Patents

Literature

173results about How to "Meet the feed requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

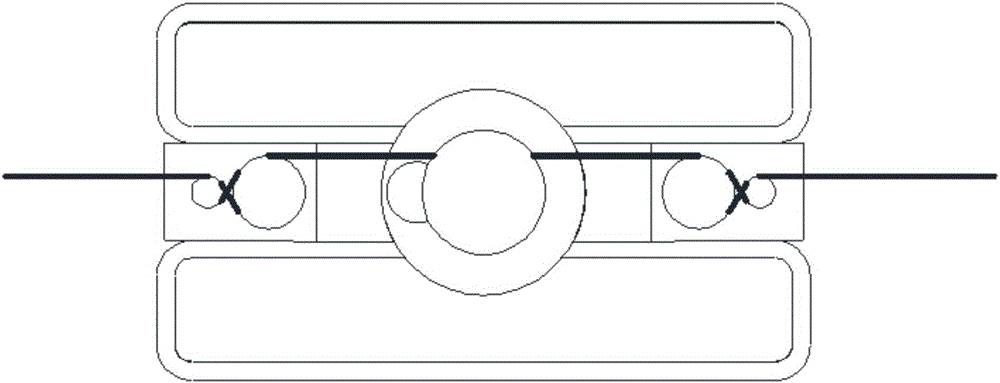

Low-cost microwave- and millimeter-wave polarized antenna of multi-layer PCB (Printed circuit board) process

InactiveCN104103906AImproving Impedance BandwidthSmall structure sizeRadiating elements structural formsSlot antennasAxial ratioDielectric substrate

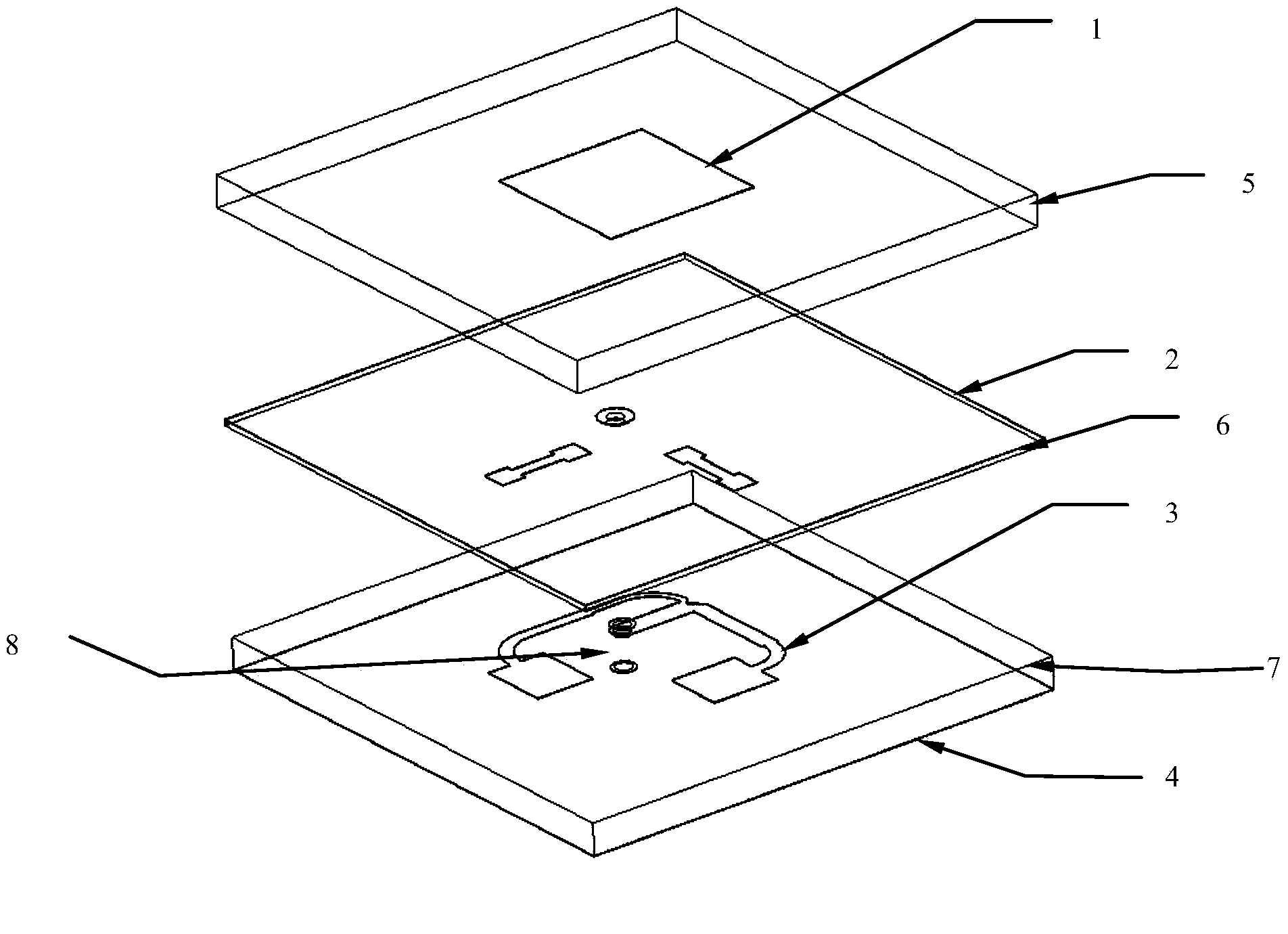

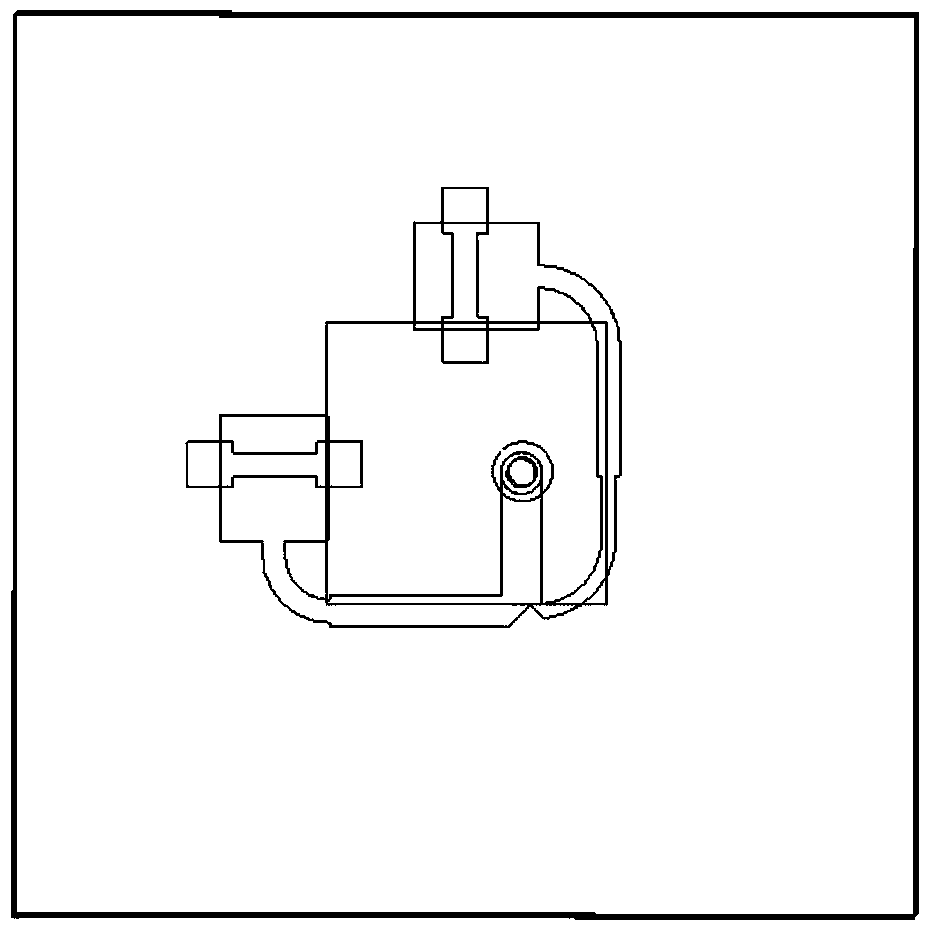

The invention discloses a low-cost microwave- and millimeter-wave polarized antenna of the multi-layer PCB (Printed circuit board) process. The polarized antenna is of a multi-layer structure and comprises a quadrate radiating metal patch, an upper dielectric substrate, a metal floor equipped with an H-shaped coupling gap, a medium dielectric substrate, a feed metal plate with power division network, a lower dielectric substrate and a bottom metal floor; the quadrate radiating metal patch is coupled with the floor equipped with the H-shaped coupling gap to realize feed; the feed network of a microstrip line structure is positioned below the floor; the metal floor equipped with the H-shaped coupling gap is connected with the bottom metal floor through a metal through hole; the feed metal plate with the power division network is connected with the bottom metal floor through a second metal through hole to form a coaxial microstrip line conversion structure by which feeding from the bottom part of the antenna is realized. The antenna has the characteristics that the frequency band is wide, the size is small, the cost is low, the manufacturing and processing are simple, and the axial ratio feature is great.

Owner:SOUTHEAST UNIV

Hydrogenation and refining method of gasoline with poor quality

ActiveCN101591565AThe method flow is simpleEasy and flexible operationTreatment with hydrotreatment processesSolventPoor quality

The invention discloses a hydrogenation and refining method of gasoline with poor quality, comprising the following steps: the base oil of gasoline contacts and reacts with hydrogenation protective agent at low temperature; after reaction effluent is mixed with circulation oil, the mixture sequentially contacts and reacts with hydrogenation desilication solvent and hyrorefining catalyst at high temperature; the reaction product is cooled and separated to obtain hydrogen-rich gas and refined gasoline fraction; and parts of refined gasoline fraction serves as circulation oil to return to the outlet of a first hydrogenation reaction area. The method can handle coker gasoline with high content of sulphur, nitrogen and olefin, and refined gasoline fraction can satisfy charging requirements of reforming pre-hydrogenation devices and steam cracking ethene preparing devices. The method of the invention can effectively slow coking speed of heating furnace tubes, greatly lowers pressure drop generation frequency of a main hydrogenation reactor, improves the operating severity of the main hydrogenation reactor and retards the deactivation speed of catalyst at the bottom of a refined reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

