Process of high purity pyrethrins

A technology of pyrethrin and a production method, which is applied in the production field of high-purity pyrethrin, can solve the problems of unseen industrialized production, impossible industrialized production, and high production cost, and achieves enhanced market competitiveness, standardized production method, and short production time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Preparation of crude pyrethroid extract:

[0020]

[0021] 2. Add 2% antioxidant BHT by weight to the crude pyrethroid extract;

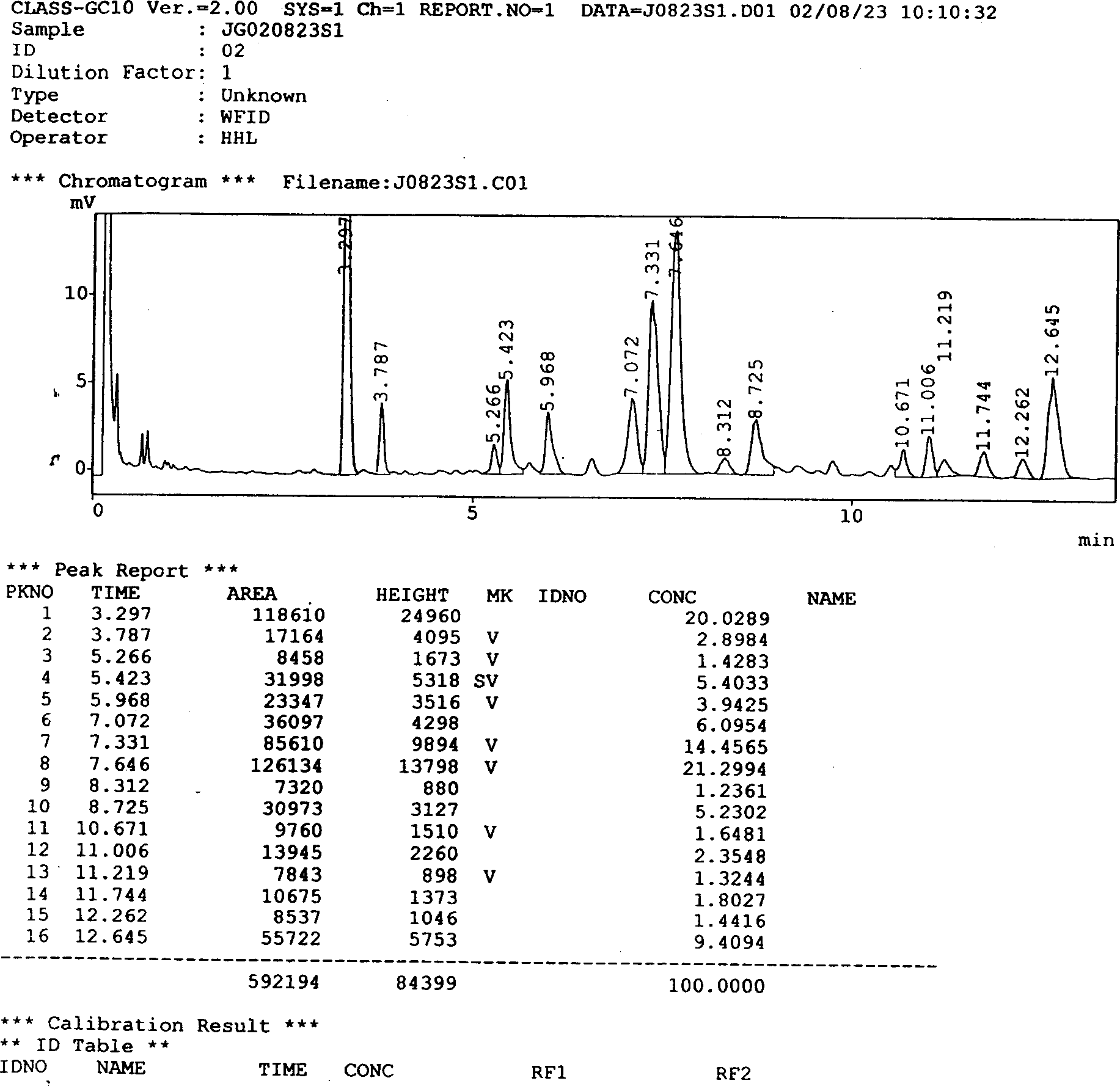

[0022] 3. Dissolution of crude pyrethroid extract: Take 228 kg of crude pyrethroid extract (the content of pyrethroid is about 29%, see figure 1 ), add 5 times ethanol and stir, dissolve at 30°C for 1.5 hours, filter to remove insoluble matter, and prepare ethanol solution;

[0023] 4. Freeze the ethanol solution. Cool the ethanol solution prepared in 2 from room temperature to -20°C, and filter to remove the frozen precipitates to obtain ethanol freezing solution;

[0024] 5. Decolorization of ethanol freezing solution: Pass the ethanol freezing solution through a decolorizing device filled with 20 kilograms of activated carbon, and then wash the activated carbon with 50 kilograms of ethanol, and the eluate is merged into the ethanol freezing solution;

[0025] 6. Recovery of solvent ethanol: at -0.060Mpa to -0.075Mpa negative pressure, wa...

