Self-powder-storing selective laser melting powder supplying flexible bidirectional non-redundancy powder laying device

A technology of laser selective melting and powder spreading device, applied in the field of additive manufacturing, which can solve the problems of low powder spreading efficiency, affecting the powder spreading quality and printing quality, etc., to avoid oxidation and shedding, and ensure the powder spreading efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

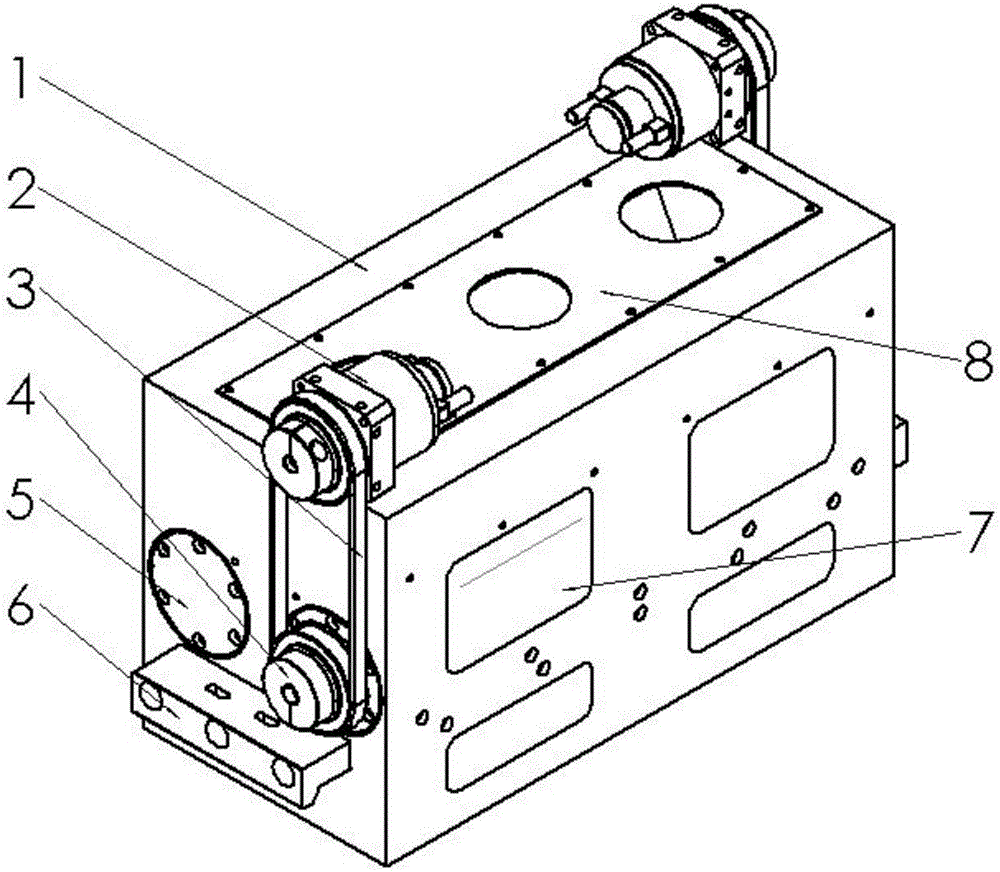

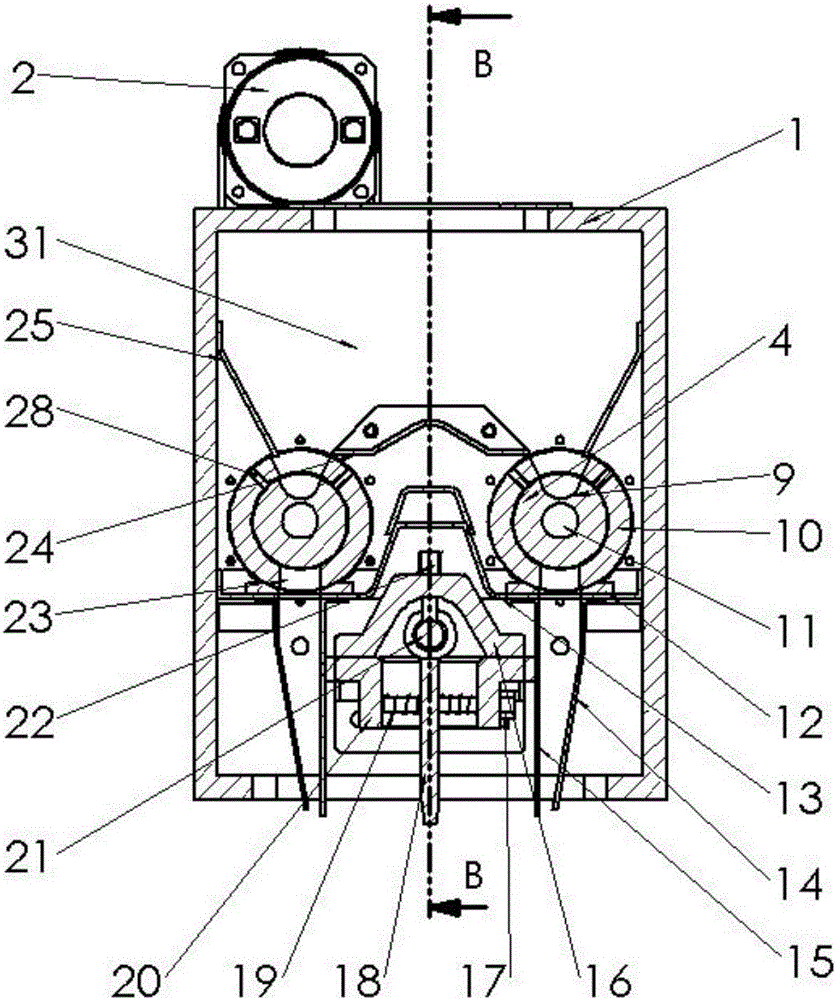

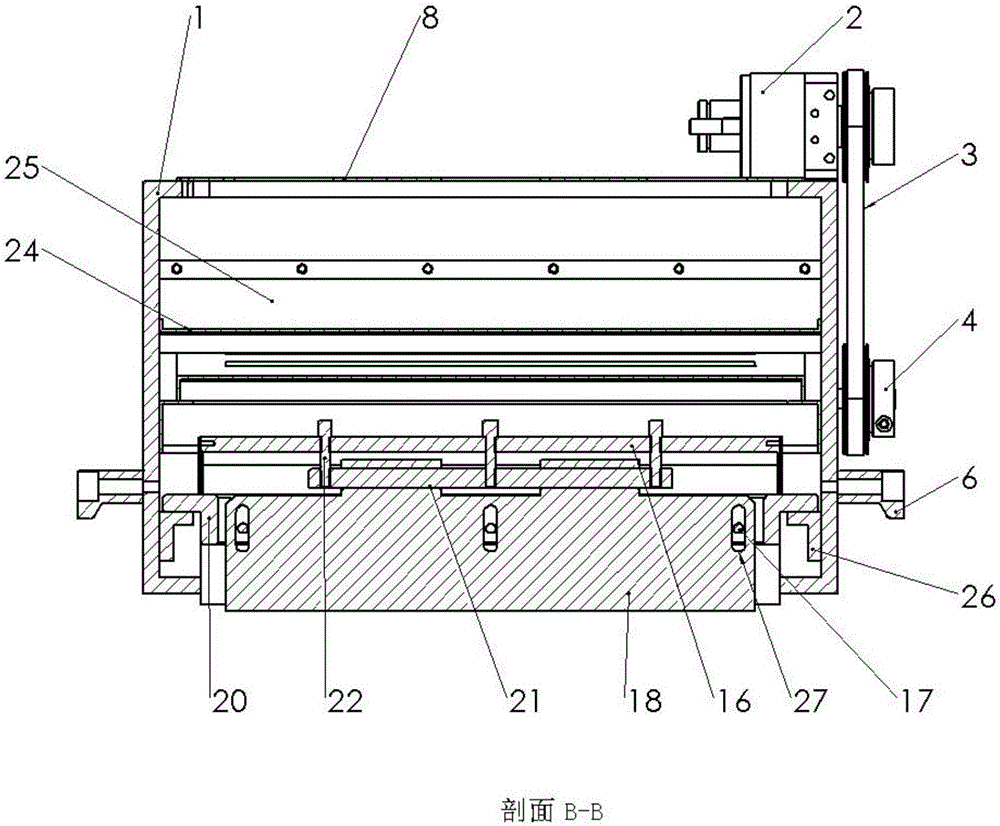

[0022] Such as figure 1 As shown, the self-storage powder laser selective melting upper powder supply flexible two-way non-redundant powder spreading device includes a powder spreading device box 1, and a swing cylinder 2 is fixed on the left and right sides of the upper part of the powder spreading device box 1, each swinging The cylinder 2 is connected to the quantitative powder supply wheel 4 across the powder spreading device box 1 through the conveyor belt 3, and the other side of the quantitative powder supply wheel 4 is connected to the powder spreading device box 1 through the bearing end cover 5, and the powder spreading device box 1 The left and right sides are respectively provided with installation positioning blocks 6 connected with the linear motion unit, and the front and rear sides of the powder spreading device box 1 are respectively provided with wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com