Patents

Literature

217results about How to "Realize the sealing function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

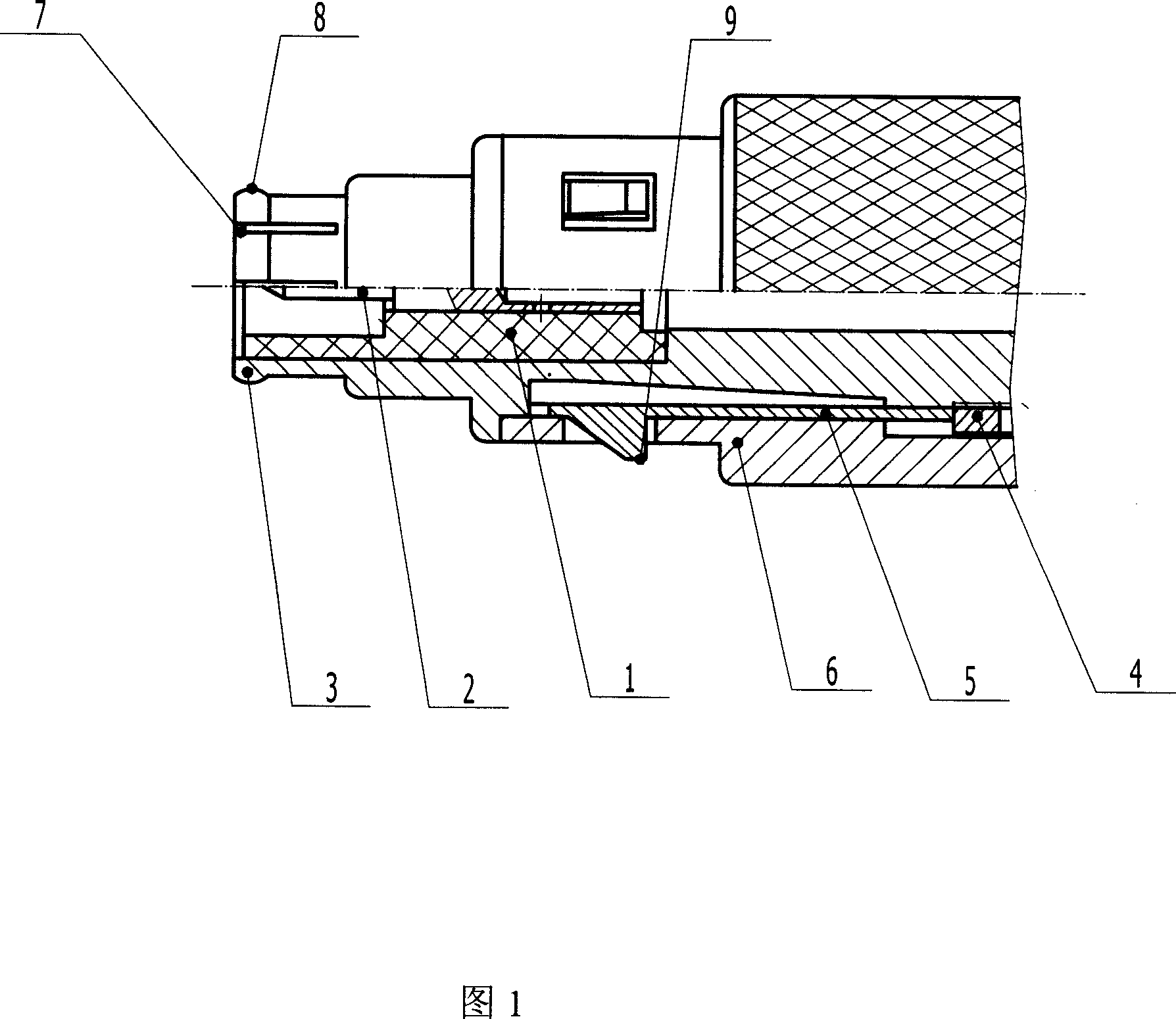

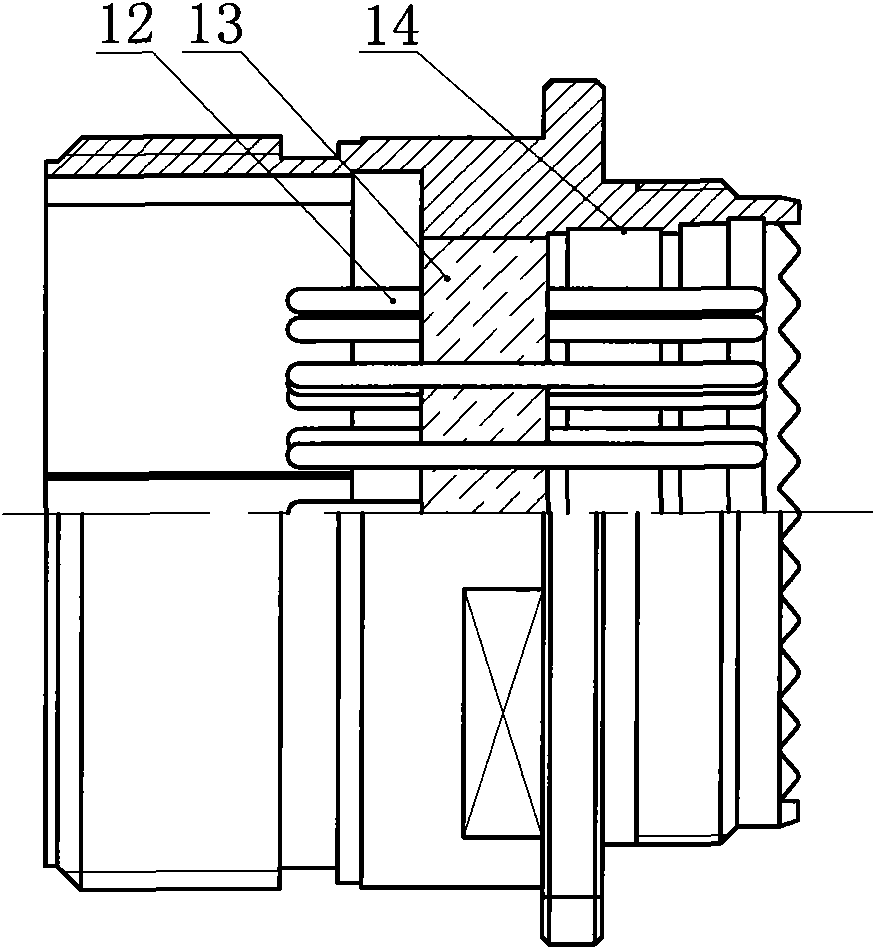

Seal radiofrequency coaxial connector with self locking mechanism

InactiveCN101005180ARealize the sealing functionQuick plugCoupling device detailsTwo-part coupling devicesLocking mechanismSelf locking

Six slots along axial line are made on head of plug body. The head portion is an arc shaped male tab. Claws are located outside the body case, and outer sheath is located outside the claws. Nut is screwed on postmedian portion of the body case. Three claws with barbs are placed between inner male tab of the body case and the nut in order to restrict axial drunkenness of claws. Radial clearance is kept between the outer sheath and the claws. There are five straight holes with different diameters and two cone shaped bores inside head of socket shell. The holes are matched to diameters of plug. The cone-shaped bores are guide holes. Outline of insulator is in step shape, where small end is extended out of the straight hole, and large end is stopped by the inner hole of shell. Full escaping lock connection between socket and plug is adopted in the invention so as to guarantee quick plugging in or out, and provide firm bond between socket and plug under execrable mechanical condition.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

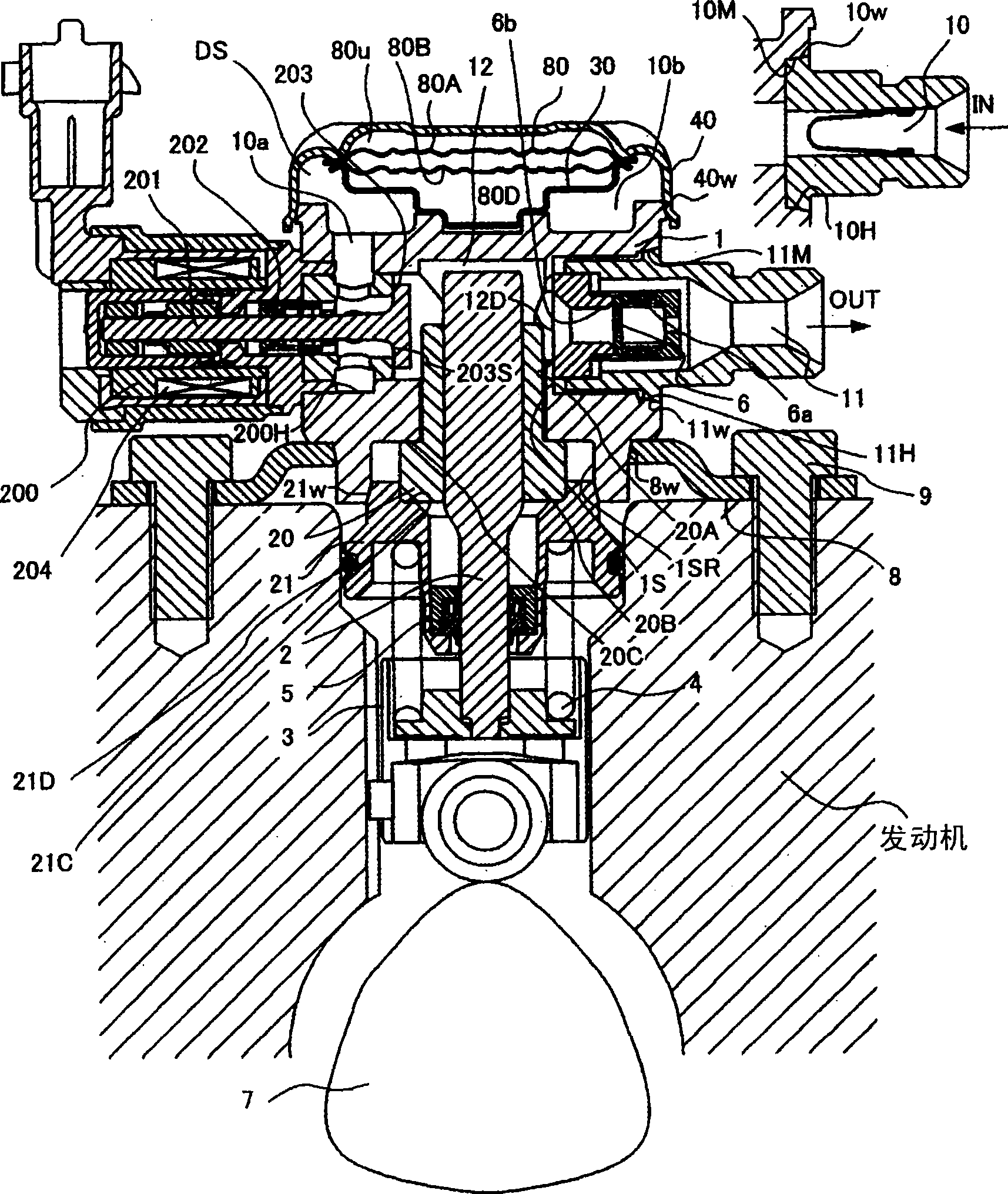

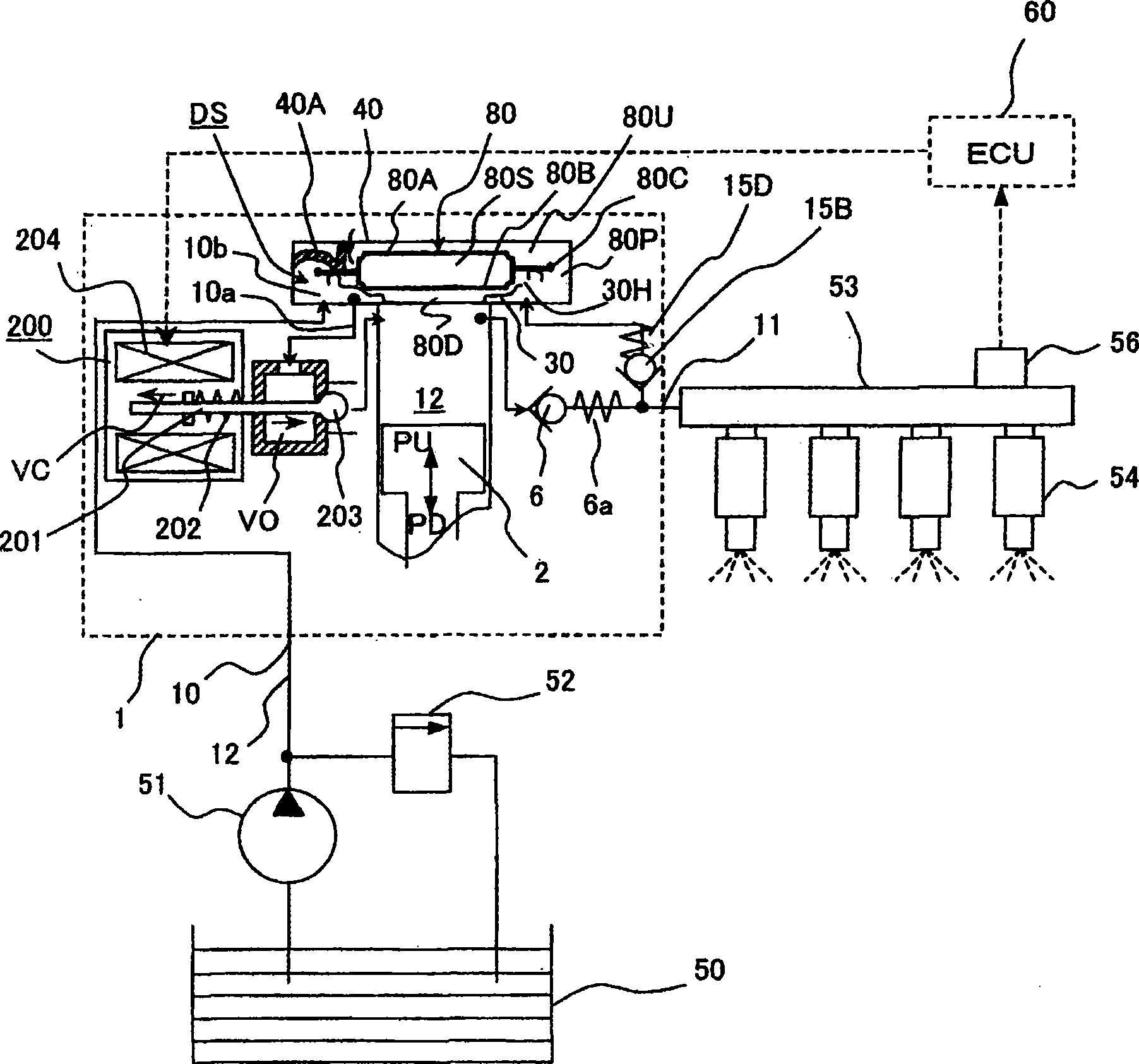

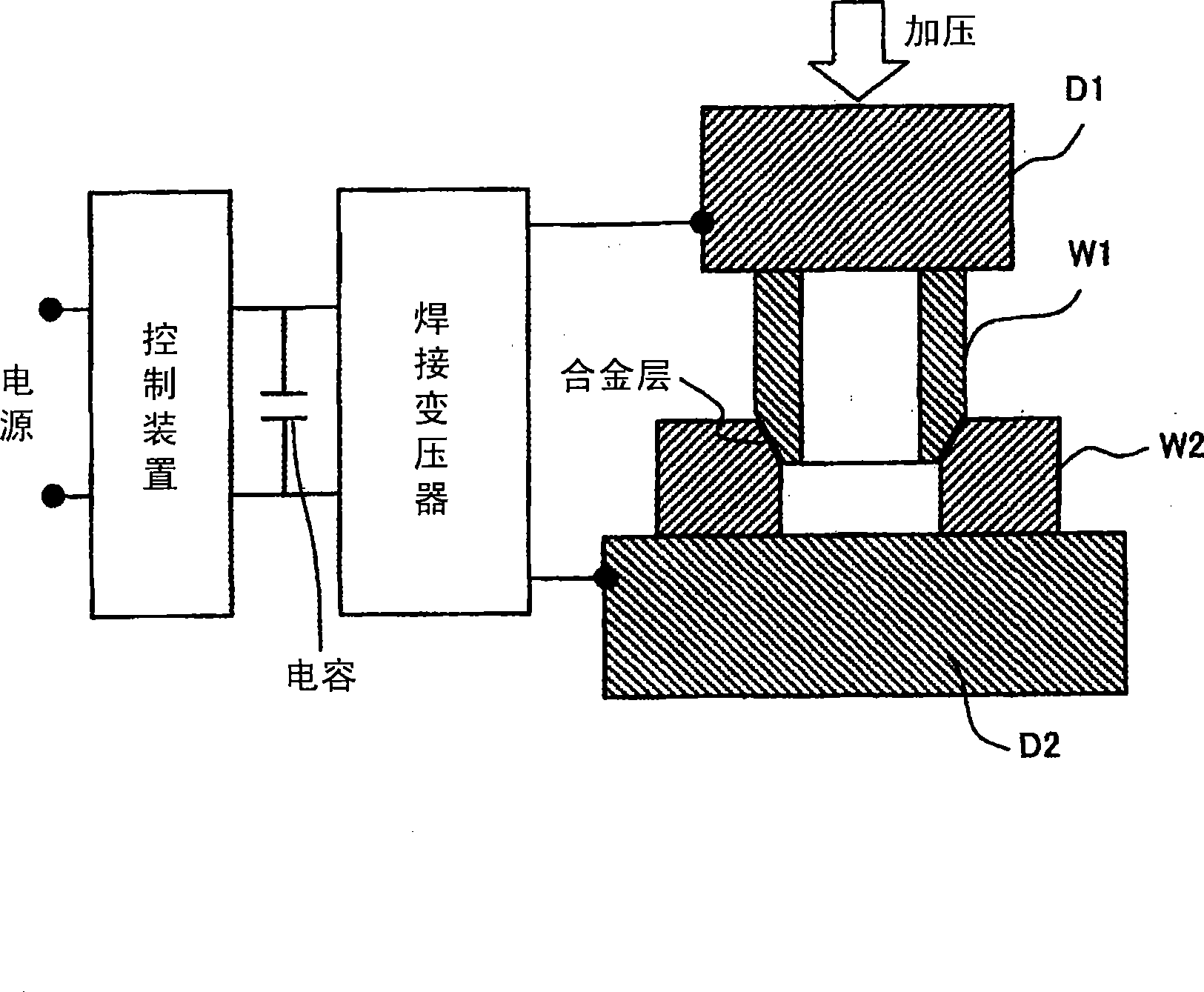

High-pressure fuel supply pump and the manufacturing method

InactiveCN101424235ARealize the joint functionRealize the sealing functionTubular articlesHollow articlesInlet valveMetallic materials

An object of this invention is to provide such a welded structure of and welding method for two metallic parts fitted together at a tubular section in a high-pressure fuel supply pump, that enables rapid joining of both metallic parts by staking (press-fitting included), screw fastening, and / or laser welding, offers high welding strength and sufficient fluid sealability, and keeps the metallic materials free from thermal changes in composition. While an electric current is supplied to any one of the welding connection surfaces formed between a pump housing and cylinder in a high-pressure fuel supply pump, between the pump housing and an installation flange, between the pump housing and an intake or discharge joint, between the pump housing and a pulsation-absorbing damper cover, between the pump housing and a relief valve mechanism, and between the pump housing and an electromagnetically driven intake valve mechanism, the particular two sections are pressed against each other to generate, along the connection surface, a plastic flow not causing melting or fusion due to heat, and form a diffusion-weld region at the connection surface by using the plastic flow and the application of the pressure.

Owner:HITACHI LTD

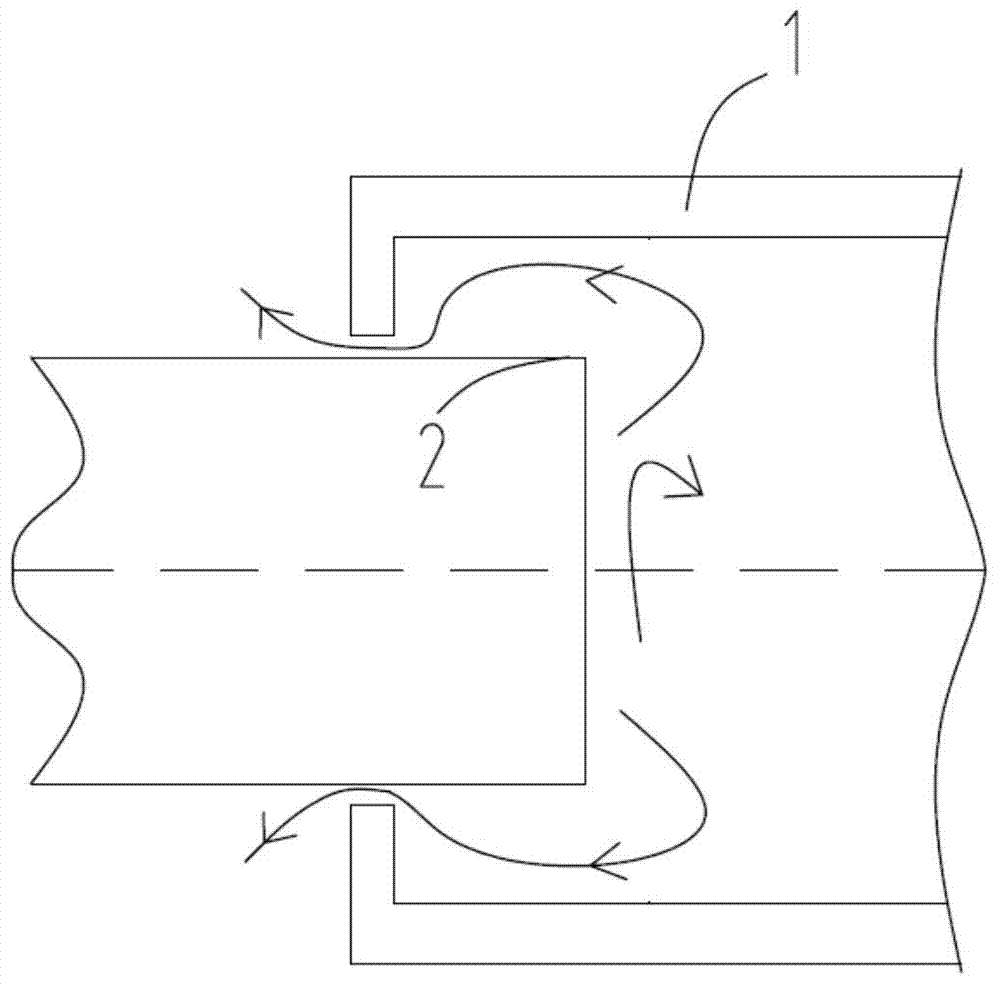

Sealing mechanism preventing gas exchange

ActiveCN104728448AAvoid swappingAvoid enteringEngine sealsSludge treatment by pyrolysisGas exchangeMechanical engineering

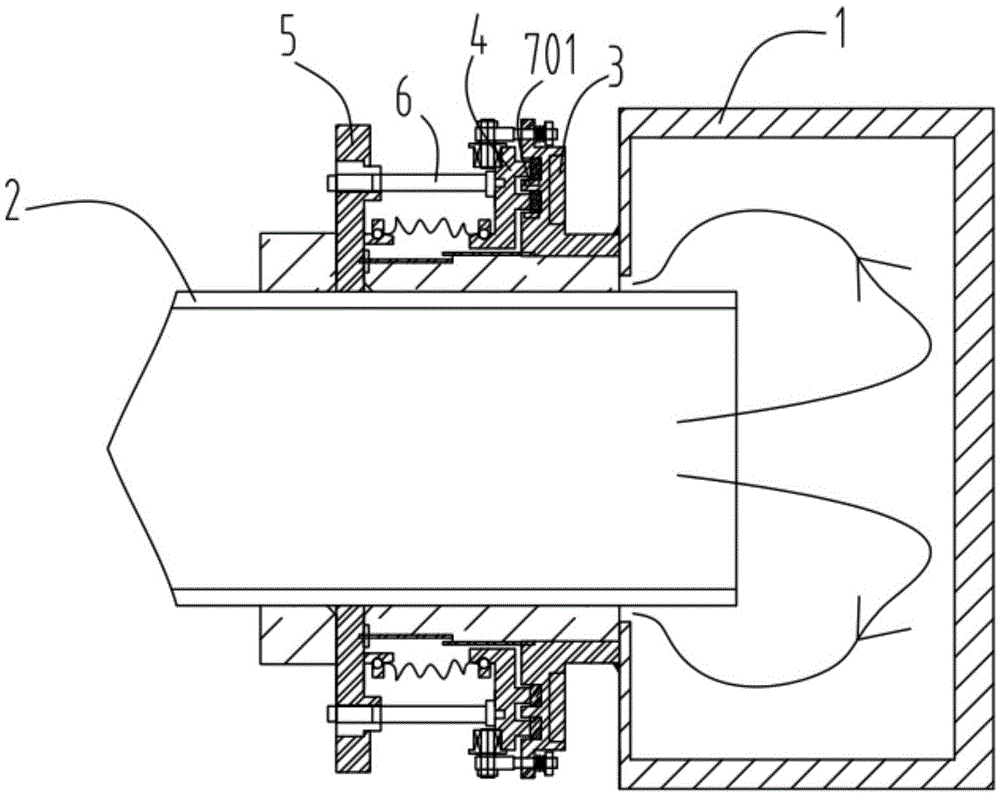

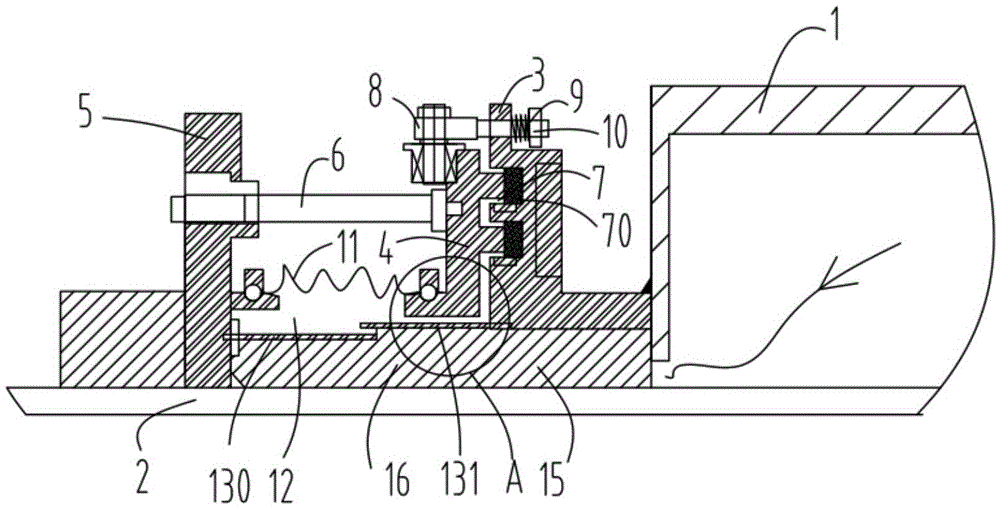

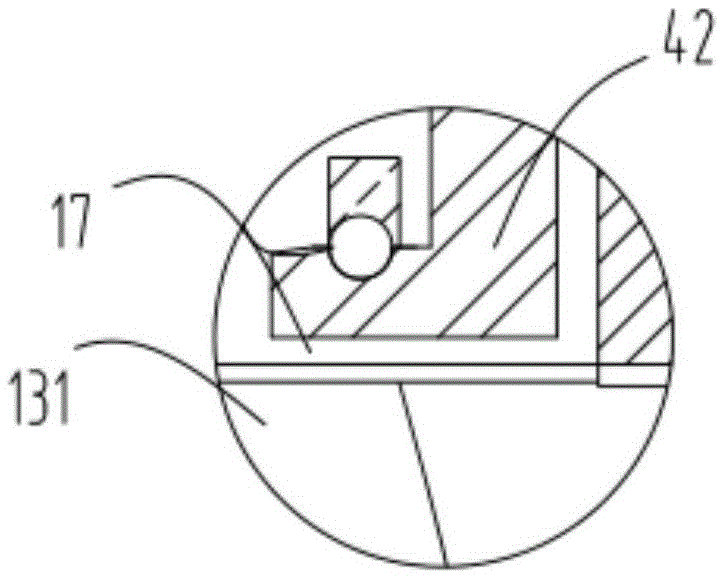

The invention relates to a sealing mechanism preventing gas exchange. The sealing mechanism comprises a stress block (3), a pressing block (4) and a compressing mechanism (5), wherein the stress block (3) is connected with a fixed part (1) and is in clearance fit with a rotating part (2); the pressing block (4) is in clearance fit with the rotating part (2) in a rotating mode; the compressing mechanism (5) is fixedly connected with the rotating part (2); the pressing block (4) presses the stress block (3) through the compressing mechanism; the stress block (3) is provided with a first sealing strip (3c); a second sealing strip (4e) is placed in a cavity (4d) of the pressing block (4); a first gap (2a) formed between the pressing block (4) and the outer wall surface of the rotating part (4) is sealed through the second sealing strip (4e); a threaded rod (7a) of a compressing screw (7) of the compressing mechanism (5) applies pressure to a force applying surface (4a2) of the pressing block (4), and the pressing block (4) compresses the first sealing strip (3c) of the stress block (3) through a first pressing surface (4a2) of a compressing surface (4a1) so that a second gap (8) formed between the pressing block (4) and the stress block (3) can be sealed. The sealing function is achieved through the simple mechanical sealing mechanism, gas exchange through the gap formed between the fixed part and the rotating part is prevented, in this way, external gas is prevented from entering the rotating part through the gap, and meanwhile gas inside the rotating part is prevented from leaking outwards through the gap.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

