Sealing corrosion-resistant structure of expansion joint of brick lining chimney

A technology of expansion joints and inner linings, which is applied in the direction of building components, building insulation materials, building types, etc., can solve problems such as leakage and difficult treatment of expansion joints, and achieve the best sealing effect, good long-term sealing function, and wide expansion and contraction range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

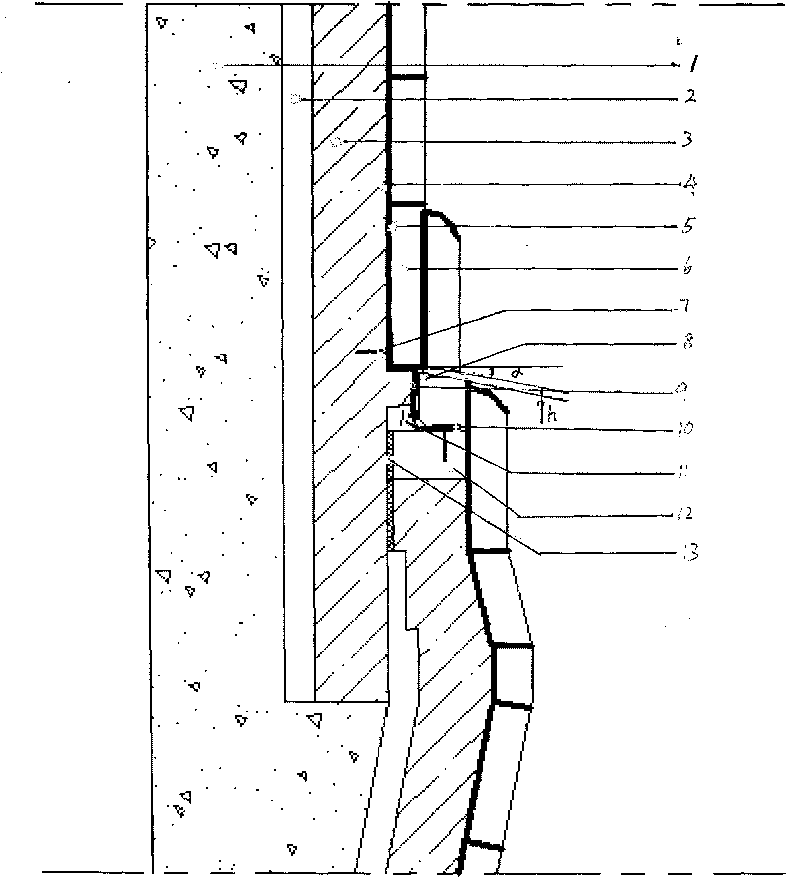

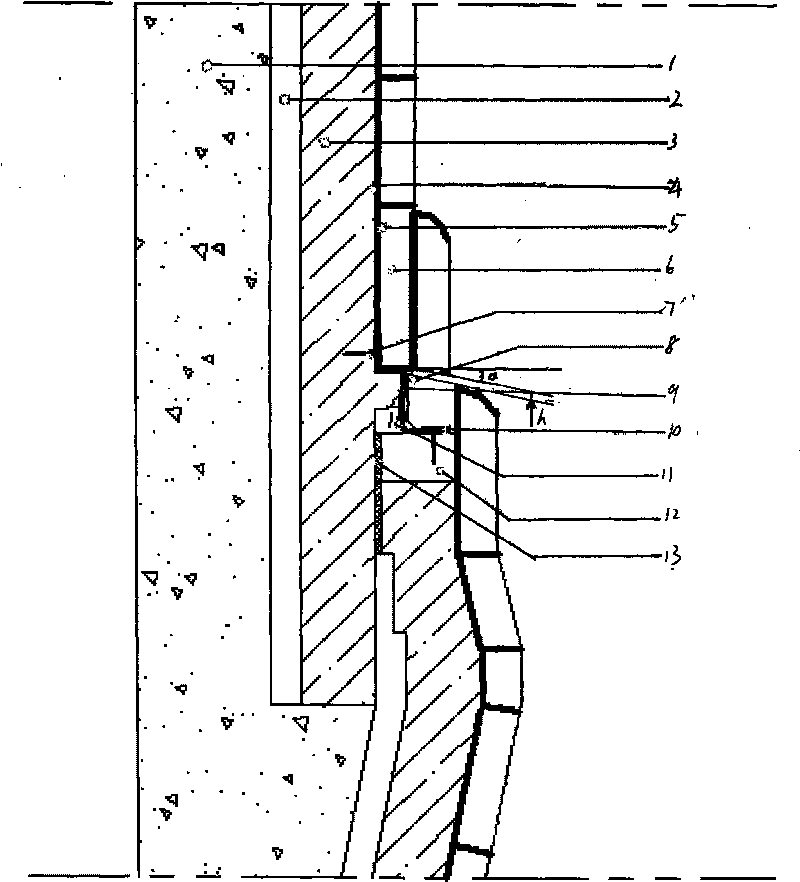

[0013] Such as figure 1 As shown, it is a sectional view of a brick-lined chimney expansion joint sealing and anti-corrosion structure provided by the present invention, which is applied on the chimney outer cylinder 1, and between the chimney outer cylinder 1 and the chimney brick lining 3 is a sealed air or heat insulation layer 2. According to the actual matrix condition, the brick 12 can also be added later. The purpose of adding this brick is to adjust the size of the expansion joint reserved under the drip plate 9. The joint should be less than 80mm. Sealing material for chimney gaps13. After cleaning or sandblasting of all brick lining surfaces, paint epoxy primer (such as Henkel's PENNTROWEL EPOEXY primer) 4, fill the reserved seam under the drip board 9 with compressible rock wool 11, and use elastic glue Adhesive (such as Henkel PENNGUARD ADHESIVE MEMBRANE) 5 coated surface and brick surface seal. The sealing film 8 is fixed on the facade of the upper brick and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com