Purification method of 4-chloromethyl-5-methyl-1,3-dioxole-2-ketone

A dioxole and purification method technology, applied in the field of medicinal chemistry, can solve the problems of low production capacity, low DMDO-Cl yield, low purity, etc., and achieve the goals of reducing energy consumption, shortening production cycle, and simplifying production operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a purification method of 4-chloromethyl-5-methyl-1,3-dioxol-2-one (i.e. DMDO-Cl), the specific operation is as follows:

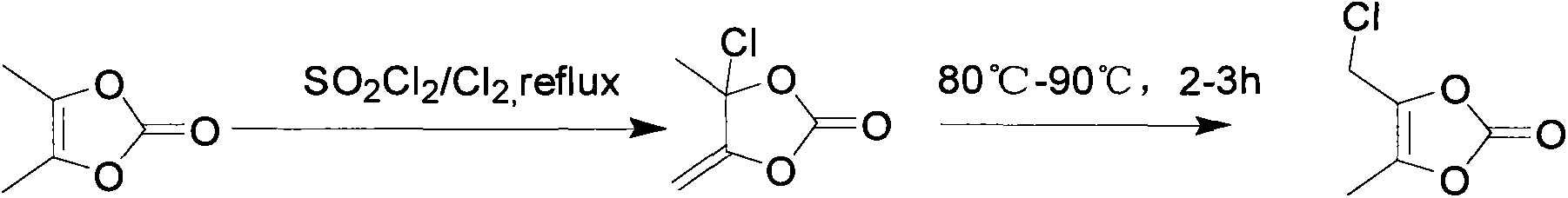

[0025] (1) Preparation of crude DMDO-Cl

[0026] Add 50.0g of 4,5-dimethyl-1,3-dioxol-2-one and 530g of dichloromethane into a 1L four-neck flask, stir to dissolve, heat up to reflux, and the internal temperature is not lower than 40 At ℃, add a mixture of 65g (1.1 equivalent) of sulfuryl chloride and 132g of dichloromethane dropwise, control the internal temperature to not lower than 40℃, keep stirring for 2 hours after dropping, then raise the temperature to 85℃ and distill off the dichloromethane at the same time. When it reaches 85°C, rearrange for 2 to 3 hours. After cooling down to room temperature, the crude product of DMDO-Cl was obtained with a GC purity of 85%-90%.

[0027] Add 30ml of methanol to the above crude product, stir and cool down to -10°C ~ -5°C, crystallize for 0 ~ 3h, filter with suction, rinse with m...

Embodiment 2

[0031] This embodiment provides a purification method of 4-chloromethyl-5-methyl-1,3-dioxol-2-one (i.e. DMDO-Cl), the specific operation is as follows:

[0032] (1) Preparation of crude DMDO-Cl

[0033] Add 50.0g of 4,5-dimethyl-1,3-dioxol-2-one and 530g of dichloromethane into a 1L four-neck flask, stir to dissolve, heat up to reflux, and the internal temperature is not lower than 40 At ℃, add a mixture of 65g (1.1 equivalent) of sulfuryl chloride and 132g of dichloromethane dropwise, control the internal temperature not lower than 40℃, keep stirring for 2 hours after dropping, then raise the temperature to 85℃ and distill off the dichloromethane at the same time. When it reaches 90°C, rearrange for 2-3h. After cooling down to room temperature, the crude product of DMDO-Cl was obtained with a GC purity of 85%-90%.

[0034] Add 30ml of ethanol to the above crude product, stir and lower the temperature to -10°C to -5°C, crystallize for 0 to 1.5h, filter with suction, rinse wi...

Embodiment 3

[0038] This embodiment provides a purification method of 4-chloromethyl-5-methyl-1,3-dioxol-2-one (i.e. DMDO-Cl), the specific operation is as follows:

[0039] (1) Preparation of crude DMDO-Cl

[0040] Add 50.0g of 4,5-dimethyl-1,3-dioxol-2-one and 530g of dichloromethane into a 1L four-neck flask, stir to dissolve, heat up to reflux, and the internal temperature is not lower than 40°C 65g (1.1 equivalent) of sulfuryl chloride and 132g of dichloromethane were added dropwise, and the internal temperature was controlled not to be lower than 40°C. After the dropping was completed, the mixture was kept warm and stirred for 2 hours, and then the temperature was raised to 85°C while distilling off the dichloromethane. When it reaches 85°C, rearrange for 2 to 3 hours. After cooling down to room temperature, the crude product of DMDO-Cl was obtained with a GC purity of 85%-90%.

[0041] Add 30ml of isopropanol to the above crude product, stir and lower the temperature to -10°C to -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com