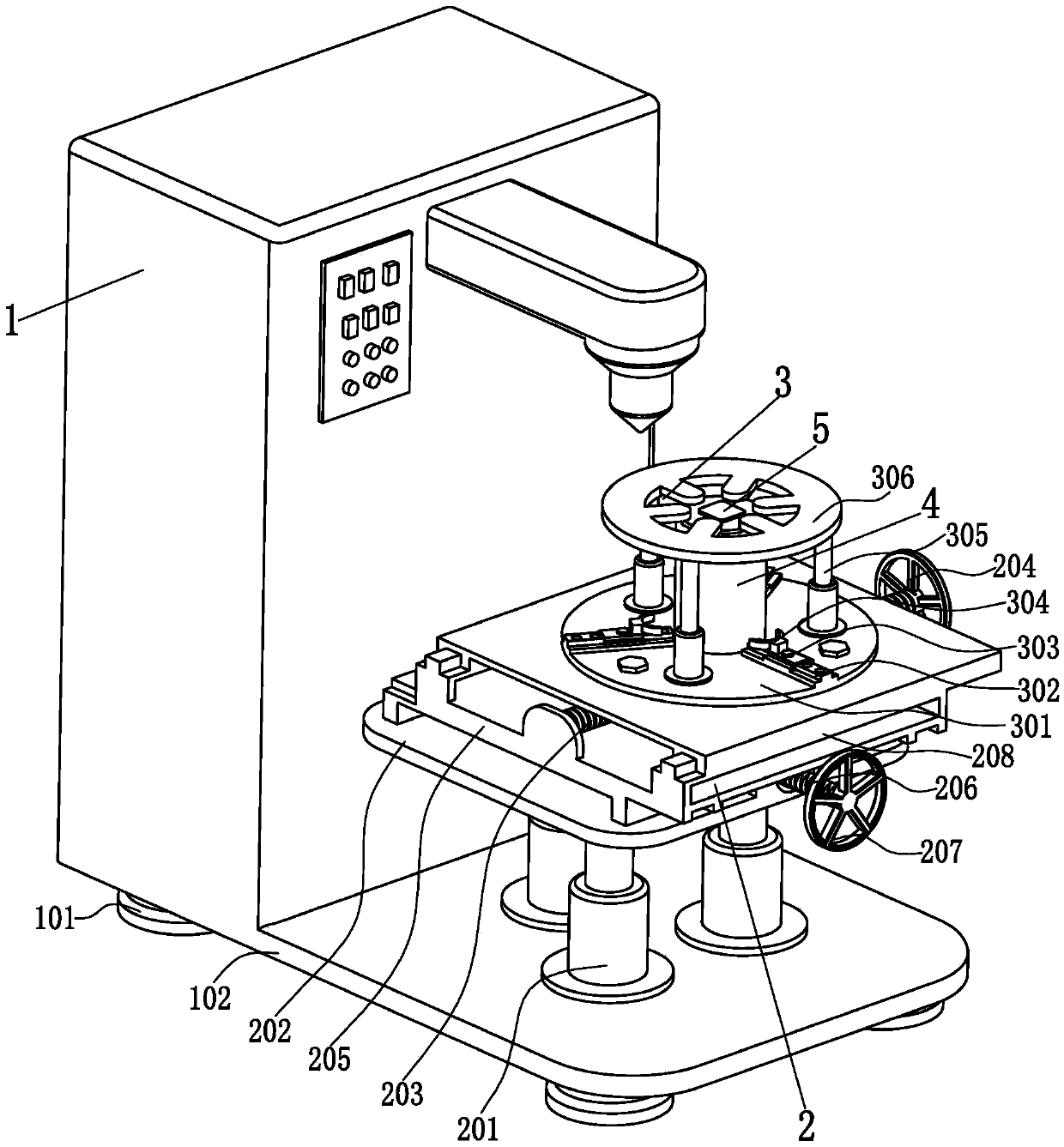

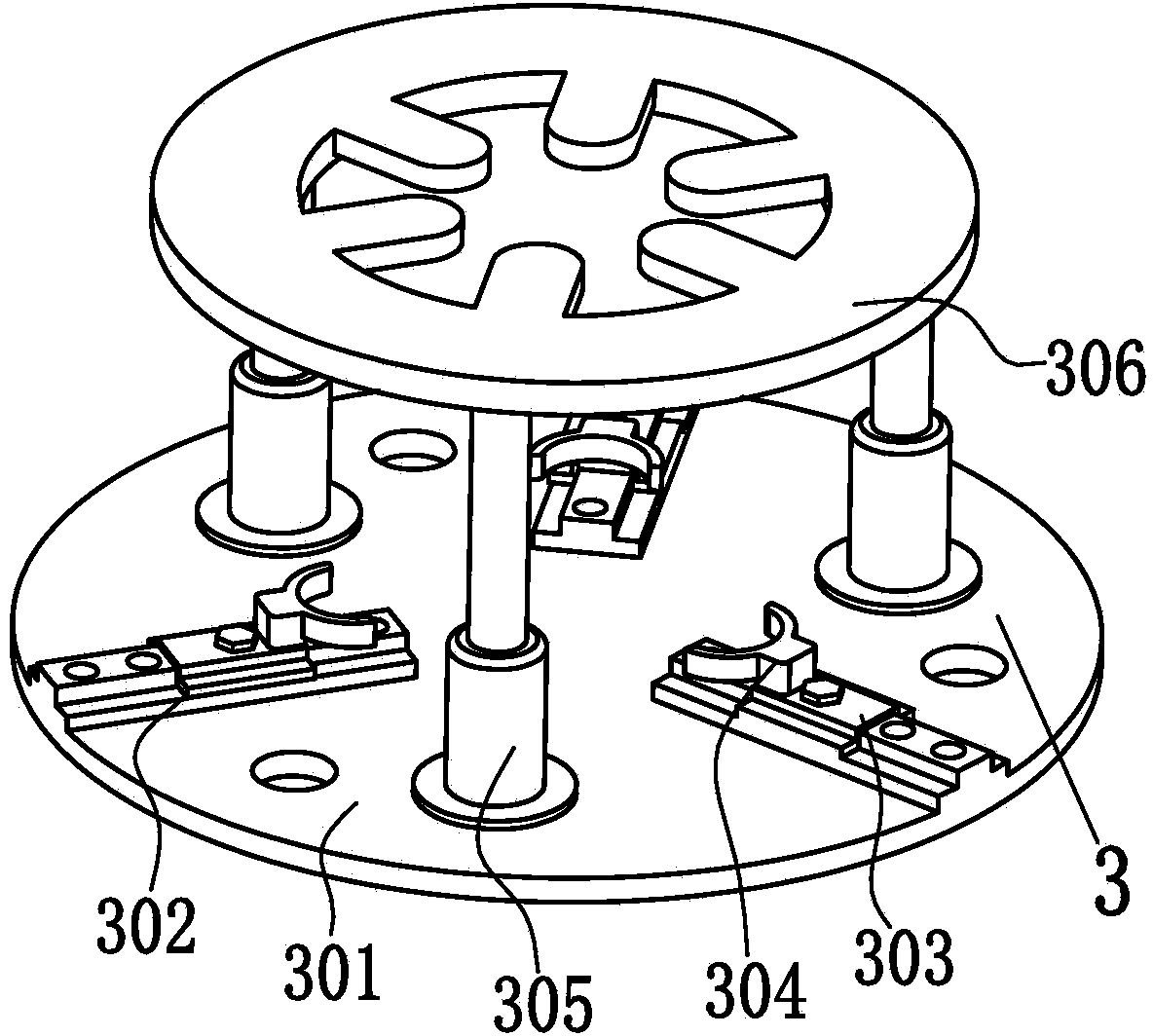

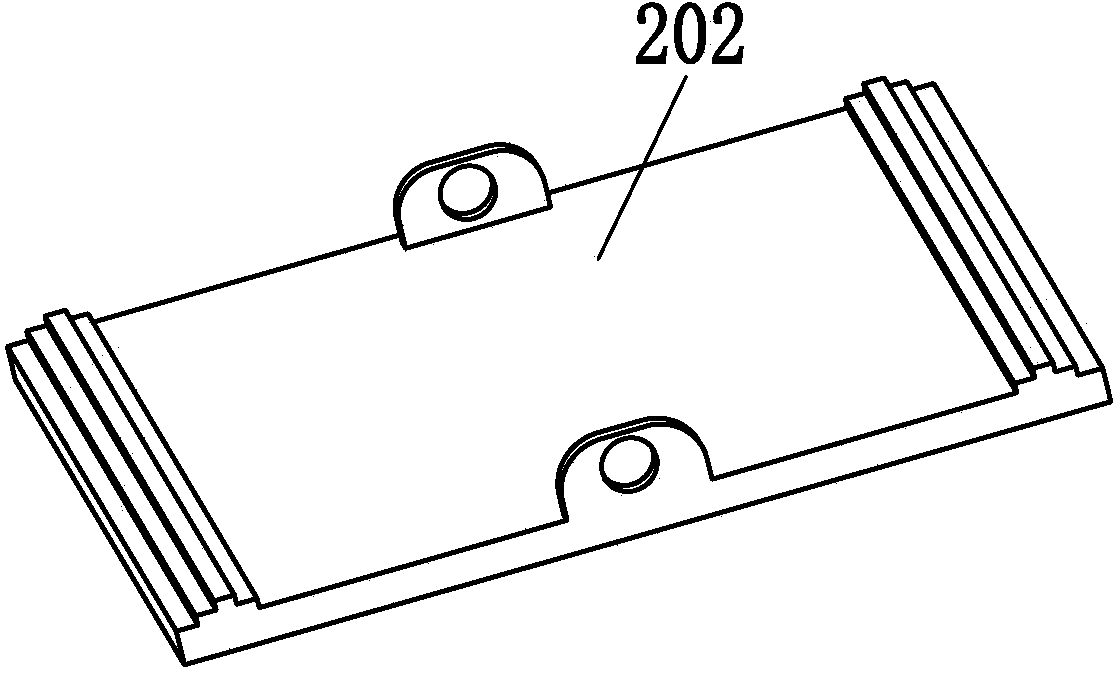

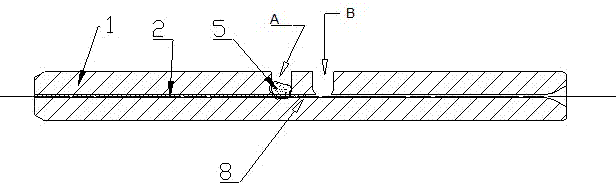

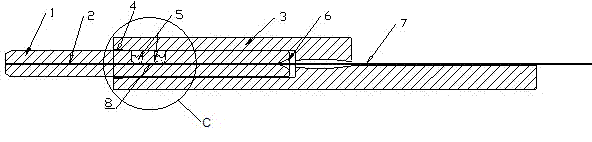

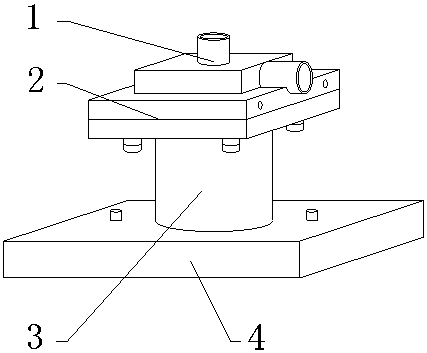

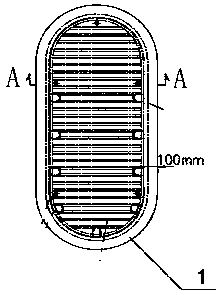

Laser penetration sealing equipment and method of lithium battery

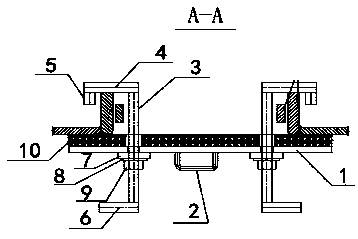

InactiveCN104002046AGuaranteed stabilityImprove the quality of laser weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMetallic Nickel

The invention relates to the field of lithium battery production, in particular to laser penetration sealing equipment of a lithium battery. The equipment comprises a laser welder body, a three-freedom-degree welding workbench and a clamping fixing device. The three-freedom-degree welding workbench is arranged on a square platform. The clamping fixing device is arranged right above the three-freedom-degree welding workbench. According to a laser penetration sealing method of the lithium battery, an electrode tab is pressed above a metal pushing column of the lithium battery, a cover plate is arranged right above the metal pushing column of the lithium battery, a square nickel metal piece is arranged in a cover plate groove, during laser welding, the nickel metal piece can be arranged in the cover plate groove in a filling mode after being molten, cracks and leakage points are generated, and the function of full sealing is achieved. The stability of a lithium battery welding position is guaranteed, the laser welding quality of the lithium battery is improved, the function of full sealing is achieved, and the attractiveness of welding is improved.

Owner:ZHEJIANG JINKAILAI NEW ENERGY TECH

Method for preparing carbon/carbon cylinder by using winding technology

InactiveCN108191448AReduce manufacturing costProcess production cycle time is shortFurnace componentsGas emission reductionFiberCarbonization

The invention provides a method for preparing carbon / carbon cylinder by using a winding technology. The method comprises the following steps that (1)a graphite material is utilized to design, manufacture and form a mold according to the dimension of the cylinder; (2) product structures of a sealed type cylinder and a structural type cylinder are designed respectively according to the using functional requirements of the cylinder; (3) winding forming is conducted by using a winding machine; (4) solidification treatment is conducted; (5) carbonization treatment is conducted; (6) CVD (chemical vapor deposition) densifying treatment is conducted; (7) high temperature treatment is conducted; and (8) machining forming is conducted. Compared with a traditional carbon / carbon cylinder production technology, the method has the following advantages that (1) the product is designed and formed in net dimension, the machining allowance of the finished product is less, the production cost is as low as 60% of the traditional technological cost; (2) the fiber content of the product is high, the basic density of the green body of the formed product is high, the product period is short, the machiningallowance is saved, and the strength is high, the method can achieve the sealing function of the carbon / carbon cylinder, the furnace internal thermal treatment efficiency is effectively improved, theservice life of a furnace external heat preservation material is prolonged, and the carbon / carbon cylinder can serve as a gas transmission pipeline, and has the generalization performance, the innovation advantage and the batch production advantage.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD

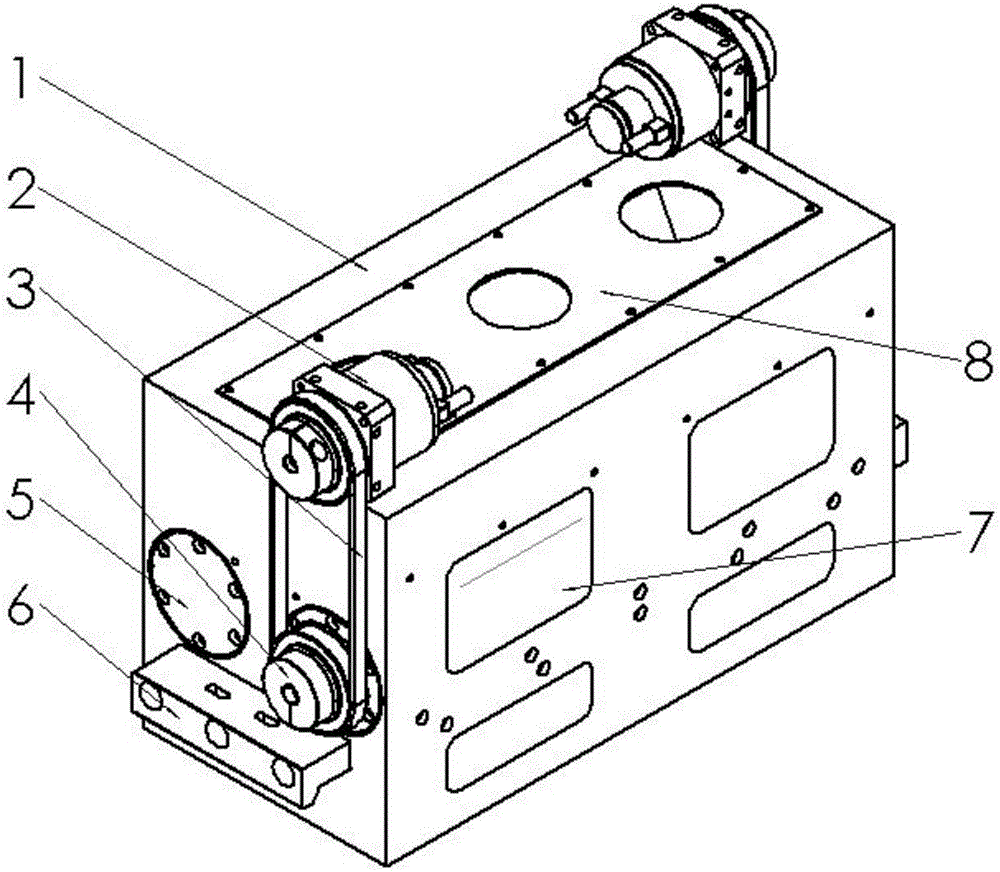

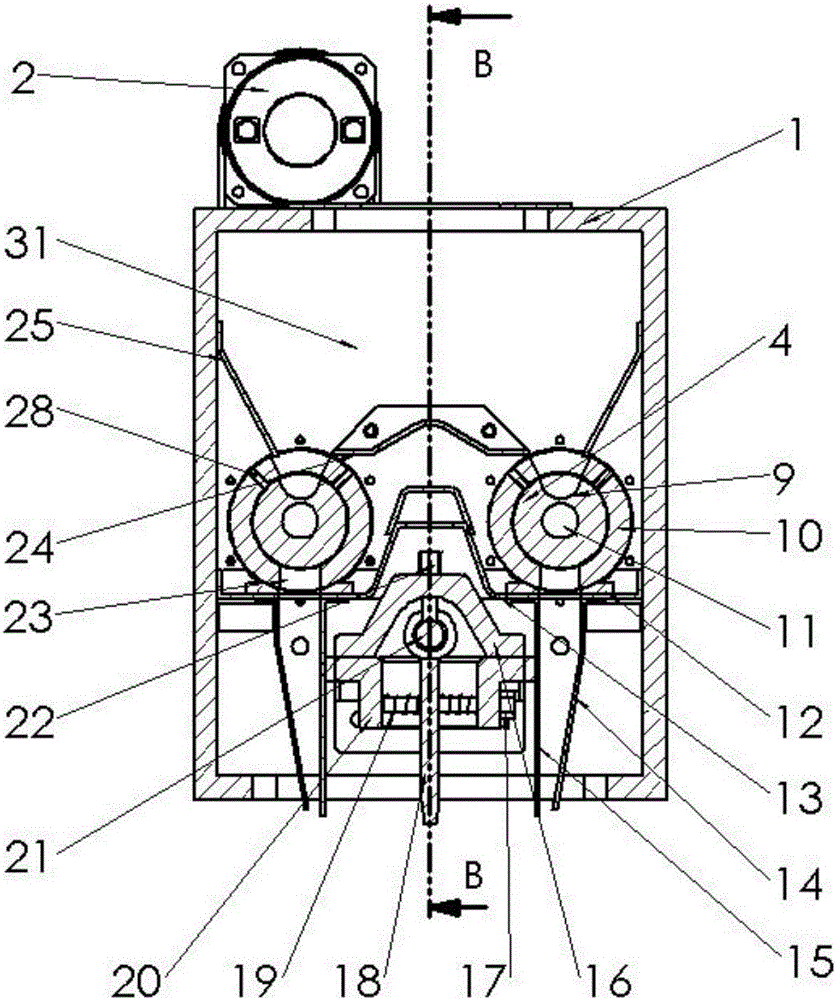

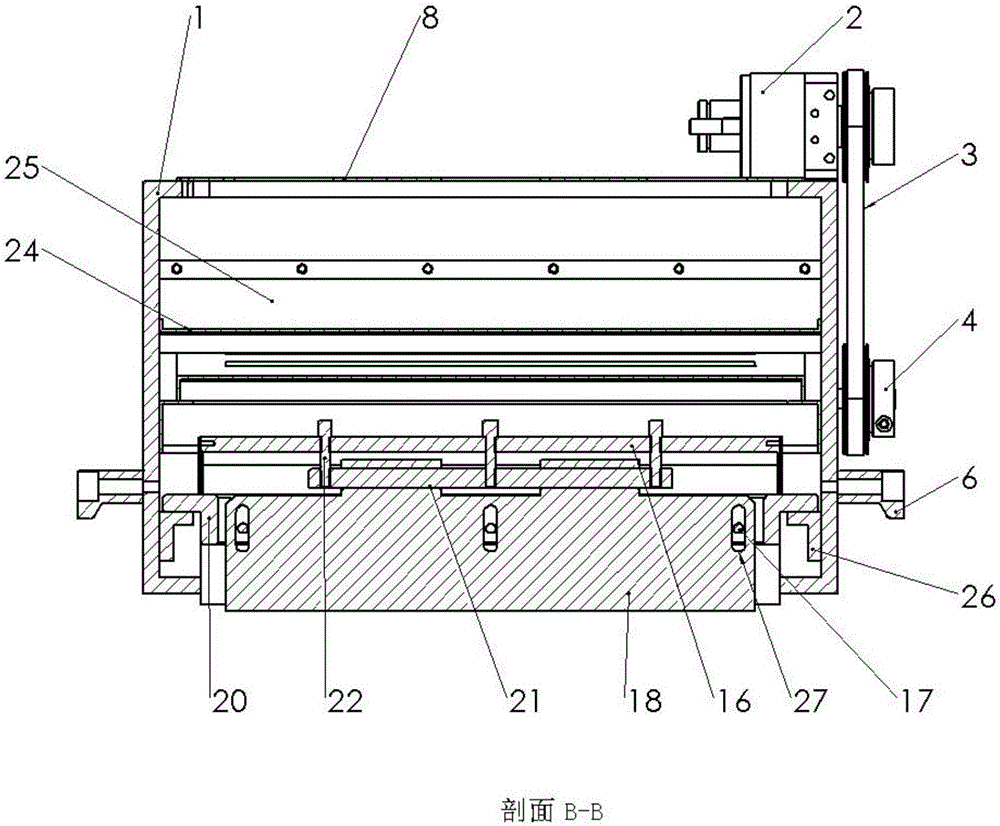

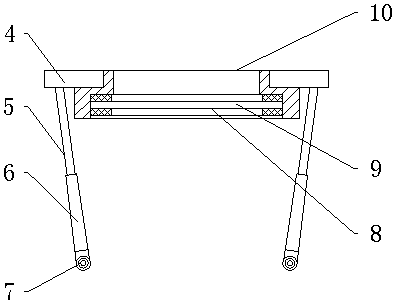

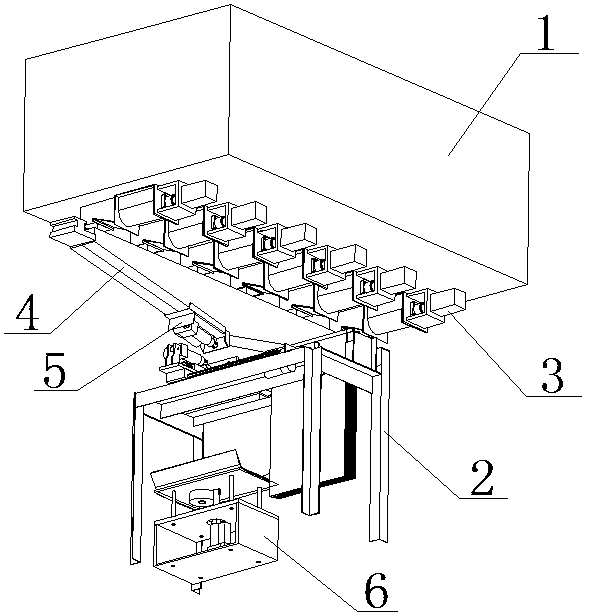

Self-powder-storing selective laser melting powder supplying flexible bidirectional non-redundancy powder laying device

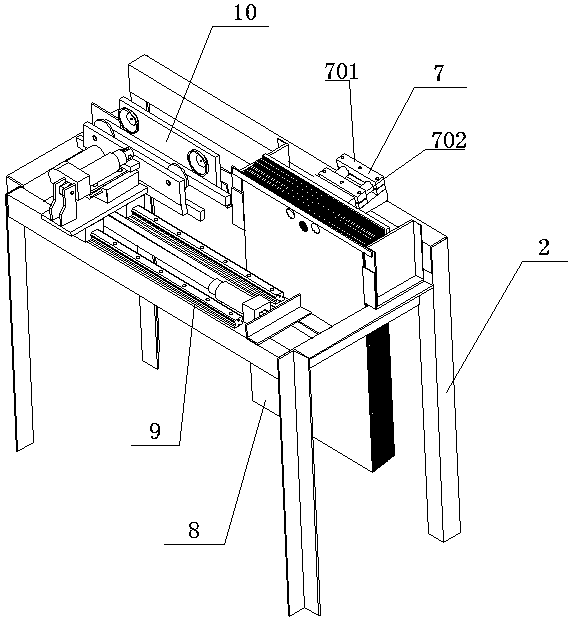

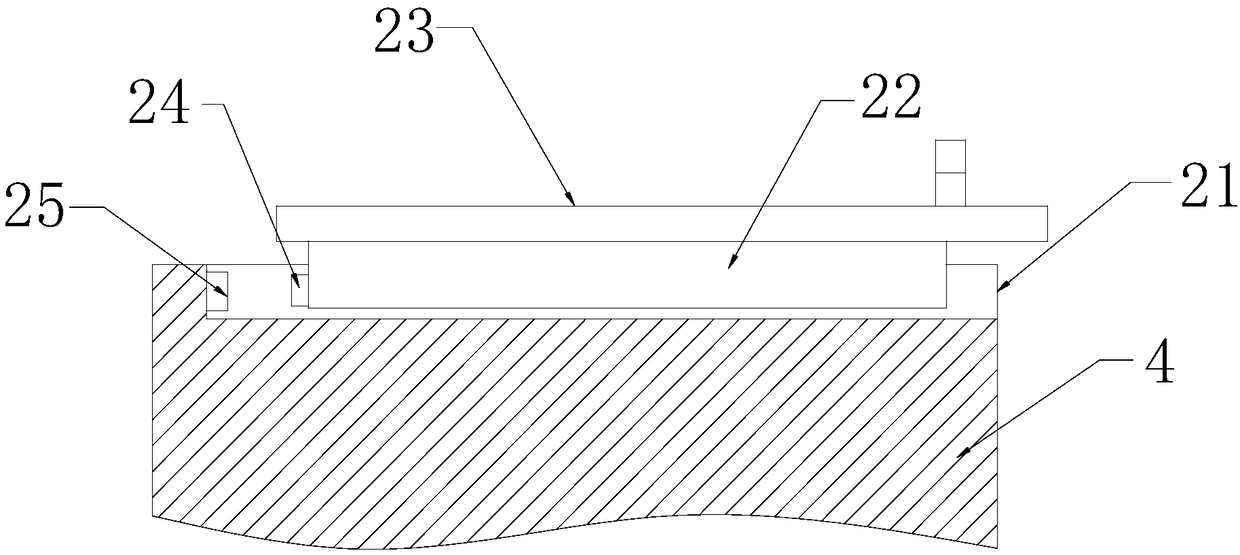

ActiveCN106346005AAvoid mixingGuaranteed efficiencyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingEngineering

The invention relates to a self-powder-storing selective laser melting powder supplying flexible bidirectional non-redundancy powder laying device. The device comprises a powder laying device box body, wherein one swinging cylinder is respectively fixed at the left side and right side of the upper part of the powder laying device box body, the swinging cylinder is connected with quantitative powder supplying wheels, window glass is arranged in front and at the back of the powder laying device box body respectively, a powder laying box cover plate is arranged at the upper part of the powder laying box body, one powder storage bin is formed inside the powder laying box body, two quantitative powder supplying wheels inside the powder laying device box body are parallel to each other horizontally, the quantitative powder supplying wheels are mounted on a mandrel, a quantitative powder supplying wheel sleeve is arranged outside the quantitative powder supplying wheels, a powder slot is formed in the upper surface and lower surface of the quantitative powder supplying wheel sleeve respectively, and the powder slots in the lower surface of the quantitative powder supplying wheel sleeve are respectively corresponding to quantitative powder supplying and powder blocking plates arranged below the powder slost; and the upper part of a powder scraping plate is mounted on a rotatable adjustable powder scraping plate shaft, and pre-tightening springs are respectively mounted on guide pin shafts at the two sides of the powder scraping plate. The device provided by the invention has the advantages that the powder laying efficiency and quality are guaranteed, and oxidation and impurities such as casts which are produced in a 3D printing process can not be easily mixed into a powder supplying cylinder.

