Waterborne epoxy modified polyamine curing agent and waterborne epoxy anti-corrosion primer coating

A water-based epoxy and anti-corrosion primer technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of few mature products, high prices, and few water-based epoxy curing agents, avoiding storage Poor stability, easy production operation, good storage stability and good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

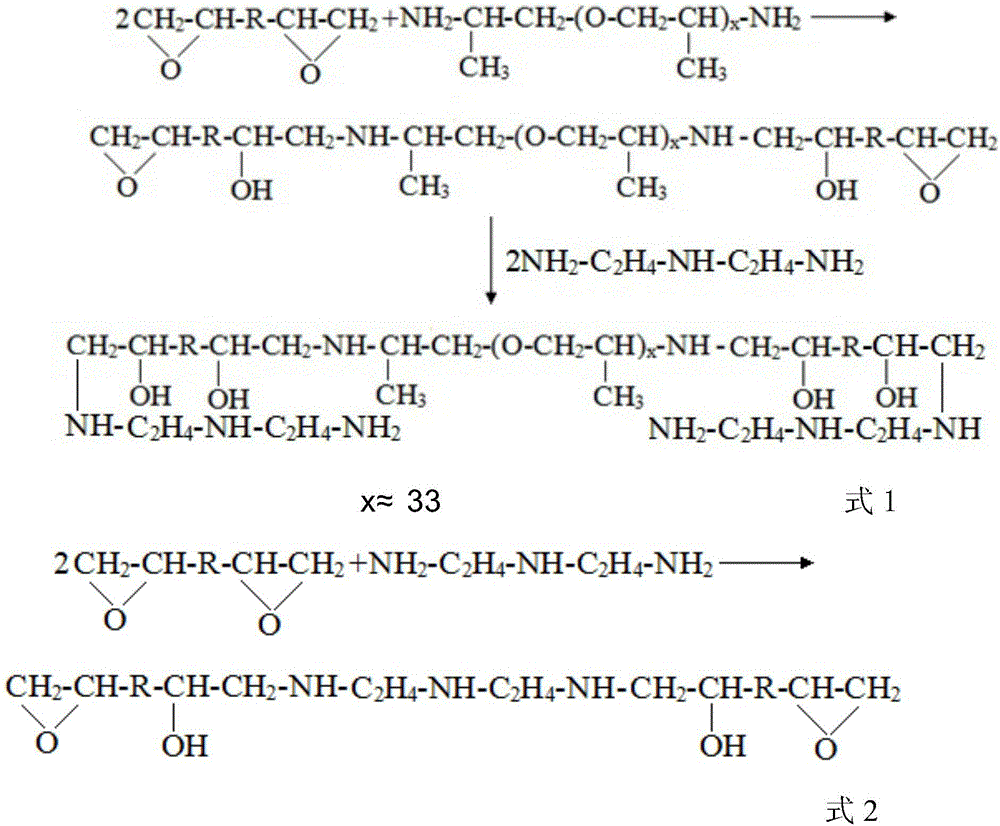

Method used

Image

Examples

Embodiment 1

[0030] A water-based epoxy modified polyamine curing agent, which is prepared by the following steps:

[0031] a Select E51 epoxy resin, ethylene glycol butyl ether, polyetheramine, diethylene triamine and deionized water as the reaction materials, and divide E51 epoxy resin and ethylene glycol butyl ether into two parts respectively, and mark as the first part E51 epoxy resin, second E51 epoxy resin, first ethylene glycol butyl ether and second ethylene glycol butyl ether. The dosages of the E51 epoxy resin, ethylene glycol butyl ether, polyetheramine, diethylenetriamine and deionized water are 38-42 parts, ethylene glycol butyl ether 10.5-11.5 parts, and polyetheramine 6.0-6.5 parts. Parts, 13.5-14.5 parts of diethylenetriamine and 28-32 parts of deionized water, based on parts by weight. Among them, the amount of the first E51 epoxy resin is 17.5-20.5 parts, the amount of the second E51 epoxy resin is 20.5-21.5 parts, the amount of the first ethylene glycol butyl ether is 4.9...