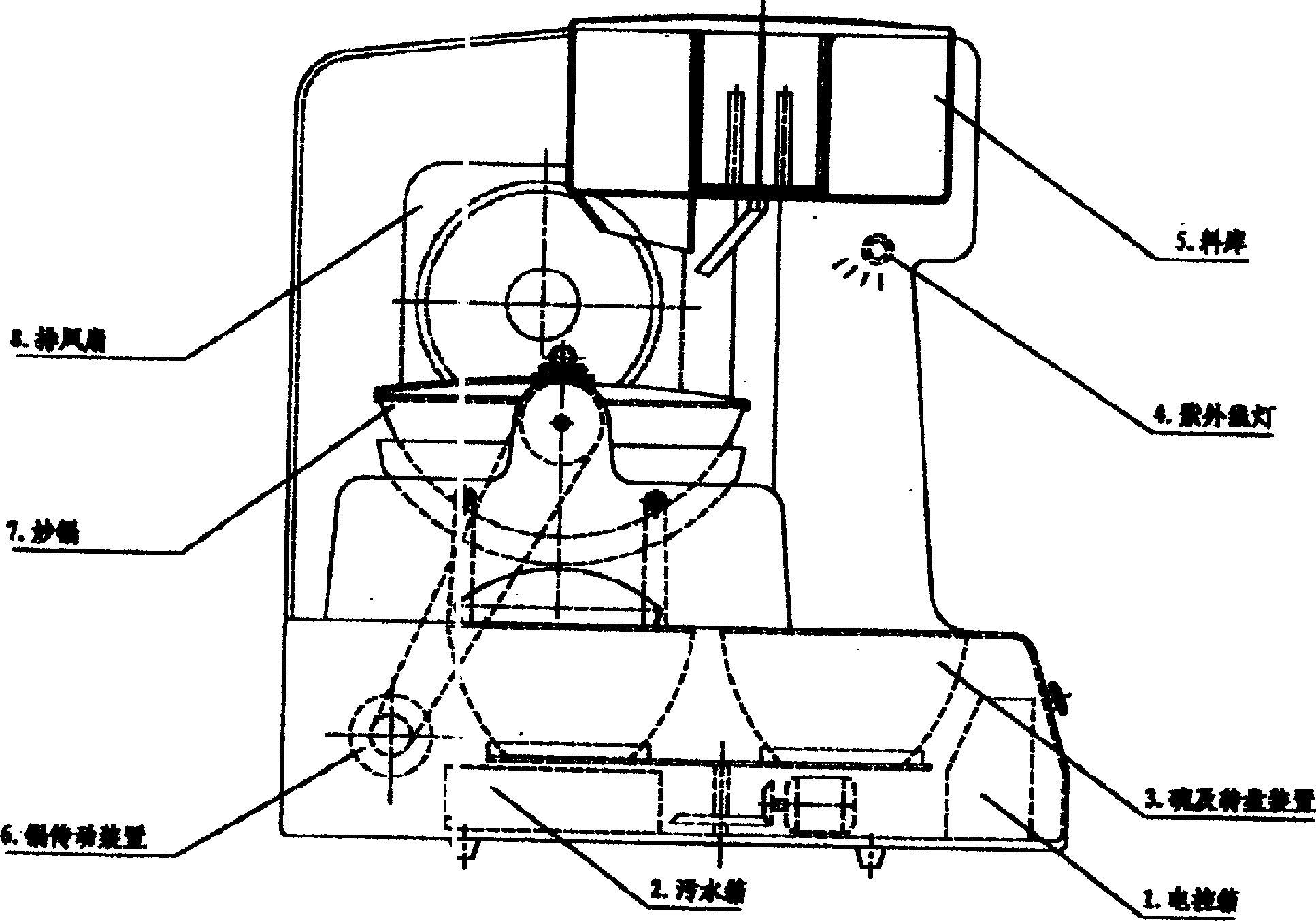

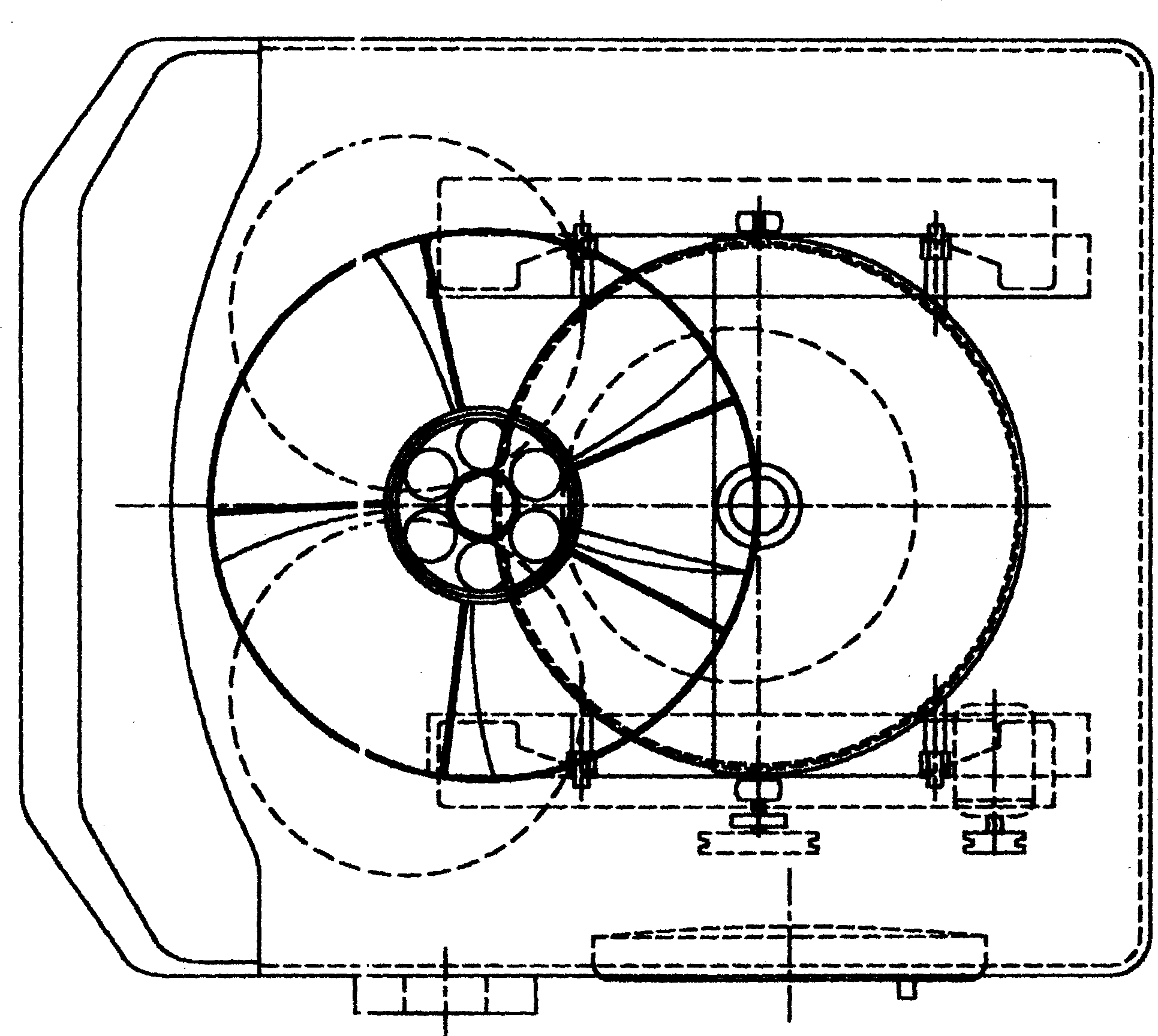

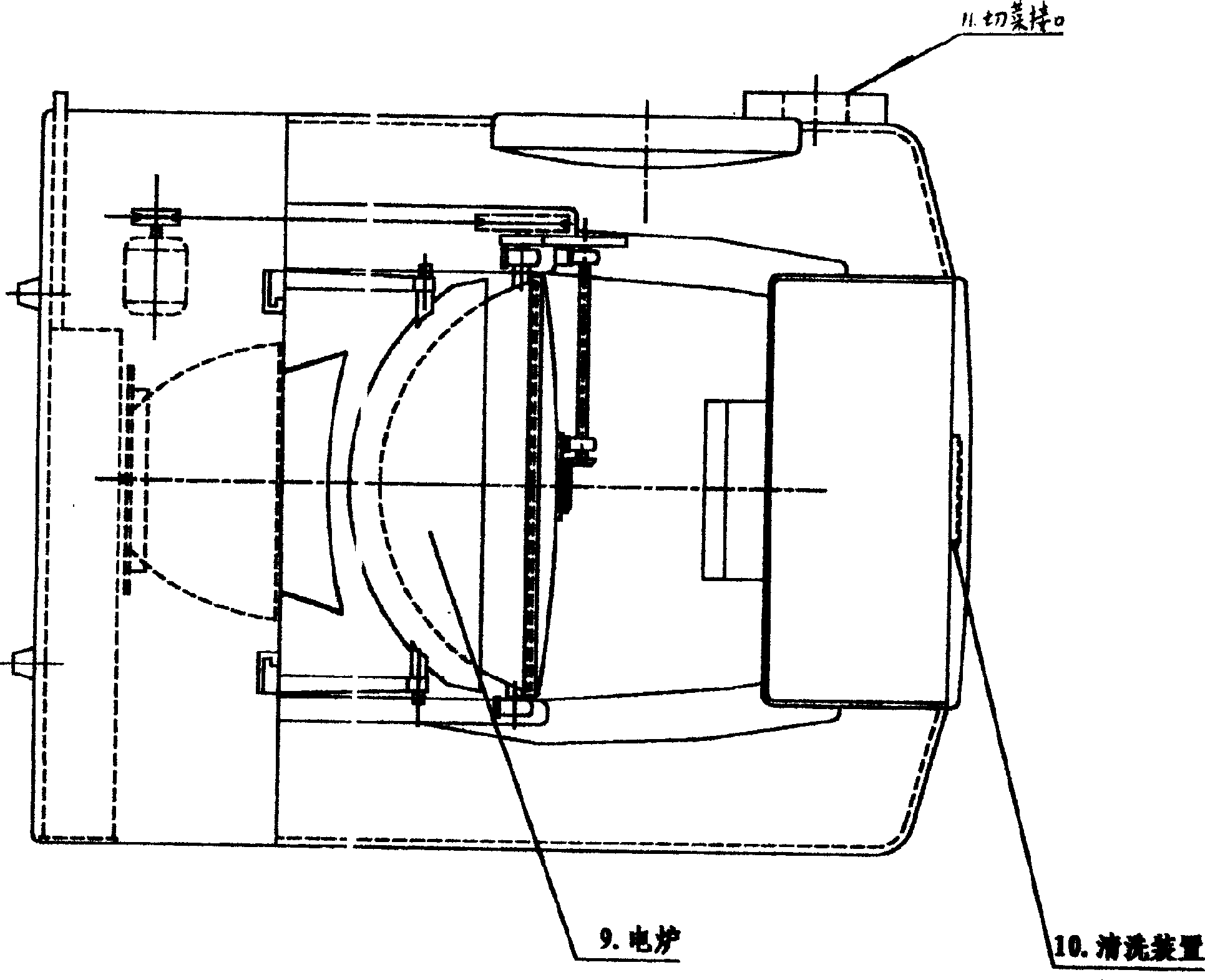

Pot for automatically cooking dishes or making soup

An automatic cooker for frying dish or stewing soup features that its complete cooking procedure is controlled by a computer according to the prestored program.

Owner:李文漫

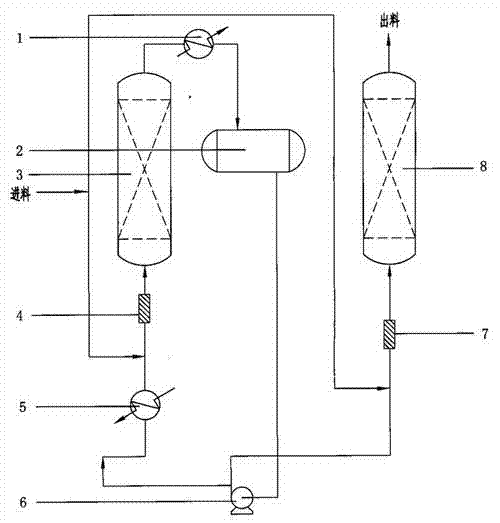

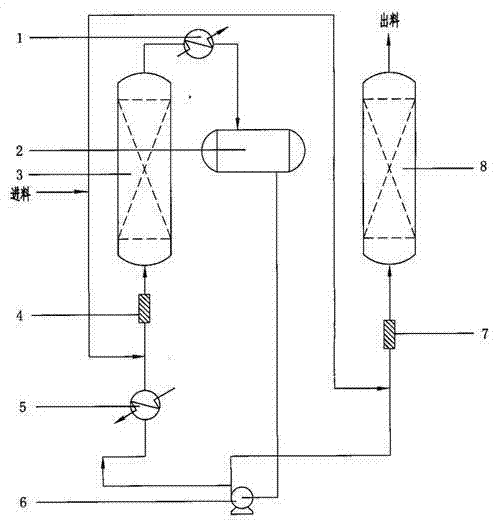

C4 two-stage hydrogenation device and process in catalytic thermal cracking to ethylene

InactiveCN102294203AControl temperature riseControl the content of butadieneChemical/physical processesHydrocarbon by hydrocarbon crackingRefluxCatalytic pyrolysis

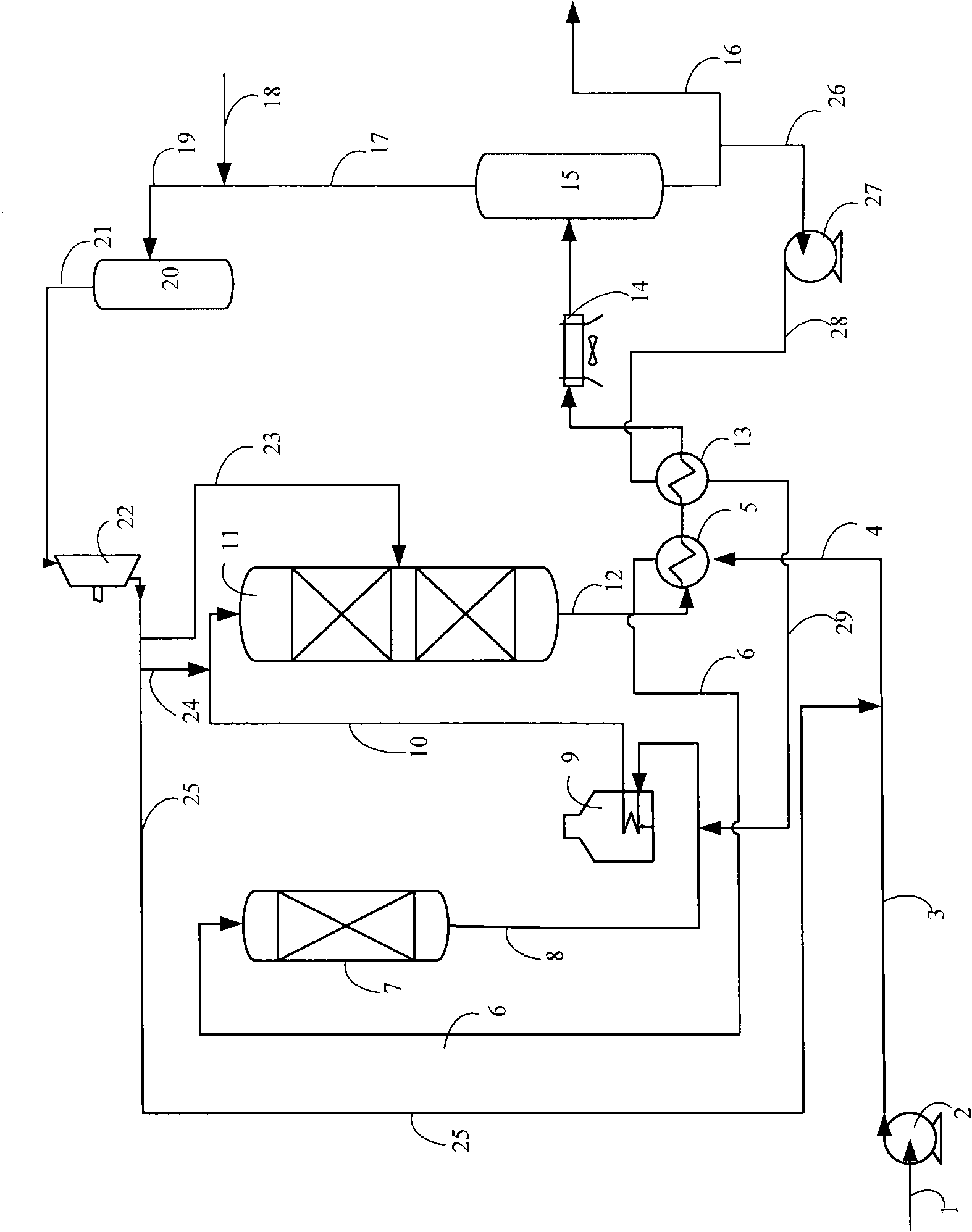

A C4 two-stage hydrogenation device in catalytic thermal cracking to ethylene, which includes a hydrogenation reactor, a mixer and a feed heater, and its technical points are: the first-stage hydrogenation reactor and the second-stage hydrogenation reactor The inlet ends are connected to feed mixers, the outlet of the first-stage hydrogenation reactor is connected to the reflux tank through the discharge cooler, the outlet of the reflux tank is connected to the inlet of the reflux pump, and the outlet of the reflux pump is connected to the feed heater and the second-stage feed mixer in parallel. The material heater is connected to the first-stage feed mixer, and the C4 material feed pipe is connected in parallel on the pipeline between the feed heater and the first-stage feed mixer, and on the pipeline between the reflux pump and the second-stage feed mixer. The present invention adopts two-stage selective hydrogenation, which avoids serious coking in the first-stage reactor caused by deep hydrogenation of 1,3-butadiene, and reduces the operation cycle of the device and the service life of the catalyst. In addition, due to the stronger adaptability to raw materials, it is not necessary to separate light and heavy carbon four, and the mixed carbon four can be directly hydrogenated, which improves the utilization rate of raw materials.

Owner:SHENYANG PARAFFIN CHEM

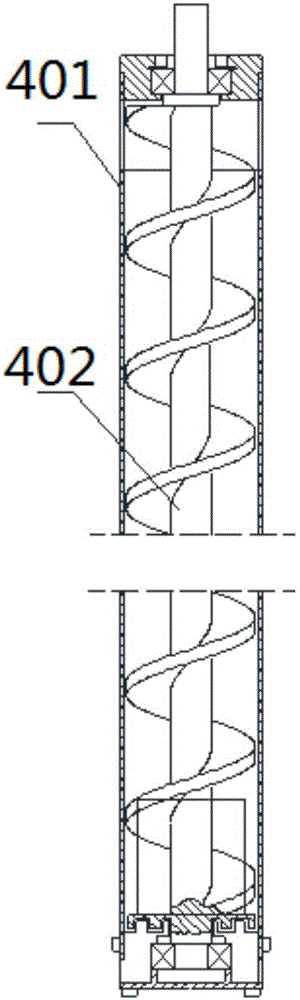

Method for preparing coal water slurry from low-rank coal

InactiveCN104962331AMeet the feed requirementsSimple methodLiquid carbonaceous fuelsHigh concentrationCoal water

The invention discloses a method for preparing coal water slurry from low-rank coal. The method is characterized by comprising the following steps: step 1: conveying the low-rank coal into a crusher to be crushed until the granularity is smaller than or equal to 5mm; conveying the crushed fine coal grains into a spiral extruding device; step 2: shearing and extruding the fine coal grains which are conveyed into the spiral extruding device under the pressure of 5 to 40MPa; after damaging inner pores in the fine coal grains, separating moisture in the fine coal grains to obtain wet sticky coal, wherein the separated moisture accounts for 10 percent to 60 percent of the total moisture; and step 3: conveying the wet sticky coal obtained by the step 2 into a mill and simultaneously adding an additive and water, and grinding the mixture into the coal water slurry with the concentration of 53 percent to 65 percent. The method for preparing the coal water slurry from the low-rank coal is extremely simple; waste heat is used for pre-heating brown coal and the brown coal is re-compacted, so that the pores of the low-rank coal can be effectively damaged and the surface properties of the low-rank coal are changed; the method has the advantages of low energy consumption, high efficiency and high slurry preparation concentration, and can be widely applied to preparation of the high-concentration coal water slurry by all types of the low-rank coal.

Owner:中国东方电气集团有限公司

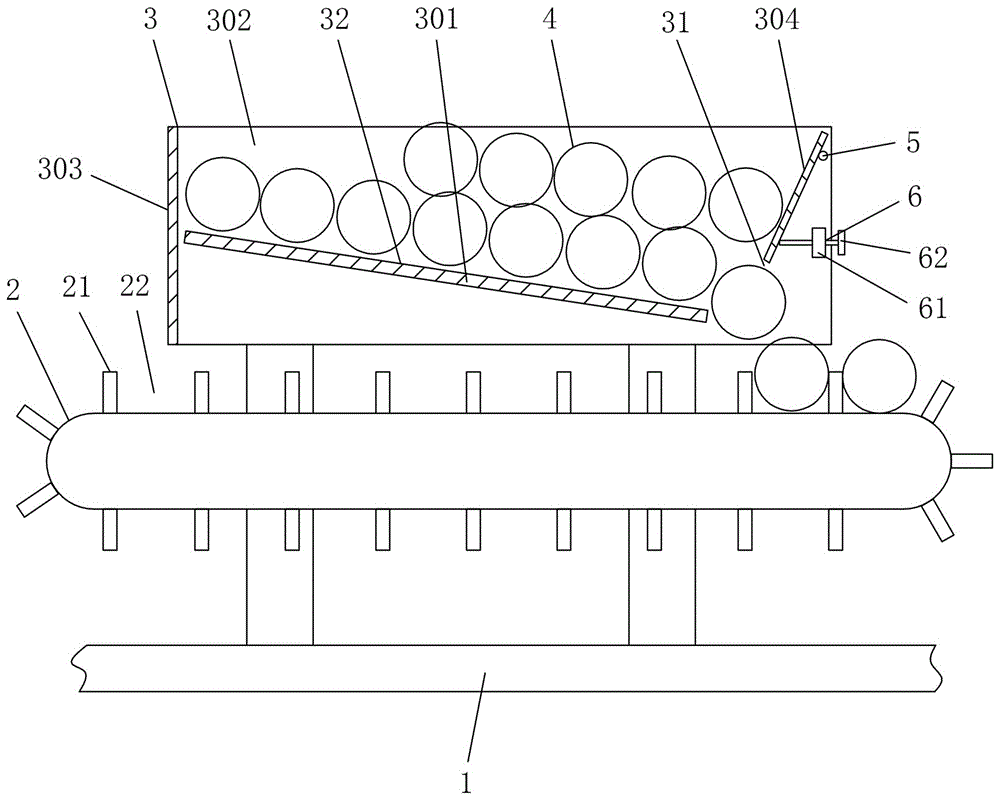

Feeding device for automobile corrugated pipe binding machine

ActiveCN106185253AMeet the feeding requirementsSimple structureConveyorsConveyor partsEngineeringUltimate tensile strength

The invention discloses a feeding device for an automobile corrugated pipe binding machine. The feeding device comprises a rack and a conveying belt mounted on the rack, wherein a storage box used for placement of automobile corrugated pipes is arranged on the rack and positioned above the conveying belt; a dropping hole used for dropping of the automobile corrugated pipes one by one is formed in the storage box; and the spacing between the dropping hole and the conveying belt in the vertical direction is greater than the diameter of each automobile corrugated pipe and less than twice the diameter of each automobile corrugated pipe. The feeding device disclosed by the invention has the advantages that the structure is simple, the manufacturing process is easy, the manufacturing cost is low, the working is stable and reliable, the labor strength can be greatly reduced, and the labor cost can be reduced.

