Method for preparing LiNi<1/3>Co<1/3>Mn<1/3>O<2> ternary cathode material

A positive electrode material and concentration technology, applied in the field of electrochemical power supply, can solve the problems of increasing the difficulty and cost of ternary material production, and achieve the effects of easy production operation, simple synthesis process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

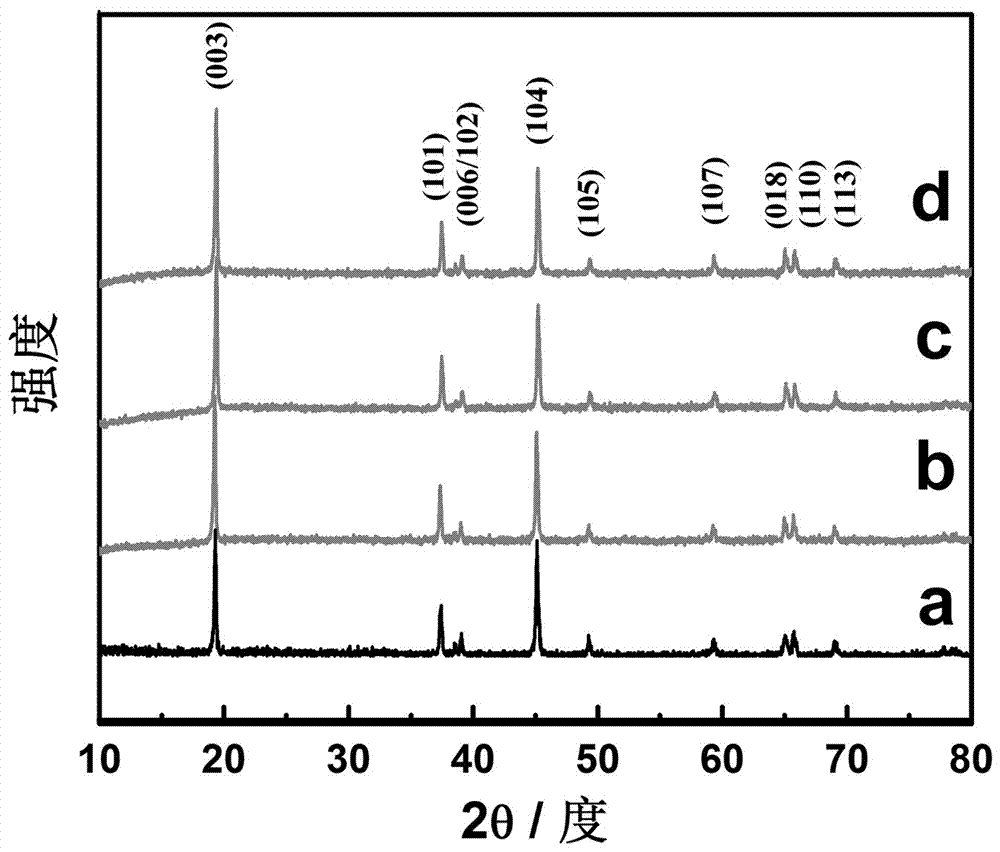

[0016] 1.7515 g NiSO 4 ·6H 2 O, 1.8731 g CoSO 4 ·7H 2 O, 1.1266 g MnSO 4 ·H 2 O was sequentially dissolved in 40 mL of deionized water at a molar ratio of 1:1:1, stirred for 30 min to dissolve completely, and at the same time, 1.6109 g of NaOH was added to 80 mL of deionized water. Then, the mixed solution containing nickel ions, cobalt ions, and manganese ions was added dropwise to the NaOH solution, and 15 mL of NaOH with a concentration of 3.35 mol L -1 ammonia water as a complexing agent, at 400 r min -1 Stir at 50-55°C temperature for 12 hours to obtain a black suspension, which is filtered after standing for 6-8 hours, washed several times, and dried in an oven at 90°C for 9 hours to obtain a precursor. Add 0.7265 g Li to the precursor (1.8 g) 2 CO 3 , after ball milling with absolute ethanol as the medium for 6 hours, dried, and sintered at 450 °C for 5 hours, then sintered at 900 °C for 12 hours, cooled and sieved to obtain LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Tern...

Embodiment 2

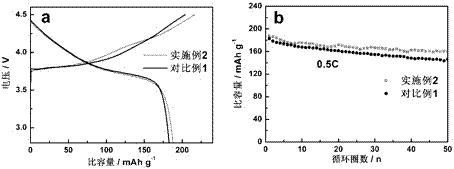

[0018] 1.7515 g NiSO 4 ·6H 2 O, 1.8731 g CoSO 4 ·7H 2 O, 1.1266 g MnSO 4 ·H 2 O was sequentially dissolved in 80 mL of deionized water at a molar ratio of 1:1:1, stirred for 30 min to dissolve completely, and at the same time, 1.6109 g of NaOH was added to 80 mL of deionized water. Then, the mixed solution containing nickel ions, cobalt ions, and manganese ions was slowly added dropwise to the NaOH solution, and 15 mL of 3.35 mol L -1 Ammonia water was used as a complexing agent, stirred at a speed of 400 r min-1, and incubated at 50-55°C for 12 hours to obtain a black suspension, which was left to stand for 6-8 hours, filtered, washed several times, and dried at 90 ℃ oven for 9 hours to obtain the precursor. Add 0.7265 g Li to the precursor (1.8 g) 2 CO 3 , after ball milling with absolute ethanol as the medium for 6 hours, dried, and sintered at 450 °C for 5 hours, then sintered at 900 °C for 12 hours, cooled and sieved to obtain LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternar...

Embodiment 3

[0020] 1.7515 g NiSO 4 ·6H 2 O, 1.8731 g CoSO 4 ·7H 2 O, 1.1266 g MnSO 4 ·H 2 O was sequentially dissolved in 200 mL of deionized water at a molar ratio of 1:1:1, stirred for 30 min to dissolve completely, and at the same time, 1.6109 g of NaOH was added to 80 mL of deionized water. Then, the mixed solution containing nickel ions, cobalt ions, and manganese ions was slowly added dropwise to the NaOH solution, and 15 mL of 3.35 mol L -1 Ammonia water was used as a complexing agent, stirred at a speed of 400 r min-1, and kept at 50-55 ° C for 12 hours to obtain a black suspension, which was filtered after standing for 6-8 hours and washed several times. ℃ oven for 9 hours to obtain the precursor. Add 0.7265 g Li to the precursor (1.8 g) 2 CO 3 , after ball milling with absolute ethanol as the medium for 6 hours, dried, and sintered at 450 °C for 5 hours, then sintered at 900 °C for 12 hours, cooled and sieved to obtain LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternary cathode mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com