Knife striking and blowing mechanism of direct connected main shaft

A technology of blowing mechanism and main shaft, applied in the directions of metal processing machinery parts, clamping, support, etc., can solve the problems of complex processing technology, high comprehensive cost, high manufacturing difficulty, etc., and achieve simplified processing technology, low comprehensive cost, and airtightness. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

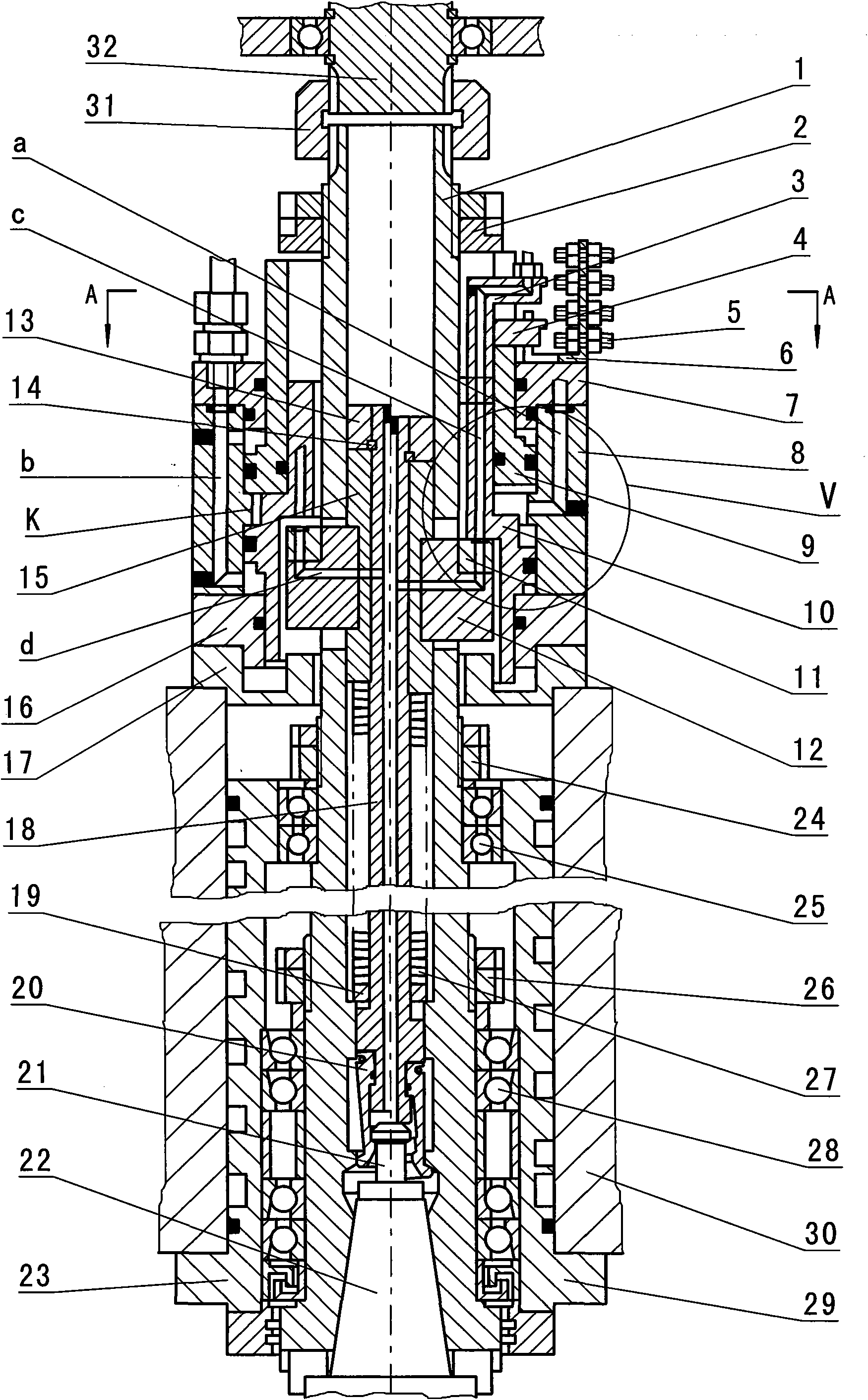