Owner:长沙成进汽车配件有限公司

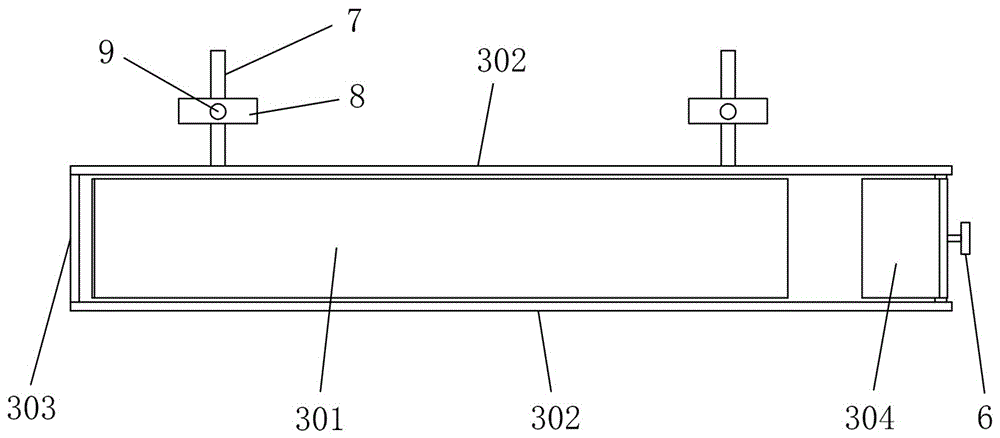

Refinery saturated dry gas recovery system and recovery method

ActiveCN104560194AReduce the amount of feedReduce circulationGaseous mixture working upRecovery methodPressure rise

The invention discloses a refinery saturated dry gas recovery system and a recovery method. The system comprises an absorption tower, a desorption tower, a reabsorber, a compressor and a heat exchanger, wherein the system is provided with a condensate stripper; a condensate outlet of the compressor is connected with the condensate stripper, and the top of the condensate stripper is connected with an inlet of the compressor. The method comprises the steps of during the pressure rising of refinery saturated dry gas, delivering an interstage condensate to the condensate stripper, and recovering stripped hydrocarbon as one of products. According to the refinery saturated dry gas recovery system and the recovery method, the products are all delivered to an ethylene unit cracking furnace, an acidic gas removal device, a deoxidation device, a dryer and the like are not required, the investment is reduced, the energy consumption is low, the flow is simple, and the recovery rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

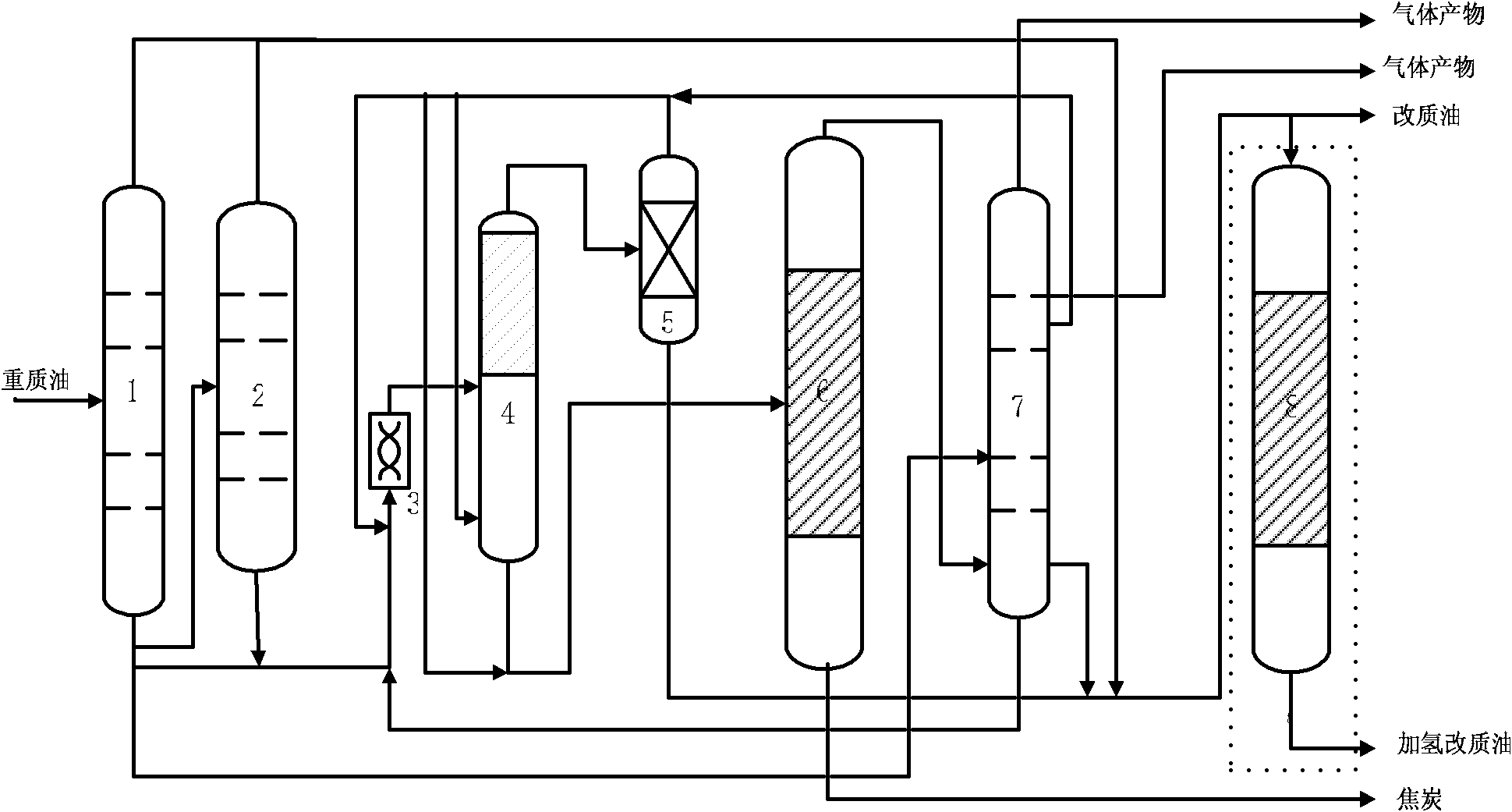

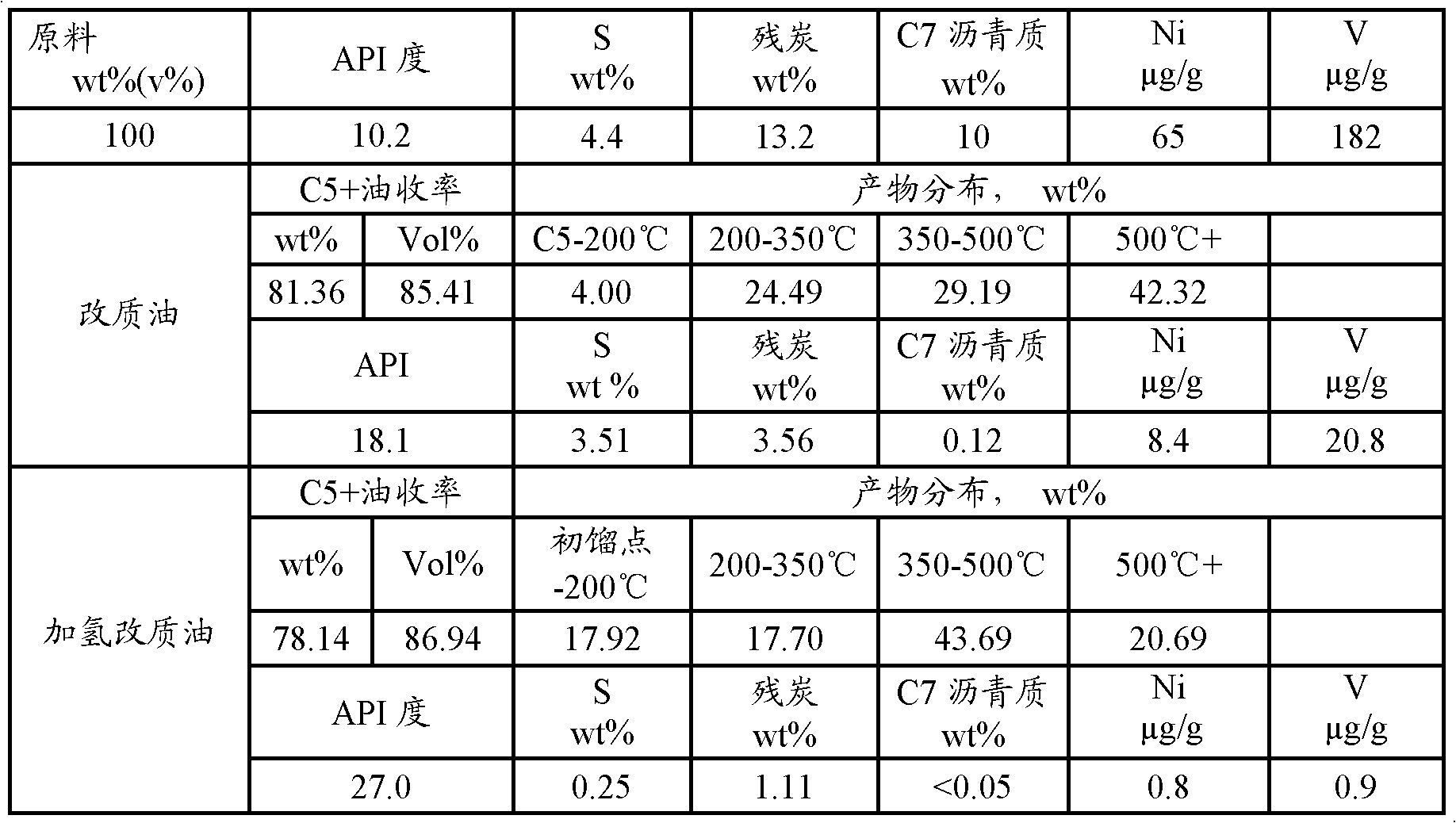

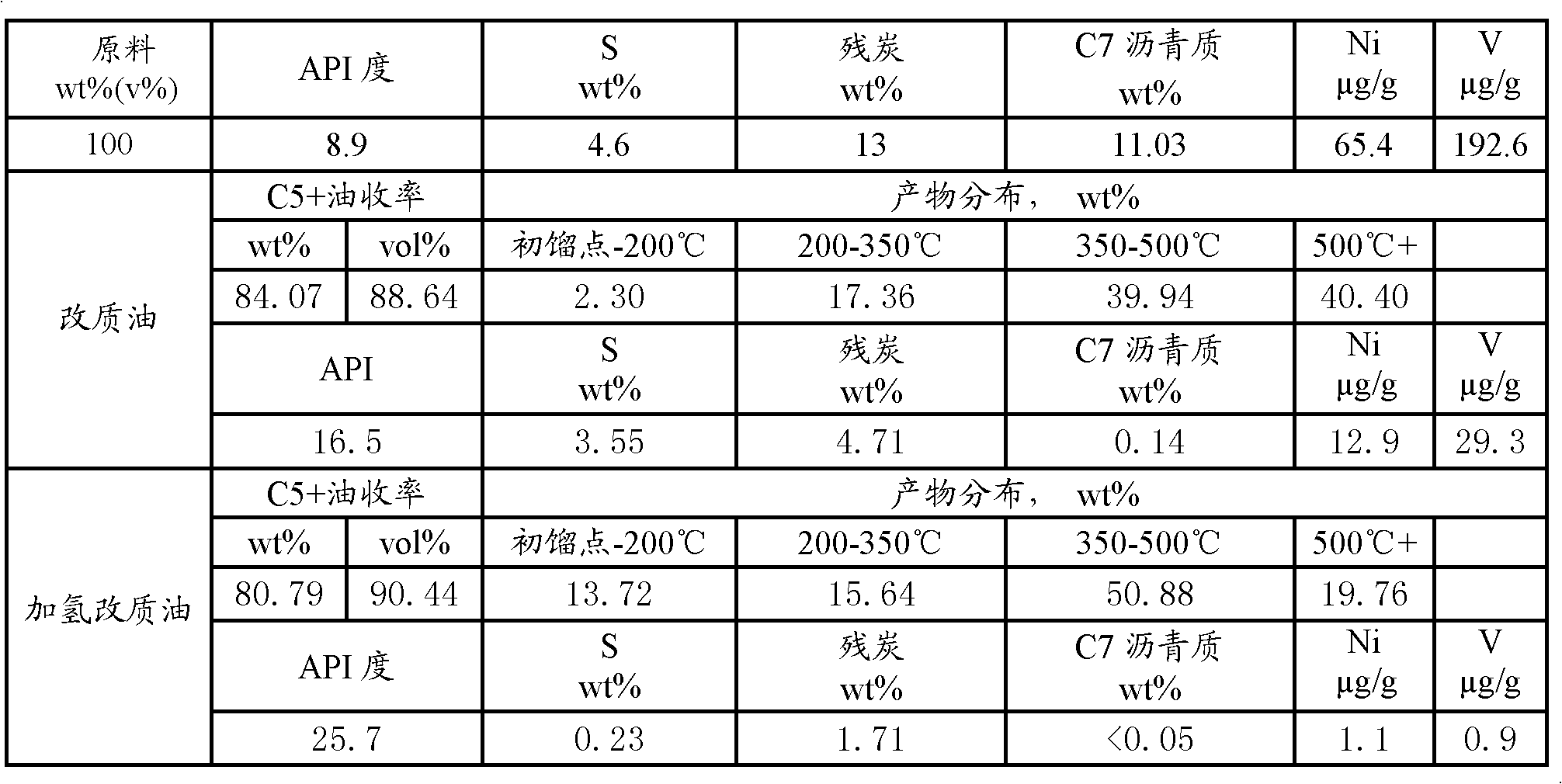

Combined technology for heavy oil processing

ActiveCN102807892AFlexible adjustmentHigh yieldTreatment with plural serial stages onlyTreatment with hydrotreatment processesOil processingSolvent

The invention provides a combined technology for heavy oil processing. The combined technology at least comprises the steps of performing solvent de-asphalting process on a heavy oil raw material and performing thermal cracking process on a de-oiling asphalt phase and a dispersing agent in a thermal cracking reactor after the de-oiling asphalt phase and the dispersing agent are mixed, wherein the de-asphalted oil and thermal cracked oil separated from a thermal cracking reaction product are mixed to obtain a modified oil; and a solvent separated from the thermal cracking reaction product and heavy wax oil are respectively returned to the solvent de-asphalting process to be used circularly and serve as a mixed feeding material to remove the asphaltene. For the implementation of the invention, the combined technology for the heavy oil processing, disclosed by the invention, has the advantages of solving the problem that the asphalt with a high softening point is difficult to separate from the solvent in the transportation and solvent de-asphalting process of the heavy oil, enabling extractable oil component in the heavy oil to avoid a heat treatment, being good for guaranteeing stability of products and improving yield of the modified oil, greatly improving API (American Petroleum Institute) degree, obviously reducing residual carbon value, C7 asphaltene and metal contents, achieving an asphaltene removal rate of higher than 96% and the metal nickel as well as vanadium removal rate of 80%-90%, and being good for producing hydrogenised modified oil with obviously improved quality.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

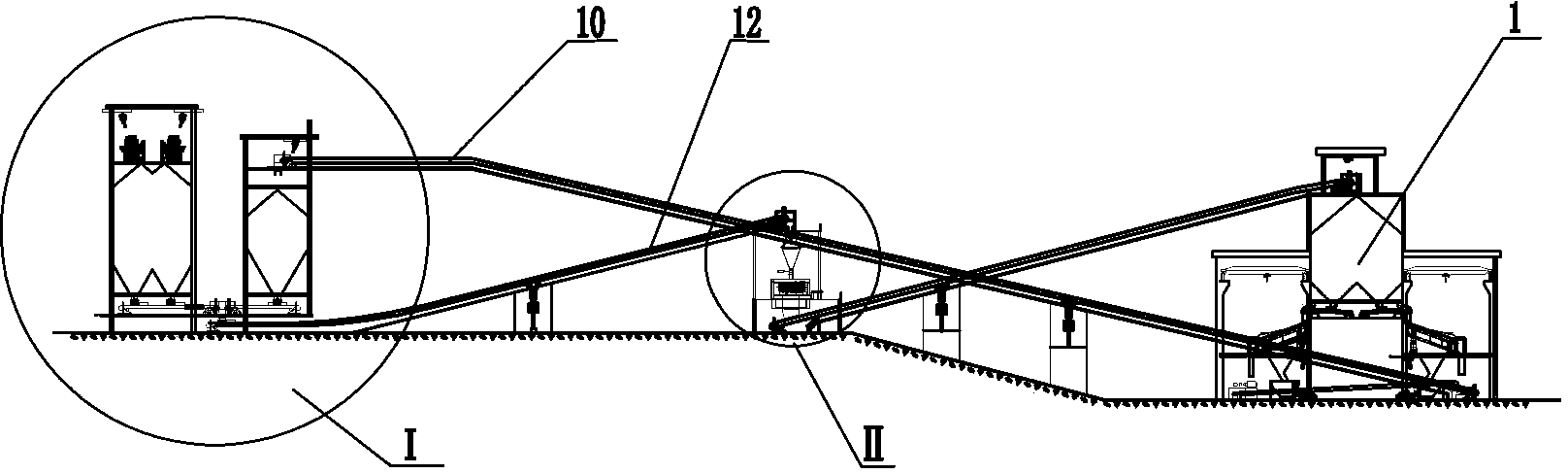

Anti-segregation ore-blending system of high-pressure roller mill

InactiveCN103464240AMeet the continuityImprove performanceGrain treatmentsGranularityProcess engineering

The invention belongs to the technical field of mineral separation in mines, and in particular relates to an anti-segregation ore-blending system of a high-pressure roller mill. The system is characterized by comprising a distributing-blending system, an aggregate conveying sealing-tape machine and a stirring system, wherein the distributing-blending system comprises a raw material cabin, an oversize return cabin, a raw material cabin chute, an oversize return cabin chute, a pneumatic valve on an outlet of the raw material cabin chute and the oversize return cabin chute, a discharging sealing-tape machine I, a discharging sealing-tape machine II, and a head funnel on a junction of the discharging sealing-tape machine I and the discharging sealing-tape machine II, and the aggregate conveying sealing-tape machine is arranged below the outlet of the head funnel. New materials and oversize returned materials are respectively fed into the raw material cabin and the oversize return cabin, and the pneumatic valve is used for controlling the mixing proportion of the new materials and the oversize returned materials according to the granularity and the ore properties of the new materials and the oversize returned materials to realize reasonable ore-blending, so that the material segregation caused by the condition that the new material and the oversize returned material are fed into the same cabin is avoided, and the continuity and the stability of feeding of the high-pressure roller mill can be guaranteed.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

