Sealing mechanism with gas exchange preventing function

A technology of gas exchange and sealing mechanism, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., which can solve the problems of reduced heat insulation performance of the furnace body, uneven pressure of the briquetting block, large spring expansion and contraction size, etc., achieving multiple times of use, Realize the effect of compaction and reduce the probability of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

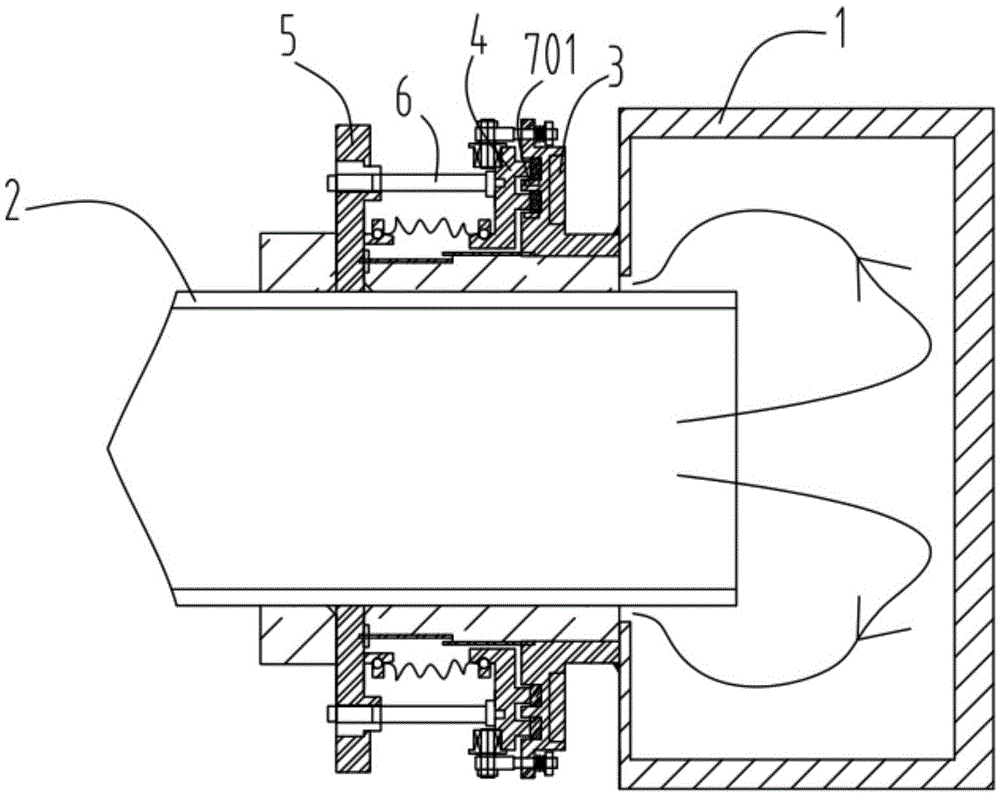

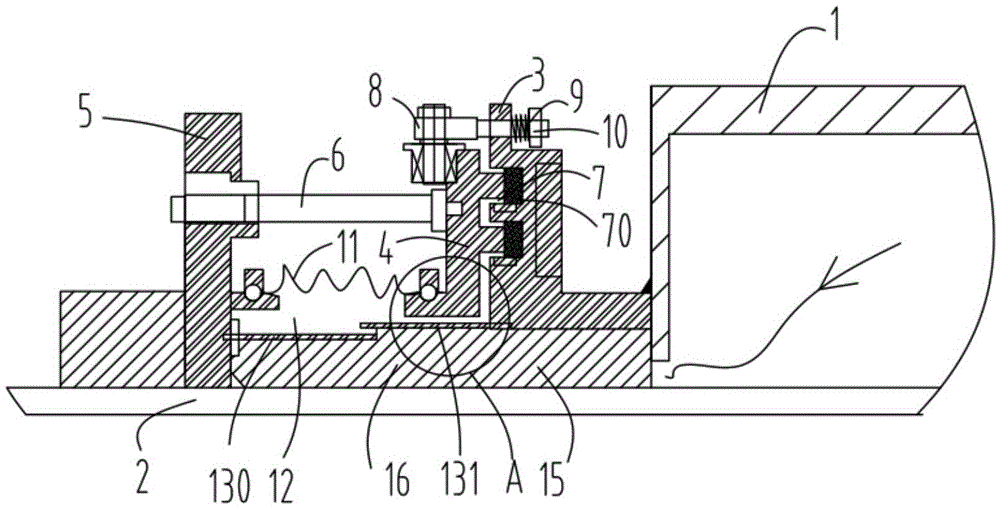

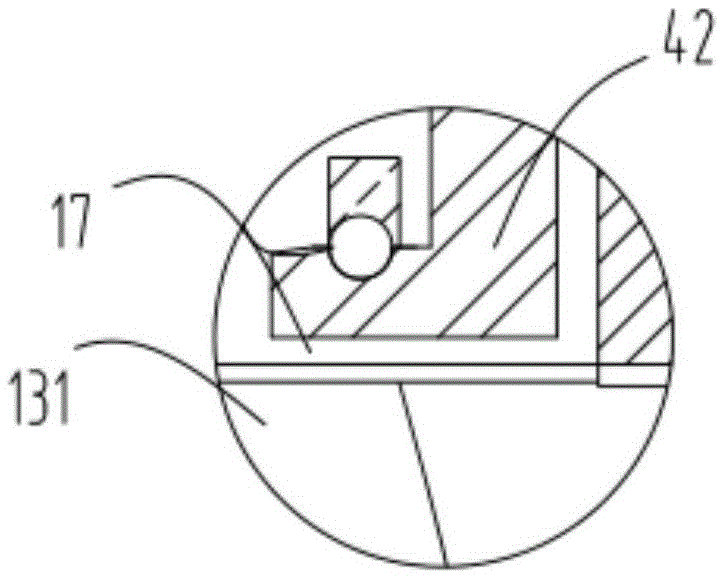

[0038] figure 1 A schematic diagram of the overall structure of Embodiment 1 of the sealing mechanism for preventing gas exchange; figure 2 It is a schematic diagram of part of the structure of the sealing mechanism for preventing gas exchange according to Embodiment 1; Figure 5 It is a schematic diagram of the structure of the guide wheel device defined in the sealing mechanism for preventing gas exchange according to the first embodiment. Such as figure 1 , figure 2 ,and Figure 5As shown, a sealing mechanism for preventing gas exchange includes a fixed part 1, a rotating part 2, a receiving block 3, a pressing block 4, a supporting part 5 and a connecting rod 6, and the rotating part 2 can surround the fixing part 1 Rotate, the receiving block 3 is fixedly arranged on the fixed member 1, the support member 5 is fixedly arranged on the rotating member 1, one end of the connecting rod 6 is fixedly connected with the support member 5, the The other end of the connectin...

Embodiment 2

[0046] Figure 8 It is a structural schematic diagram of the briquetting block in the sealing mechanism for preventing gas exchange according to the second embodiment; Figure 9 It is a schematic structural diagram of the receiving block in the sealing mechanism for preventing gas exchange according to the second embodiment. Such as Figure 8 and Figure 9 As shown, the pressing block 4 has a protruding block 41, and the receiving block 3 is provided with a groove 40 at a corresponding position, and the protruding block 41 is mated with the groove 40 and tightly fitted to form two connections Office 7. It should be noted that, except for this, other structures of this embodiment may be the same as those of Embodiment 1, which need not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com