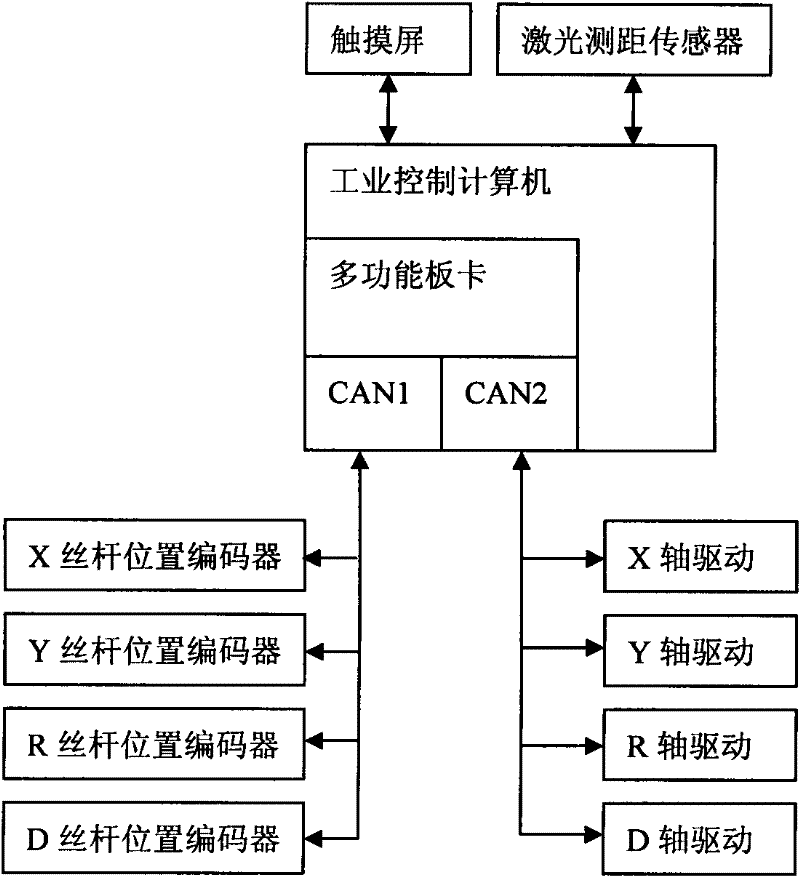

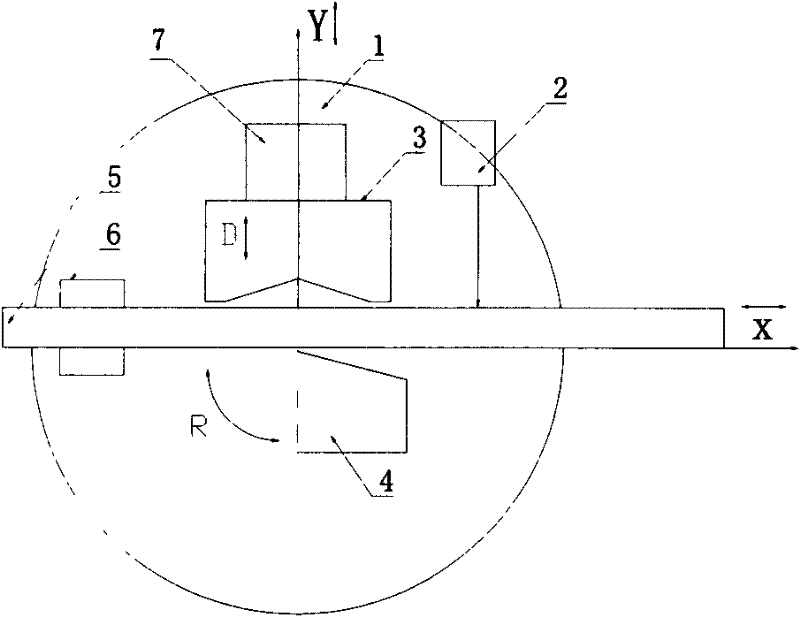

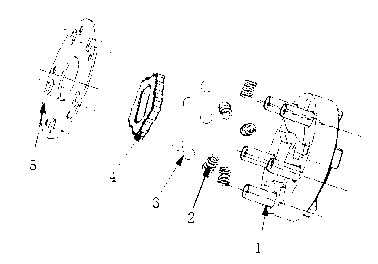

Fitting incremental forming control system and method

ActiveCN102306009AIncrease productivitySimple production operationNumerical controlBus interfaceLaser ranging