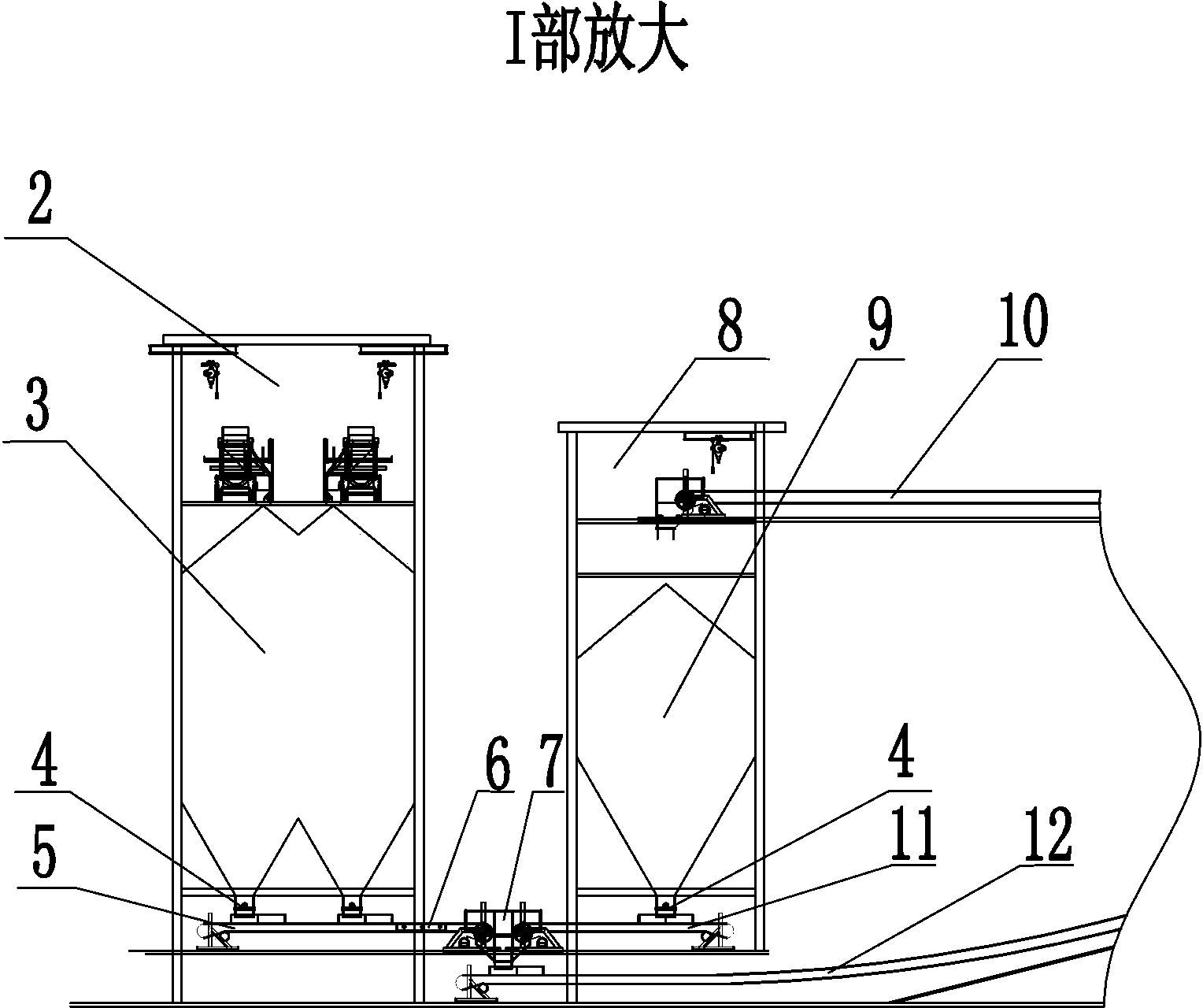

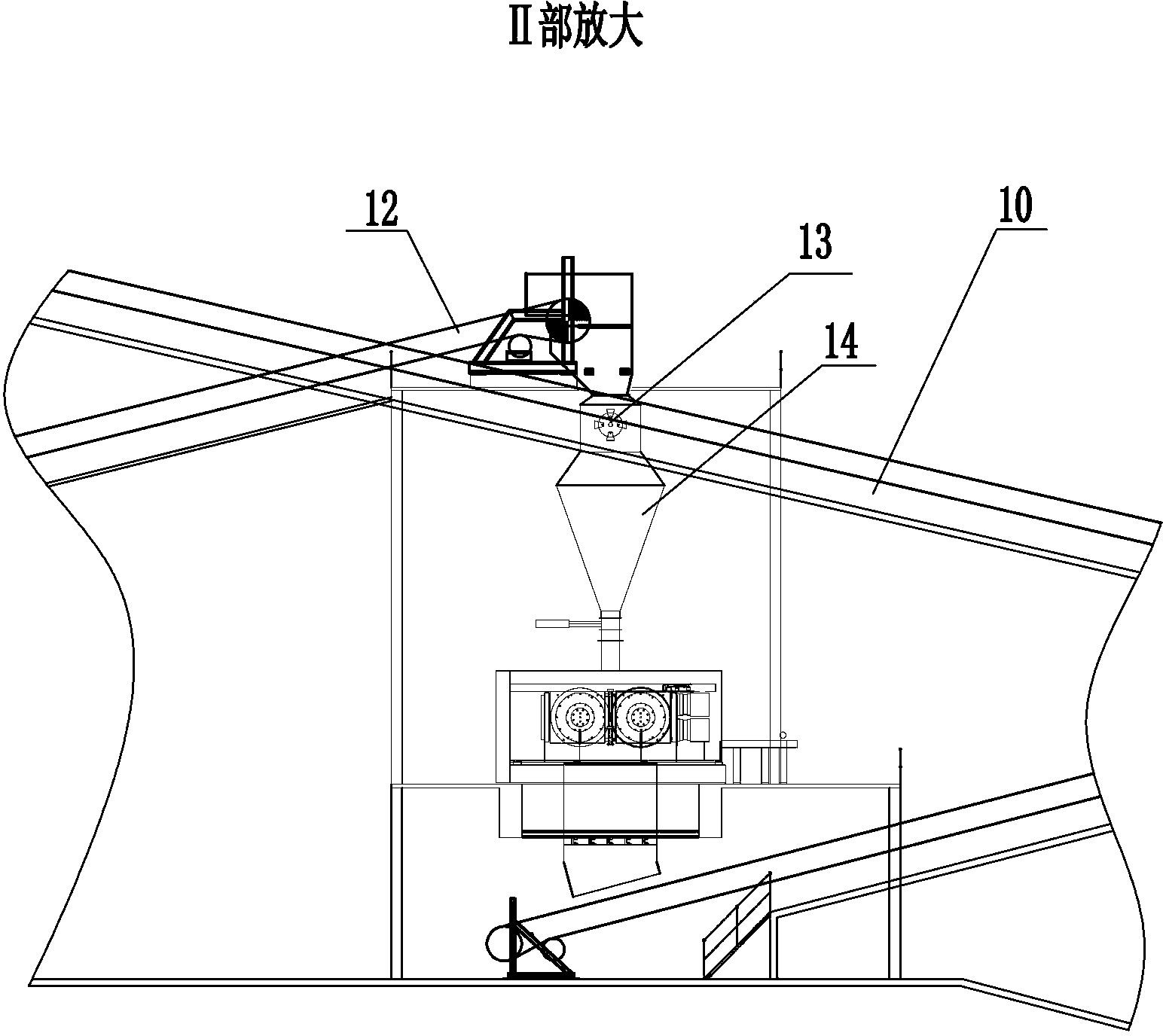

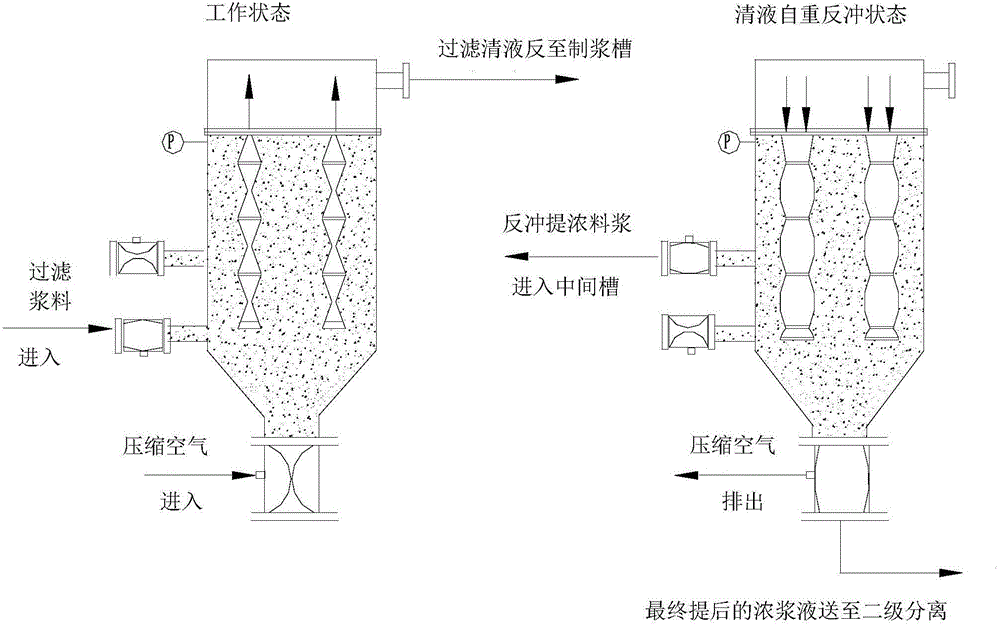

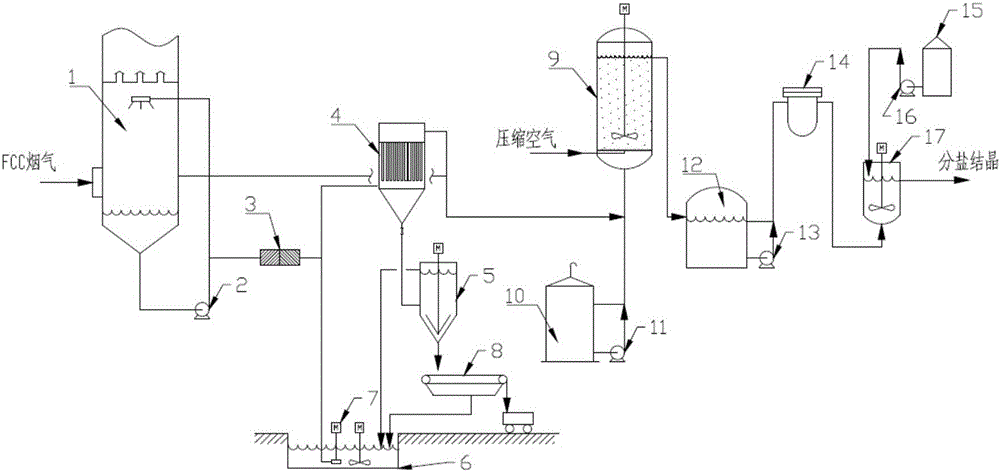

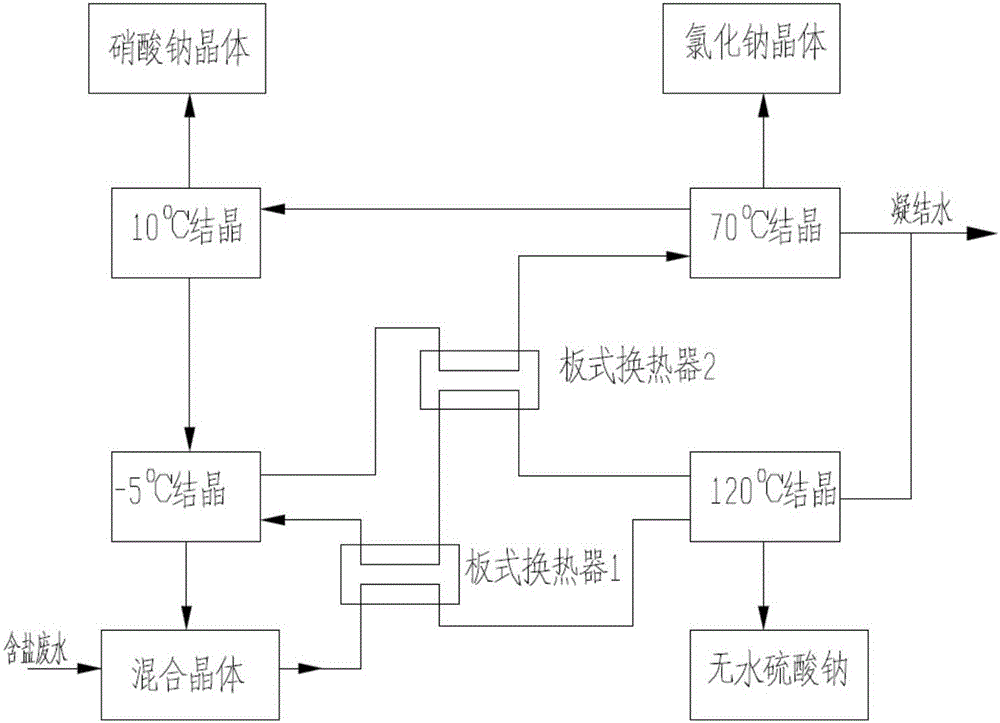

Treatment method of catalytic cracking flue gas desulfurization wastewater

InactiveCN106007148ASolve the emission problemSolve the problem of mixed salt hazardous wasteTreatment involving filtrationSulfate/bisulfate preparationChemical oxygen demandHigh energy

The invention provides a treatment method of catalytic cracking flue gas desulfurization wastewater. The treatment method comprises the following steps: fully utilizing waste heat of high-temperature flue gas, concentrating circulation slurry in a washing tower, and controlling the concentration of the circulation slurry, thus ensuring normal operating of a desulfurization system; meanwhile, carrying out pretreatment (flocculating, filtering, removing calcium and magnesium ions, reducing COD (Chemical Oxygen Demand) through oxidization and the like) on concentrated discharged wastewater, enabling the wastewater to meet the feeding requirements of a concentration system, and then carrying out evaporation and crystallization (multi-effect evaporation or MVR (Mechanical Vapor Recompression)), thus realizing zero emission of salt-containing wastewater and recycling of inorganic salt. According to the technology, a sodium alkaline flue gas desulfurization technology and an inorganic salt evaporative crystallization recovery technology are organically integrated, the problems of membrane pollution and membrane scaling during a membrane concentration process, large investment, high energy consumption and the like are avoided, the emission problem of salt-containing wastewater in an alkaline washing technology is completely solved, and zero emission is really realized; meanwhile, separated crystallization is carried out on inorganic sodium salt products, the recycled products are used as products, the problems of mixed salt and hazard waste are solved, and secondary pollution is removed.

Owner:SINOPEC ENG GRP CO LTD

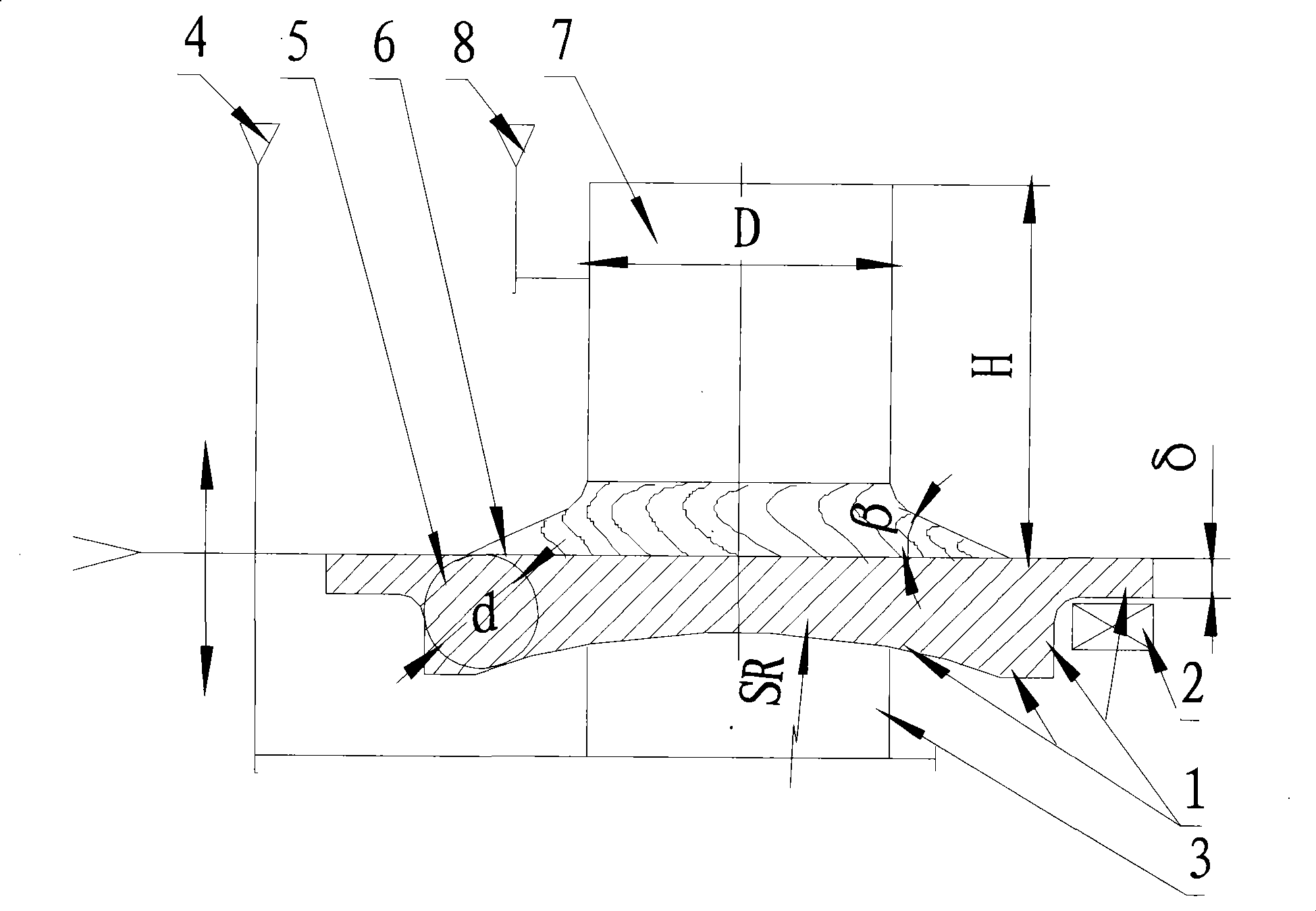

Foundry technique method of lower support board of ball type support

InactiveCN101462149AAdverse effects of changing the pouring position to a large planeReduce trachomaFoundry mouldsFoundry coresFoundryBall type

The invention discloses a technological method for casting a lower support plate of a ball shaped support. The technological method comprises the following steps: according to the structural shape of the lower support plate of the ball shaped support, namely, a square plate, manufacturing a sand mold, adopting a shape of a water glass quartz sand pit, using an upward large plane of the lower support plate as a parting surface, and horizontally pouring the parting surface; scraping a lower middle circular lug boss and a concave spherical surface on the other side by a scraper (1), pounding the rest parts by natural patterns, and providing outer chill blocks (2) at four cast corners thereof; providing a pouring head outside the sand mold, and adopting a reverse-bottom pouring head in an inner pouring channel (3); and pounding an upper mold by a sand box, and providing a shrink head table and a shrink head horizontal reinforce (6) in the center part. The technological method reduces the defects such as planar sand holes, sand marks, and the like on the cast, meets the feeding requirement of the cast, ensures compactness inside the cast, improves quality of the cast, and reduces production cost.

