Bulk rice automatic packaging vending machine

A vending machine, automatic technology, applied in the directions of packaging, transportation and packaging, special packaging objects, etc., can solve the problems of low utilization of the effective space of the vending cabinet, the customer is not convenient and intelligent, and the machine does not automatically seal, etc. Simple, low cost and easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

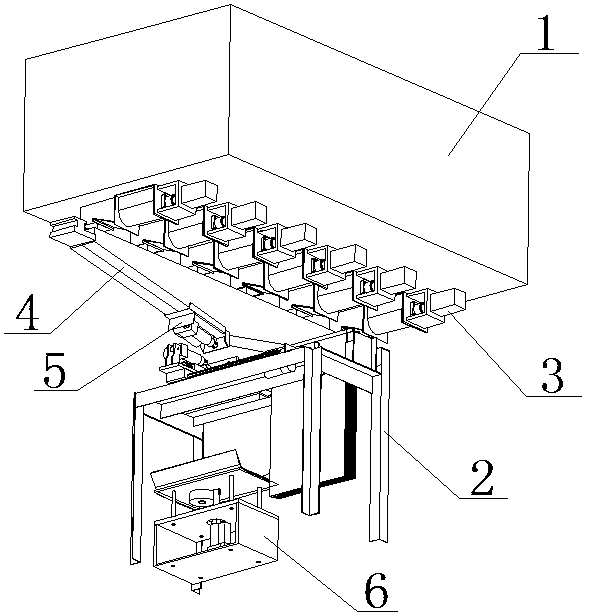

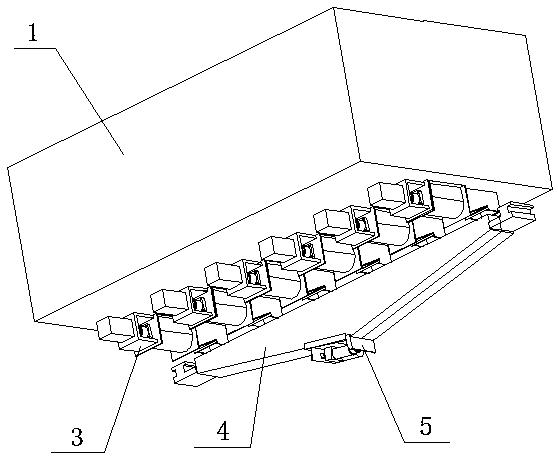

[0040] Such as figure 1 A loose rice automatic packaging vending machine shown includes: a rice bin 1 for storing loose rice; the rice bin 1 is divided into a plurality of rice racks for placing different types of rice, and the rice bin 1 is fixed On the frame of the cabinet of the vending machine shell.

[0041] Fixedly installed under the rice bin 1 to export the loose rice in the rice bin 1 and send it to the rice output device 3 in the weighing funnel 4 fixedly arranged at the lower part of the rice bin 1; the weighing funnel 4 is located directly below the rice bin 1 , and the rice outlet device 3 is located at the top of the weighing funnel 4 and the rice outlet of the rice outlet device 3 is aligned with the feed port in the weighing funnel 4, so that the loose rice in the rice warehouse 1 can be entered by the rice outlet device 3 In the weighing funnel 4, the weighing funnel 4 is common knowledge in the technical field and belongs to common knowledge. In the specific...

Embodiment 2

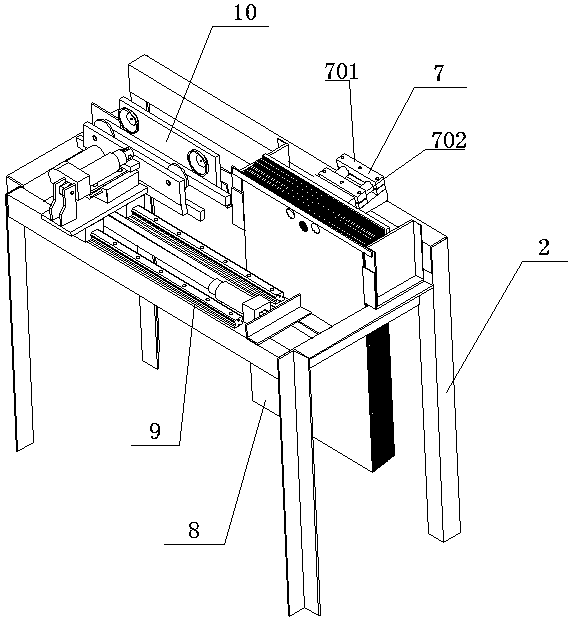

[0048] On the basis of embodiment 1, in order to further realize this invention creation in detail, as figure 2 and Figure 4 The bag taking device 9 includes a parallel guide rail pair 901 fixedly arranged on the fixed support 2, a mounting plate 904 arranged on the parallel guide rail pair 901, and a parallel slide block 905 that is fixedly arranged on the bottom of the mounting plate 904 and moves in conjunction with the parallel guide rail pair 901, The switch between the parallel guide rail pairs 901 pushes the electric cylinder 902, and the cylinder body of the switch pushes the electric cylinder 902 is fixedly connected with the fixed bracket 2, and the telescopic end of the switch pushes the electric cylinder 902 and the bottom of the mounting plate 904 is fixedly connected; The plate 904 can slide on the parallel guide rail pair 901 driven by switching and pushing the electric cylinder 902, so as to ensure that the equipment provided on the mounting plate 904 can mov...

Embodiment 3

[0059] On the basis of embodiment 2, in order to be able to hold the rice bag when carrying out rice filling, as Figure 7 The bottom of the fixed support 2 is provided with a supporting mechanism 6 for supporting a rice bag 8 .

[0060] Supporting mechanism 6 comprises supporting bracket 602, is located at the tray 601 above supporting bracket 602, and is fixedly provided with supporting bag electric cylinder 603 perpendicular to this supporting bracket 602 bottom surface in supporting bracket 602, and this supporting bag electric cylinder 603 The telescoping end passes through the through hole located above the support bracket 602 and is fixedly connected to the bottom of the tray 601, and the telescopic rod of the bag holder electric cylinder 603 is clearance-fitted with the through hole provided above the support bracket 602. The bag-holding electric cylinder 603 drives the tray 601 to lift the rice bag containing loose rice, and after the rice is filled, the bag-holding e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com