Embodiment 2

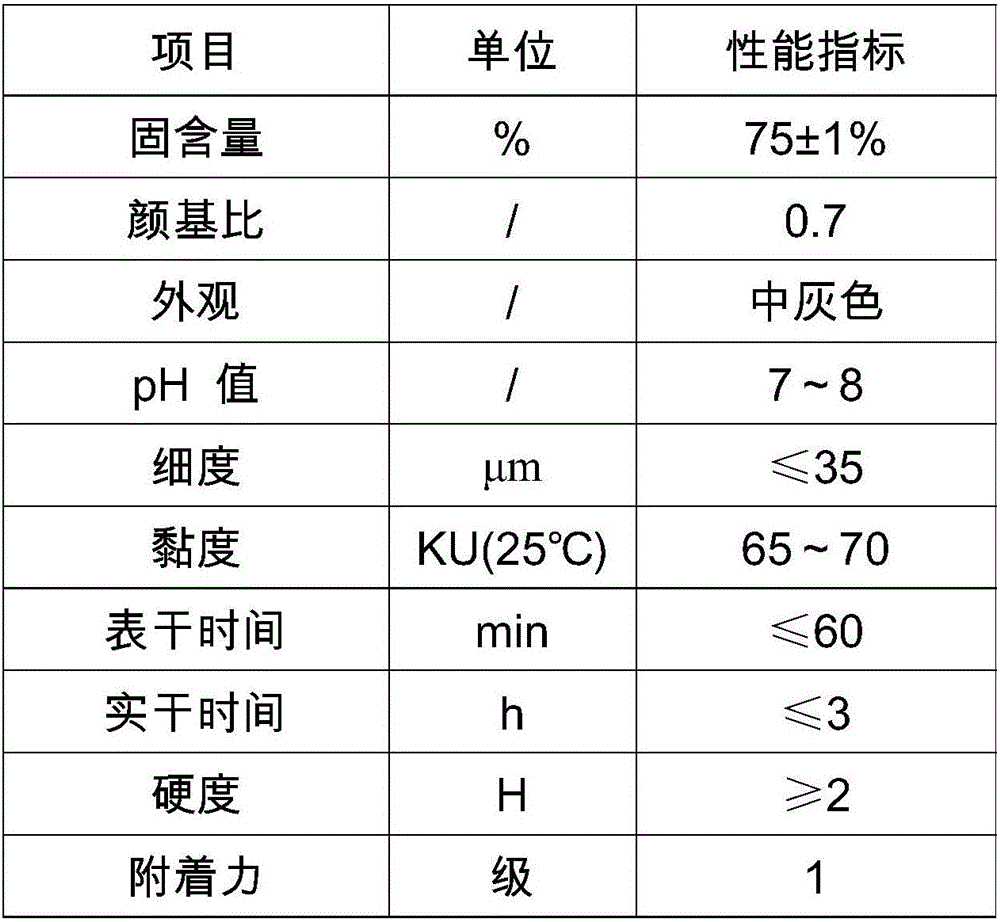

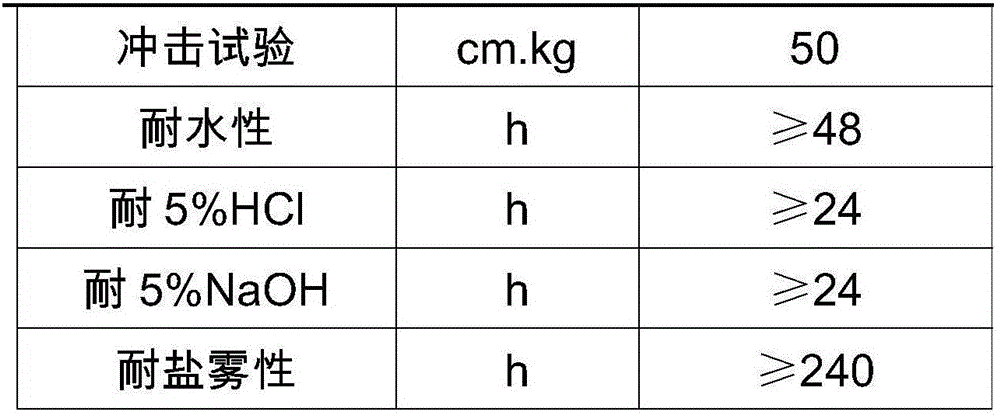

[0042] A waterborne epoxy anticorrosive primer, which is composed of component A and component B, said component A is 32 parts by weight of EPON828 epoxy resin, and said component B is made of the following parts by weight Ingredients: 44 parts of waterborne epoxy modified polyamine curing agent prepared in Example 1, 12.3 parts of deionized water, 0.6 parts of dispersant, 0.1 parts of TEGO830 defoamer, 10 parts of titanium dioxide, 4 parts of iron oxide black, precipitation 15 parts of barium sulfate, 12 parts of aluminum tripolyphosphate, 0.3 parts of water-based bentonite, 0.6 parts of anti-flash rust additive, 0.4 parts of substrate wetting agent, 0.1 part of BYK-028 defoamer, 0.5 part of RM-2020 thickener , 0.1 part of RM-8W thickener.

[0043] The above-mentioned dispersant is TEGO755W dispersant; the anti-flash rust additive is Raybo 60 anti-flash rust additive; the substrate wetting agent is TEGOTWIN 4100 substrate wetting agent.

[0044] The preparation steps are as follo...

Embodiment 3

[0050] A water-based epoxy anticorrosive primer, which is composed of component A and component B, said component A is 30 parts by weight of 128 epoxy resin, and said component B is made of the following parts by weight Composition: 45 parts of waterborne epoxy modified polyamine curing agent prepared in Example 1, 15 parts of deionized water, 0.5 parts of dispersant, 0.1 parts of TEGO830 defoamer, 12 parts of titanium dioxide, 3 parts of iron oxide black, precipitation 12 parts of barium sulfate, 10 parts of aluminum tripolyphosphate, 0.5 part of water-based bentonite, 0.5 part of anti-flash rust additive, 0.3 part of substrate wetting agent, 0.1 part of BYK-028 defoamer, 0.6 part of RM-2020 thickener , 0.1 part of RM-8W thickener.

[0051] The above-mentioned dispersant is BYK-192 dispersant; the anti-flash rust additive is Raybo 60 anti-flash rust additive; the substrate wetting agent is TEGOTWIN 4100 substrate wetting agent.

[0052] The preparation steps are as follows:

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com