Owner:LUOYANG XINGRONG IND

Vacuum centrifugal static spinning device

ActiveCN104328514AMeet the positioning requirementsMeet the feed requirementsElectro-spinningElectrospinningHeating system

The invention discloses a vacuum centrifugal static spinning device, which mainly consists of eight major systems including a transmission system, a feeding system, a heating system, a sealing system, a spinning system, a collecting system, a temperature control system and a box body system, and is used for melt or solution centrifugal electrostatic spinning. The transmission system drives a yarn spraying device to rotate at a high speed, a receiving device is connected with a high-voltage power supply, the heating device heats polymer particles, a melt is stored in the yarn spraying device, an infrared temperature measuring instrument measures the temperature through emitting infrared rays and feeds back the result to the heating system for controlling the spinning temperature, under the effect of centrifugal force and electrostatic force, the melt is spun out, and nanometer level fiber is formed on the collecting device. In the whole spinning process, a transmission device, a feeding device and a magnetic fluid sealing device are positioned in a protection box body, the heating device, the yarn spraying device, the collecting device and a temperature control device are positioned in a vacuum box. The vacuum centrifugal static spinning device has the advantages that no disturbance of jet flow in vacuum environment can be ensured, and the goal of more stably preparing high-performance and high-quality nanometer fiber is achieved.

Owner:BEIJING UNIV OF CHEM TECH

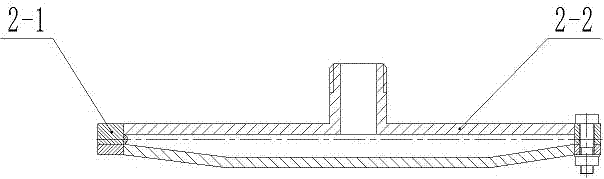

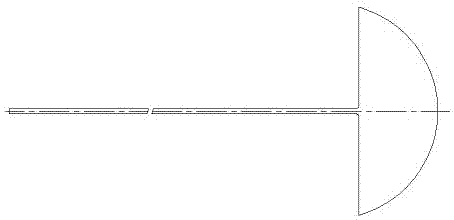

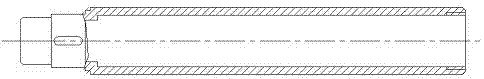

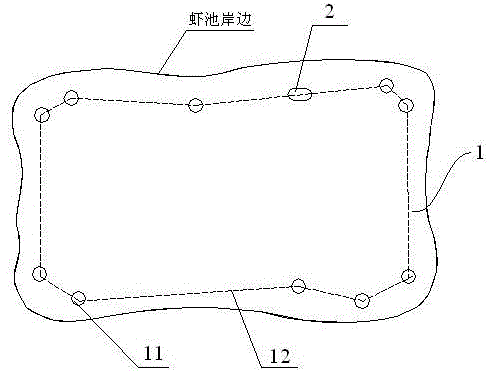

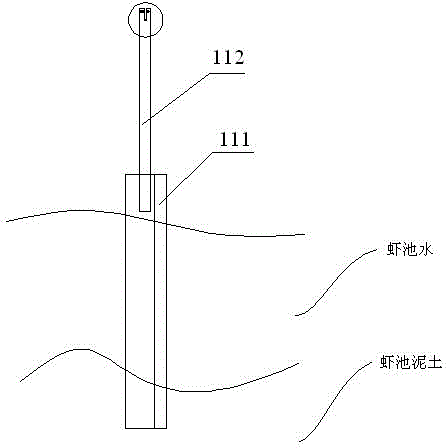

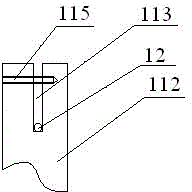

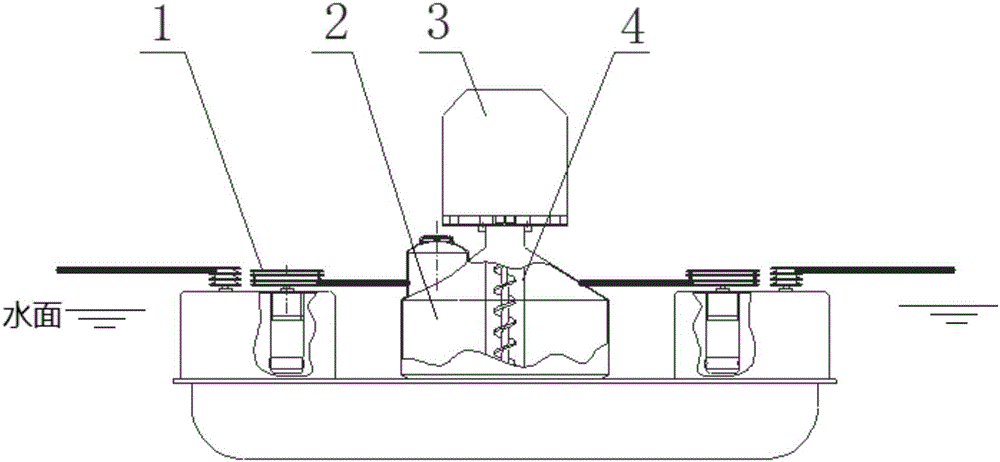

Auto-cruise precise feeding device for shrimp pond

InactiveCN104304139AMeet feeding requirementsReduce the cost of farmingPisciculture and aquariaShrimpControl system

An auto-cruise precise feeding device for a shrimp pond comprises an annular zigzag track along the shrimp pond and an automatic feeding device moving along the track and feeding, wherein the annular zigzag track comprises a bracket which is arranged in the shrimp pond and the top end of which stretches out of water and an annular pull line arranged at the top end of the bracket; the automatic feeding device comprises a feeding ship, a feeding machine arranged in the feeding ship and a sensing control system which is arranged between the feeding ship and the feeding machine; a line clamp which matches with the pull line in the track is arranged on the bottom surface of the feeding ship. According to the auto-cruise precise feeding device for the shrimp pond, uniform feeding can be implemented automatically along the shrimp pond, and the feeding time, the feeding amount and the distance between a feeding site and the side of the shrimp pond can be arranged and adjusted, so that the feeding requirements of shrimps in different growth stages can be met.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

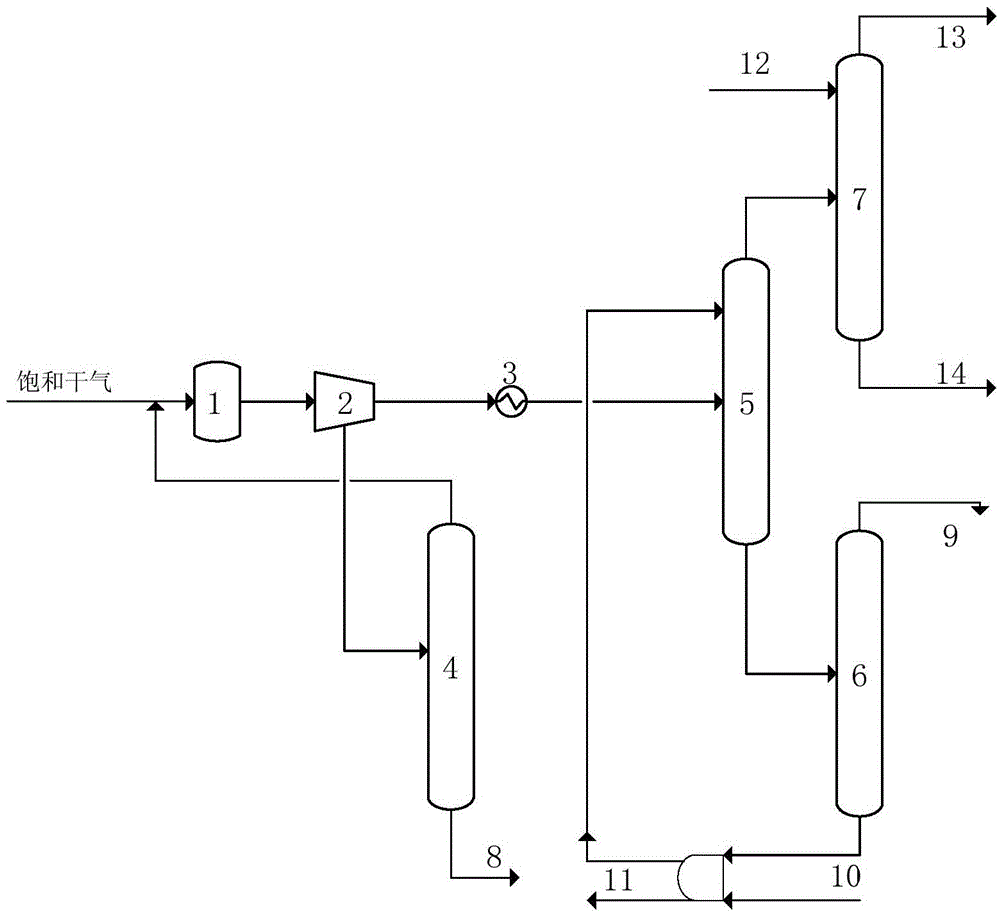

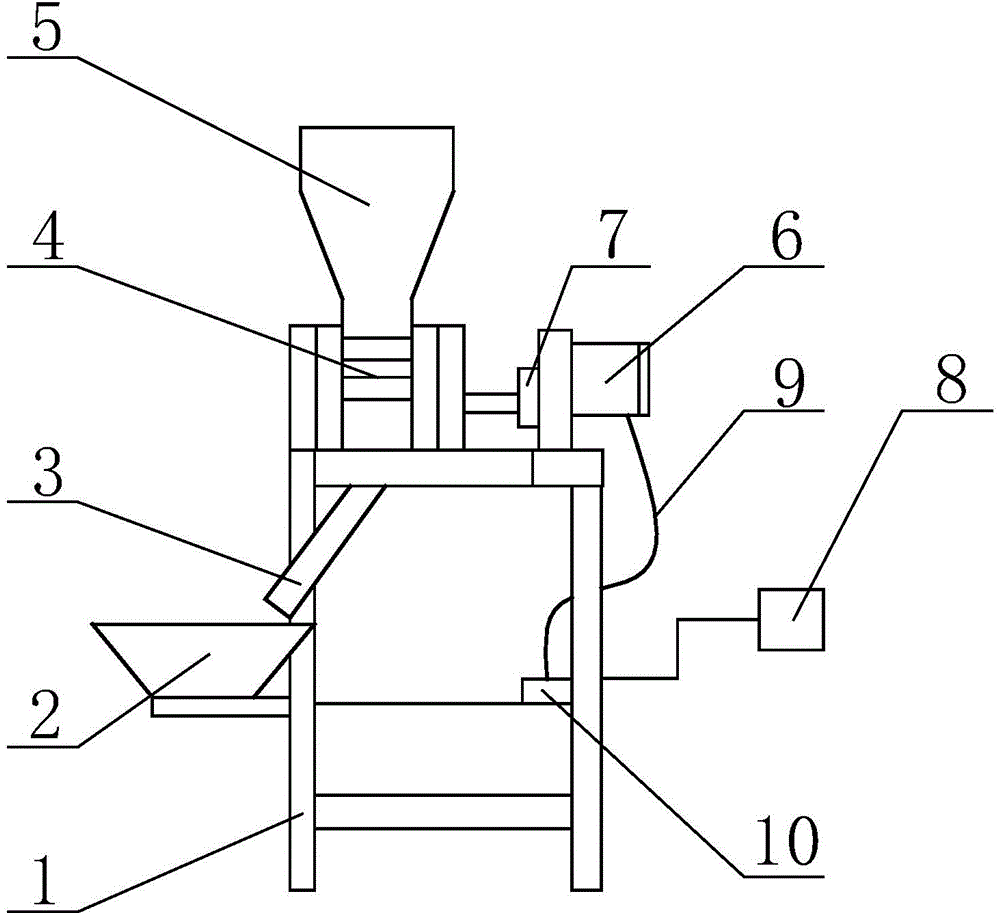

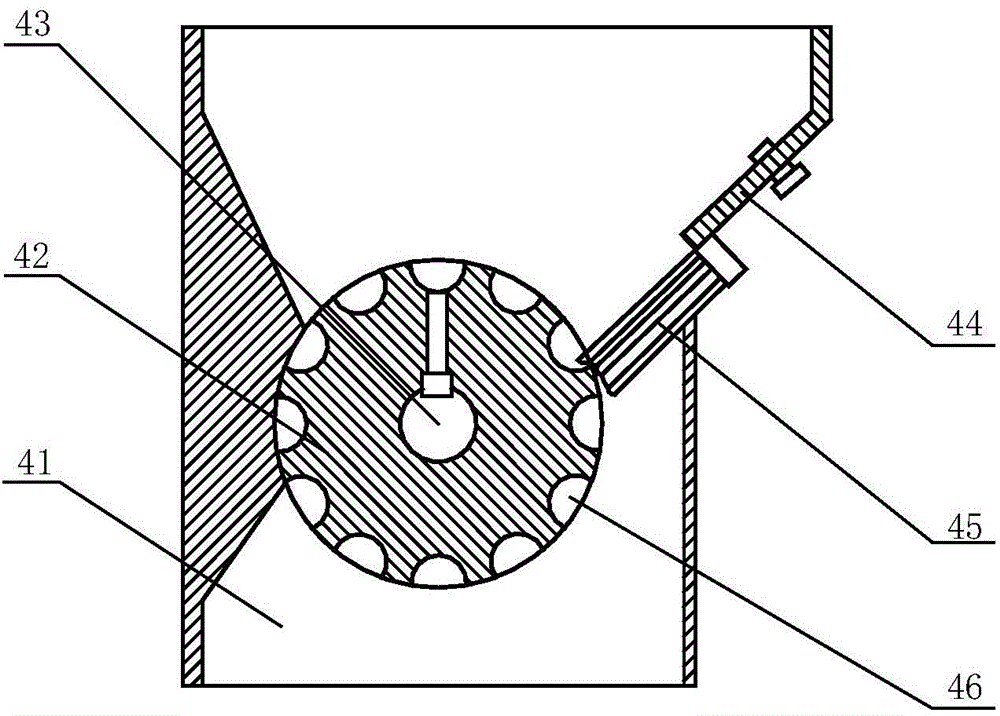

Individual intelligent variable supplementary concentrated feed feeding device for dairy cow

InactiveCN104663486AAccurate ingredientsAvoid interferenceAnimal feeding devicesMilk cow'sEngineering

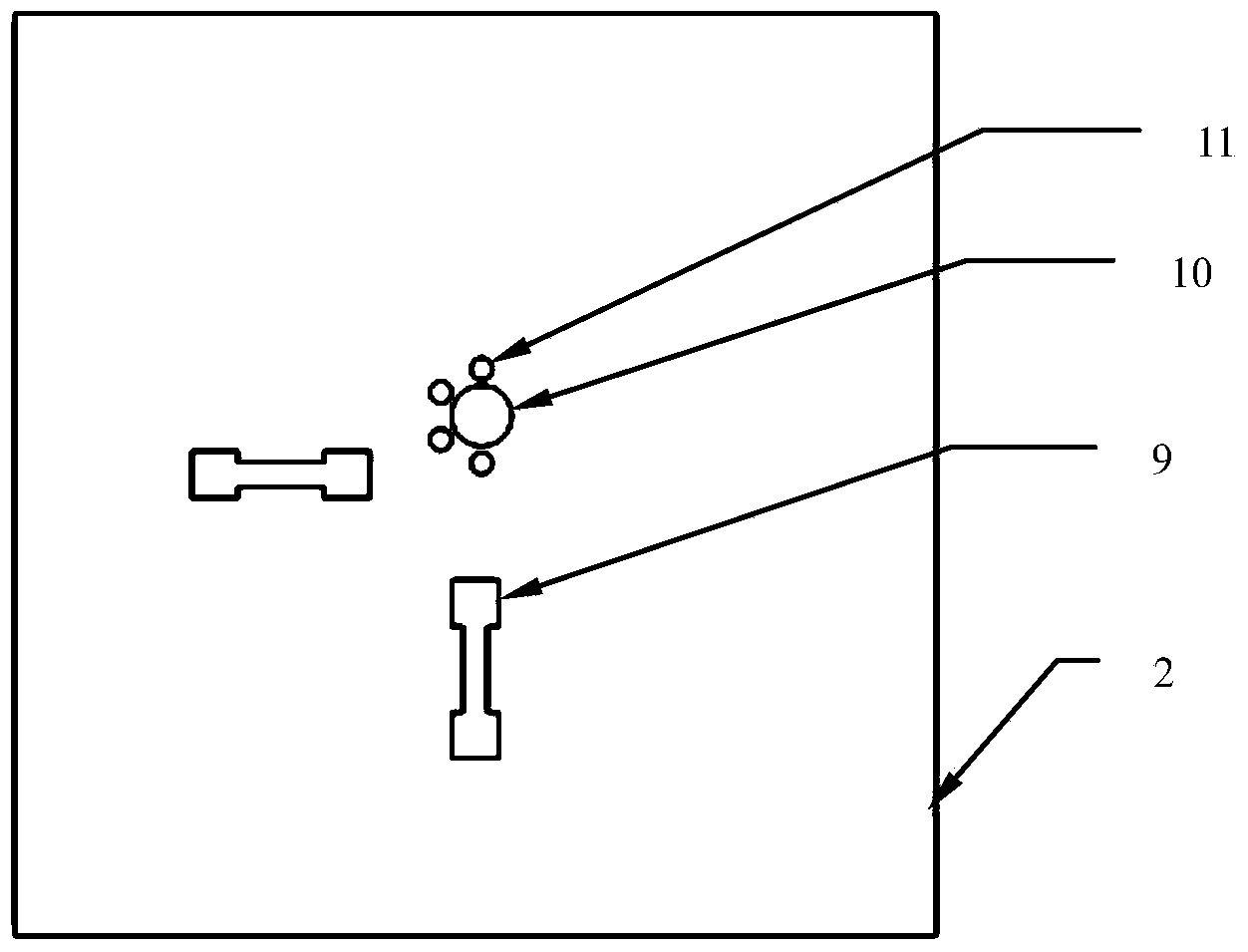

The invention belongs to the technical field of dairy cow breeding equipment, in particular to an individual intelligent variable supplementary concentrated feed feeding device for dairy cow. The individual intelligent variable supplementary concentrated feed feeding device for the dairy cow comprises a stand (1), a feeding control center, a feeding discharge device and a drive device, the feeding control center is arranged at one side of the stand (1), and the stand is further provided with the feeding discharge device and drive device. The feeding control center is composed of a control terminal (8), a signal wire (9) connected with the control terminal (8) and a step motor driver (10) connected with the signal wire (9). The feeding discharge device is composed of a feeding groove (2), a discharge funnel (3) located at one side of the upper end of the feeding groove (2), a stock bin (5) located at the top end of the stand (1), and a metering device (4) located at the bottom end of the stock bin (5), wherein the discharge funnel (3) is located at the lower end of the metering device (4). The individual intelligent variable supplementary concentrated feed feeding device for the dairy cow uses the scored pulley type metering device and is capable of realizing the precise dosing and synchronous feeding of various concentrated feed.