The invention discloses a fitting incremental forming control system, which comprises a touch screen, a laser ranging sensor, an industrial control computer, a multifunctional card, an X screw rod position encoder, a Y screw rod position encoder, an R screw rod position encoder, a D screw rod position encoder, an X axis drive, a Y axis drive, an R axis drive and a D axis drive, wherein the touch screen, the industrial control computer, the X axis drive, the Y axis drive, the R axis drive and the D axis drive are arranged in a control cabinet; the multifunctional card comprises a controller area network (CAN1) bus interface and a CAN2 bus interface and is arranged in an insertion slot of the industrial control computer; the X screw rod position encoder, the Y screw rod position encoder, the R screw rod position encoder and the D screw rod position encoder are arranged on the tails of an X screw rod, a Y screw rod, an R screw rod and a D screw rod respectively; and the laser ranging sensor 2 and the touch screen are connected with the industrial control compute respectively through cables. By the system and the method, fitting incremental forming control over tubular materials is realized; die machining is not required after the tubular materials are annealed; automatic forming control over various tubular materials can be realized; and system configuration and a die are not needed to change.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

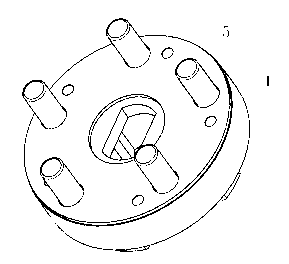

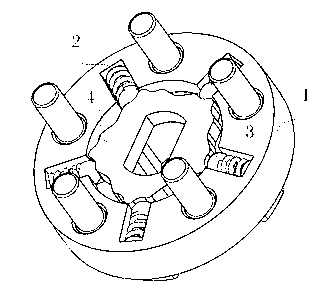

Planet carrier and preparation method thereof

ActiveCN102705500ASimple production operationSuitable for automated productionGearing detailsPowder metallurgyCam

The invention discloses a planet carrier and a preparation method thereof. The planet carrier comprises a powder metallurgy planet carrier, springs, steel balls, a cam and a spacer, wherein the cam is arranged in a powder metallurgy planet carrier cavity; the springs and the steel balls which are matched with each other for use are arranged between the cam and the powder metallurgy planet carrier; the spacer is fixedly arranged on the powder metallurgy planet carrier from the outer side; the springs, the steel balls and the cam are sealed in the powder metallurgy planet carrier, so that the cam and the steel balls relatively and bilaterally slide to realize a self-locking function; and the powder metallurgy planet carrier comprises the following powder metallurgy raw materials in parts by weight: 90.0-98.0 parts of Fe, 0-1.0 part of C, 1.0-5.0 parts of Ni, 0-1.0 part of Mo and 1.0-3.0 parts of Cu. The planet carrier and the preparation method thereof have the advantages of easiness in production operation, suitability for automatic production, high production efficiency, capability of producing 3000PCS products every 8H, low production cost, stable product performance, excellent economic prospect and capability of producing excellent social benefit.

Owner:扬州意得机械有限公司

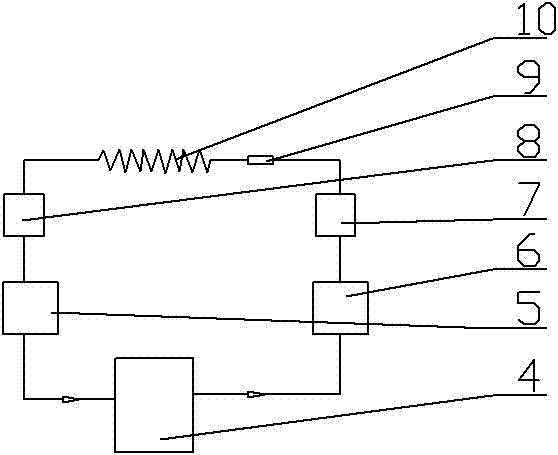

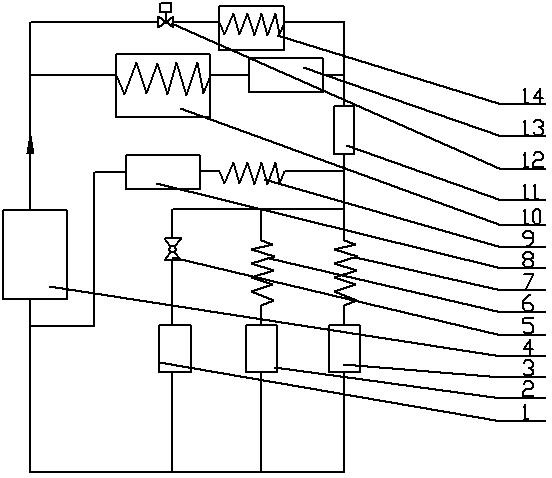

Multi-purpose refrigerating system

InactiveCN102435009ASimple to make and installSimple production operationCompression machines with several evaporatorsFluid circulation arrangementEvaporatorEngineering