Owner:XI AN JIAOTONG UNIV

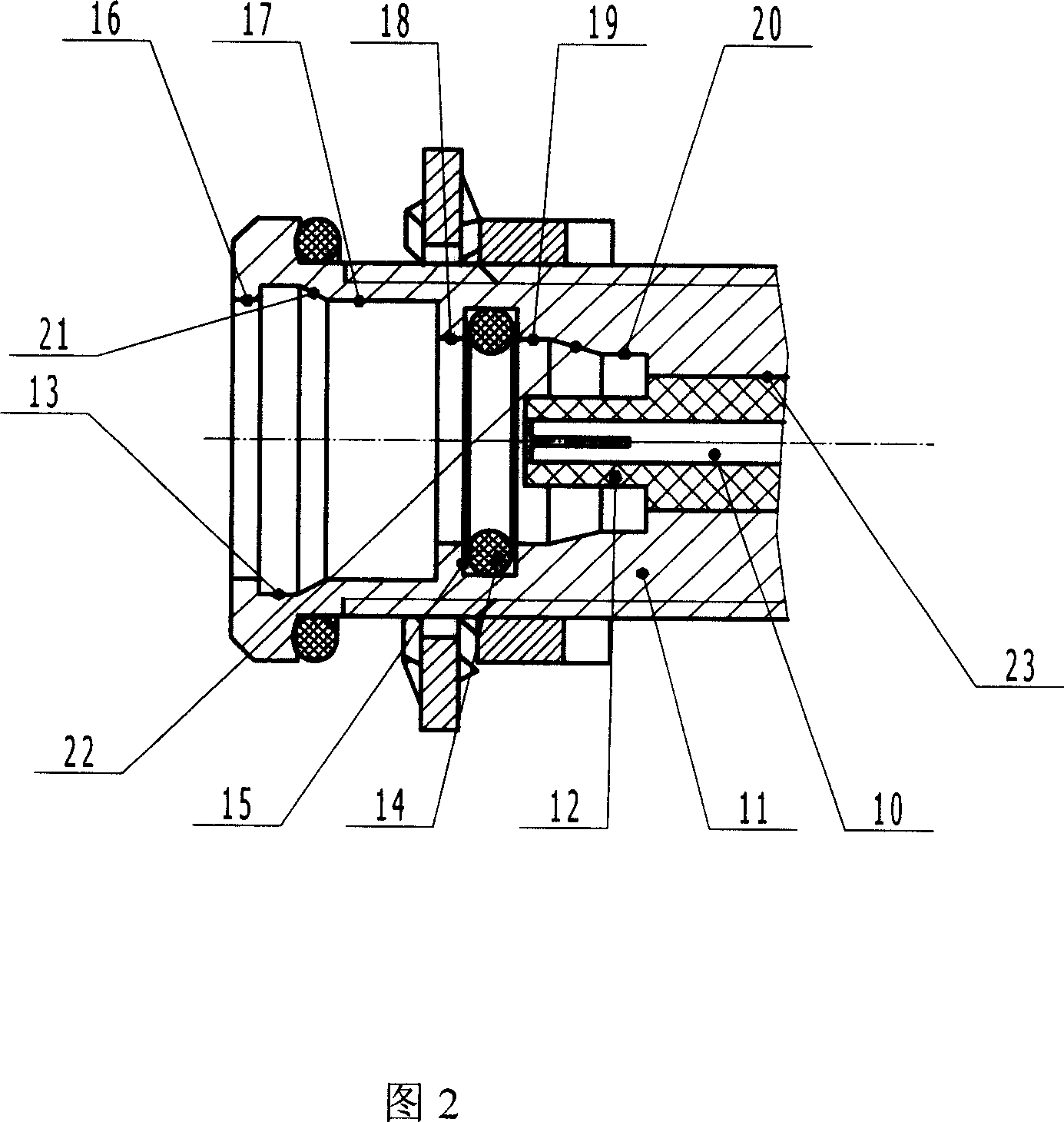

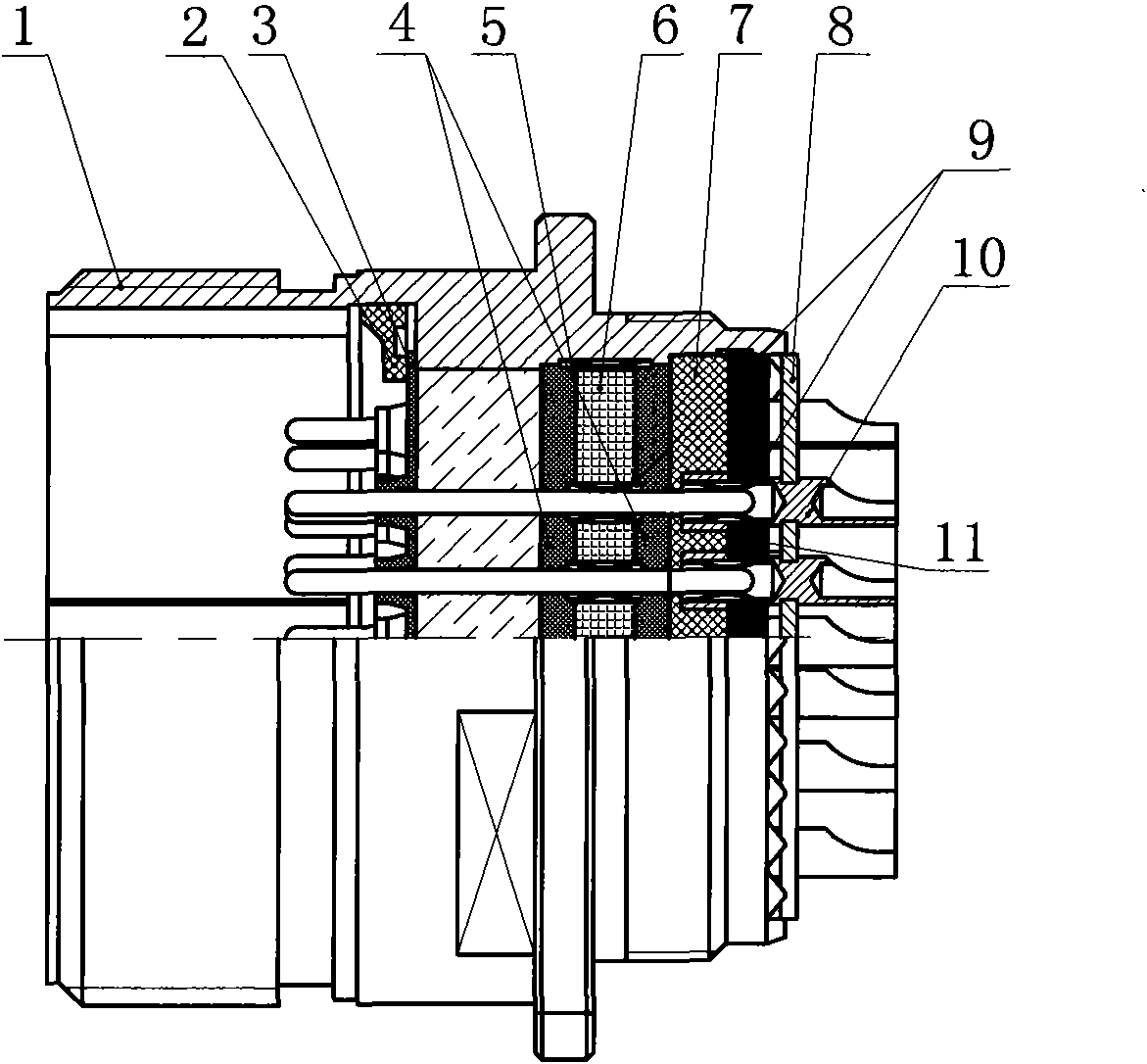

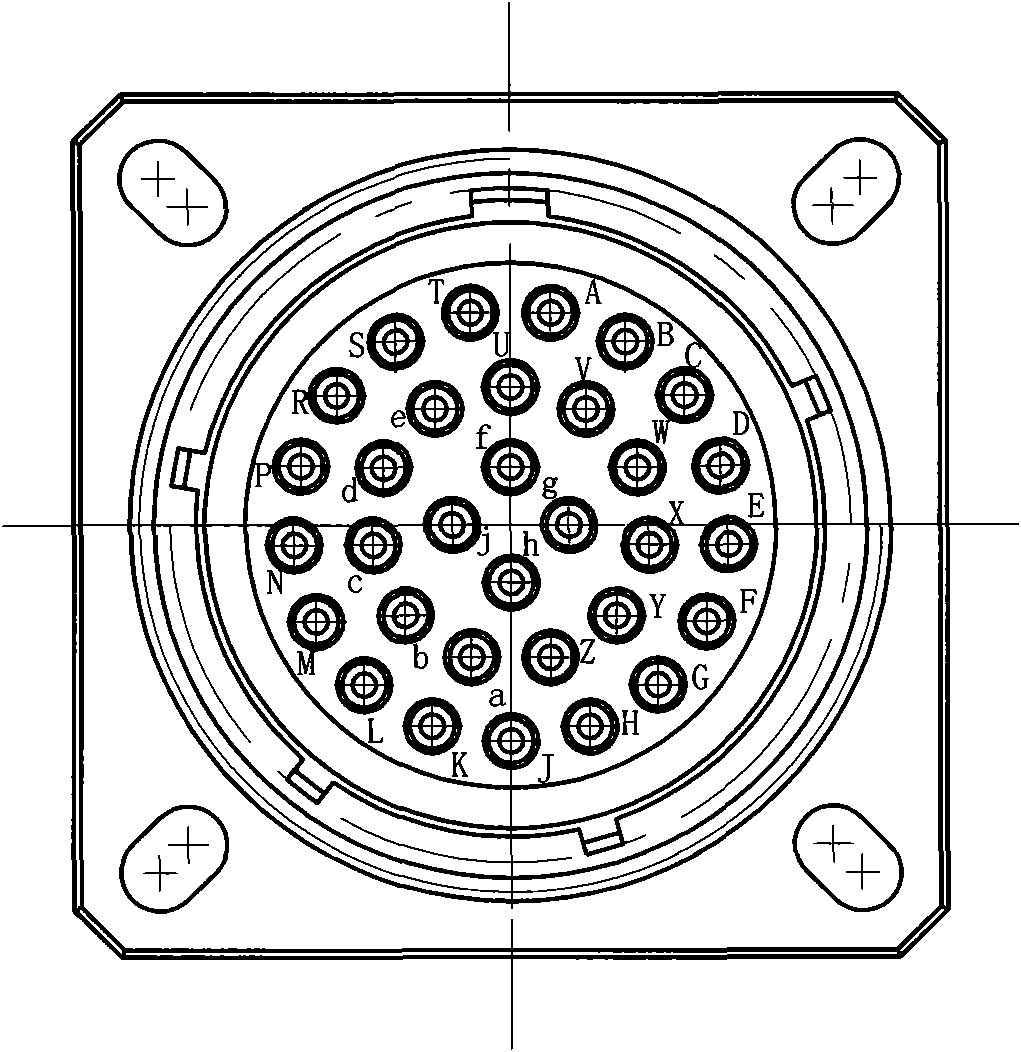

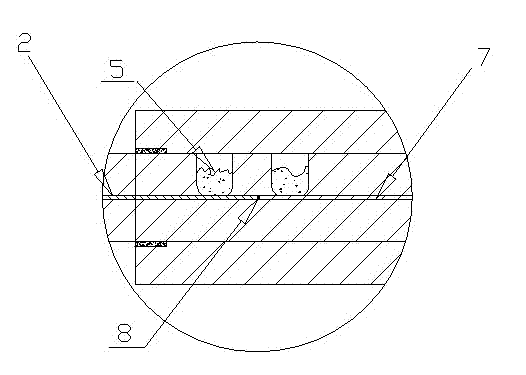

Air-tight sealing filtering socket

InactiveCN101540452AImprove anti-electromagnetic interference performanceRealize the sealing functionCoupling for high frequencyCouplings bases/casesCapacitanceElectromagnetic interference

The invention relates to an air-tight sealing filtering socket which realizes air-tight sealing by adopting a glass sintering structure, realizes anti-electromagnetic interference of the socket by additionally arranging a filter capacitor, simplifies the assembly by a crown reed and a connecting hole structure, structurally realizes anti-mechanical stress of planar array tabular capacitor by a grounding reed and a rubber gasket and achieves moisture-proof of the capacitor by sealing glue; the socket comprises a shell, a sealing ring, an interface sealing gasket, the rubber gasket, the grounding reed, the planar array tabular capacitor, a baffle, a hole location identifier rubber gasket, the crown reed, the connecting hole, the sealing glue, a contact pin, a glass insulator and a trough of the shell; the contact pin and the glass insulator are connected and fixed together by glass sintering at the middle part of the socket, and the glass insulator fixes the contact pin by sintering to form a shell fitting; and the grounding reed is loaded in the trough of the shell after being rounded into a circle. The air-tight sealing filtering socket improves the anti-electromagnetic interference capability of a filter connector, simplifies the assembly technology and realizes the functions of air-tight sealing and moisture-proof.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

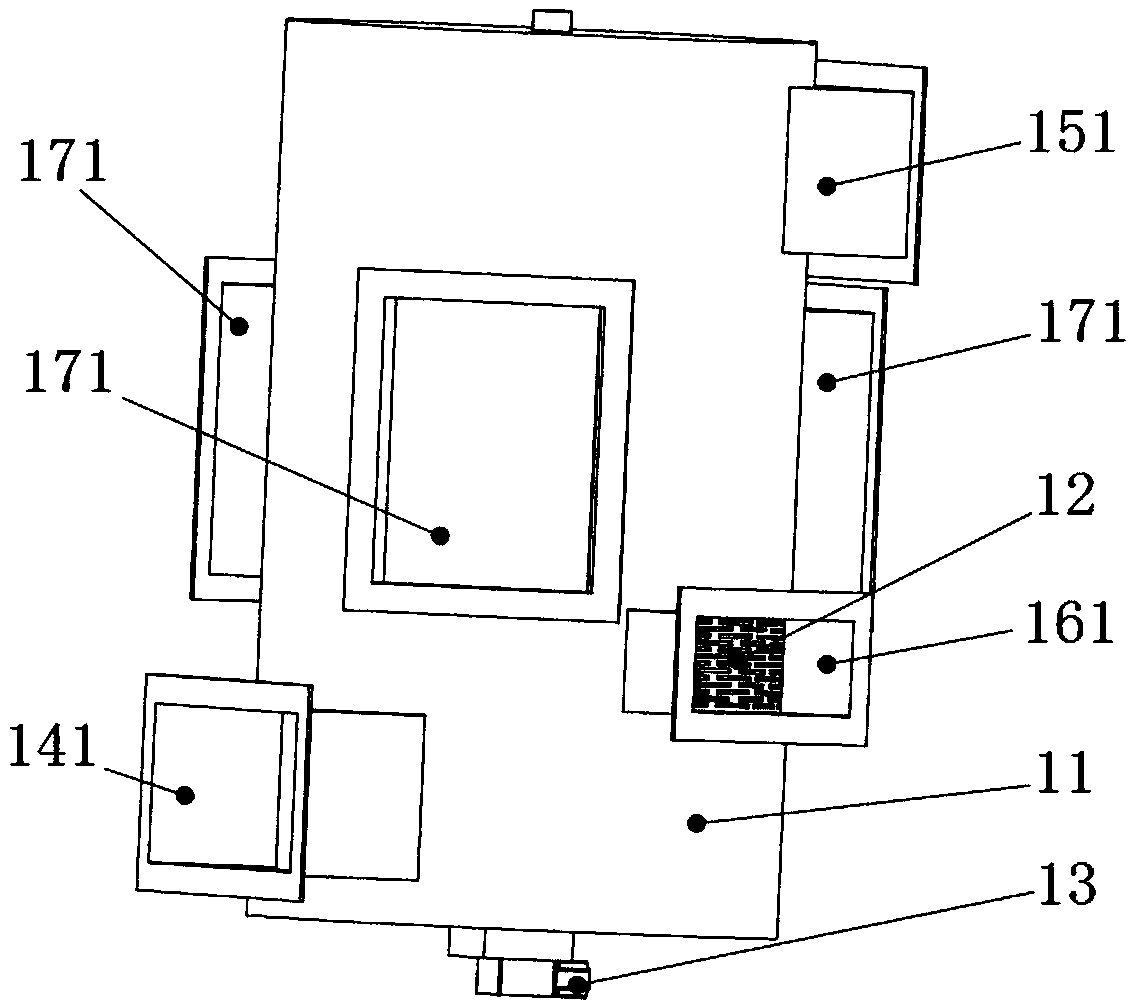

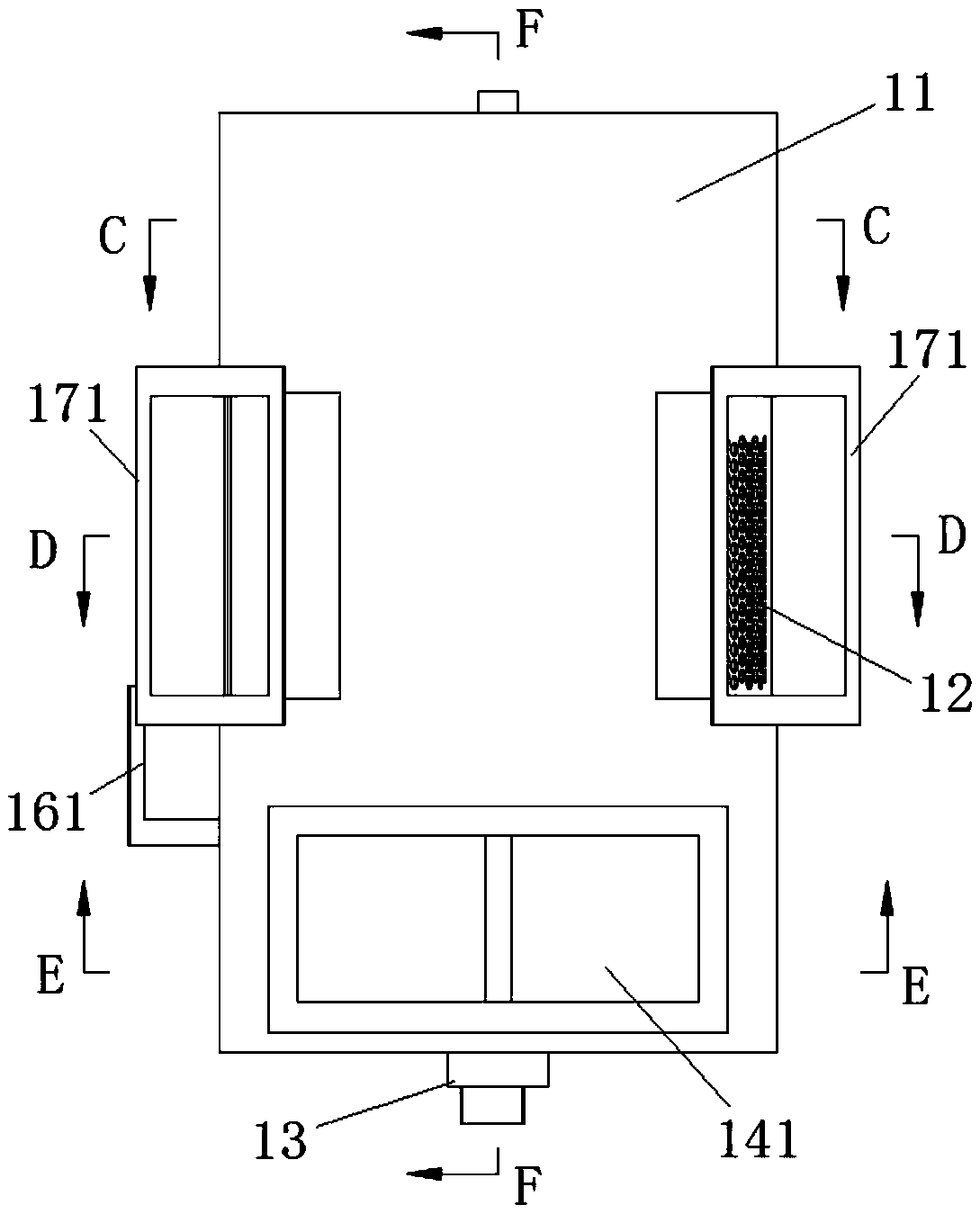

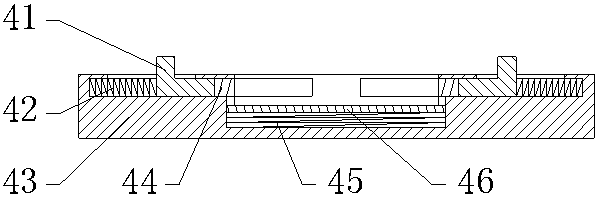

Vacuum centrifugal static spinning device

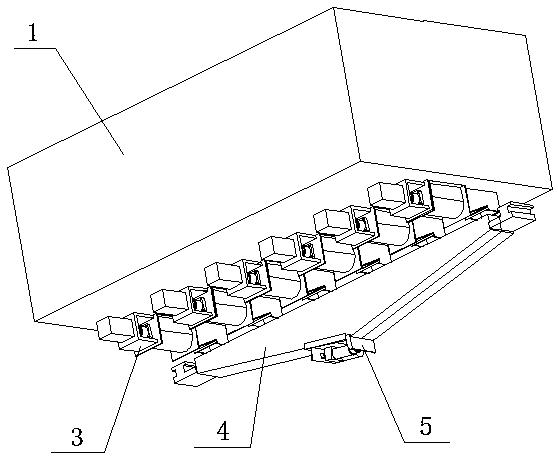

ActiveCN104328514AMeet the positioning requirementsMeet the feed requirementsElectro-spinningElectrospinningHeating system

The invention discloses a vacuum centrifugal static spinning device, which mainly consists of eight major systems including a transmission system, a feeding system, a heating system, a sealing system, a spinning system, a collecting system, a temperature control system and a box body system, and is used for melt or solution centrifugal electrostatic spinning. The transmission system drives a yarn spraying device to rotate at a high speed, a receiving device is connected with a high-voltage power supply, the heating device heats polymer particles, a melt is stored in the yarn spraying device, an infrared temperature measuring instrument measures the temperature through emitting infrared rays and feeds back the result to the heating system for controlling the spinning temperature, under the effect of centrifugal force and electrostatic force, the melt is spun out, and nanometer level fiber is formed on the collecting device. In the whole spinning process, a transmission device, a feeding device and a magnetic fluid sealing device are positioned in a protection box body, the heating device, the yarn spraying device, the collecting device and a temperature control device are positioned in a vacuum box. The vacuum centrifugal static spinning device has the advantages that no disturbance of jet flow in vacuum environment can be ensured, and the goal of more stably preparing high-performance and high-quality nanometer fiber is achieved.