Owner:史莉娟

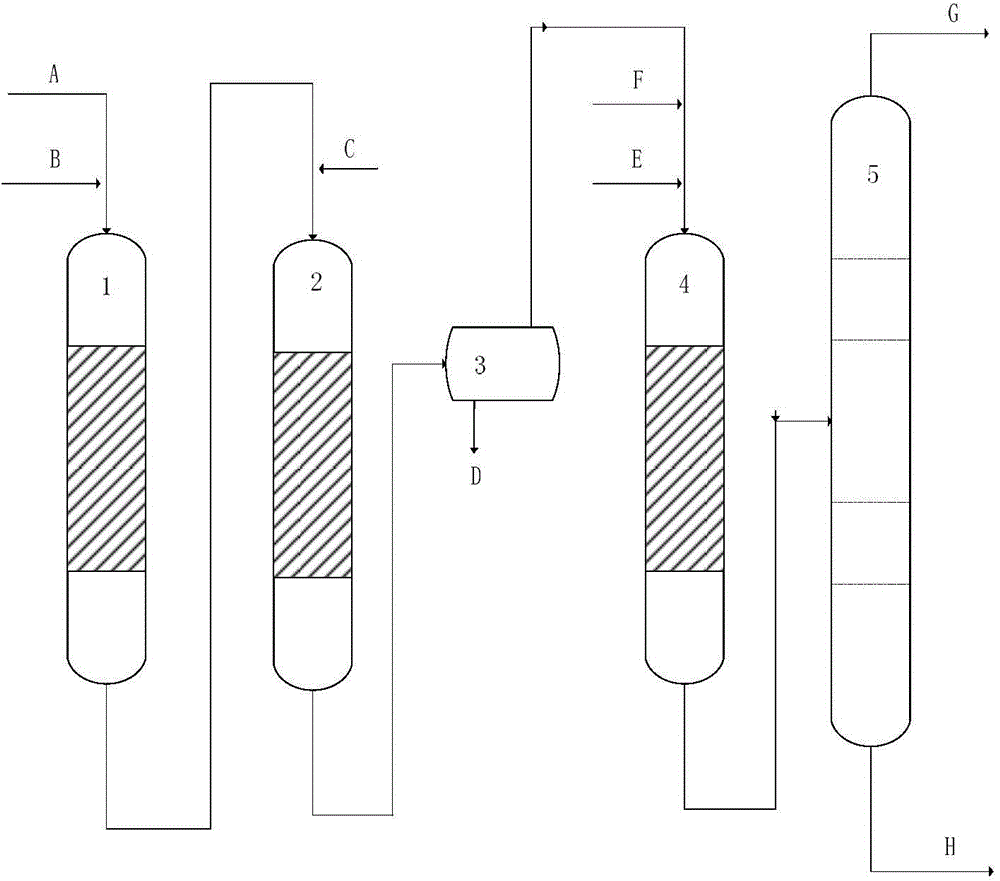

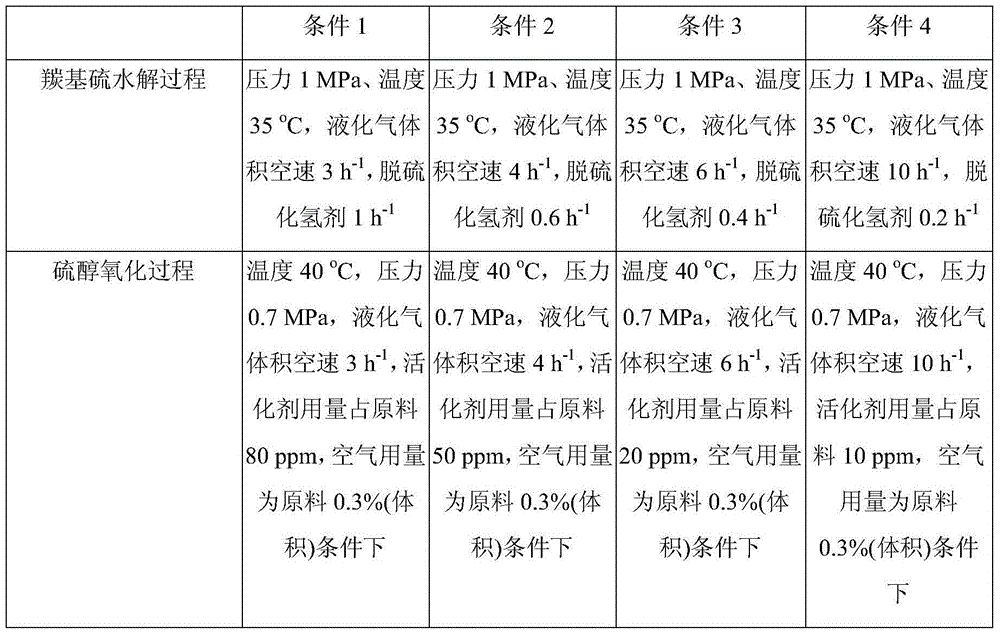

Deep desulfurization and refining combined technology for liquefied petroleum gas

InactiveCN104403688AMeet the feed requirementsReduce sulfur contentGaseous fuelsGaseous mixture working upHydrogen SulfateSulfate

The invention relates to a deep desulfurization technology for liquefied petroleum gas. A carbonyl sulfate water-washing tower is adopted to remove hydrogen sulfate and carbonyl sulfate in the liquefied petroleum gas respectively according to different nature characteristics of sulfides contained in the liquefied petroleum gas, small-molecular mercaptan in the liquefied petroleum gas is converted into disulfides with higher boiling points through an oxidation tower, then the sulfides and a liquefied petroleum gas product are separated with a rectification method, sulfur-enriched C5 or heavy C4 components are arranged at the tower bottom, and the ultra-low-sulfur liquefied petroleum gas product is arranged at the tower top. The content of sulfur in the liquefied petroleum gas is decreased to be lower than 5 mu g / g in the process, the desulfurization rate is high, and no alkali residue is discharged.

Owner:XI'AN PETROLEUM UNIVERSITY

Method of producing catalytic reforming raw material

ActiveCN100448951CHigh Hydrodenitrogenation ActivityReduce contentRefining to eliminate hetero atomsCatalytic reformingNaphtha

The invention is a method for producing catalytic reforming raw material, cutting secondary gasoline raw material into light gasoline fraction, medium gasoline fraction and heavy gasoline fraction, where the medium gasoline fraction, optional virgin naphtha and hydrogen gas contact with first hydrofining catalyst to make alkene saturated reaction, the resultant effluent is not separated but directly contacts with second hydrofining catalyst to make hydrodesulfurization and hydro- denitrogenation reactions, and the extracted hydrogen-enriched gas is recycled and the extracted liquid enters a distillation dehydrating tower and is purified to obtain naphtha. And it can process secondary gasoline with high sulfur, nitrogen and alkene contents, and provides qualified raw material with sulfur and nitrogen contents both less than 0.5 mug / g for catalytic reforming.

Owner:CHINA PETROLEUM & CHEM CORP

Mobile fish pond feeder device

ActiveCN106719225AImprove stabilityLower center of gravityClimate change adaptationPisciculture and aquariaButt jointEngineering

The invention discloses a mobile fish pond feeder device which comprises a floating body, a straight running gear, a storage tank, a feeding device and a discharging device. The straight running gear includes a cable fastened to the banks of a fish pond. The whole mobile fish pond feeder device moves back and forth on the water surface by the cable as being driven by an actuating unit fastened to the floating body. The storage tank with the feeding device inside is fixed to the floating body. The feeding device comprises a packing auger sleeve and a feeding packing auger. The lower end of the storage tank is sealed and more than a half of the volume of the storage tank is below the surface of the water. The discharging device comprises a discharging motor and a rejection tray, wherein the discharging motor is arranged above the rejection tray. The discharging motor and the rejection tray are connected in a transmission way. The feeding device and the rejection tray are connected in a coaxial butt joint from bottom to top. The discharging motor is further connected with the feeding packing auger in a transmission way. The mobile fish pond feeder device significantly enlarges the feeding range and lowers the gravity center and improves the water surface running stability. Only one discharging motor is adopted as the actuating unit to realize the feeding from bottom to top and horizontal wide range of discharge.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

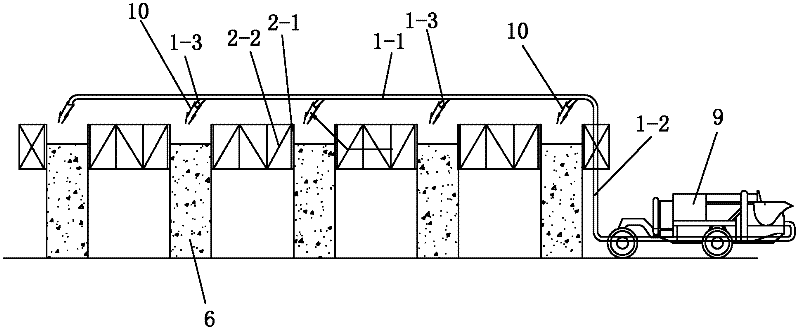

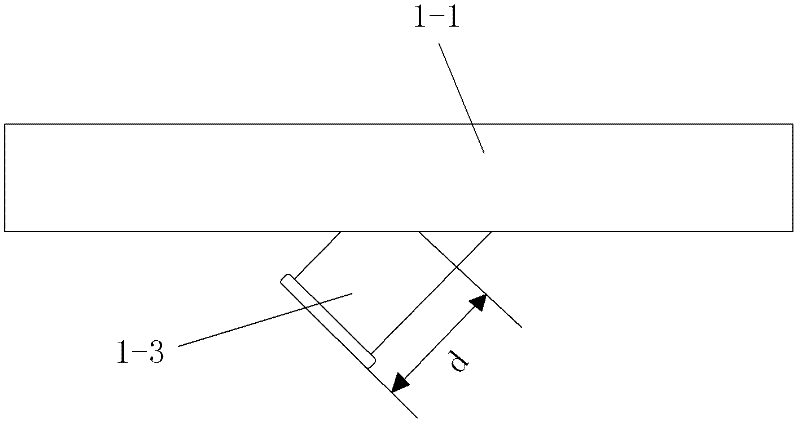

Slip form construction device and method for single concrete pump in synchronous multi-bin number pouring

ActiveCN102409858ASimple structureEasy to installForms/shuttering/falseworksBuilding material handlingSynchronous motorStructural engineering

The invention discloses a slip form construction device and method for a single concrete pump in synchronous multi-bin number pouring, wherein the device comprises a concrete pumping device, a concrete pumping pipeline, slip forms which are used for carrying out slip form construction on a plurality of concrete structures to be poured respectively, and a plurality of concrete branched pumping pipelines which are used for pumping concrete into the slip form planes of the plurality of slip forms from top to bottom respectively; and all the concrete branched pumping pipelines are provided with control flashboards. The method comprises the following steps of: firstly, construction preparation; secondly, slip form construction, wherein a concrete pouring process of the plurality of concrete structures to be poured is completed, and in the concrete pouring process, the material feeding speed is controlled by controlling the control flashboards. The construction method disclosed by the invention has the advantages of simple steps, convenience in realization, high construction efficiency and easily guaranteed construction quality, and can be used for solving the problems of repeated assembly / disassembly of the concrete pumping pipelines, low concrete pouring speed, large labor input, low construction efficiency, poor construction quality and the like in the conventional single concrete pumping in-bin manner.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Pyrogenic copper smelting white smoke resource comprehensive utilization method

InactiveCN106834705AMeet the feed requirementsReduce manufacturing costArsenites/arsenatesProcess efficiency improvementElectrolysisLead smelting

The invention discloses a pyrogenic copper smelting white smoke resource comprehensive utilization method. The method comprises the following specific steps: white smoke and caustic soda are mixed in proportion; sodium sulfate is added, so that solution has a certain SO42- concentration; air is fed at 80-95 DEG C for oxidation leaching; then, the filtration is performed; and a proper amount of water is used for washing filter cakes. Filtrate has the main component of sodium arsenate, and is evaporated, condensed, cooled, crystallized, filtered and separated to obtain a sodium arsenate double salt product; and mother liquor after separation of sodium arsenate is returned to the white smoke for alkali leaching. The filter cakes in alkali leaching are pulped; sulfuric acid is added for acid leaching at 80-95 DEG C; then, the filtration is performed; the filter cakes have the main component of lead sulfate; and lead sulfate serves as a lead concentrate for lead smelting. Filtrate is copper sulfate solution; iron powder is added for replacement to obtain sponge copper; and the sponge copper is returned to a pyrogenic copper smelting system for refining as electrolyzed copper. The leaching rate of arsenic in the white smoke can reach above 95%; such precious metals as copper, lead, gold and silver are nearly not leached; the leaching rate of copper is higher than 98%; the content of lead in acid leaching slag is higher than 50%; and such precious metals as gold and silver are further enriched.