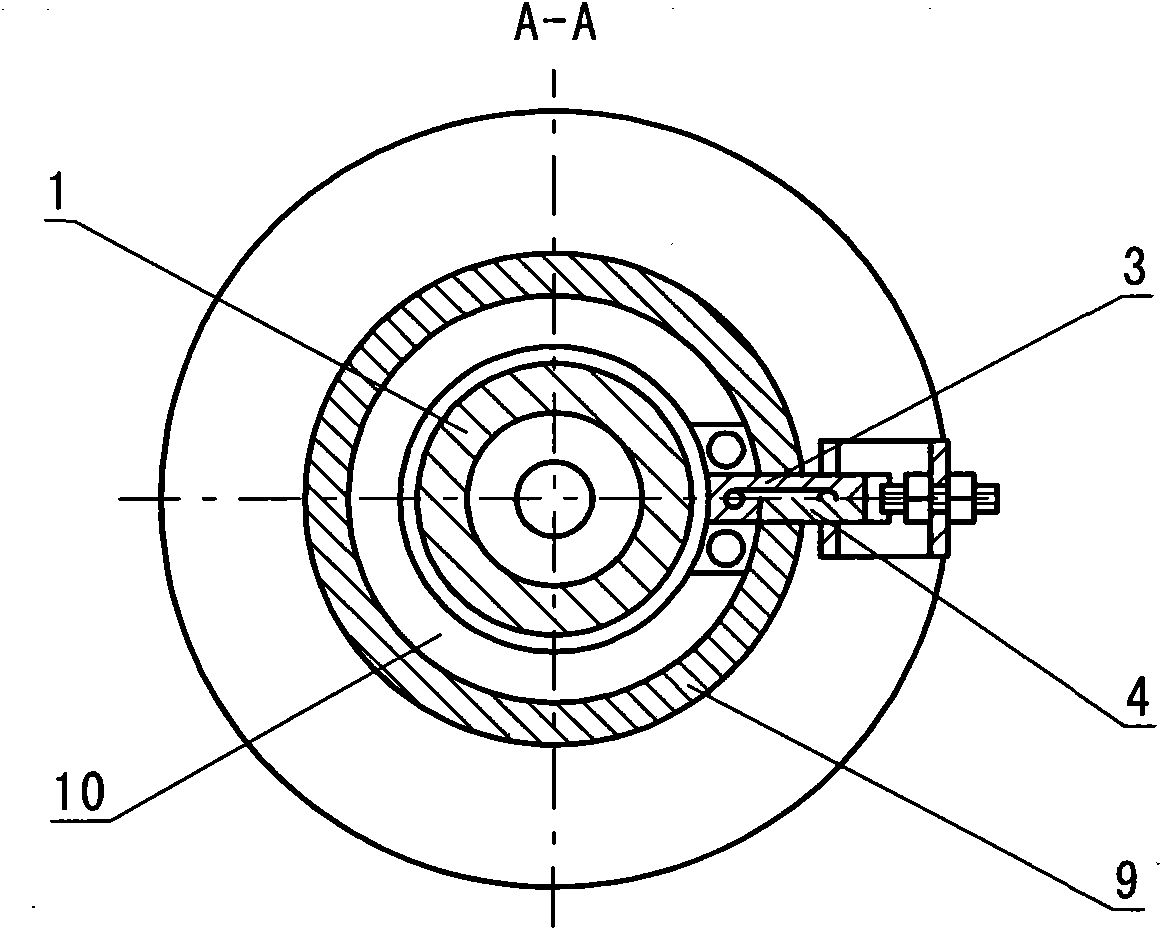

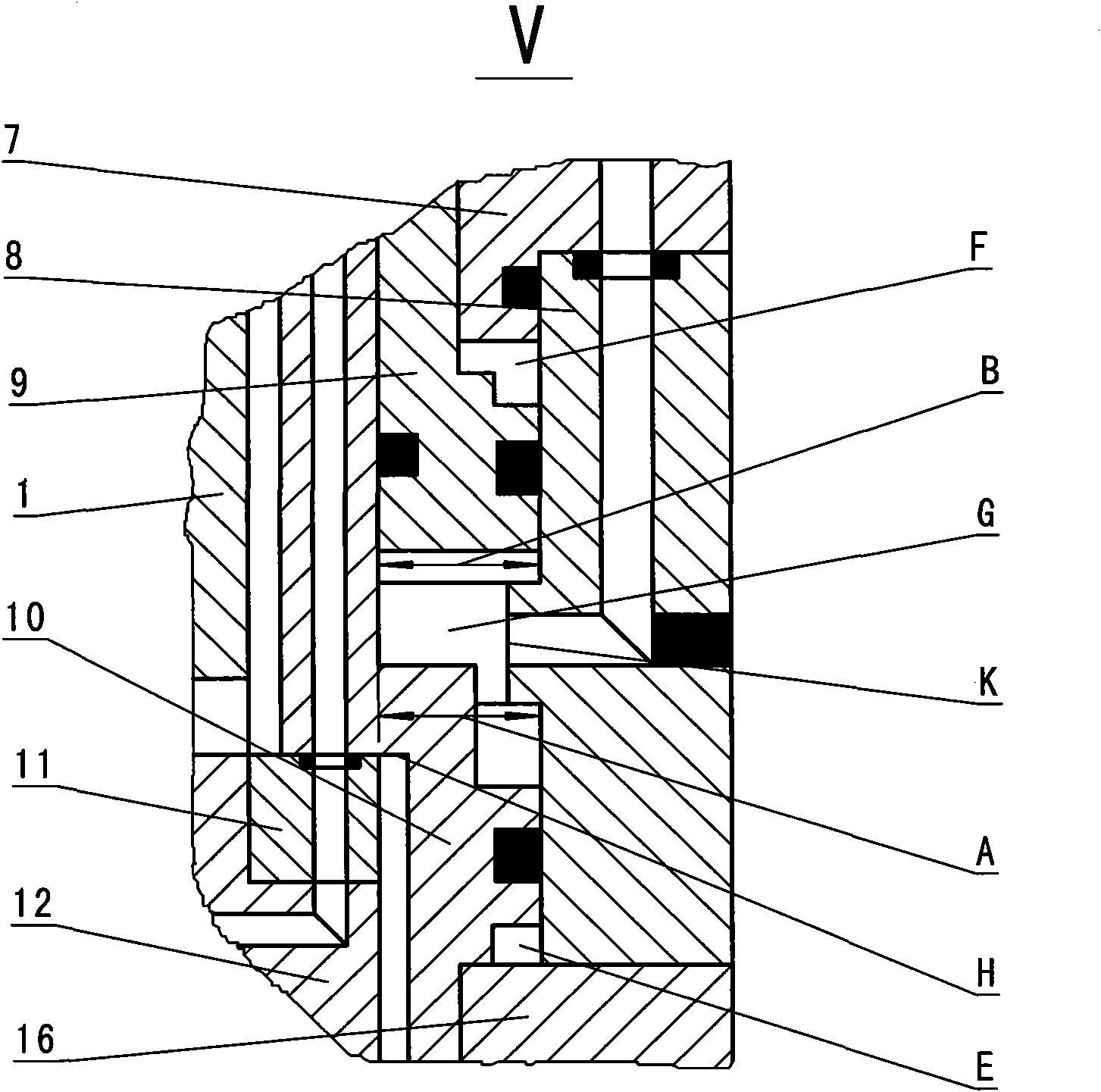

[0028] The present invention mainly comprises main shaft 1, front and rear bearing assembly 28,25, sleeve 23, pull rod 18, connecting rod 15, disc spring 27, pull claw 20 and beating knife oil cylinder. The tail of the main shaft 1 can be connected to a motor or a direct drive shaft assembly 32 through a coupling 31 . This embodiment is for connecting the direct drive shaft assembly. See figure 1 .

[0029] The main shaft 1 is supported in the main shaft housing 30 by the front and rear bearing assemblies 28, 25 and the sleeve 23, the front and rear bearing assemblies 28, 25 are axially fixed by lock nuts 26, 24 respectively, and the end of the main shaft 1 is provided with an end cover 29, The sleeve 23 and the end cover 29 are fixedly connected with the spindle housing 30 . The main shaft 1 can rotate relative to the sleeve 23 and the main shaft housing 30 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com