Embodiment 2

[0029] 1. Preparation of crude pyrethroid extract: the same as in Example 1;

[0030] 2. Add 3% antioxidant BHT by weight to the crude pyrethroid extract,

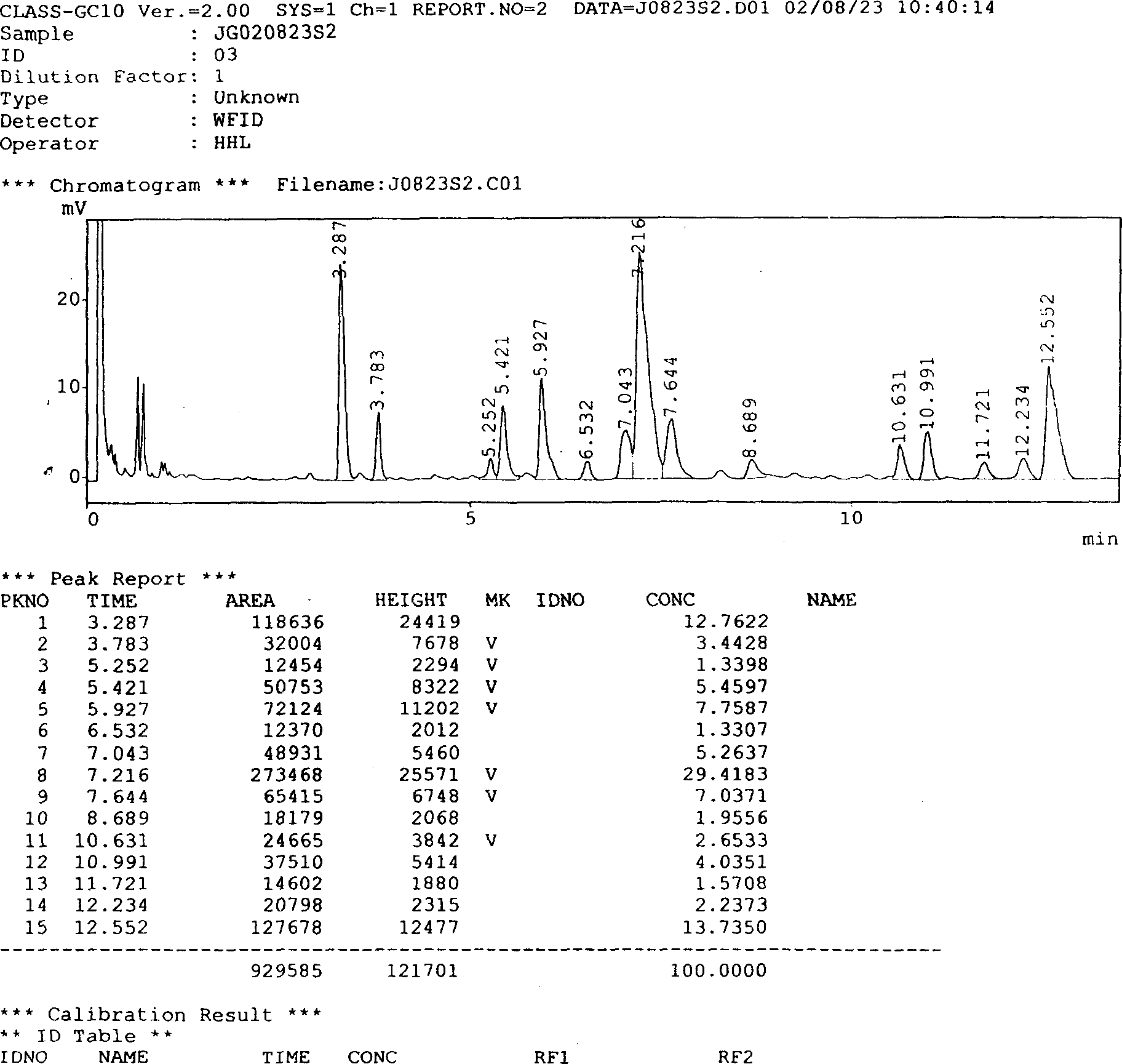

[0031] 3. Dissolution of crude pyrethroid extract: Take 260.34 kg of crude pyrethroid extract (the content of pyrethroid is about 20.0%, see image 3 ), add 6 times methanol and stir, dissolve at 35°C for 1.5 hours, filter to remove insoluble materials, and prepare methanol solution;

[0032] 4. Freeze the methanol solution. Cool the methanol solution prepared in 2 from room temperature to -20°C, filter and remove the frozen precipitates to obtain methanol freezing solution;

[0033] 5. Decolorization of methanol freezing liquid: the methanol freezing liquid is passed through a decolorizing device filled with 20 kg of activated carbon, and then 50 kg of methanol is used to wash the activated carbon, and the eluent is merged into the methanol freezing liquid;

[0034] 6. Recovery of solvent methanol: at -0.060Mpa to -0.075Mpa n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com