Owner:HENAN ZHONGYUAN GOLD SMELTERY

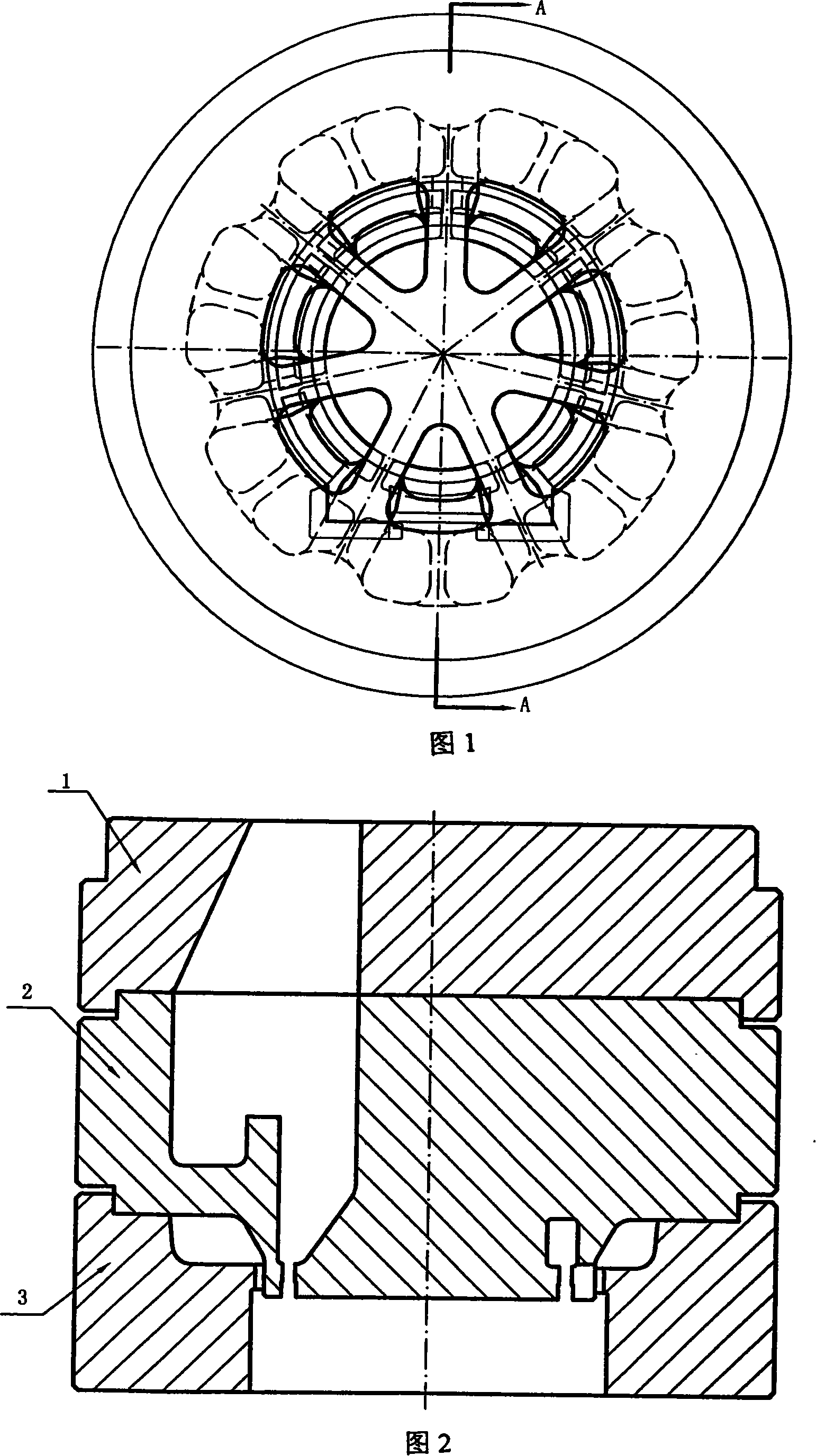

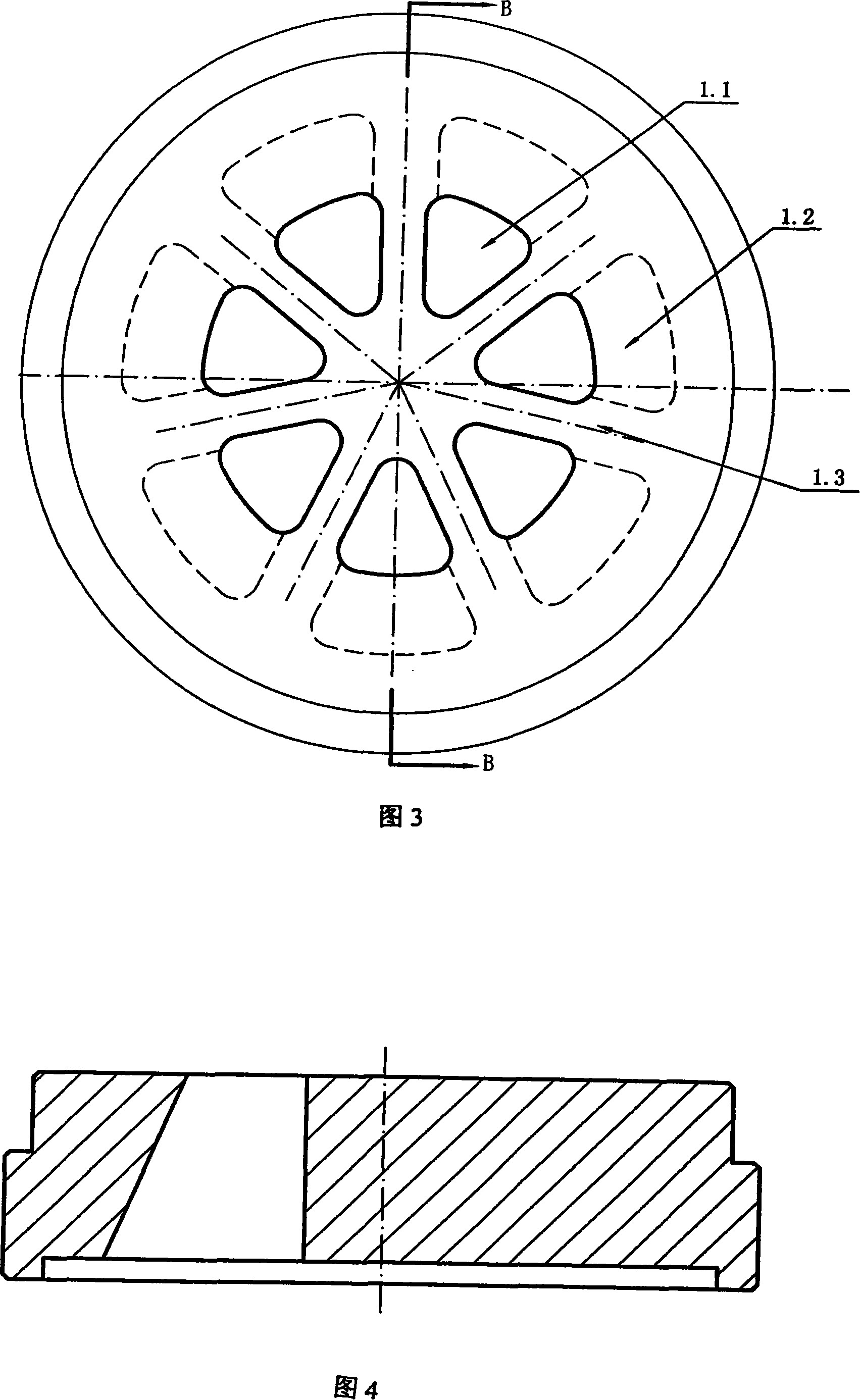

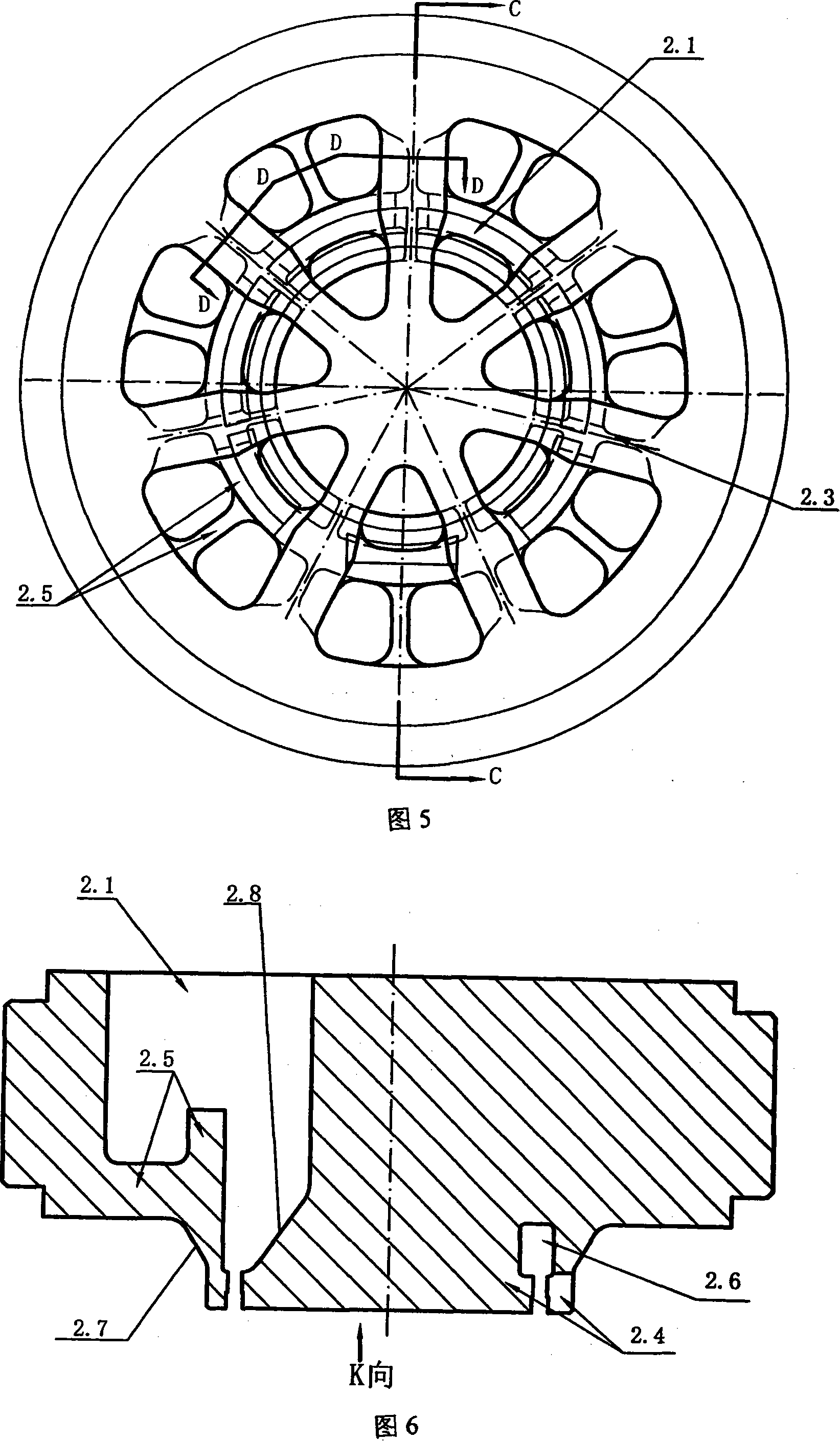

Multi- structure motor enclosure aluminium alloy hot-extrusion die

InactiveCN101081412AMeet the feed requirementsPlay a protective effectExtrusion diesManufacturing dynamo-electric machinesMetal flowAluminium alloy

The hot extruding die for producing hollow motor housing of aluminum alloy consists of one guide die, one upper die and one lower die superposed together. The guide die has in the feeding side seven bridge sites and seven shunting holes; the upper die has seven bridge sites and seven material shunting holes in the feeding side, and 21 discharge shunting holes separately in two circles, inner bridge sites and eight die cores in the discharge side; and the lower die has one welding chamber and two choking lugs in the feeding side. The hot extruding die can equalize the metal flow, capacity of ensuring high product quality and yield, and long service life.

Owner:JIANGYIN GIANSUN MOLD

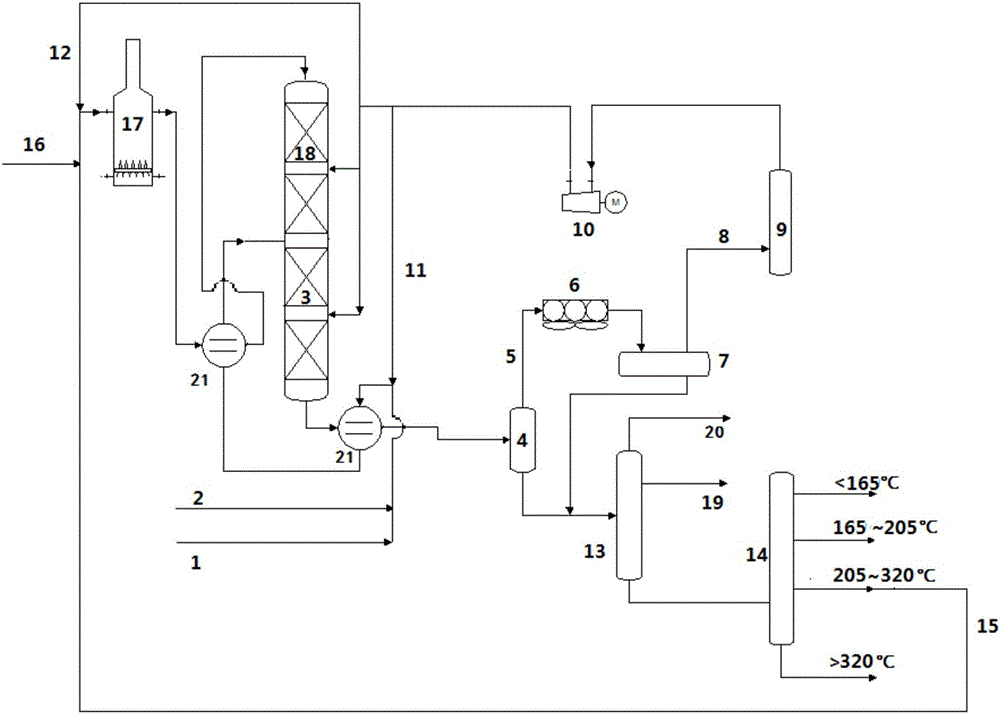

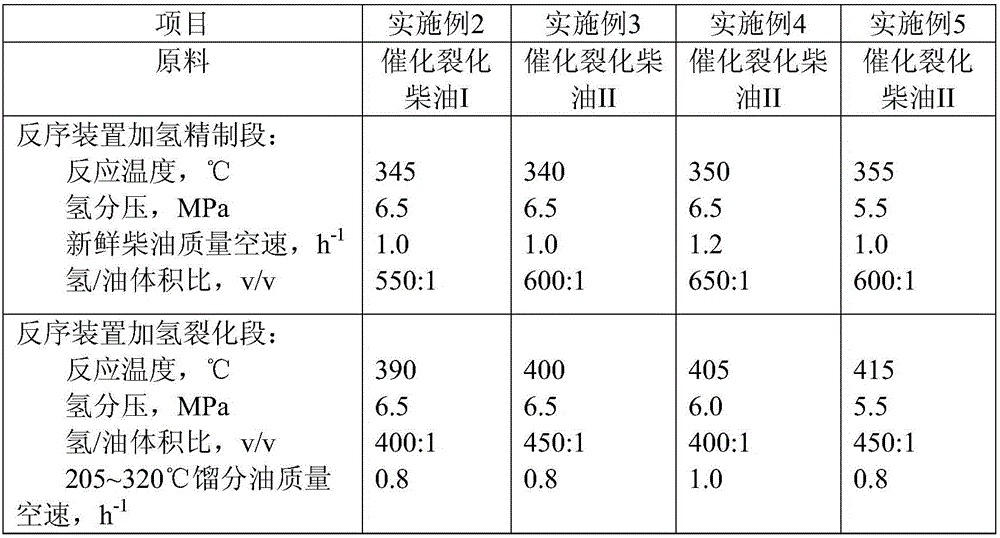

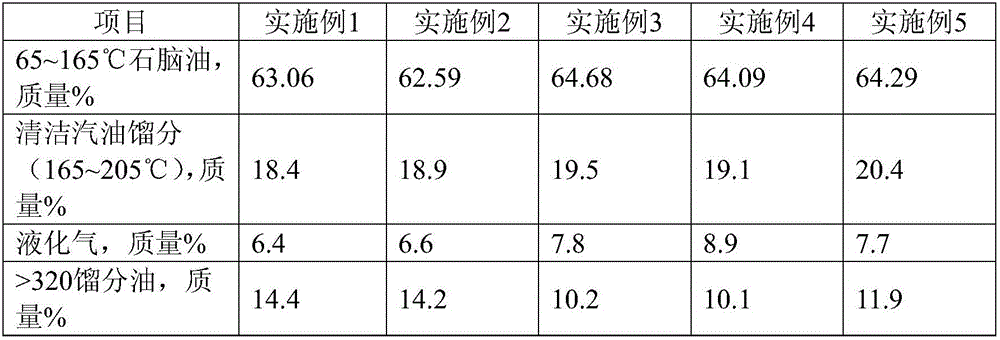

Method for producing naphtha and clean gasoline by catalytic cracking diesel oil

ActiveCN105694966AMeet the feed requirementsLight distillationTreatment with hydrotreatment processesHydrocarbon oils treatment productsCatalytic reformingNaphtha

The invention provides a method for producing naphtha and clean gasoline by catalytic cracking diesel oil. The method comprises the following steps of mixing the catalytic cracking diesel oil and hydrogen gas; enabling the mixture to enter the middle part of a reverse sequence filling hydrocracking reactor-hydrofining reactor to be mixed with cracking products from the hydrocracking reactor; enabling the mixture to enter the hydrofining reactor to perform a hydrofining reaction so as to remove impurities such as sulfur and nitrogen; performing an olefin saturated reaction and arene hydrogenation saturation; performing cutting processing on products after the hydrofining; using distillate oil below 165 DEG C as a naphtha product to be used as a raw material for a catalytic reforming unit; using distillate oil being 165 to 205 DEG C as a clean gasoline conditioning ingredient; returning distillate oil being 205 to 320 DEG C into the top of the reverse sequence filling hydrocracking reactor-hydrofining reactor; performing hydrocracking and hydrofining reactions; returning distillate oil being higher than 320 DEG C into a catalytic cracking device for further cracking, or enabling the distillate oil being higher than 320 DEG C to enter other hydrogenation devices for processing treatment. The method has the advantages that high yield of naphtha products is taken as the goal; the clean gasoline can be produced at the same time.