Owner:BEIJING UNIV OF CHEM TECH

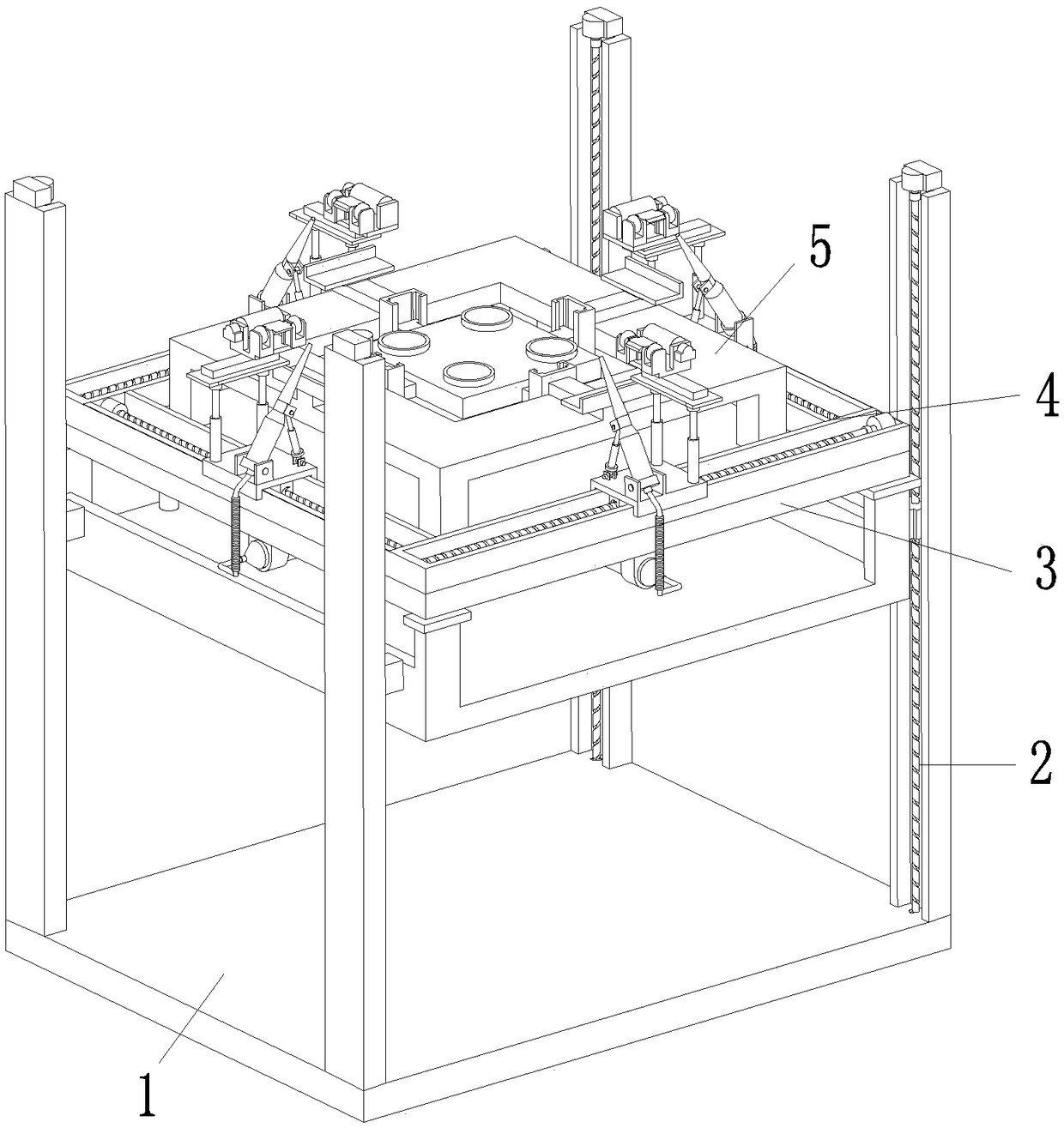

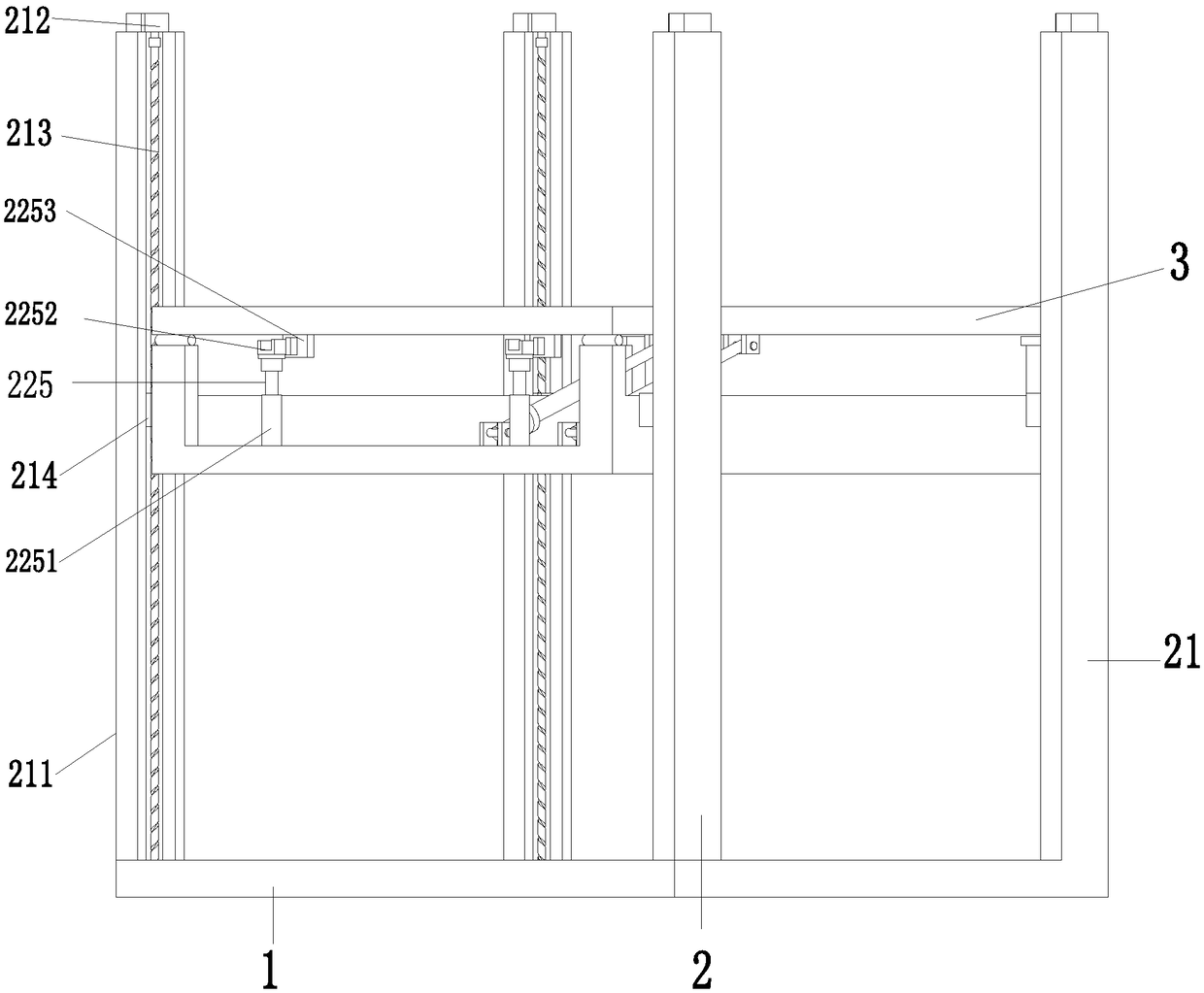

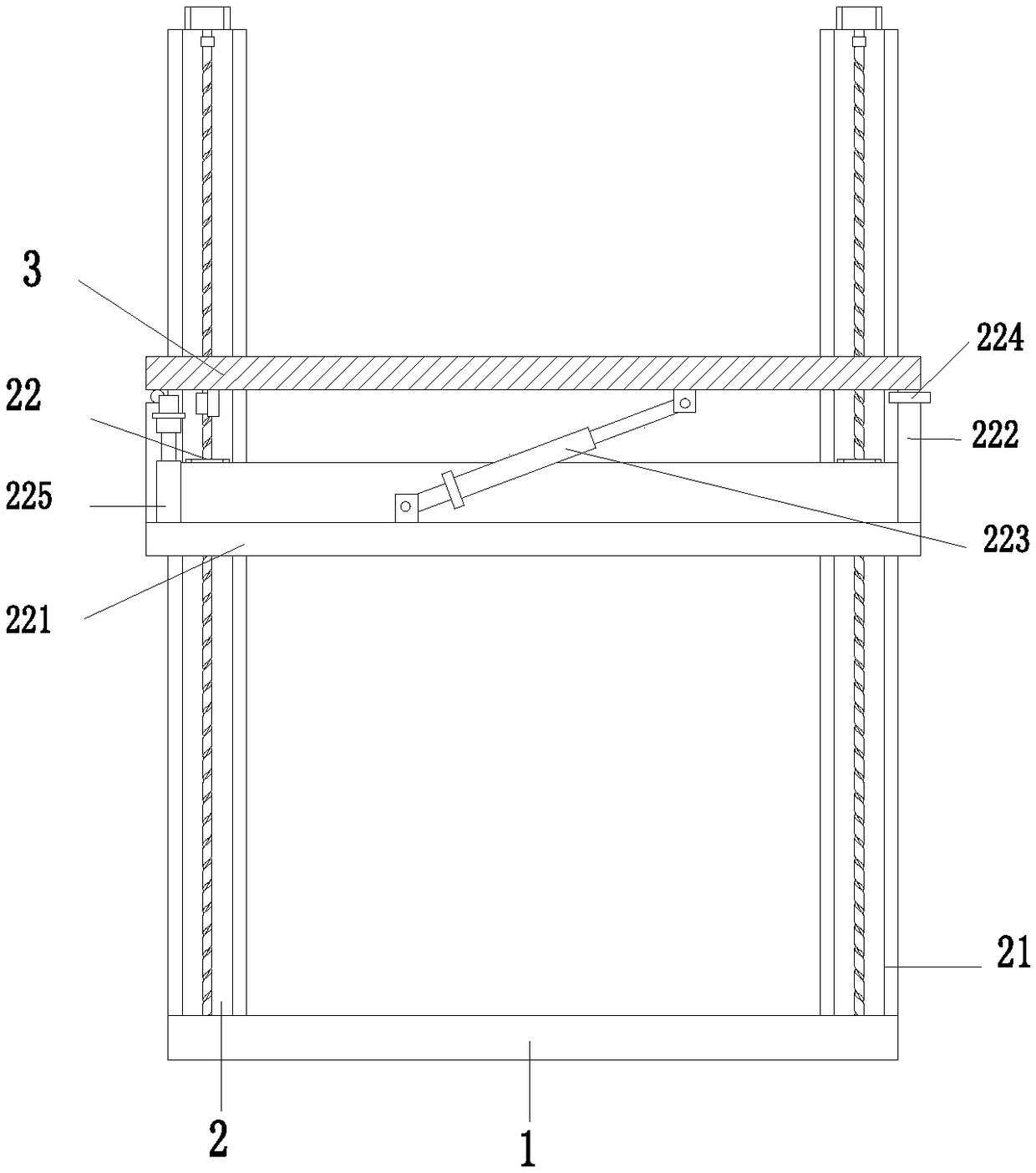

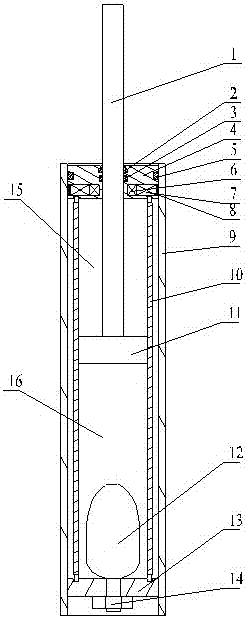

Automatic mounting equipment and method of aluminum-plastic panel

ActiveCN109057284AReduce manual operationsImprove work efficiencyBuilding constructionsUltimate tensile strengthSealant

The invention relates to automatic mounting equipment and method of an aluminum-plastic panel. The automatic mounting equipment comprises a bottom plate, an adjusting device, a fixed plate, four glueinjection devices and a clamping device. The adjusting device is mounted at the upper end of the bottom plate, and the fixed plate is mounted at the upper end of the adjusting device. The four glue injection devices are evenly mounted on the outer side of the upper end of the fixed plate, the clamping device is mounted on the inner side of the upper end of the fixed plate, and the clamping deviceis located among the four glue injection device. According to the automatic mounting equipment and method of the aluminum-plastic panel, the problems that the aluminum-plastic panel is usually mountedmanually in the existing aluminum-plastic panel mounting and glue injection process; during mounting and glue injection, a worker needs to work in the air, due to the fact that the operation space isnarrow, the worker cannot mount the aluminum-plastic panel on a ceiling and a wall easily, and potential safety hazards are possibly caused by improper operation in long-time aloft work; in the manual glue injection process, the glue injection amount is hard to control, redundant sealant cannot be removed in time when too much glue is injected, the operation difficulty is large, the labor intensity is large, and the work efficiency is low can be solved.

Owner:安徽利凌建筑材料科技有限公司

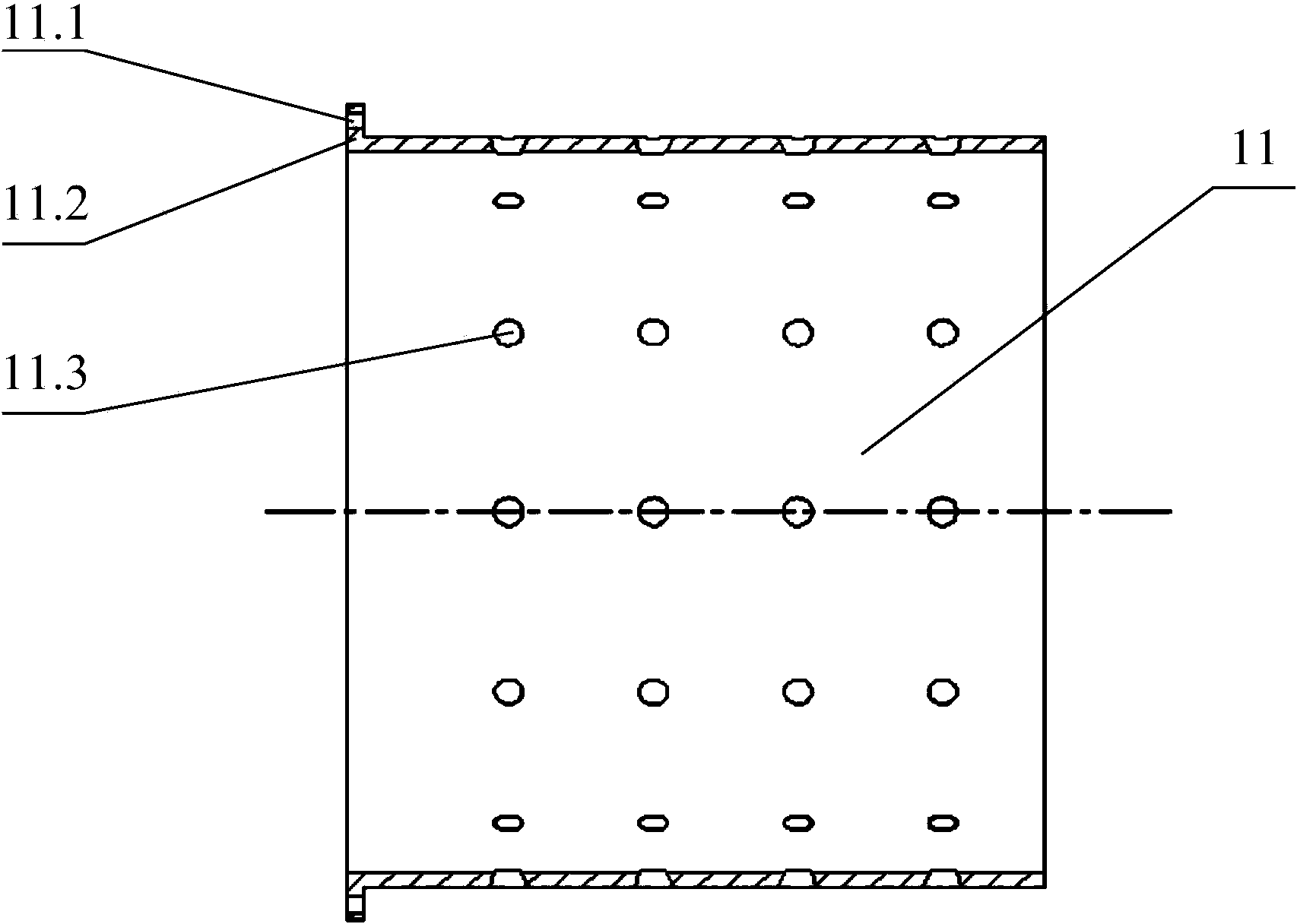

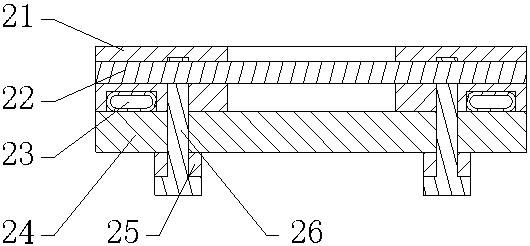

Double-cylinder type magneto-rheological damper with inner and outer coils

ActiveCN107314077ASimple structureLow processing and assembly costsSpringsNon-rotating vibration suppressionEngineeringMagneto rheological damper

The invention discloses a double-cylinder type magneto-rheological damper with inner and outer coils. The double-cylinder type magneto-rheological damper comprises a piston rod, a piston, an inner cylinder barrel, an outer cylinder barrel, an end cover, a dustproof ring, the inner coil, the outer coil, a coil protective layer, a compensation air bag, a bottom locating piece and a nut, wherein the piston rod is tightly connected with the piston; the piston is positioned in the inner cylinder barrel; the inner cylinder barrel is fixed with the bottom locating piece through the end cover; the bottom locating piece is tightly connected with the outer cylinder barrel; a through hole is formed in the middle of the bottom locating piece and used for compensating for an air bag valve port so as to enable the air bag valve port to extend out of the damper; the compensation air bag is mounted at the bottom of the inner cylinder barrel; the end cover is tightly connected with the outer cylinder barrel; the inner coil and the outer coil are wound on the end cover; the dustproof ring is mounted at the top of the inner hole of the end cover; and an end part groove is formed in the part below the end cover. The double-cylinder type magneto-rheological damper with inner and outer coils has the benefits as follows: the structure is simple, the processing and manufacturing are convenient, the cost is low, the damping force of the damper is adjusted, the inner coil has a sealing function, and the sealing performance is good.

Owner:YANCHENG BUGAO AUTO PARTS MFG CO LTD

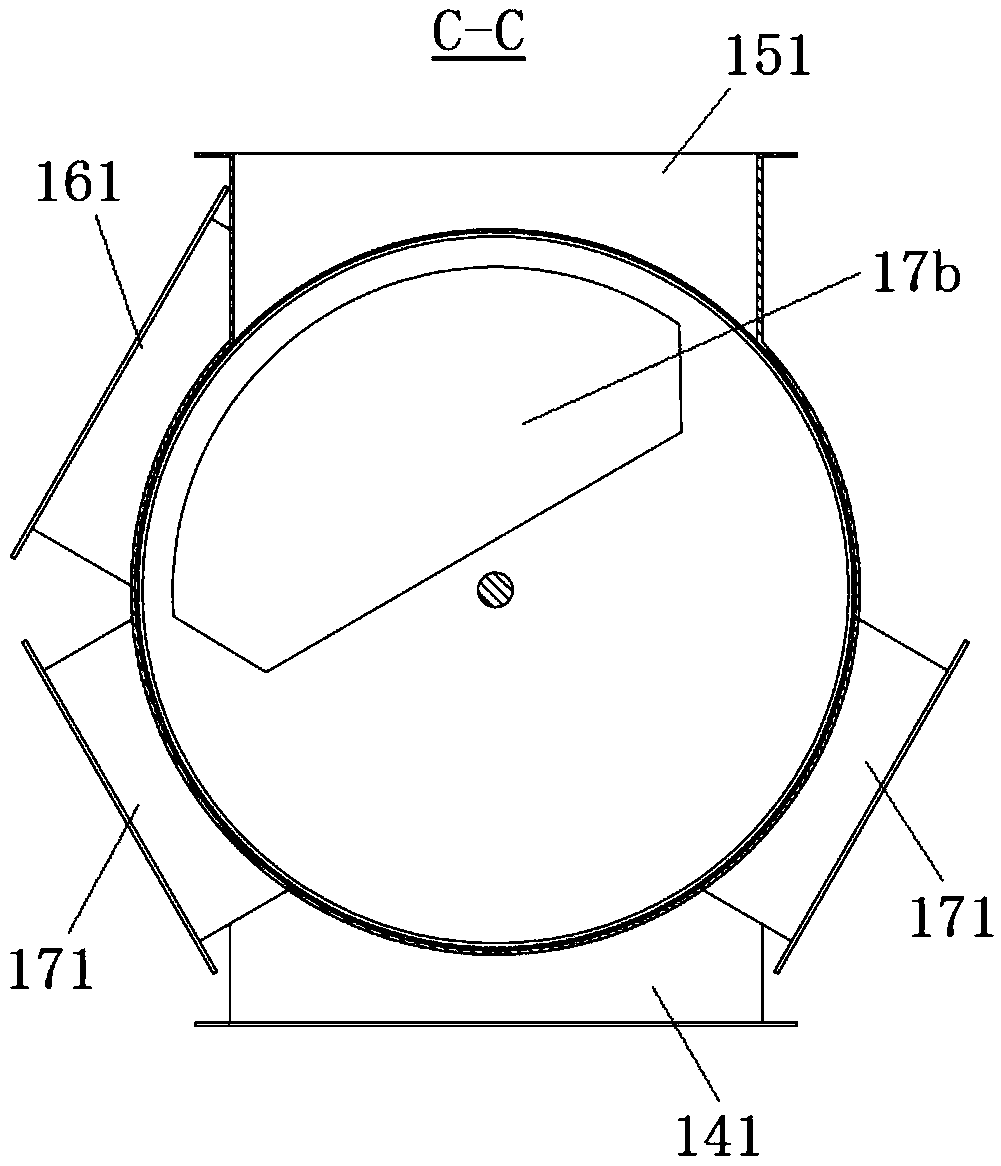

Rotary reversing valve and rotary heat-accumulation waste gas incinerator

ActiveCN105509072AReduced power ratingReduce energy consumptionIncinerator apparatusPositive pressureEngineering

The invention provides a rotary reversing valve which comprises a valve body and a valve core, wherein a clearance is left between the valve body and valve core; the valve core is driven by a drive unit to rotate; a gas inlet region, a gas discharge region, a purging region and at least two distribution regions are arranged between the valve core and valve body; the valve body is provided with a plurality of inlet / outlet ports respectively communicated with all the regions; the distribution regions are respectively a to-be-treated gas distribution region and a treated gas distribution region; the to-be-treated gas distribution region is communicated with the gas inlet region to form a to-be-treated gas passage; the treated gas distribution region is communicated with the gas discharge region to form a treated gas passage; the valve core is in a hollow structure and is communicated with the purging region to form a purging gas passage; and when the purging gas passage is under positive pressure or negative pressure, the purging region obstructs the mutual communication between the to-be-treated gas passage and the treated gas passage. The rotary reversing valve has the advantages of simple structure, low energy consumption, favorable sealability, low cost and the like. The invention also provides a rotary heat-accumulation waste gas incinerator using the rotary reversing valve.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

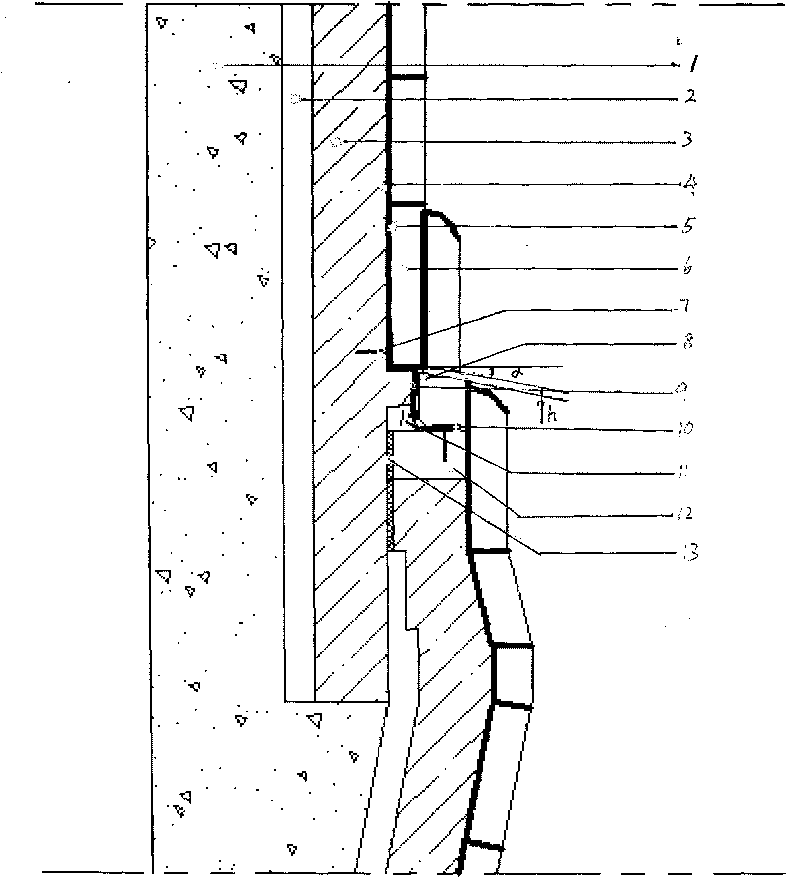

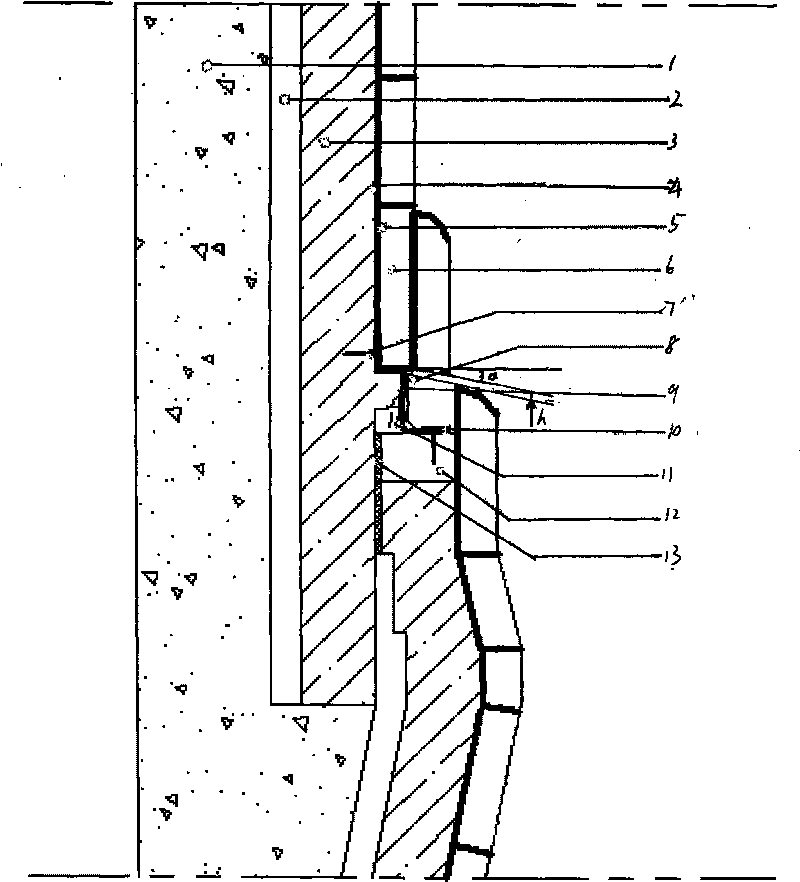

Sealing corrosion-resistant structure of expansion joint of brick lining chimney

InactiveCN101725270ARealize the sealing functionRealize the scaling functionTowersBuilding insulationsBrickHigh intensity

The invention relates to a sealing corrosion-resistant structure of an expansion joint of a brick lining chimney, which comprises rock wool. The structure is characterized in that the rock wool is filled into the sealing expansion joint with elastic adhesive; an isolating membrane with high intensity, high temperature resistance, and good corrosion resistance and good ageing resistance is taken as a sealing membrane; the sealing membrane is fixed on the upper-layer and lower-layer brick lining with bolts and press plates; the surface of the brick lining is evenly covered with corrosion-resistant and ageing-resistant adhesive to be formed into the sealing structure; the outer surface of the sealing membrane is protected by foaming bricks; and the foaming bricks are glued to the outer sides of the sealing membrane and the brick lining with priming paint and the adhesive to be formed into a protection layer. The sealing corrosion-resistant structure has the advantages of corrosion resistance, ageing resistance, wide expansion bound, safety and reliability, good sealing capability, and good integrity.

