Continuous clean deodorizing method for activated sludge fermentation gas

An activated sludge and gas technology, which is applied in deodorization, separation methods, biological sludge treatment and other directions, can solve problems such as unpleasant gas and unpleasant smell, and achieve the effect of simple equipment, easy production and operation, and clean removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below by specific embodiment:

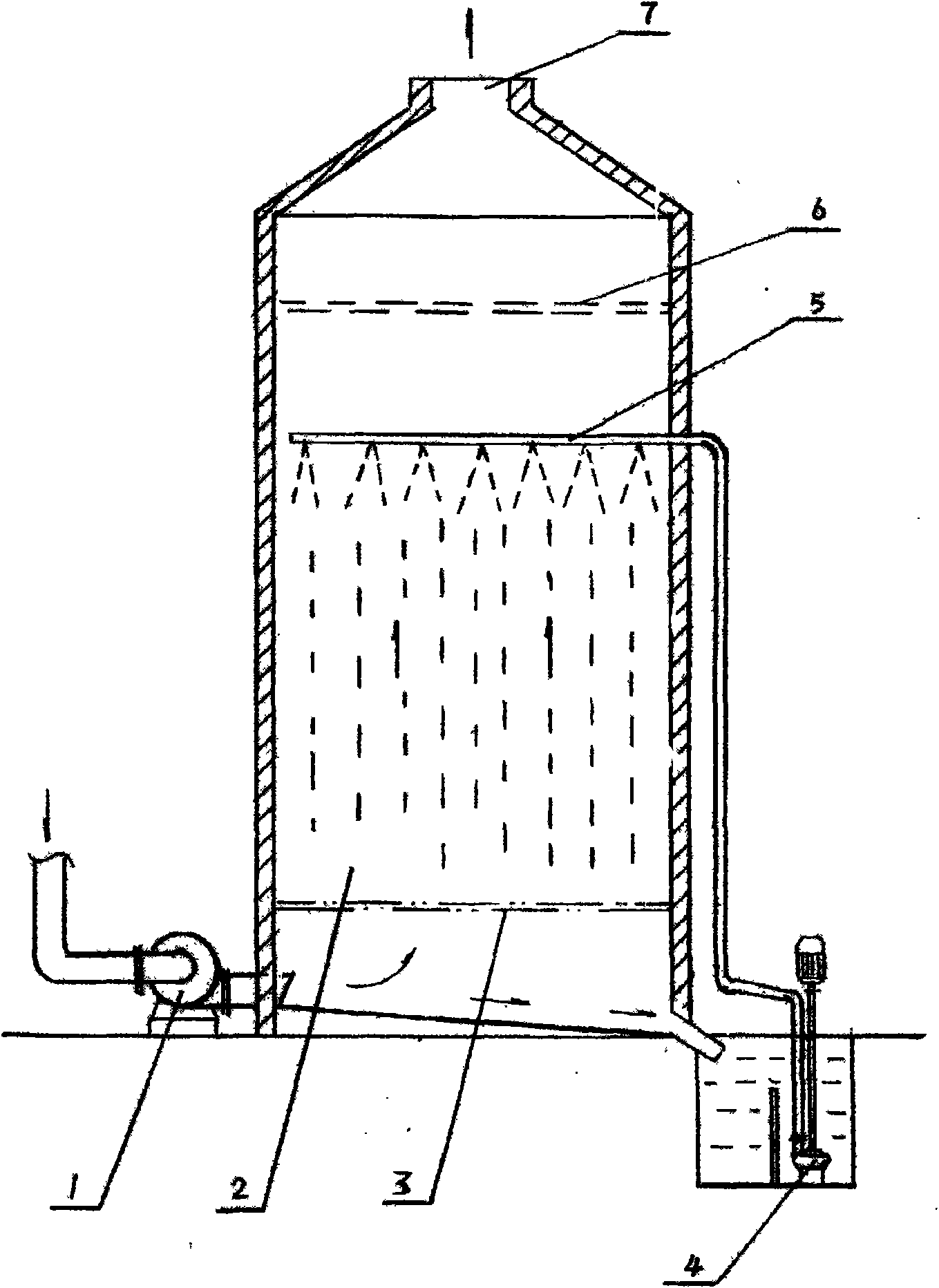

[0015] refer to figure 1 , activated sludge fermentation gas continuous clean deodorization method, including spray washing liquid and gas washing device, liquid medicine with 100 kg of tap water, add 4 kg of sodium chlorite, and then add a small amount of liquid potassium hydroxide , add the amount of liquid potassium hydroxide to adjust the pH value of the liquid medicine to 8.8, then add 0.4 kg of active zinc oxide, and the above components are mixed evenly to spray the liquid medicine; press figure 1 Shown, make a vertical garden cylindrical washing tower (2), install an exhaust fan (1) next to the tower, the inlet of the exhaust fan (1) is connected with the gas that the activated sludge fermentation field produces, the exhaust fan (1) The outlet is connected to the lower part of the washing tower (2), and the washing tower (2) is equipped with a distribution screen (3), a liquid spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com