The invention relates to refrigerating equipment, in particular to a multi-purpose refrigerating system, which comprises an air-conditioning evaporator, an ice-making machine evaporator, a water fountain cold water evaporator, a compressor, a throttling valve, a first capillary pipe, a second capillary pipe, a refrigerator evaporator, a third capillary pipe, a water heater, a drying filter, an electromagnetic valve, a condenser and a water fountain water heater, wherein the compressor, the water heater, the condenser, the drying filter, the throttling valve and the air-conditioner evaporator are in closed loop connection in sequence; an exhaust pipe of the compressor is connected with one end of the electromagnetic valve; and the other end of the electromagnetic valve is connected to a pipeline between the water heater and the condenser after being connected with water fountain water heater. The invention has the advantages that: after the multi-purpose refrigerating system is put into use, the refrigerator, an air conditioner, the water heater, the water fountain and an ice-making machine are integrated together, and share one compressor, so that the fault rate is lowered; condensing heat is recovered for heating the water heater and the water fountain water heater, so that energy is saved; and the system is easy to control, manufacture, install, produce and operate.

Owner:林勇

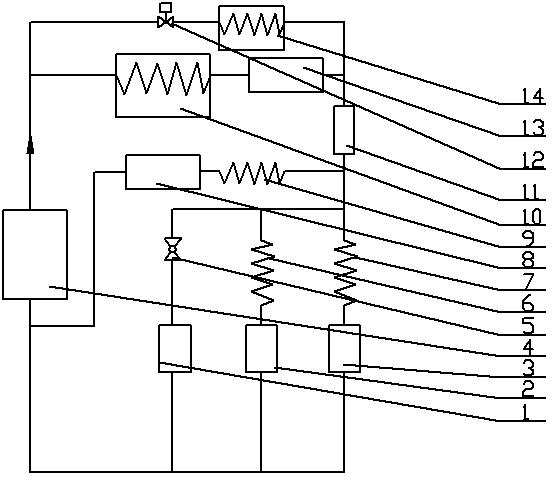

Production method of crop straw-based degradable polymer sheet

InactiveCN108546418ASimple production operationGood process specification and versatilityEnvironmentally friendlyCrop

The invention relates to a production method of a crop straw-based degradable polymer sheet. The method comprises the following steps: straw preprocessing, mixing, milling, and molding processing. Themethod has the advantages of simplicity in production operation, good technology standardability and versatility, low labor intensity, low production cost, safe and environmentally-friendly production raw materials, effectiveness in the improvement of the recycling rate of straws and waste plastics, effectiveness in the improvement of the degradability and the antibacterial and bacteriostatic ability of the sheet on the premise of meeting the structural strength and the toughness of the sheet, effectiveness in improvement of the application range and the use performances of the straw producedsheet, and avoiding of pollution to the circumferential environment and resource wastes.

Owner:河南省现代农业研究院

Batching stirrer

PendingCN112892374ASimple production operationExquisite appearanceTransportation and packagingRotary stirring mixersMechanical engineeringThermodynamics

The invention provides a batching stirrer, and relates to the field of stirrers. The batching stirrer comprises a ground and a wall body arranged on the ground; the top of the ground is provided with a bearing plate, the top of the bearing plate is provided with a shell, the shell is sleeved with a gas-collecting hood, the gas-collecting hood is provided with a gas outlet, and the side wall of the wall body is provided with a bearing plate. A waste gas collecting main pipe is fixedly installed at the top of the bearing plate and communicates with the gas outlet through a waste gas collecting hose, and a stirring mechanism is arranged in the shell. According to the novel waste gas collecting hood, a waste gas compartment is removed, production operation is convenient, the appearance is exquisite, a visual window and an operation window are installed, production operation and observation are convenient, the waste gas scattering range is small, collection is easy, and environmental protection detection reaches the standard.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