Owner:上海德昊化工有限公司

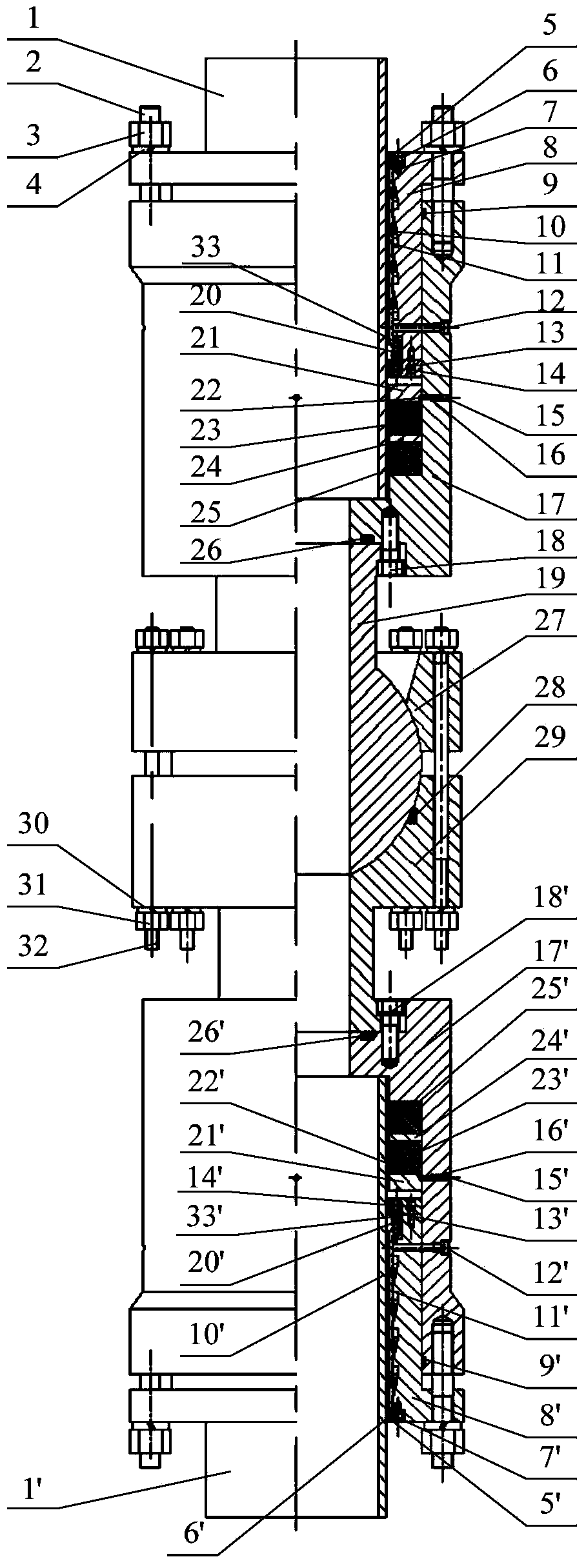

Self-adaptive double-sealing-steel-ball clamping underwater pipeline connector

ActiveCN104019303AAvoid installationAvoid corrosionAdjustable jointsPipe elementsEngineeringSteel ball

The invention provides a self-adaptive double-sealing-steel-ball clamping underwater pipeline connector. A spherical base body has three rotation freedom degrees relative to an outer cavity of the base body. When two pipelines with axes not coinciding with each other are connected, the relative positions of the spherical base body and the outer cavity of the base body are adjusted, so that the first pipeline and the second pipeline are smoothly placed into a first spherical cage and a second spherical cage, the tail ends of the pipelines reach pipeline thrust surfaces, nuts on a double-end stud are fastened, a flange ring and the outer cavity of the base body are tightly pressed on the spherical face of the spherical base body through axial force, and the relative positions of the spherical base body and the outer cavity of the base body are fixed; meanwhile, a metal sealing ring is tightly pressed on the spherical face of the spherical base body through axial force, so that reliable sealing operation between the spherical base body and the outer cavity of the base body is achieved. The two pipelines with an axis angle ranging from -10 degrees to 10 degrees can be connected through the self-adaptive double-sealing-steel-ball clamping underwater pipeline connector.

Owner:HARBIN ENG UNIV

Optical fiber fast terminating assembly

InactiveCN102368105ARealize the sealing functionImprove performanceCoupling light guidesButt jointEngineering

The invention discloses an optical fiber fast terminating assembly which comprises a body and an internal hole located in the body, wherein two grooves are formed on the body till the internal hole is exposed; a butt-joint end surface of an optical fiber is located at the position of the internal hole between the grooves; and the two grooves are used for filling matched gels. The grooves respectively prevents the fixed pre-buried optical fiber glue from covering the pre-buried optical fiber butt-joint end surface due to capillary action and pre-placing enough matched gels to eliminate Fresnel reflection when an access optical fiber is butt jointed with the pre-buried optical fiber. The optical fiber butt-joint end surface is located between the two grooves of an insert core body, coaxial butt-jointing of the optical fibers can be realized by utilizing the insert core body high-precision internal hole tube bundle butting optical fiber, thereby realizing fast terminating of the optical fiber on the operation site. With the assembly provided by the invention, two grooves are sealed by sealing sleeves sleeved on the insert core body, so that the matched gels can be prevented from being volatilized or contaminated, and the product can be ensured not to be failed when being used under harsh environment conditions.

Owner:CHAOZHOU THREE CIRCLE GRP

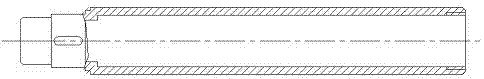

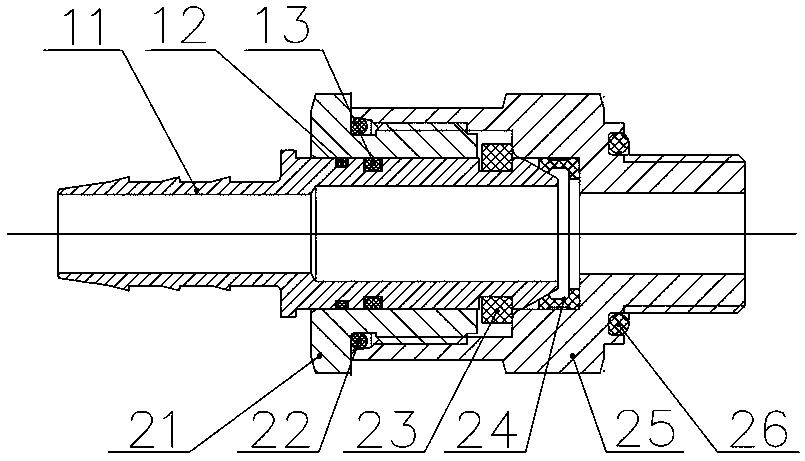

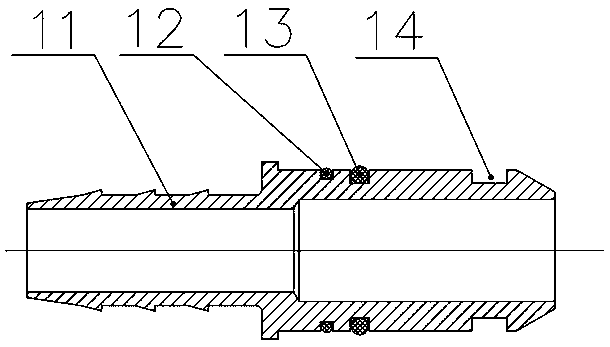

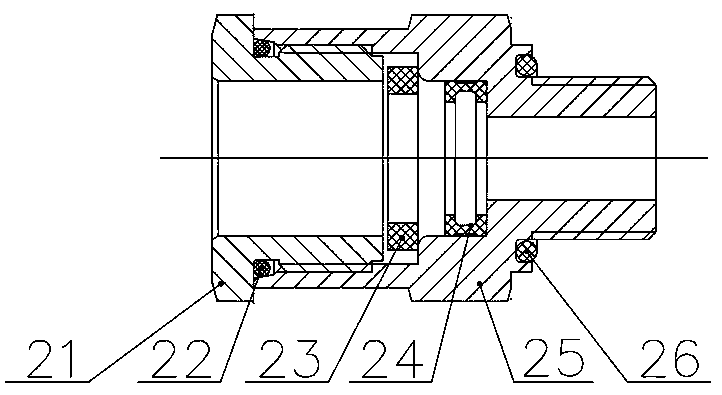

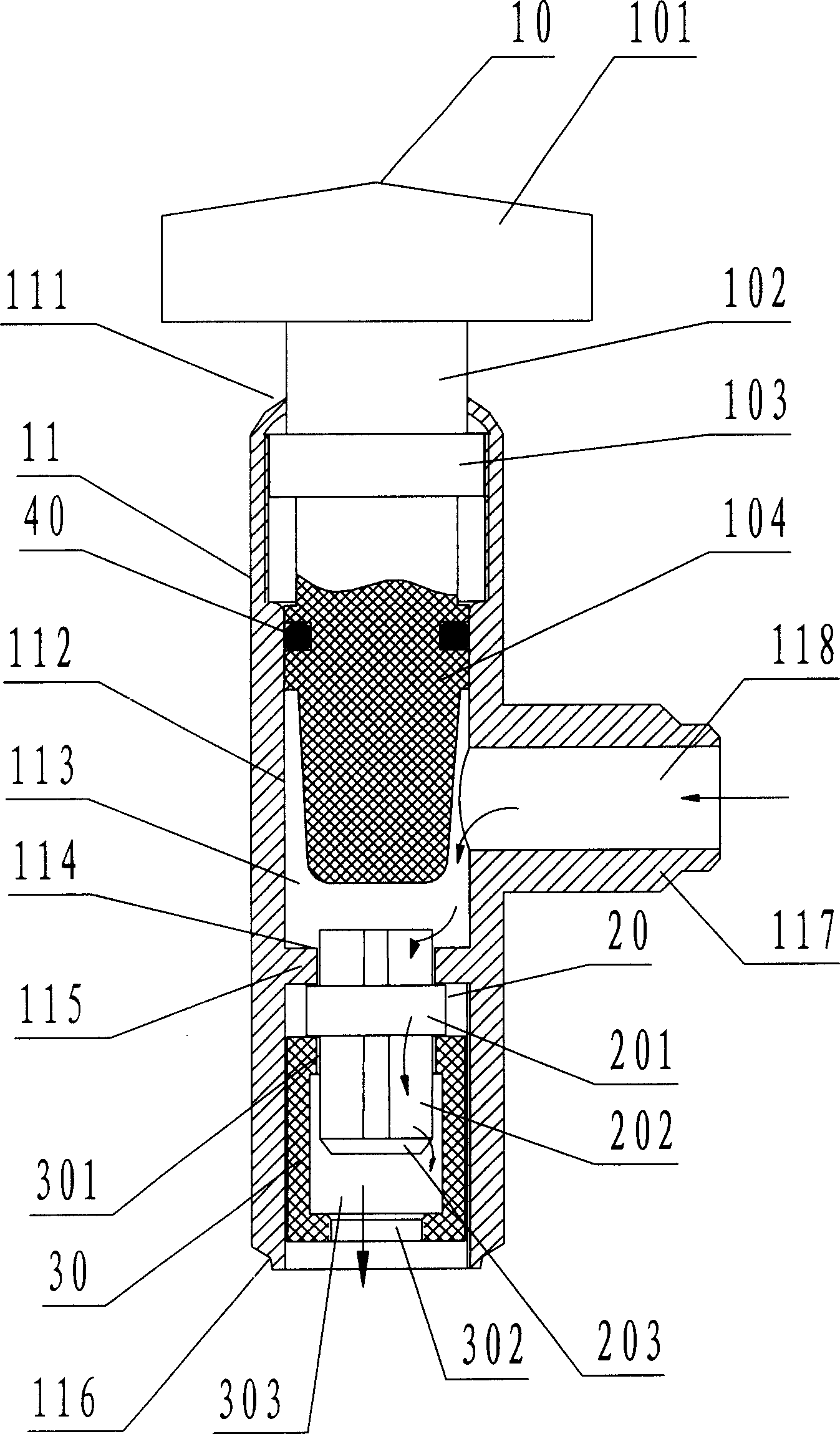

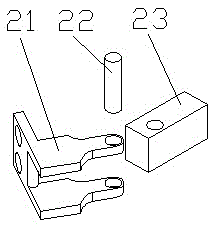

Quickly inserted joint assembly for vehicle pipeline system

PendingCN108843867ARealize the locking functionRealize the sealing functionScrew threaded jointsEngineeringSelf locking

The invention discloses a quickly inserted joint assembly for a vehicle pipeline system. The quickly inserted joint assembly for the vehicle pipeline system comprises a quickly inserted joint assemblyand a joint body assembly. One end of the quickly inserted joint assembly is a quickly inserted end and is assembled in the joint body assembly; the other reverse end is a pipeline connecting end andis assembled in a hose of a pipeline; the quickly inserted joint comprises a joint main body, a first seal ring, a second seal ring and a lock ring; one end of the joint body assembly is a barrel main body for inserting the quickly inserted joint and the other end of the joint body assembly is an external thread connected to a pipe connecting part; the joint body assembly comprises a barrel mainbody, a third seal ring, a joint main body and a fourth seal ring; and a self-locking fixing device is formed between the quickly inserted assembly and the joint body assembly to achieve one-way locking of the quickly inserted joint assembly. By implementing the quickly inserted joint assembly disclosed by the invention, the quantity of parts of the quickly inserted joint assembly is reduced and the parts are subpackaged conveniently; the lock ring is locked and reset through a primary locking position and a secondary locking position, and the secondary locking function is increased equivalently, so that the connecting reliability among the parts is improved.

Owner:CHANGCHUN CHINAUST AUTOMOBILE PARTS

LED down lamp convenient to clean and install

InactiveCN107575791ASmooth rotationEasy to placeGas-tight/water-tight arrangementsLight fasteningsEngineeringThreaded rod

Owner:惠勇

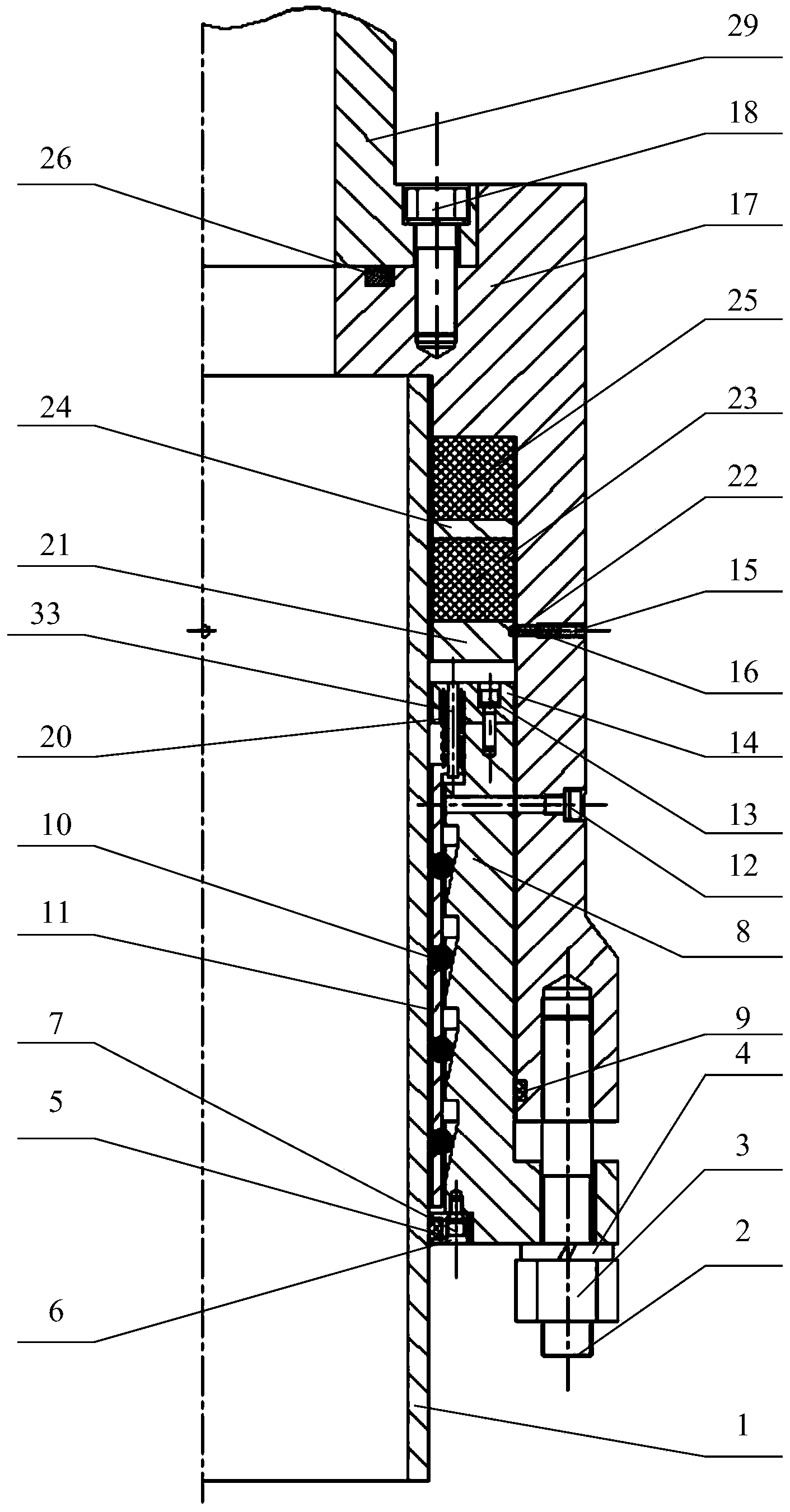

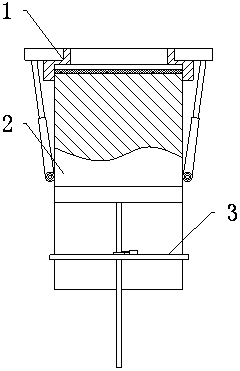

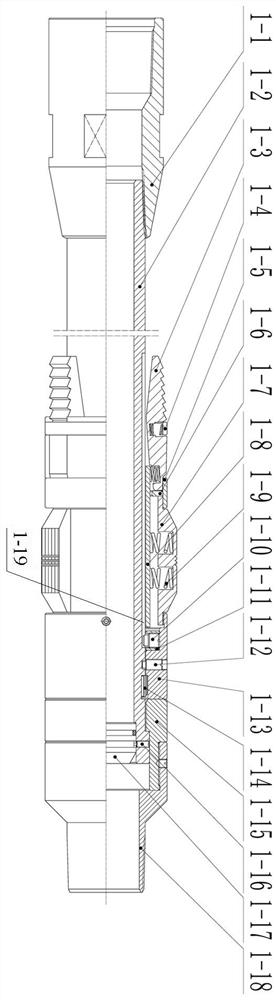

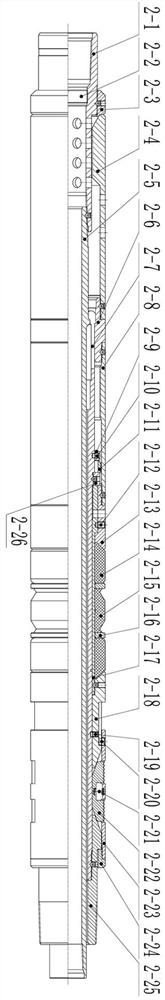

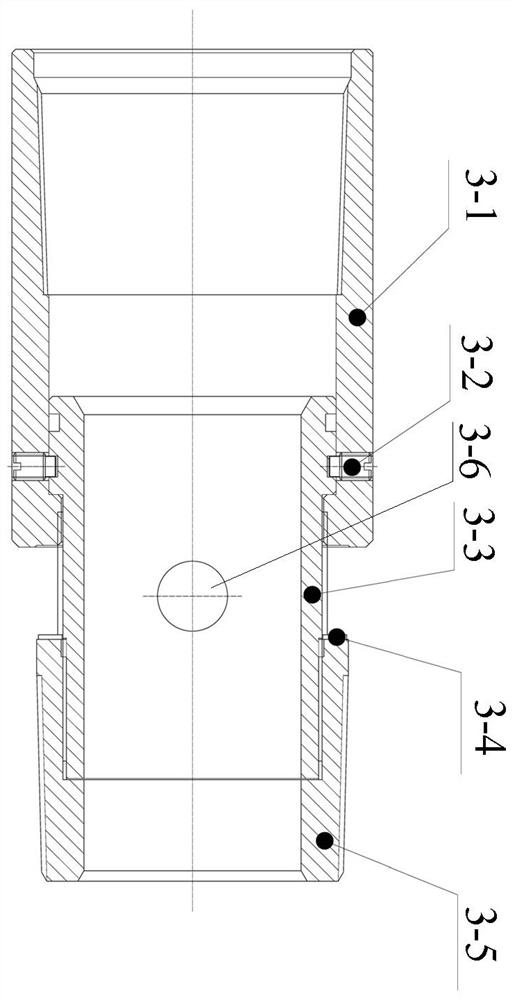

Novel blowout-prevention and anchoring integrated tool

The invention relates to a novel blowout-prevention and anchoring integrated tool. The tool comprises an anti-rotation part, a releasing part, a pressure relief channel part, an anchoring part, a gravity valve part and a through rod, wherein the anchoring part comprises a supporting slip; an upper joint of an anti-rotation anchor is connected with the lower end of a screw pump; a lower joint of the anti-rotation anchor is connected with a sieve pipe; the lower end of the sieve pipe is connected with a connecting joint of a releasing packer; the lower end of a connecting rod is connected with the through rod; an upper joint of a pressure relief channel is connected with a lower joint of the releasing packer; an upper joint of the supporting slip is connected with a lower joint of the pressure relief channel; an upper joint of a gravity valve is connected with a central pipe of the supporting slip; and a lower joint of the gravity valve is connected with an oil pipe through threads. According to the novel blowout-prevention and anchoring integrated tool, the anti-rotation effect is more ideal, the failure caused by insufficient engagement force after the long-term use of the releasing packer is prevented, the danger of upward channeling of a tubular column during operation can be avoided through the pressure relief channel part, and the failure of a float switch caused by sand sinking accumulation of a fractured well can be avoided.

Owner:LIAONING XINHUA INSTR CO LTD

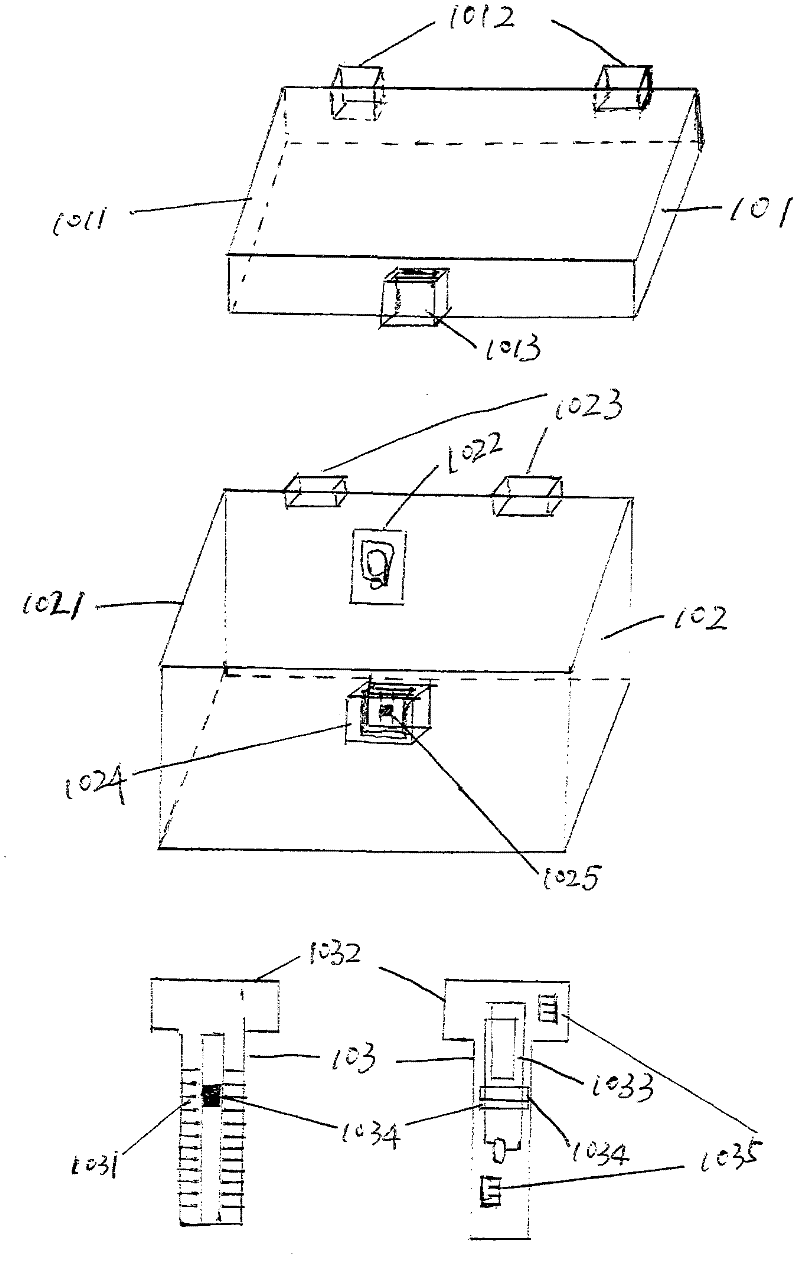

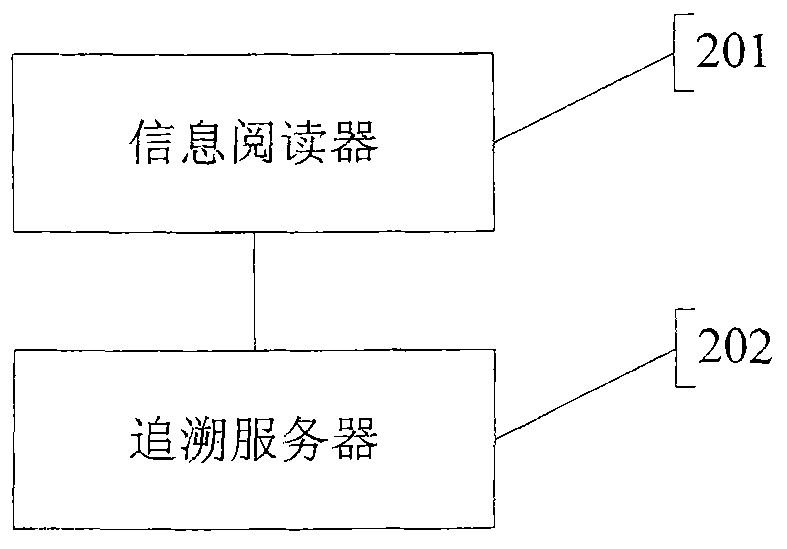

Packing box with information identifying function, built-in article tracing system and method

InactiveCN102306337ARealize the sealing functionLogo authenticitySensing record carriersLocking devicesComputer science

The invention provides a packing box with an information identifying function, which comprises a box body,a box cover and a seal, wherein the box body and the box cover are used for packing an article and support the insertion of the seal and the embedding of the identifying information of the box body; and the seal is used for sealing the box cover on the box body and supports the reading of the identifying information of the seal. The invention also provides an article tracing system and a method. The article tracing system is characterized by comprising an information reader and a tracing server which are connected sequentially, wherein the information reader is used for reading and sending the identifying information related to the packing box and the information of the built-in article; and the tracing server is used for receiving and processing the identifying information and the article information and generating tracing information and supervision information thereof related to the information article contents.

