Cast-weld conveyor for lead-acid storage battery

A technology of lead-acid batteries and conveyors, applied in the direction of lead-acid batteries, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the problems of high labor intensity, heavy battery fixtures, low efficiency, etc., to simplify production operations, Reasonable structural design and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

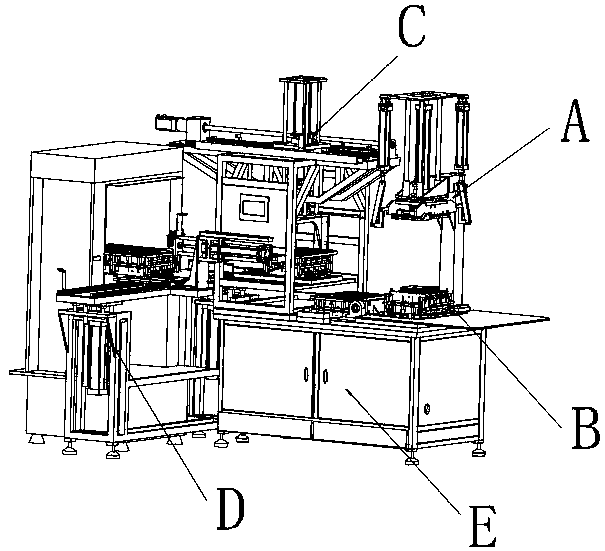

[0021] like figure 1 As shown, the lead-acid battery casting welding conveyor has a structure including the whole ear and turning module A, the cutting brush module B, the dipping liquid and conveying module C and the casting welding docking module D, wherein the whole ear and turning module A and the dipping liquid and The conveying module C is set on the frame E, the brush cutting module B is set on the inner side of the frame E under the brush cutting panel between the whole ear and turning module A and the dipping liquid and conveying module C, and the casting and welding docking module D is set on the dipping The liquid and delivery module C is on the outside of the frame E.

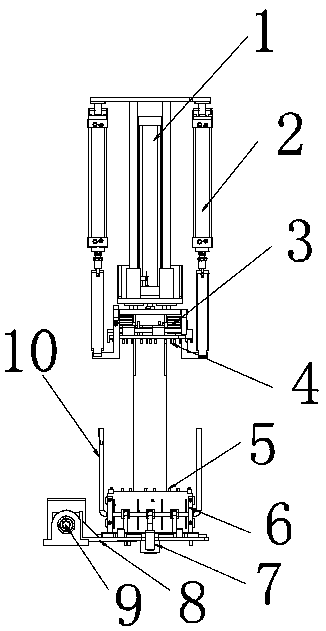

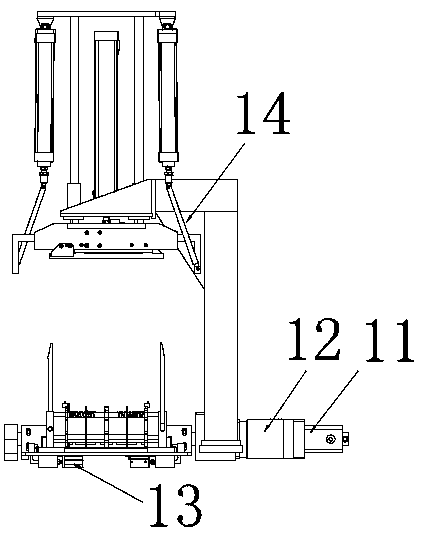

[0022] like Figure 2-1 , 2-2 As shown, the whole ear and turning module A includes A lifting cylinder 1, pressing handle cylinder 2, whole ear cylinder 3, A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com