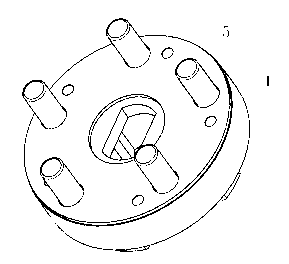

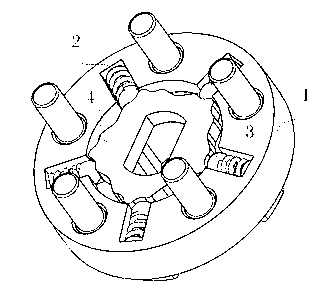

Planet carrier and preparation method thereof

A technology of planet carrier and powder metallurgy, which is applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of long production cycle, troubles in actual production, high production cost, etc., and achieve low production cost and suitable for automation The effect of high production and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

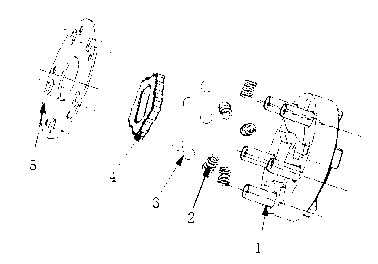

[0014] The production method of the planetary carrier is to perform operations such as forming, sintering, carburizing, and finalizing the powder metallurgy planetary carrier, and then through assembly, put the spring, steel ball, and cam into the planetary carrier cavity, and finally connect the gasket to the end face of the planetary carrier It is integrated into a whole by resistance welding, specifically:

[0015] (1) Dosing powder metallurgy planetary carrier according to the following parts by weight of powder metallurgy raw materials: Fe: 92.0 parts, C: 0.8 parts, Ni: 4.5 parts, Mo: 1.2 parts, Cu: 1.5 parts;

[0016] (2) Forming (100-ton forming machine), sintering (1120°C×0.5H), carburizing (830°C×2H, Cp:0.8) and finalization (ordinary 1-ton press) and other operations are carried out in sequence; out of the powder metallurgy planetary frame.

[0017] (3) Place the spring, steel ball, and cam into the cavity of the planetary carrier in sequence.

[0018] (4) The gask...

Embodiment 2

[0022] The method is the same as in Example 1, wherein the powder metallurgy planetary carrier ingredients are: Fe: 95.4 parts, C: 0.6 parts, Ni: 2.5 parts, Cu: 1.5 parts.

[0023] To test the product, the main testing parameters are shown in the table below:

[0024] Product Features Required specification value Product actual value product density 7.0g / cm 3 MIN 7.15g / cm 3 Shaft breakout force 150kgf MIN 165~190kgf Product torque 1000kgf MIN 1250~1500kgf Gasket and planet carrier breakout force 60kgf MIN 80~120kgf MIN

Embodiment 3

[0026] The method is the same as in Example 1, wherein the powder metallurgy planetary carrier ingredients are: Fe: 95.4 parts, C: 0.6 parts, Ni: 2.5 parts, Cu: 1.5 parts.

[0027] To test the product, the main testing parameters are shown in the table below:

[0028] Product Features Required specification value Product actual value product density 7.0g / cm 3 MIN 7.15g / cm 3 Shaft breakout force 150kgf MIN 165~190kgf Product torque 1000kgf MIN 1250~1500kgf Gasket and planet carrier breakout force 60kgf MIN 80~120kgf MIN

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com