Owner:田小平

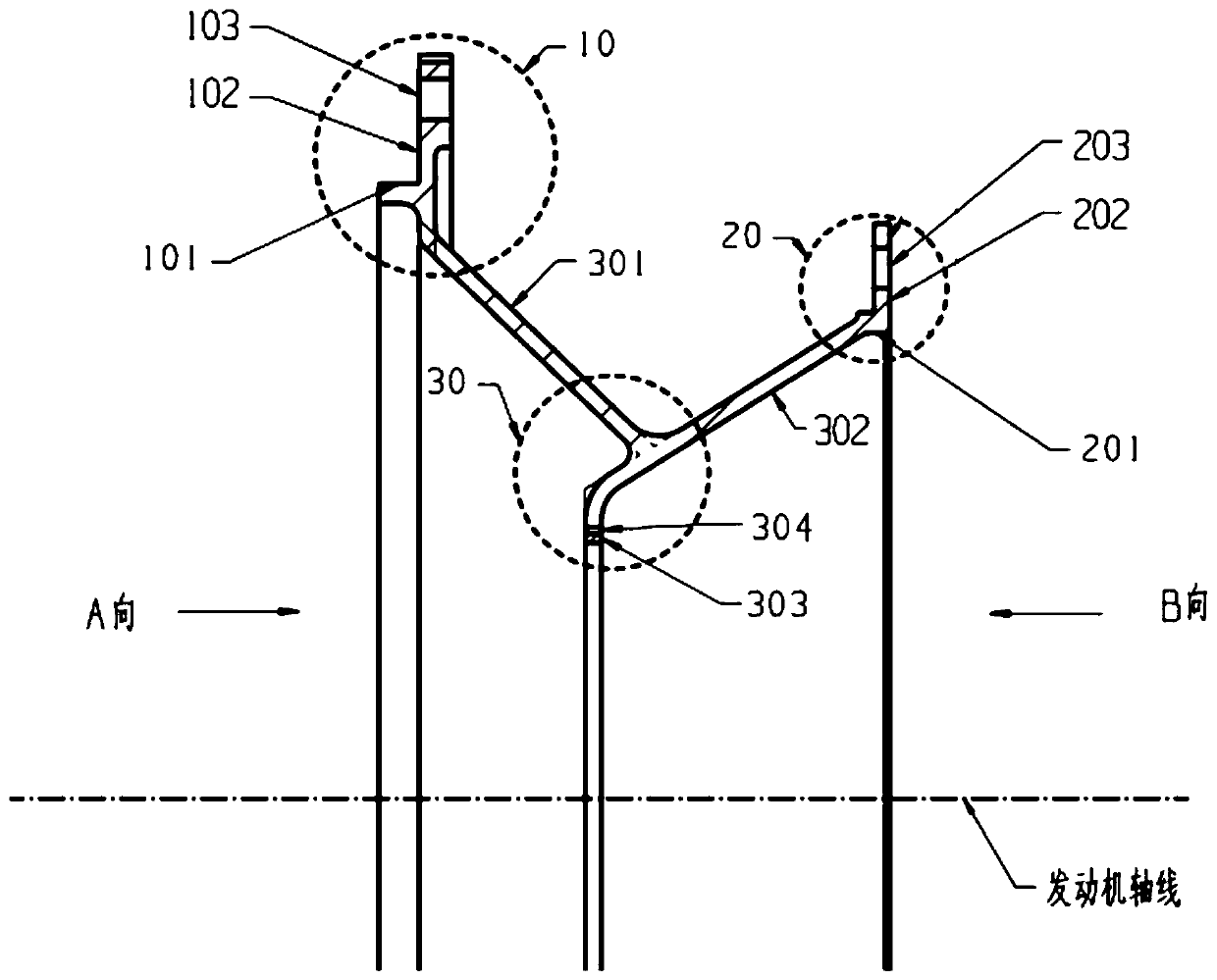

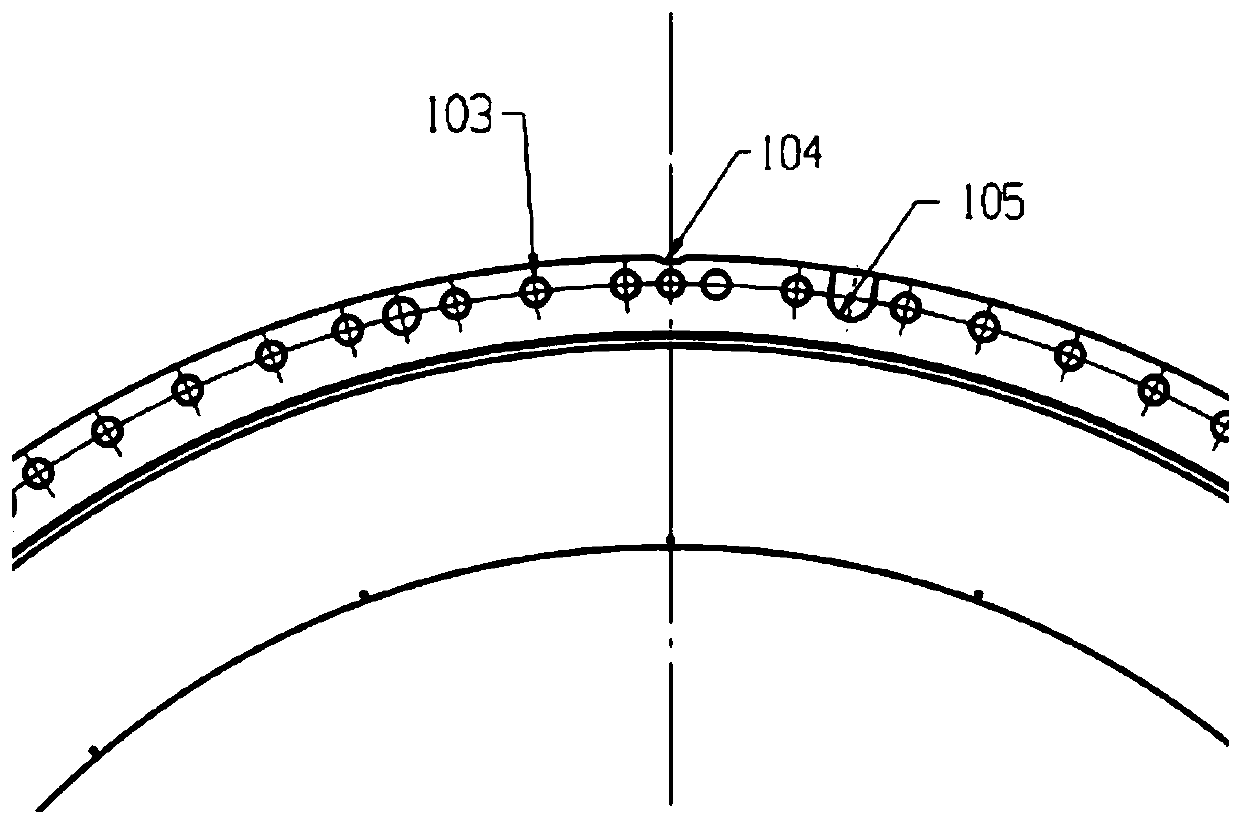

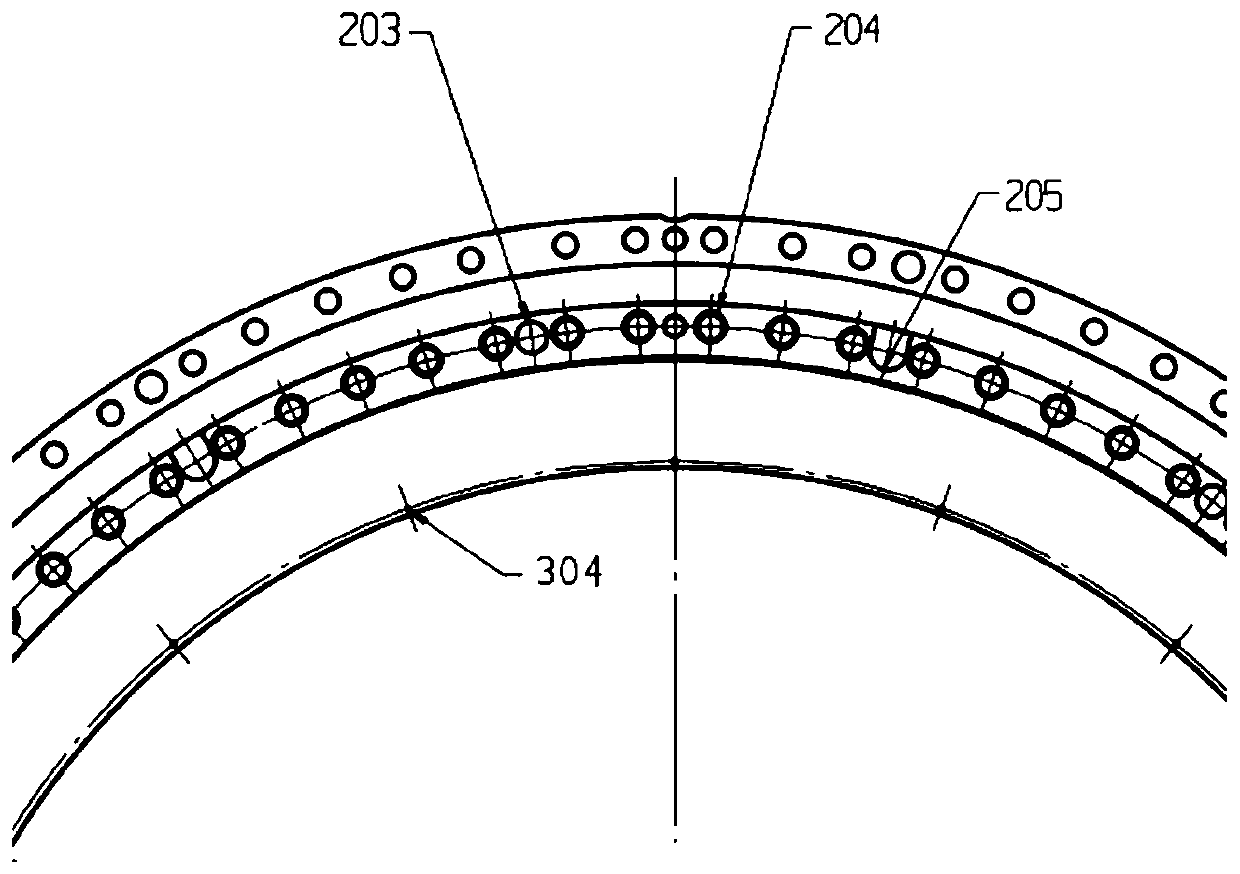

Auxiliary force transmission casing structure of gas turbine

ActiveCN111042878AAdaptableFirmly connectedMachines/enginesEngine componentsEngineeringControl theory

The invention provides an auxiliary force transmission casing structure of a gas turbine. The casing structure is arranged between a turbine outer ring and a low-pressure turbine rotor outer casing and comprises a left flange edge, a right flange edge and a Y-shaped support structure. A left flange edge and a right flange edge with seam allowance positioning are cooperated and connected with the turbine outer ring and the low-pressure rotor outer casing. By using the auxiliary force transmission casing of the gas turbine, a function of transmitting a force from the low-pressure turbine rotor outer casing to the turbine outer ring is achieved, and at the same time, when a temperature changes, buffering is added for deformation of the auxiliary force transmission casing, a relative positionbetween the low-pressure turbine rotor outer casing and the turbine outer ring is guaranteed, and a problem that the casing deforms unharmoniously due to a temperature difference between an inner ringand an outer ring and the like is solved. The auxiliary force transmission casing of the gas turbine is simple and compact in structure, easy to machine and good for reducing manufacturing cost of anaero-engine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

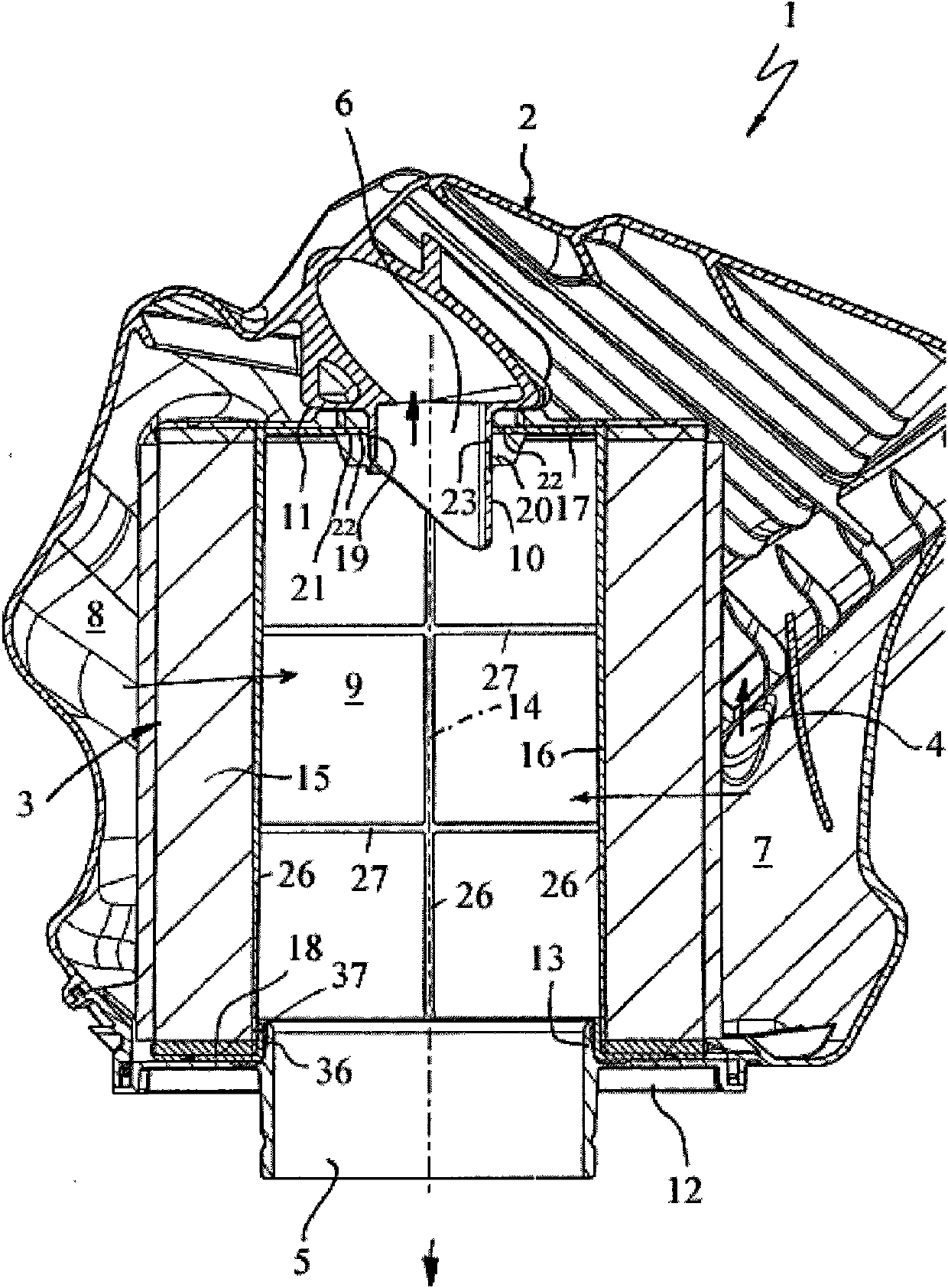

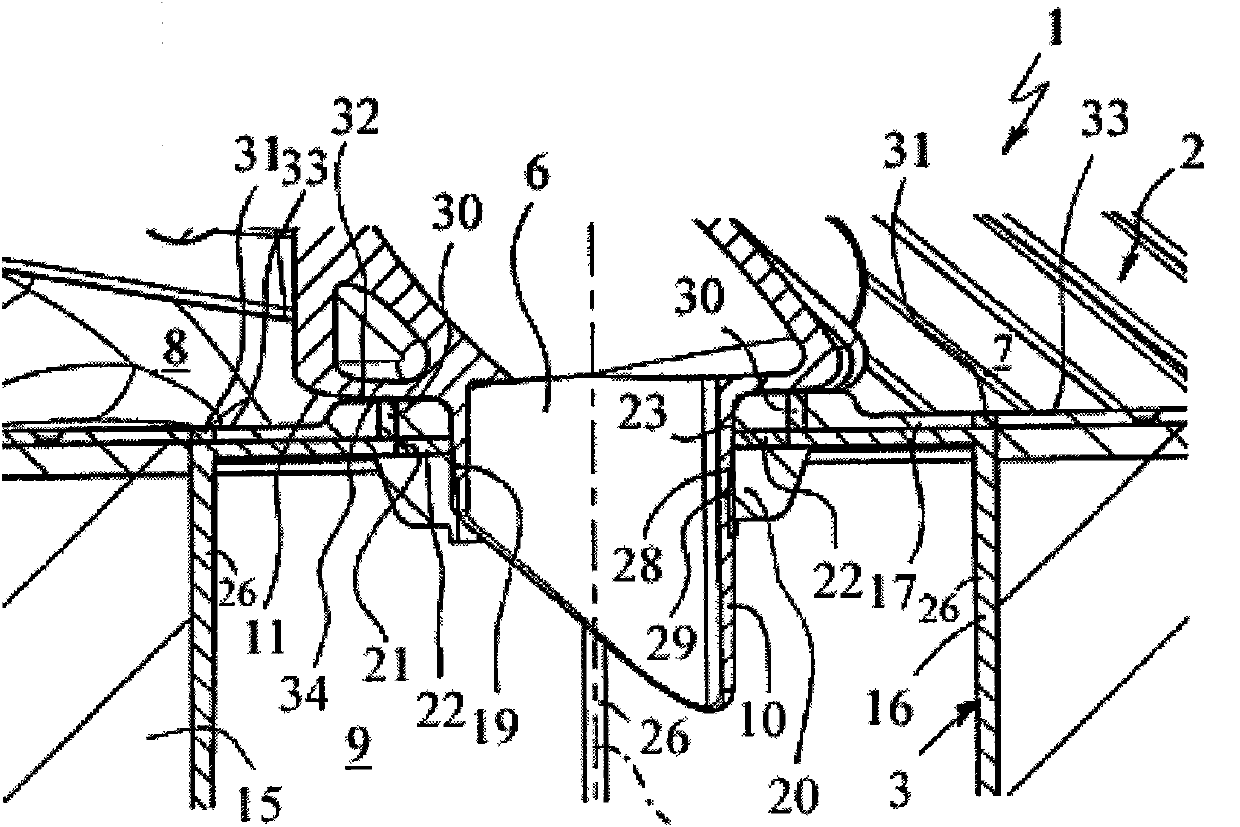

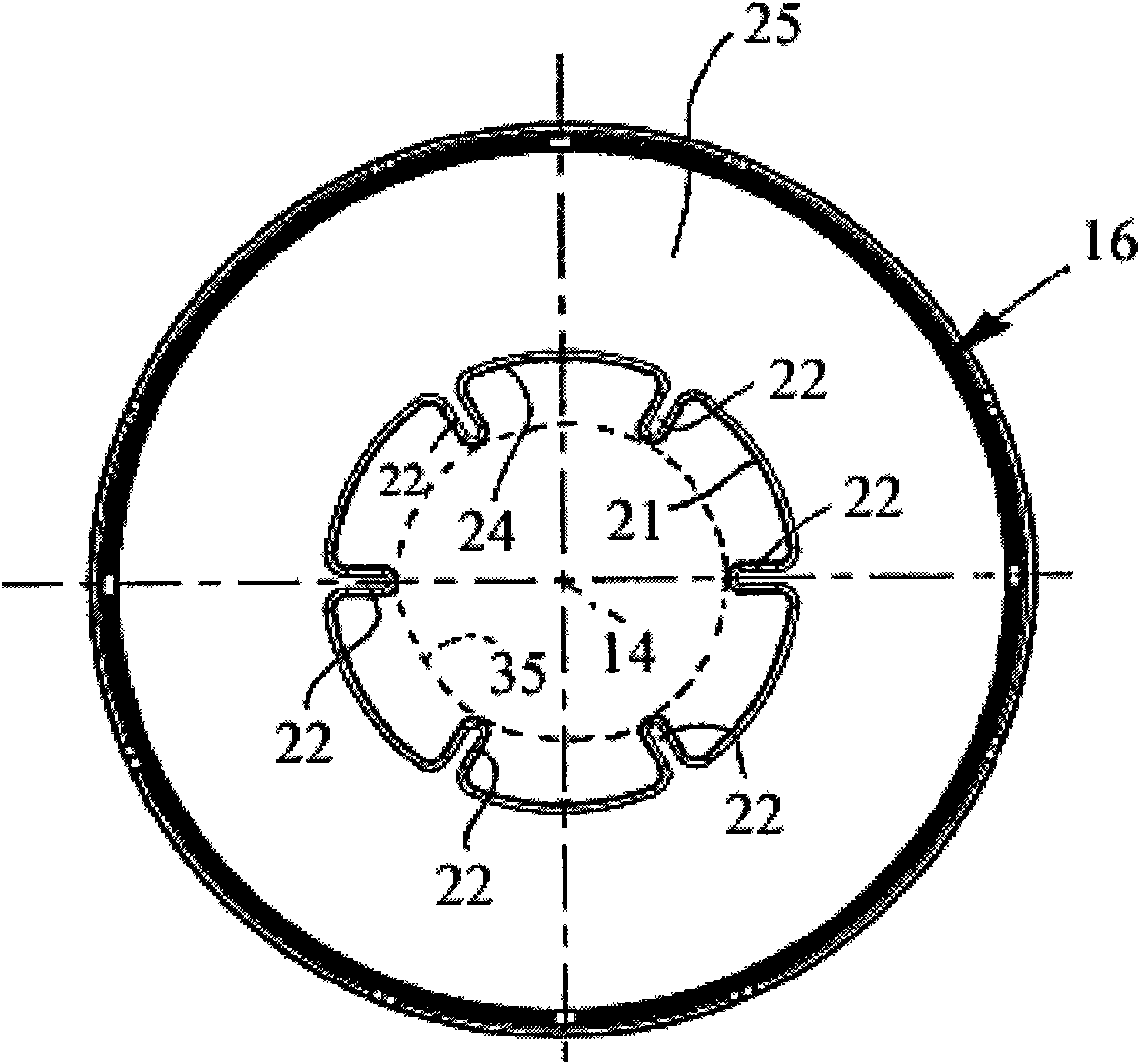

Filter element and filter device

InactiveCN102166461AReduce loadReduce risk of damageDispersed particle filtrationCombustion-air/fuel-air treatmentExternal combustion engineAir filter

The present invention relates to a filter element, in particular for an air filter of a fresh air system of a vehicle or an internal combustion engine. The filter element comprises: an annular filter body made of a filter material, an internal support frame, wherein said filter body is supported radially on the inside of said internal support frame, at least one end disk disposed at the filter body and the internal support frame, wherein the end disk has a central disk opening, a radial seal arranged coaxially to the disk opening, the internal support frame has a plurality of radial centering elements distributed in the circumferential direction and projected inwardly and extending to a radial end on the inside at an inner wall of the end disk, wherein the inner wall encloses the disk opening.

Owner:MAHLE INT GMBH

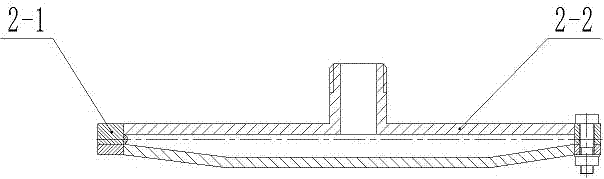

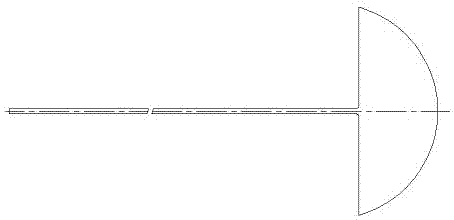

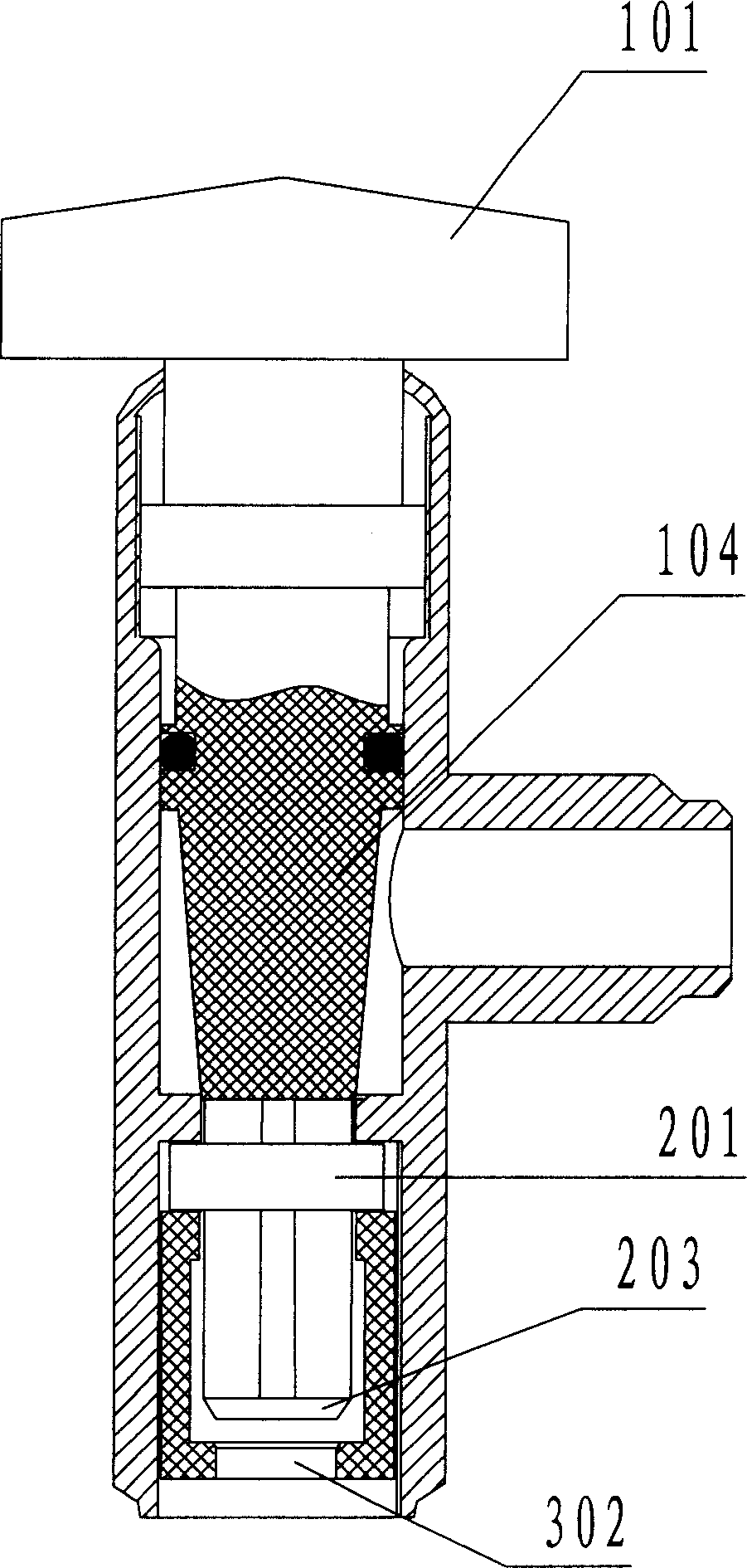

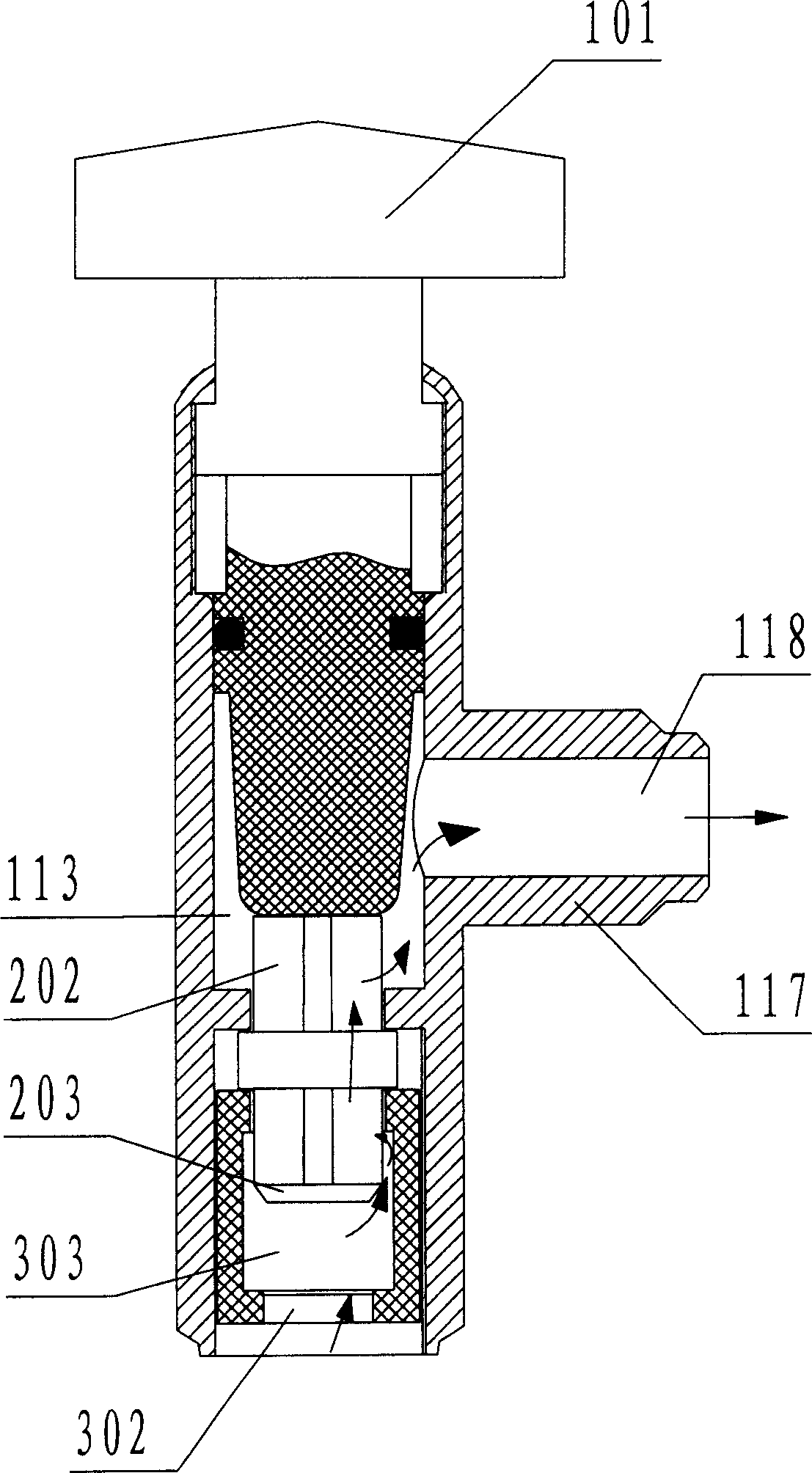

Non-refillable valve for steel welded cylinder

A nonrepeated charging valve of steel cylinder consists of valve body, valve mouth, valve internal components including valve stem component, bottom spool and support sleeve for supporting bottom spool. It is featured as setting bottom of bottom spool to be sealed head, setting media flowing channel on rod body and forming two stages of sealing surfaces by top spool and bottom spool in valve stem component.