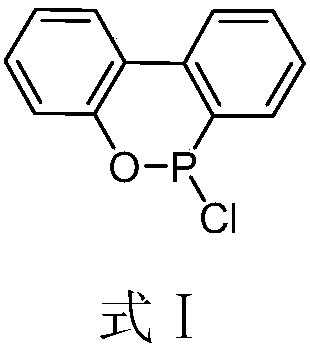

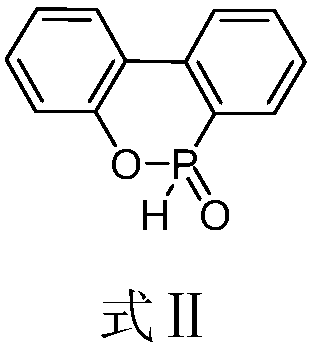

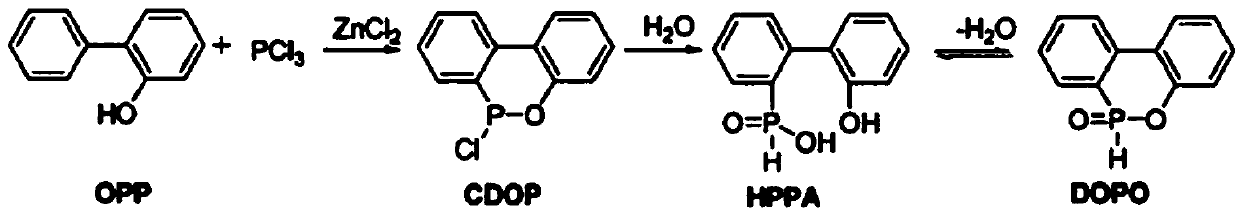

Preparation method of DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) and intermediate of DOPO

ActiveCN107556343ASimple production operationEasy to operateGroup 5/15 element organic compoundsOxideZinc

The invention relates to a preparation method of DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) and an intermediate of DOPO and belongs to the field of chemistry. Aiming at solving the technical problems, the invention provides the preparation method of the DOPO intermediate CDOP; the method comprises the following steps: raising the temperature of a mixture of o-phenylphenol, zinc chloride and phosphorus trichloride to 60 DEG C to 140 DEG C and carrying out esterification reaction; continually raising the temperature to 160 DEG C to 220 DEG C and reacting to obtain the product. Byadopting the preparation method provided by the invention, the phosphorus trichloride can be added in one step in a material feeding process and the excessive phosphorus trichloride and reaction byproducts do not need to be removed by decompressing and distilling after the reaction is finished, so that the production operation is greatly simplified; compared with an existing technology, the preparation method has remarkable advantages.

Owner:LIER CHEM CO LTD +1

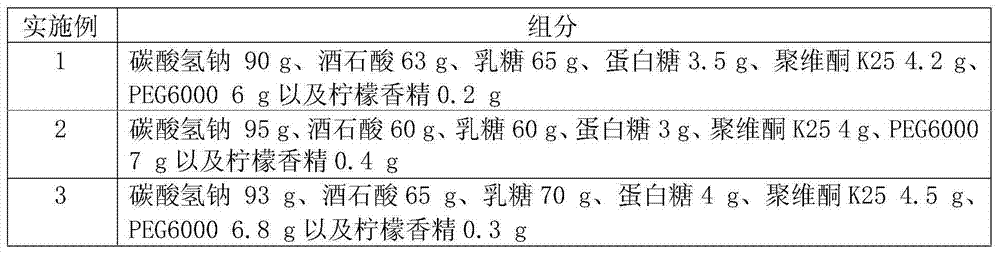

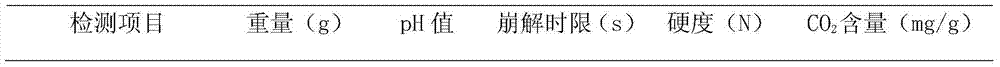

Soda effervescent tablet

InactiveCN104489852ALower requirementSimple production operationFood scienceSodium bicarbonateLactose

The invention discloses a soda effervescent tablet which is prepared from the following raw materials in parts by weight: 90-95 parts of sodium bicarbonate, 60-65 parts of tartaric acid, 60-70 parts of lactose, 3-4 parts of aspartame, 4-4.5 parts of povidone K25, 6-7 parts of PEG 6000 and 0.2-0.4 part of lemon essence. The soda effervescent tablet has the advantages that: 1) tartaric acid with smaller hygroscopicity is selected to replace citric acid to serve as an acid source, so that the requirements on the tabletting environment are reduced and the production and operation are convenient; 2) a direct powder tabletting method is adopted in the invention, so that the operation is simple and the technological process is short; 3) after the prepared soda effervescent tablet is dissolved in water, weak alkaline nutritive water with a pH value of 7.5-8 is obtained, the effect is the same as that of soda water, but the soda effervescent tablet is more convenient to store, carry and use compared with the soda water.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com