Owner:郑卸果

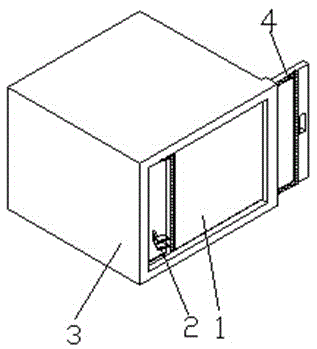

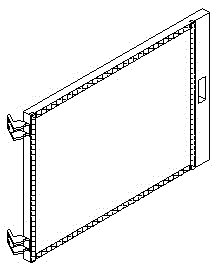

Steam cabinet provided with sliding door

ActiveCN105534294ARealize the sealing functionDoes not damage the sealing effectCooking vesselsFixed hingeEngineering

The invention discloses a steam cabinet provided with a sliding door. The steam cabinet comprises a box body, a door plate movably connected with the box body and hinges mounted on the door plate, each hinge comprises a movable hinge piece, a fixed hinge piece and a hinge shaft, each movable hinge piece is hinged to one end of the corresponding fixed hinge piece through the corresponding hinge shaft, the other end of each fixed hinge piece is fixedly connected with a corresponding hinge mounting groove formed in the left end side of the door plate, each movable hinge piece comprises a plate-shape gripper and wing plates which are arranged at the same end side of the plate-shape gripper and are parallel to each other, each wing plate comprises a guiding portion and a limiting portion, arc-shaped end faces used for guiding are arranged on the inner end face and the outer end face of each guiding portion, each guiding portion is provided with a through hole matched with the hinge shaft, the inner end face and the outer end face of each limiting portion are horizontal planes, a side opening matched with the inner end faces and the outer end faces of the limiting portions in width is formed in the right end of an open end of the box body, and positioning holes are formed in each plate-shaped gripper; a plate-shaped hinge poking block corresponding to a gap between the two corresponding wing plates is arranged on the inner wall of the left side of the box body, and hinge positioning nails corresponding to the positioning holes in the plate-shaped grippers are mounted on the inner wall of the right side of the box body.

Owner:乐科工业设备有限公司

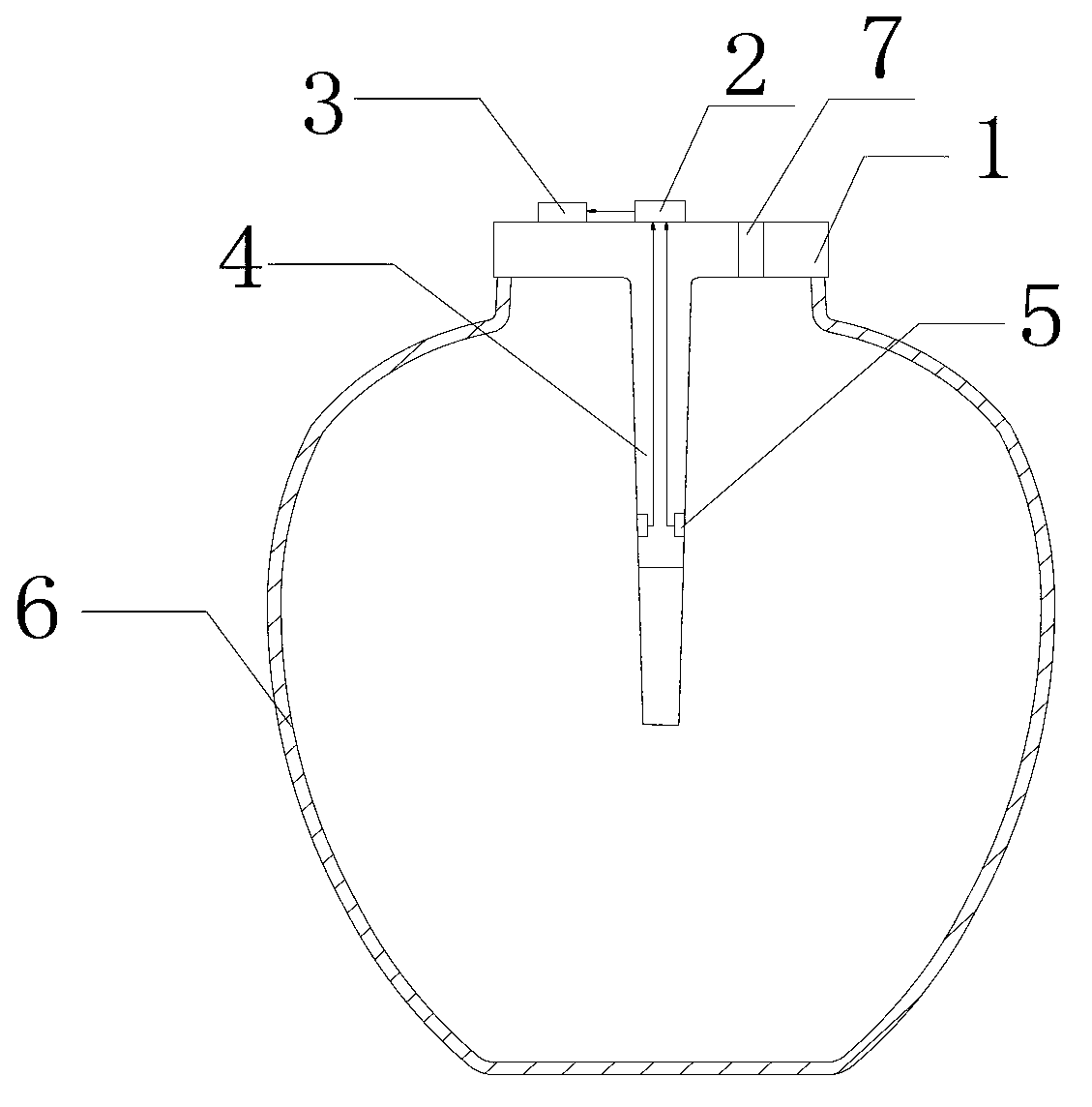

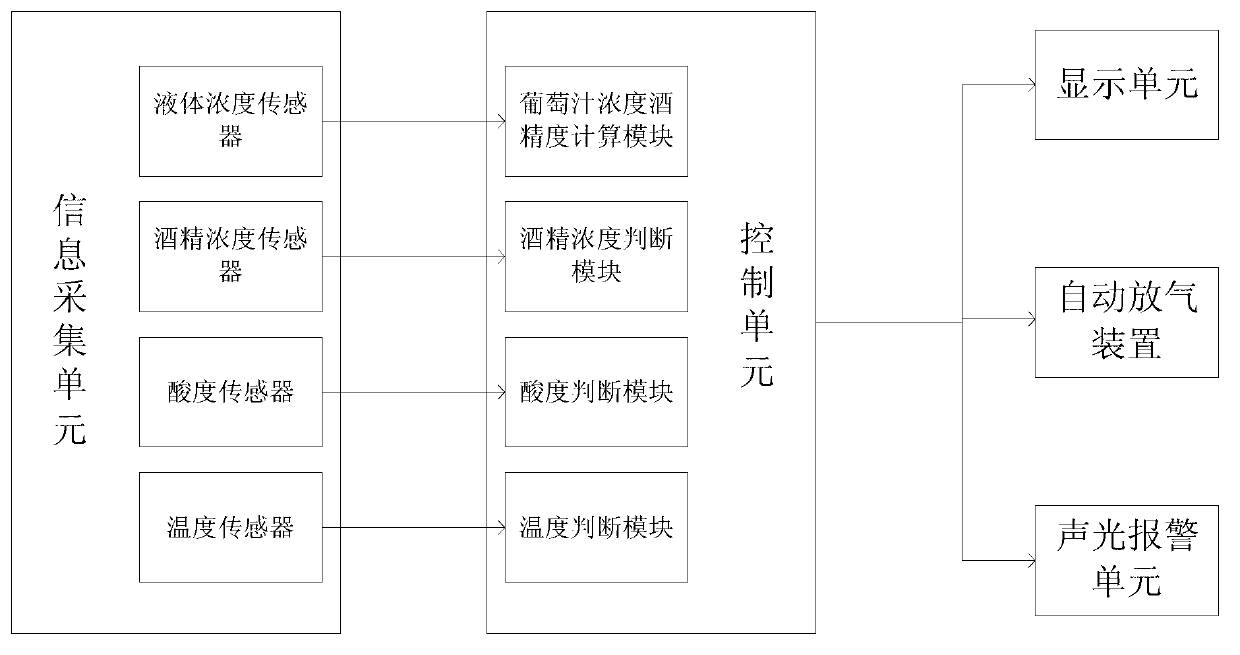

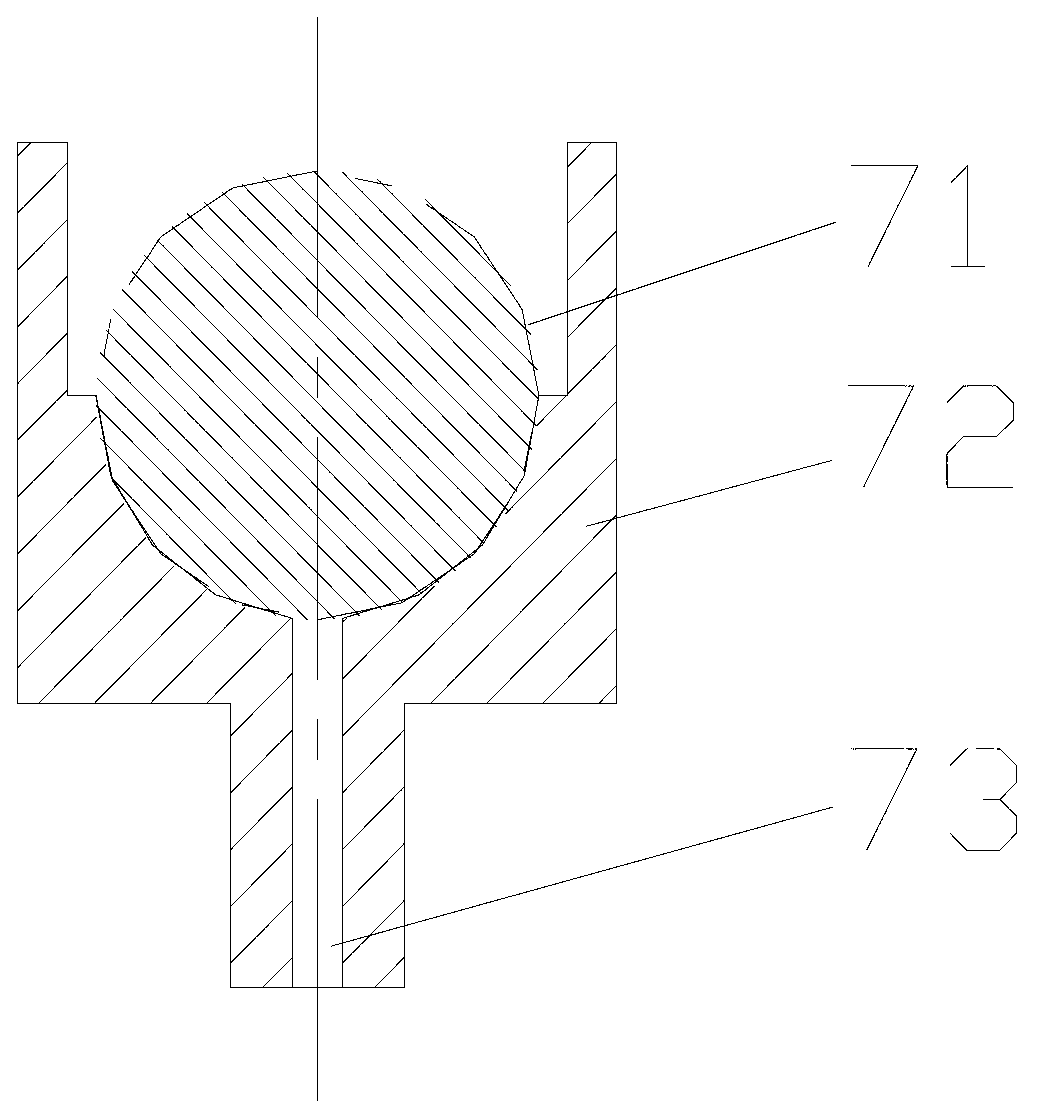

Household wine brewing device and cover body

InactiveCN103131574AAffect qualityImprove qualityWine preparationControl systemAgricultural engineering

The invention discloses a household wine brewing device and a cover body, which comprises a wine brewing container and the wine brewing cover body matched with the wine brewing container, a wine brewing control system and an exhaust channel are provided on the cover body, an automatic exhaust apparatus is provided on the exhaust channel, an overhanging rod used for stretching in the wine brewing container and connecting to a liquid is provided in the cover body, each sensor is placed on the overhanging rod, and a control unit and a display unit are arranged outside the cover body. A wine brewing control system is arranged on the cover body, and the replacing is convenient, and continuous brewing of the high quality wine can be realized. An automatic exhaust apparatus is provided on the wine brewing container for realizing the household wine brewing, the safety is high, the alcohol concentration can be controlled, the brewed wine has high quality, the structure is simple, and the usage operation is very convenient.

Owner:HENAN UNIV OF SCI & TECH

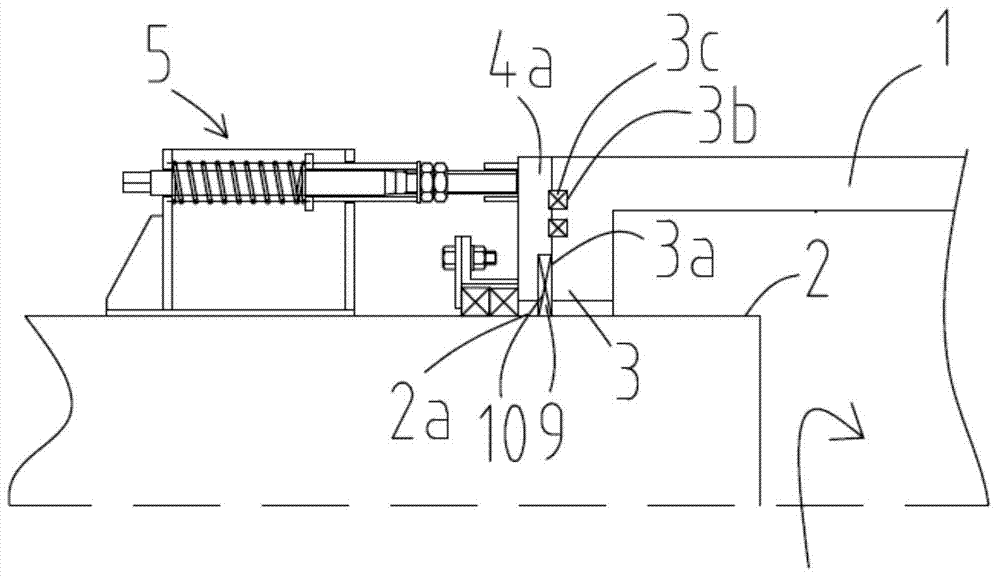

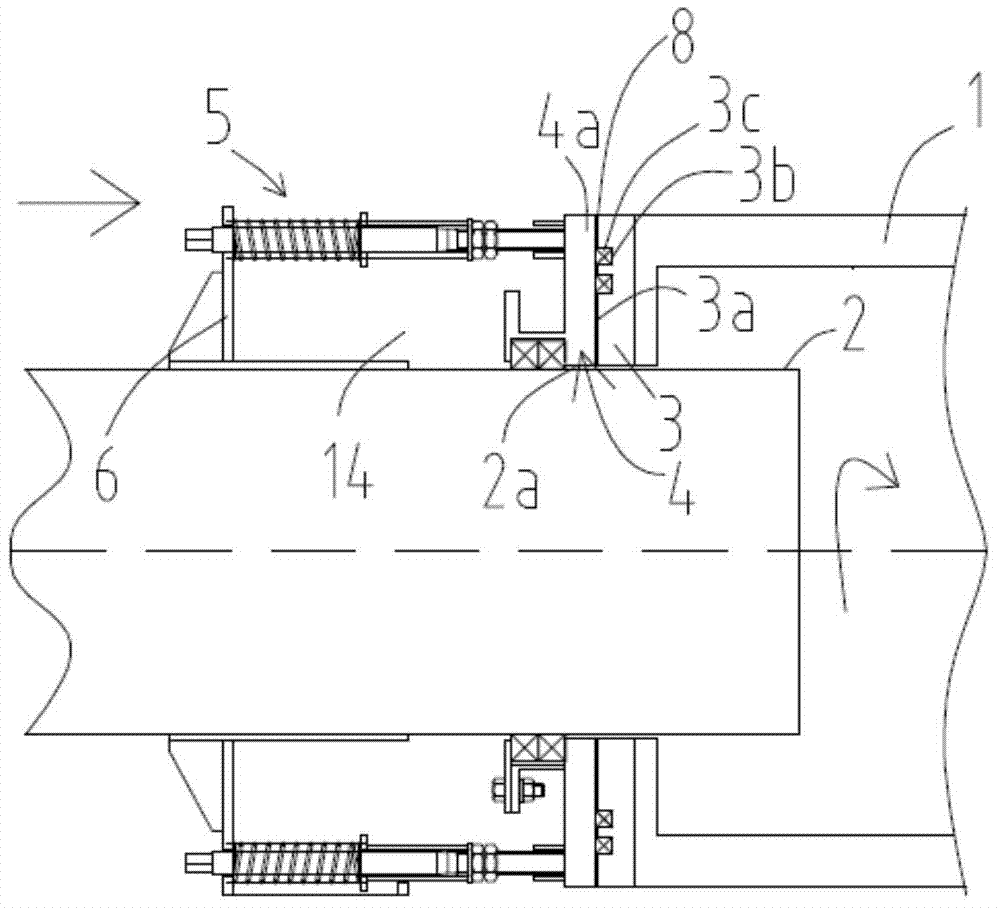

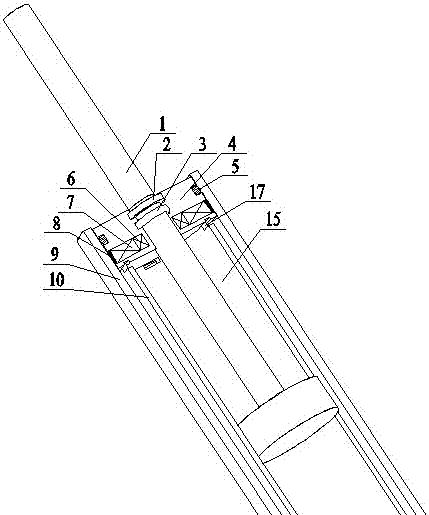

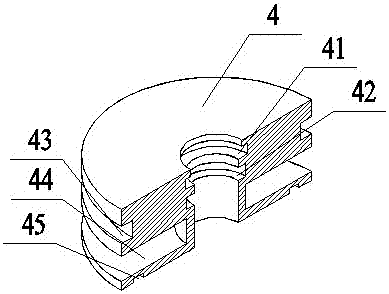

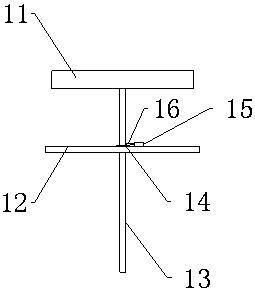

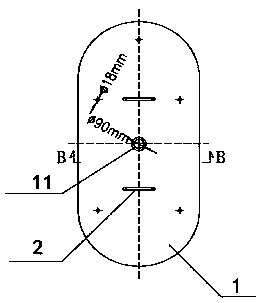

Sealing mechanism with gas exchange preventing function

ActiveCN105587863APlay a sealing roleImprove sealingEngine sealsSludge treatment by pyrolysisEngineeringGas exchange

The invention relates to sealing mechanism with a gas exchange preventing function. The sealing mechanism comprises a fixing part (1), a rotating part (2), a bearing block (3), a pressing block (4), a supporting part (5) and a connecting rod (6), wherein the supporting part (5) is fixedly arranged on the rotating part (1); one end of the connecting rod (6) is fixedly connected with the supporting part (5); the other end of the connecting rod (6) is fixedly connected with the stress surface (40) of the pressing block (4); the pressing block (4) comprises lug bosses (41); grooves (30) are formed in the positions, corresponding to the lug bosses (41), of the bearing block (3); connecting parts (7) are formed by connecting the lug bosses (41) and the grooves (30) in a close fit manner; and sealing strips (70) are arranged in the connecting parts (7). By adoption of the sealing mechanism, the joint between a main body and the rotating part can be effectively sealed, so as to prevent the situation that gas passes through the gap between the main body and the rotating part for exchange; the pressure of the pressing block is uniform; and the sealing mechanism is simple to adjust, simple in integral structure and high in heat-insulating performance.

Owner:苏州正益诚新能源科技有限公司

Bulk rice automatic packaging vending machine

PendingCN110874889ASimple structureImprove space utilizationSolid materialApparatus for dispensing fluids/granular materialsAgricultural scienceAgricultural engineering

The invention relates to a bulk rice automatic packaging vending machine that comprises: a rice bin; a rice discharging device fixedly arranged below the rice bin and used for guiding out the bulk rice in the rice bin and feeding the bulk rice into a weighing funnel fixedly arranged on the lower portion of the rice bin; a rice loading device that is arranged below the weighing funnel and is used for loading the bulk rice in the weighing funnel into a rice loading bag; a fixed bracket that is positioned below the rice bin; a bag warehouse that is arranged on the fixed bracket and is used for placing rice bags; a bag taking device that is fixedly arranged on the fixed bracket and used for taking down the rice bags placed on the bag warehouse, conveying the rice bags to the position right under the rice loading device and opening the rice bags. By using the machine, weighing can be achieved; after weighing is completed, the machine can automatically complete bagging and sealing actions ofrice, manual assistance is not needed, and convenience is provided for automatic selling.

Owner:杨铁军

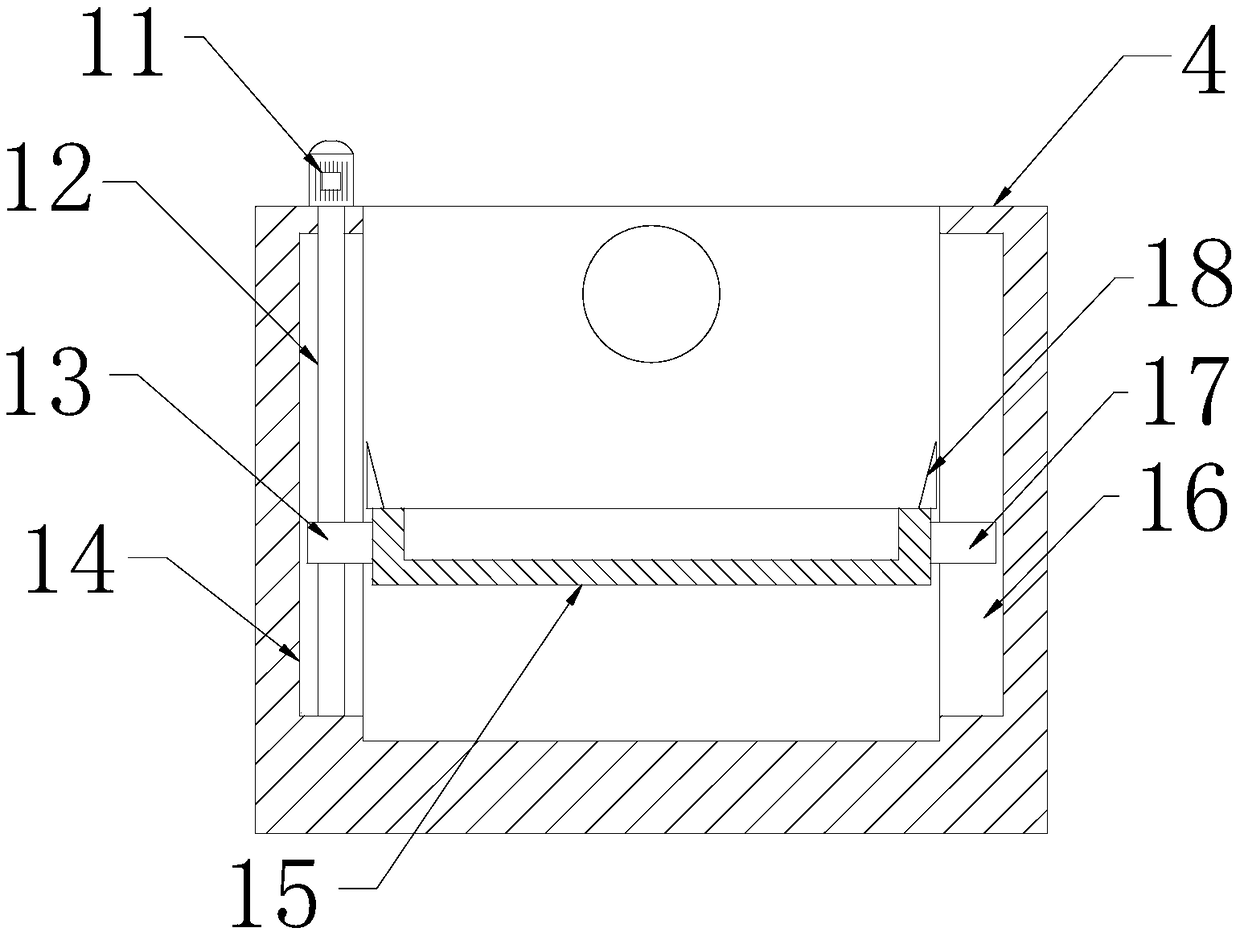

Environment-friendly industrial sewage treatment device

InactiveCN108607244AEasy to cleanRealize the sealing functionSettling tanks feed/dischargeSedimentation settling tanksSludgeEngineering

The invention provides an environment-friendly industrial sewage treatment device. The device comprises a motor, a longitudinal screw rod, a nut seat, a guide block, scraper plates, a T-shaped groove,a T-shaped slider, an upper sealing cover, a metal block and an electromagnet, wherein the motor is mounted in the front position of the upper surface of a settling pond, the longitudinal lead screwis mounted in a groove I, the nut seat is fixed on the front end surface of a sludge loading plate, the guide block is fixed on the rear end surface of the sludge loading plate, and the scraper plateis fixed in the rear position of the upper end surface of the sludge loading plate. By means of the design, the rapid clearing function of settling sludge is realized, the T-shaped groove is formed inthe left side of the upper surface of the settling pond, the T-shaped slider is fixed on the lower end surface of the upper sealing cover arranged on the upper surface of the settling pond, the metalblock is fixed on the front end surface of the T-shaped slider, and the electromagnet is mounted on the front side surface in the T-shaped groove. By means of the design, the sealing function of thesettling pond is realized. The environment-friendly industrial sewage treatment device is reasonable in structure, high in sludge clearing efficiency, good in environment friendliness, complete in function and good in stability.

Owner:临清鑫浩环保科技有限公司

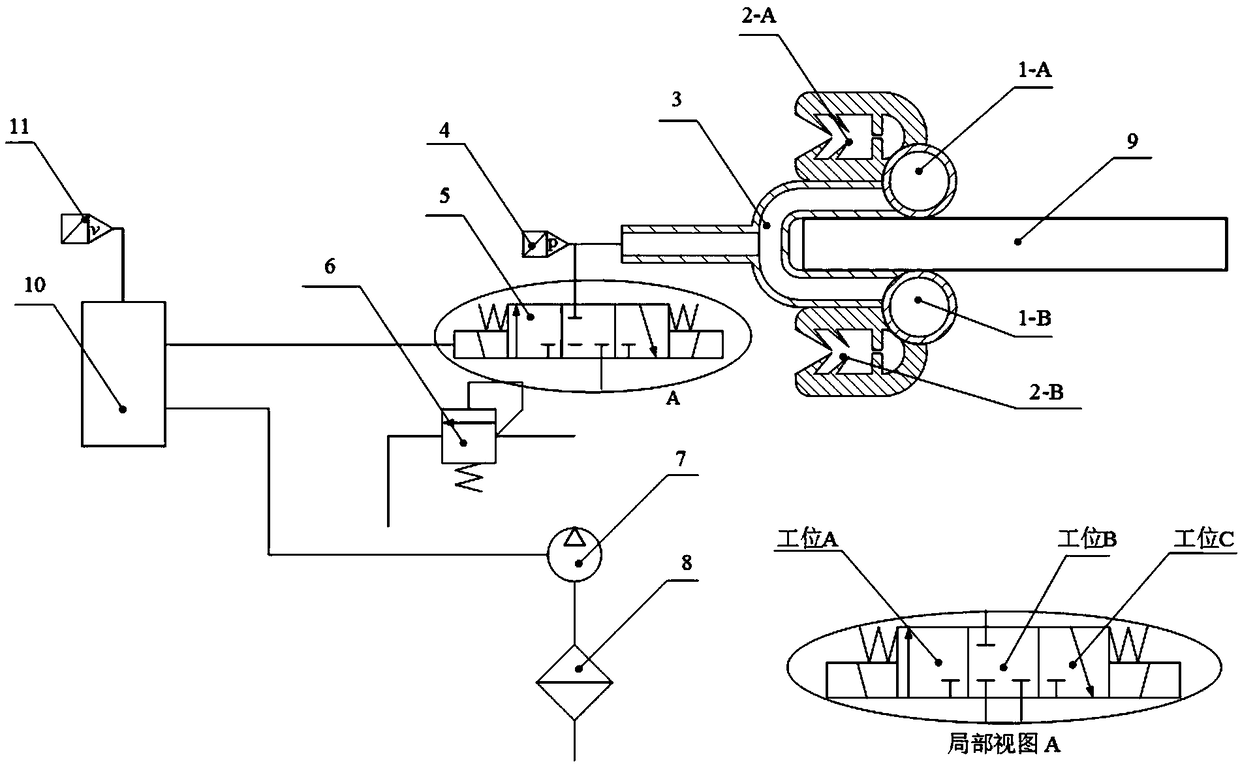

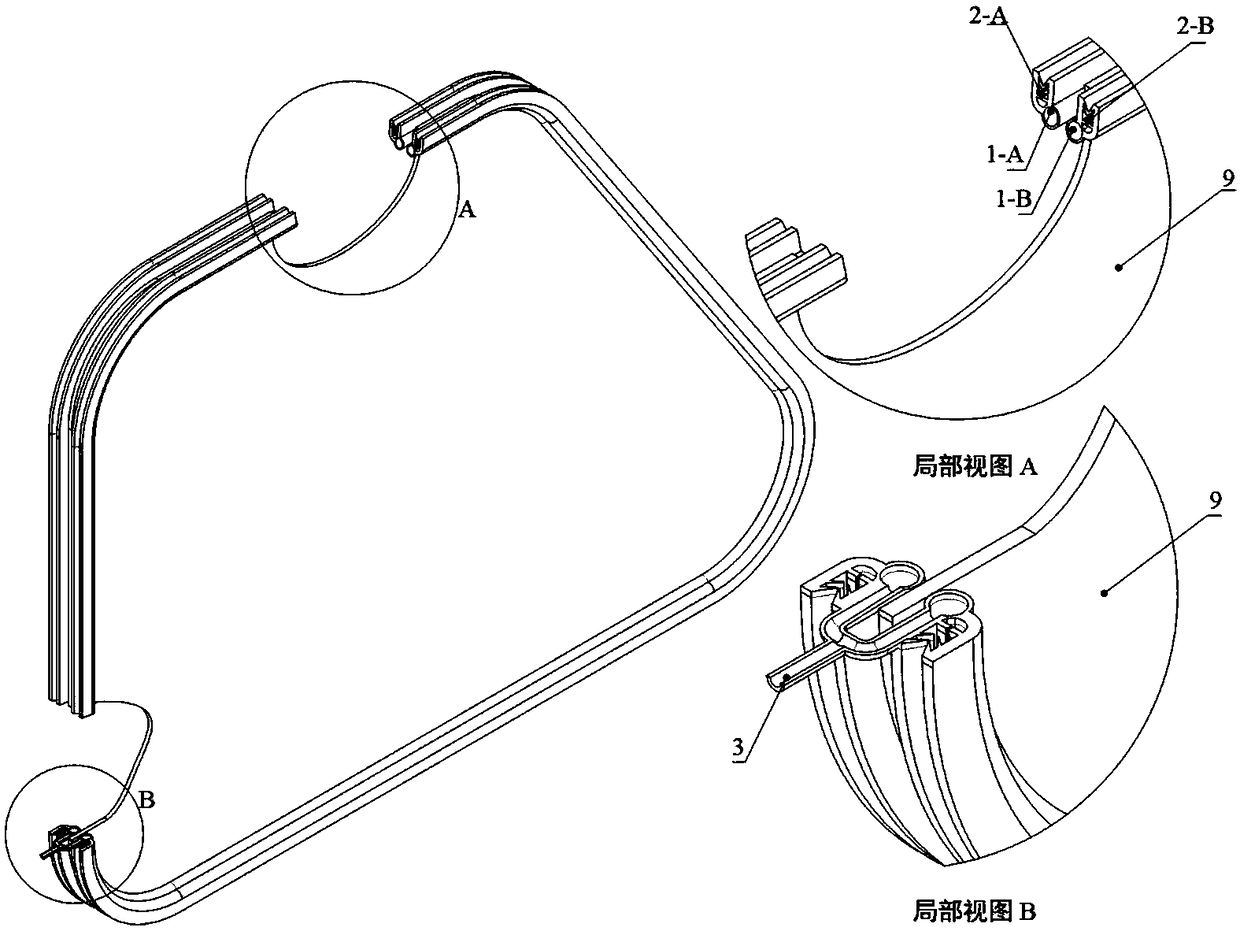

Vehicle window air pressure sealing system

ActiveCN108528181AReduce air pressureAvoid damageEngine sealsVehicle sealing arrangementsInternal pressureAir pump

The invention discloses a vehicle window air pressure sealing system. The system comprises an assembly positioning lip side, air pressure hoses, a loop interface, a three-position three-way solenoid directional valve, a decompression valve, an air pump, a filter, an air pressure sensor, a vehicle speed sensor and a controller. The assembly positioning lip side is fixedly connected with a vehicle body, and the two air pressure hoses are fixed at the inner and outer sides of vehicle window glass; the two air pressure hoses are communicated through the loop interface and form a gas loop with thethree-position three-way solenoid directional valve, the decompression valve, the air pump and the filter; and the air pressure sensor, the vehicle speed sensor, the controller, the three-position three-way solenoid directional valve and the air pump form a control loop. The vehicle window air pressure sealing system has the advantages that signals of the air pressure sensor and vehicle speed sensor serve as input, the controller controls the three-position three-way solenoid directional valve and the air pump to work, and the internal pressure in the air pressure hoses is adjusted to ensure that the vehicle window glass always fits the air pressure hoses to prevent the noise from being transmitted into a vehicle; the elasticity and damping of the air pressure hoses reduce the vibration ofthe vehicle window glass and have the advantages of vibration and noise reduction.

Owner:SHANDONG UNIV OF TECH

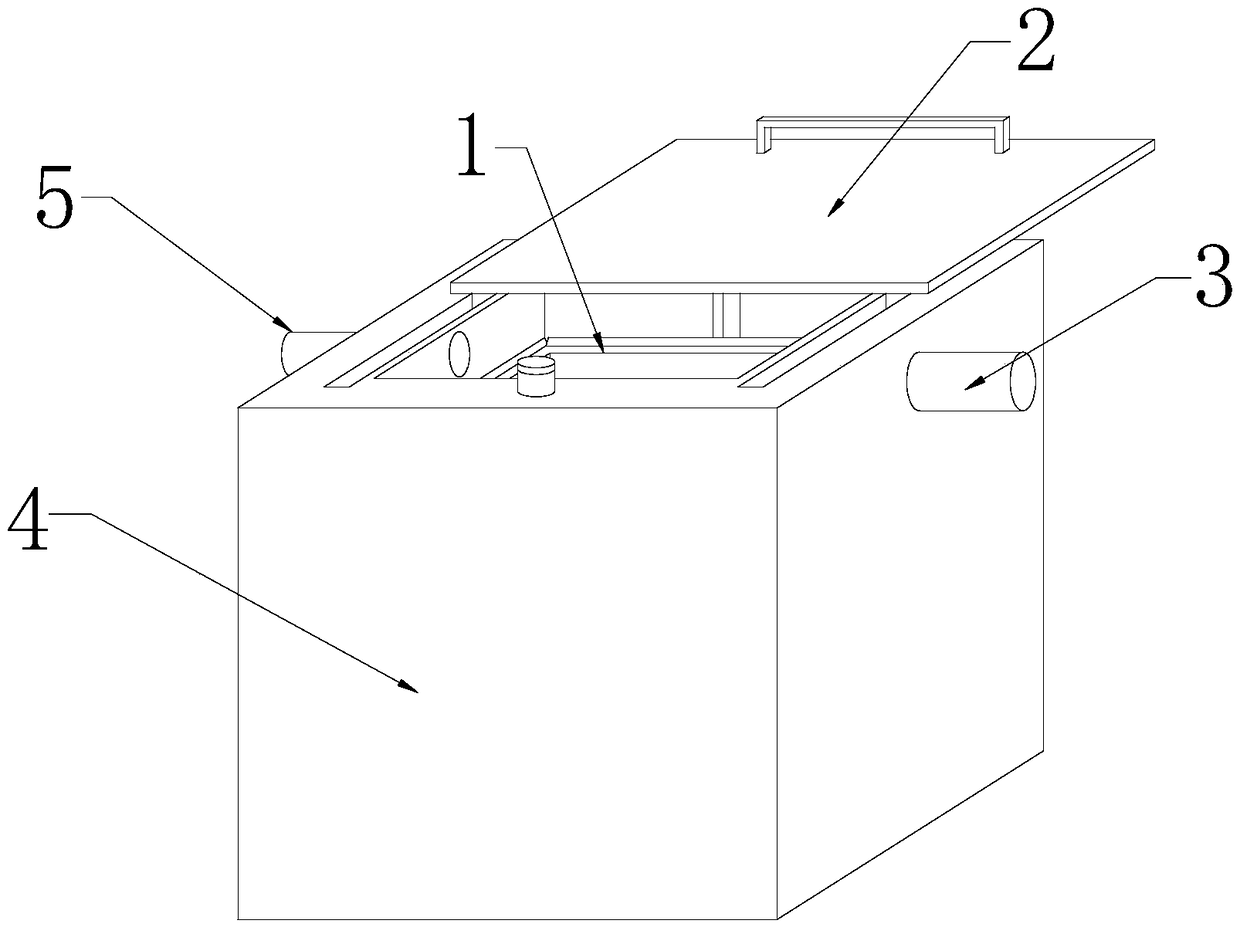

Waterproof test device for small and special electric machine

InactiveCN107894305AImprove sealingPrevent water leakageFluid-tightness measurement using fluid/vacuumRubber ringElectric machine

The invention provides a waterproof test device for a micro-special motor, which includes an upper fixing plate, a latch rod, an annular air bag, a lower fixing plate, an annular rubber ring, a connecting rod, an L-shaped sliding rod, a spring one, a base plate and a clamping ring. The lower end of the upper fixing plate is provided with a lower fixing plate, the upper end of the lower fixing plate is pasted with an annular air bag, the annular air bag is embedded in the lower end of the upper fixing plate, and the lower end of the lower fixing plate is provided with an annular rubber ring, and the annular rubber ring Installed on the connecting rod, the upper end of the connecting rod is set inside the upper fixing plate, the connecting rod is equipped with a latch rod, and the latch rod is assembled inside the upper fixing plate, this design improves the sealing effect, and the clamping An L-shaped sliding rod is fixed on the outer end of the ring, and the outer end of the L-shaped sliding rod is equipped with a spring one. This design improves the supporting effect. The present invention is easy to use, easy to operate, improves the sealing effect, and can prevent falling.

Owner:朱雪亭

Sealing device for ultra-deep water marine working ship sea chest

InactiveCN109747777ARealize the sealing functionWork lessSelf-bailing equipments/scuppersVessel partsEngineeringOcean bottom

The invention discloses a sealing device for an ultra-deep water marine working ship sea chest. The sealing device comprises a sealing blind plate, a handle, screws, vertical stop round steel, horizontal stop round steel, handle round steel, sealing rubber, and water pumping valves. Small round holes are formed in the sealing blind plate. A large round hole is formed in the middle of the sealing blind plate. The handle is fixed to one side of the sealing blind plate. The sealing rubber is arranged on the other side of the sealing blind plate. The screws, the vertical stop round steel and the horizontal stop round steel are welded together to form an integral structure. The integral structure formed by the screws, the vertical stop round steel and the horizontal stop round steel is insertedin the small round holes of the sealing blind plate. The handle round steel and the screws are welded to form a rotating C-shaped component. The water pumping valves are welded to the middle large round hole of the sealing blind plate in an aligned mode. According to the sealing device for the ultra-deep water marine working ship sea chest, the sea chest can be sealed underwater, a water discharging flexible pipe is adopted to discharge water in the sea chest, and the sea chest can be maintained.

Owner:COSCO DALIAN SHIPYARD

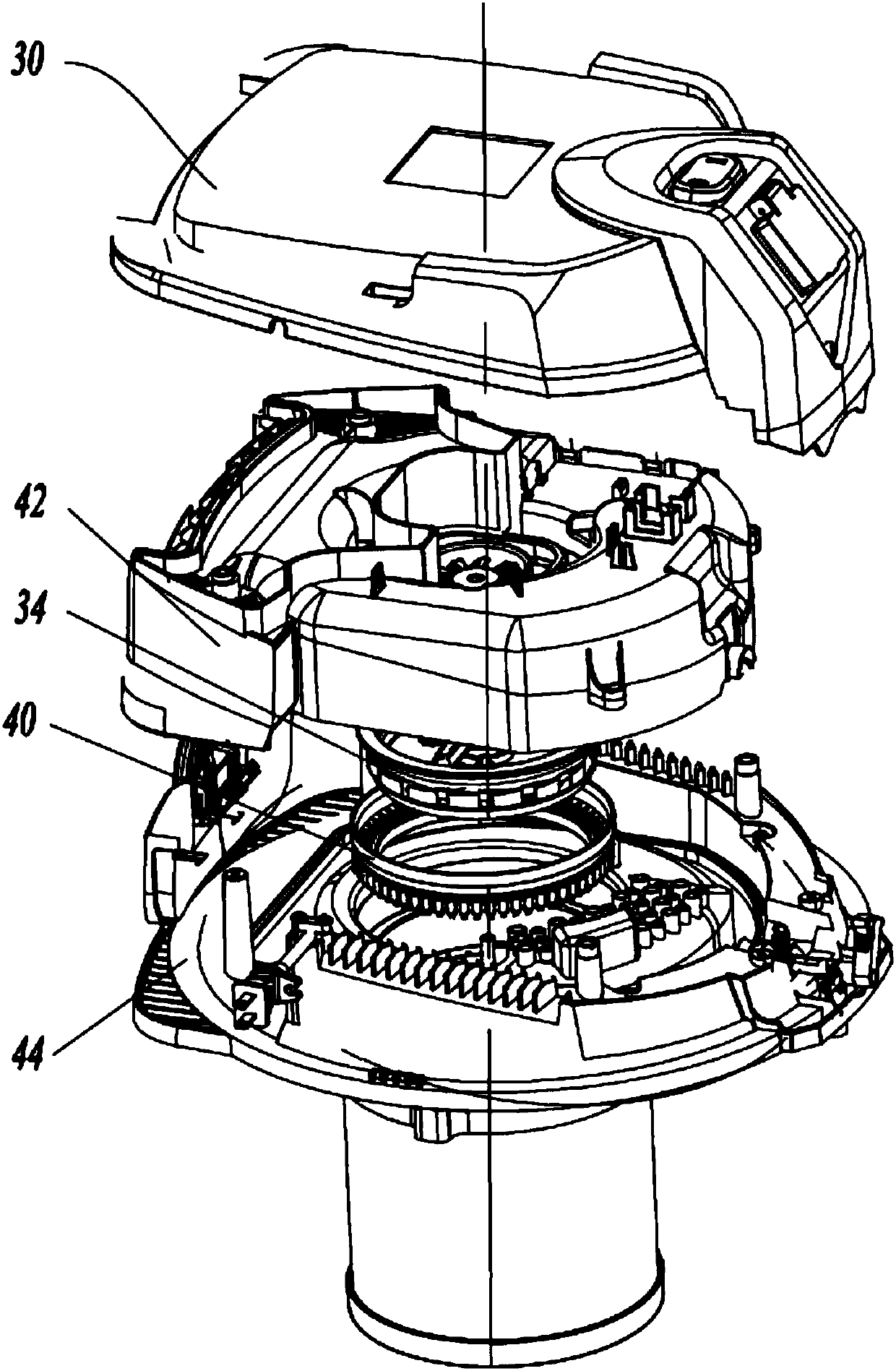

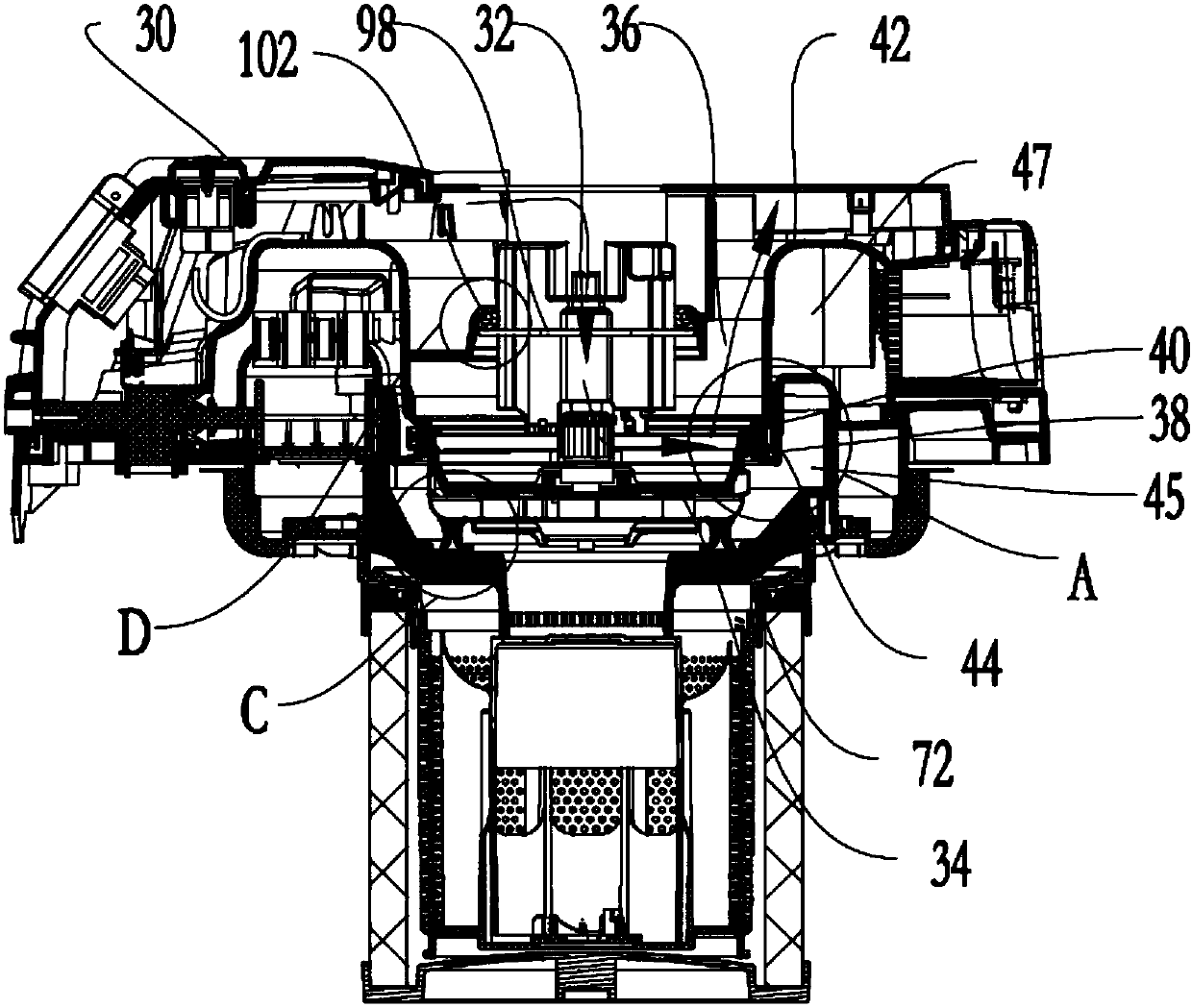

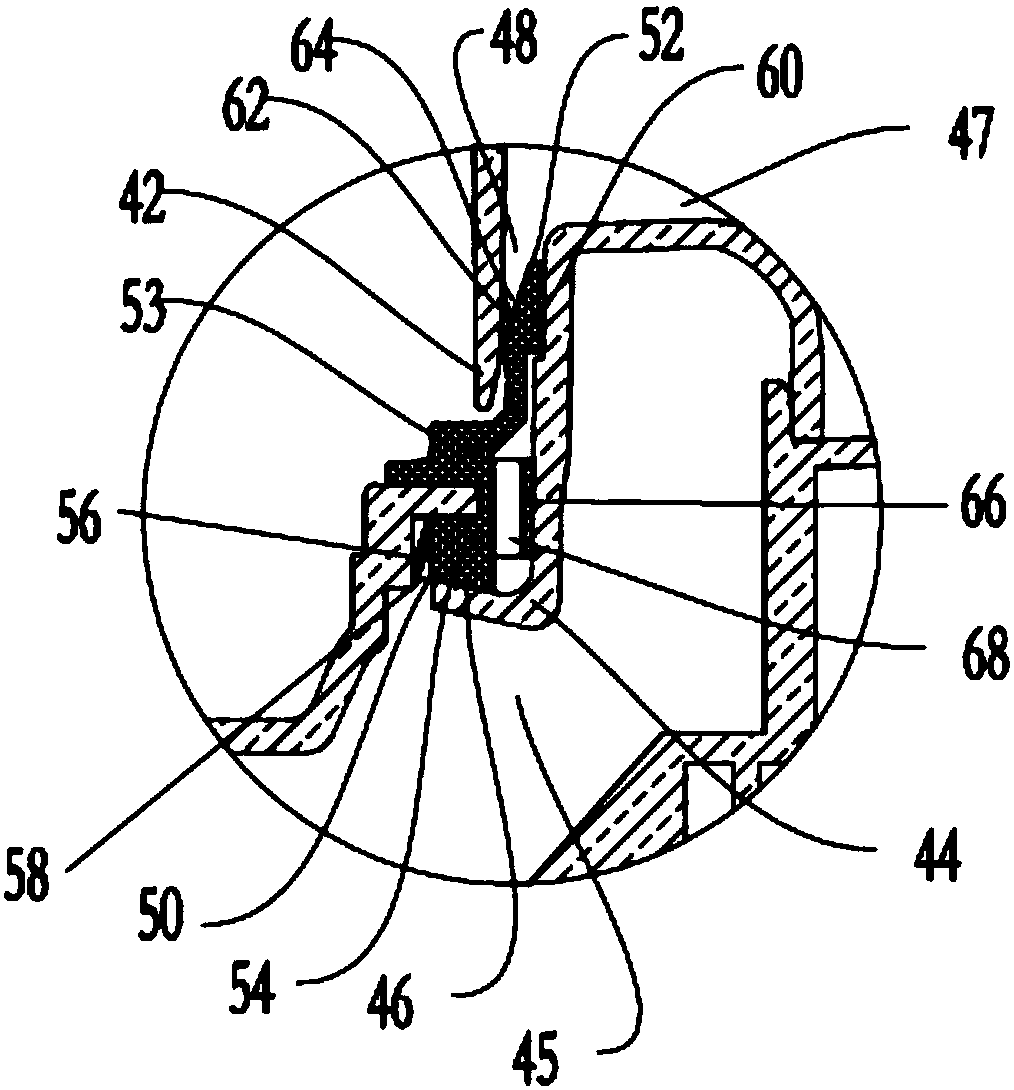

Sealing installation mechanism of motor in small and medium-sized electrical appliance

ActiveCN107863834AStrong noise absorption and noise reduction abilityRealize the sealing functionMotor fan assembly mountingExhaust-air diffusionEngineeringNoise reduction

The invention discloses a sealing installation mechanism of a motor in a small and medium-sized electrical appliance. The sealing installation mechanism comprises a shell, a motor in the shell and a motor seat which supports the motor. The shell is internally provided with at least one isolation cover. The motor is axially arranged between the shell and the motor seat. A motor chamber accommodating the motor is formed among the shell, the motor seat and the isolation cover. A sealing end of the motor chamber has a mating gap along a radial direction. The mating gap has a radially-mated first seal member. The sealing installation mechanism provided by the invention has strong noise absorption and noise reduction ability.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com