Owner:CHINA NAT OFFSHORE OIL CORP +3

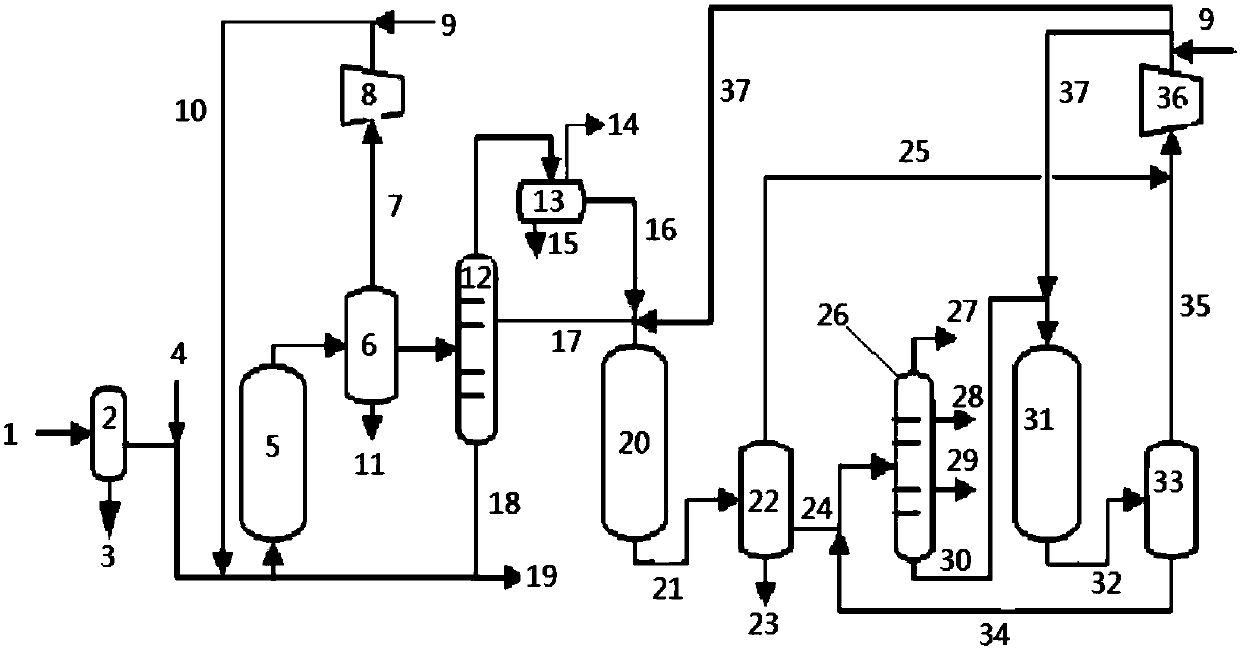

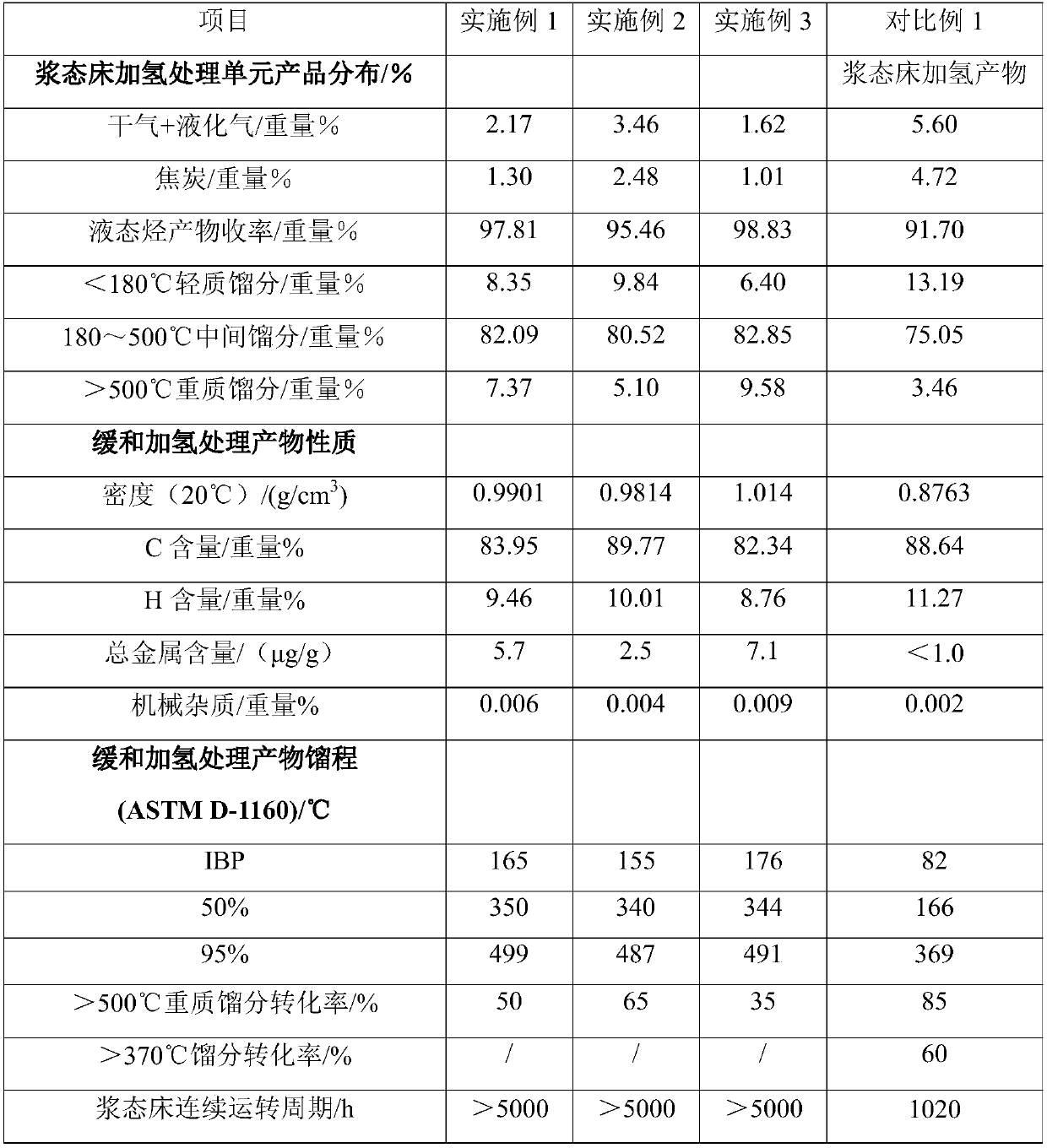

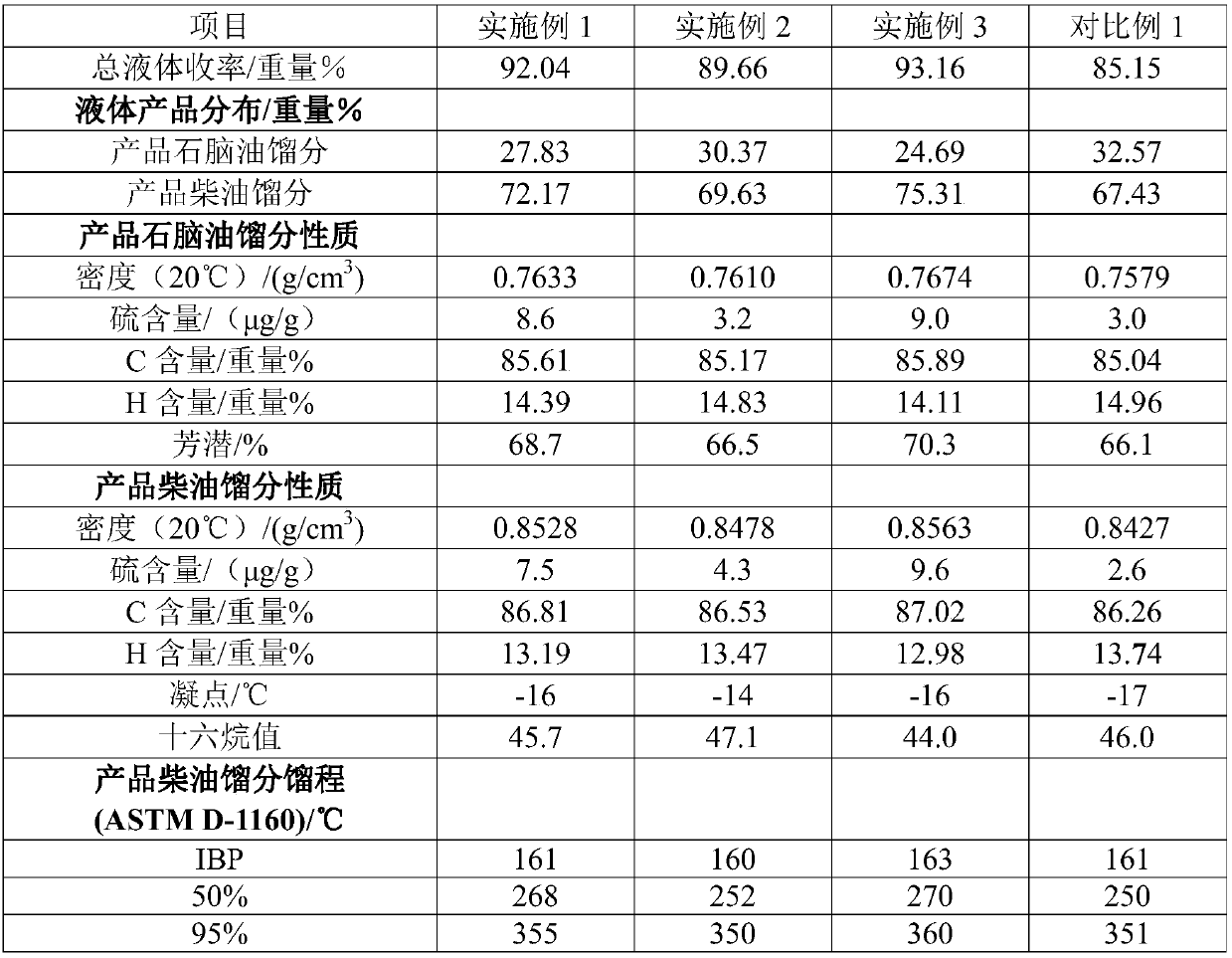

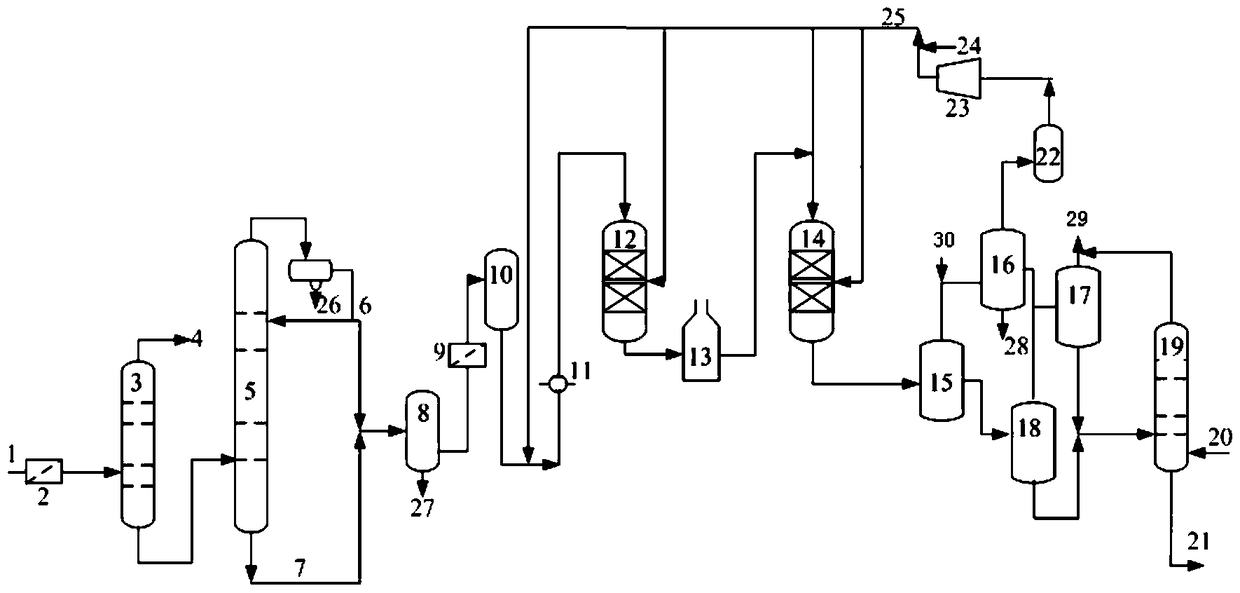

Hydrogenation method for coal tar combination bed and system used for coal tar combination bed hydrogenation

ActiveCN107557064AImprove liquid yieldLong operating period of the deviceTreatment with hydrotreatment processesWaxChemistry

The invention relates to the field of coal tar processing, and discloses a hydrogenation method for a coal tar combination bed and a system used for coal tar combination bed hydrogenation. The methodcomprises the following steps: introducing a coal tar raw material, and performing water removing and / or impurity removing pretreatment; performing mild-hydrogenation treatment on the above materialsunder hydrogen and a slurry bed catalyst; performing gas-liquid separation on obtained materials, and performing fractional distillation to obtain a light distillate, an intermediate distillate and aheavy distillate; recycling the remainder heavy distillate to a slurry bed reactor, and performing mild-hydrogenation treatment; performing a hydrogenation refining reaction on the light distillate and the intermediate distillate; and performing gas-liquid separation on an effluent of a refining reactor, and performing fractional distillation to obtain a naphtha distillate, a diesel oil distillateand a wax oil distillate. According to the invention, a combination of a slurry bed and a static bed is utilized, thus clean and high-efficiency utilization of a coal tar resource is realized, a liquid yield and a utilization ratio and utilization value of the coal tar resource are improved, and a running period of a device is prolonged to a certain degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method of coal tar raw material hydrogenation pretreatment

ActiveCN106147853BEfficient removalEfficient preprocessingTreatment with hydrotreatment processesHydrogenation reactionReaction zone

The invention relates to the field of coal tar processing, and discloses a method for hydrogenation pretreatment of coal tar raw materials. The method is implemented in a reaction system including a first prehydrogenation reaction zone and a second prehydrogenation reaction zone. The method includes : (1) the coal tar raw material to be pretreated is degassed and dehydrated successively to obtain the dehydrated coal tar raw material, wherein the dissolved oxygen content in the dehydrated coal tar raw material is lower than 1 μL / L, and the water content less than 500 μg / g; (2) In the presence of hydrogen, the dehydrated coal tar raw material is sequentially entered into the first pre-hydrogenation reaction zone and the second pre-hydrogenation reaction zone. When the method of the present invention is used to treat coal tar, the utilization rate of the hydrogenation protection catalyst in the coal tar treatment process can be significantly improved, and the above method of the present invention has low energy consumption, simple process, long device operation period and high product yield Advantages of excellent properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

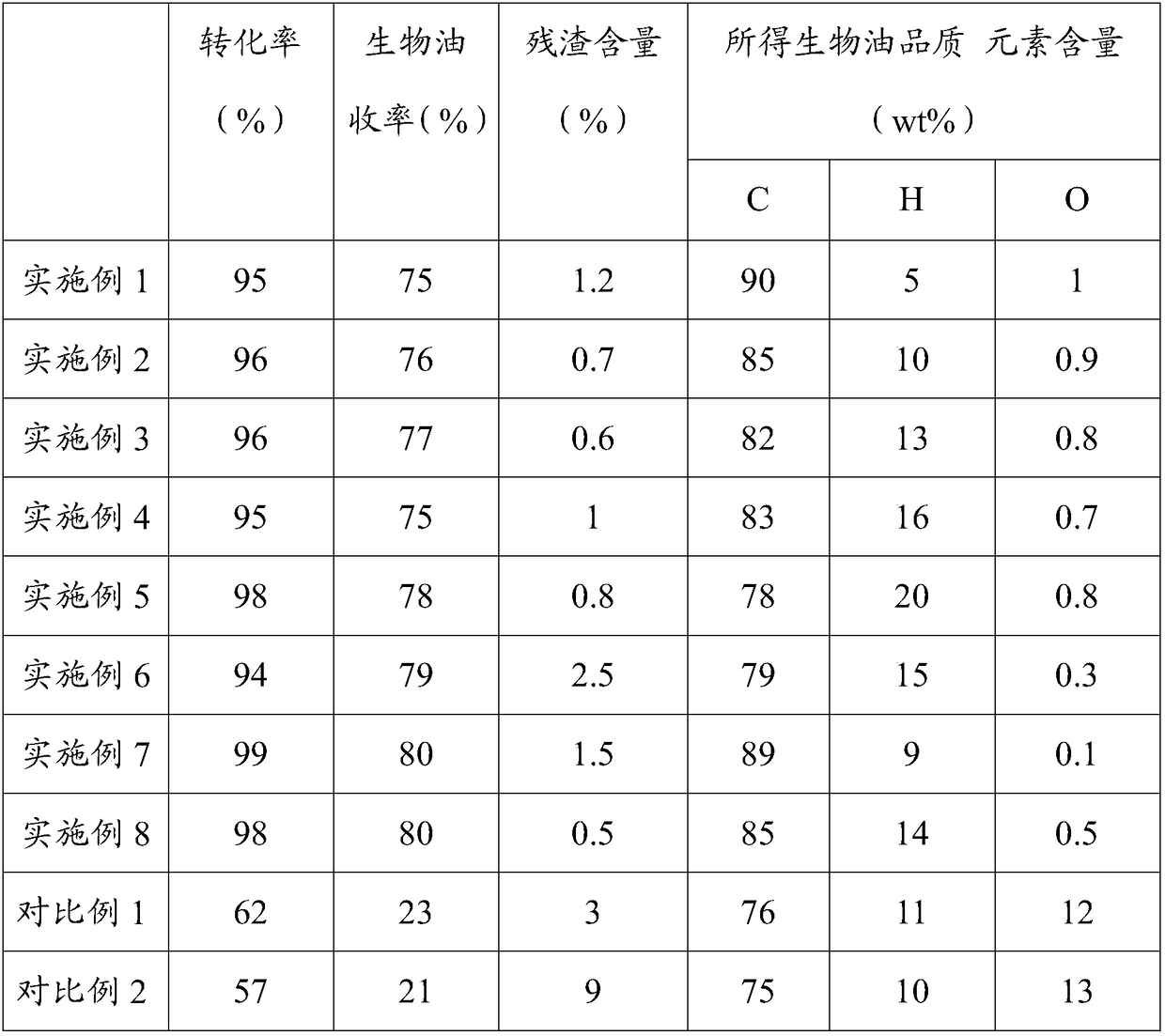

Multi-grade liquefying technology of coal and biomass

ActiveCN108285808ARealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionSolventBiomass

The invention relates to the technical field of clean energy, and specifically provides a multi-grade liquefying technology of coal and biomass. The technology is characterized in that the coal and the biomass raw materials are processed by crushing, compressing and crushing again, then the sizing is prepared, so that biomass diesel oil which is high in solid content and can be stably conveyed through a pump can be obtained; high-viscosity waste oil which cannot be used as a coal and biomass liquefying solvent in the prior art can be utilized. According to the technology, coal and biomass canbe liquefied under high pressure and high temperature in the existence of proper volume of water; the liquefying product is sequentially subjected to primary cracking, hydrogenation reaction and deepcracking and hydrogenation reaction under the effects of resisting hydrogen and a first catalyst and a second catalyst, so that the coal and the biomass can be converted into biomass oil, and the biomass oil can be refined; the conversion rate of the biomass and the coal is up to 95-99%; the yield of the biomass oil is up to 70-80%; and moreover, the residue content is less than 2.5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

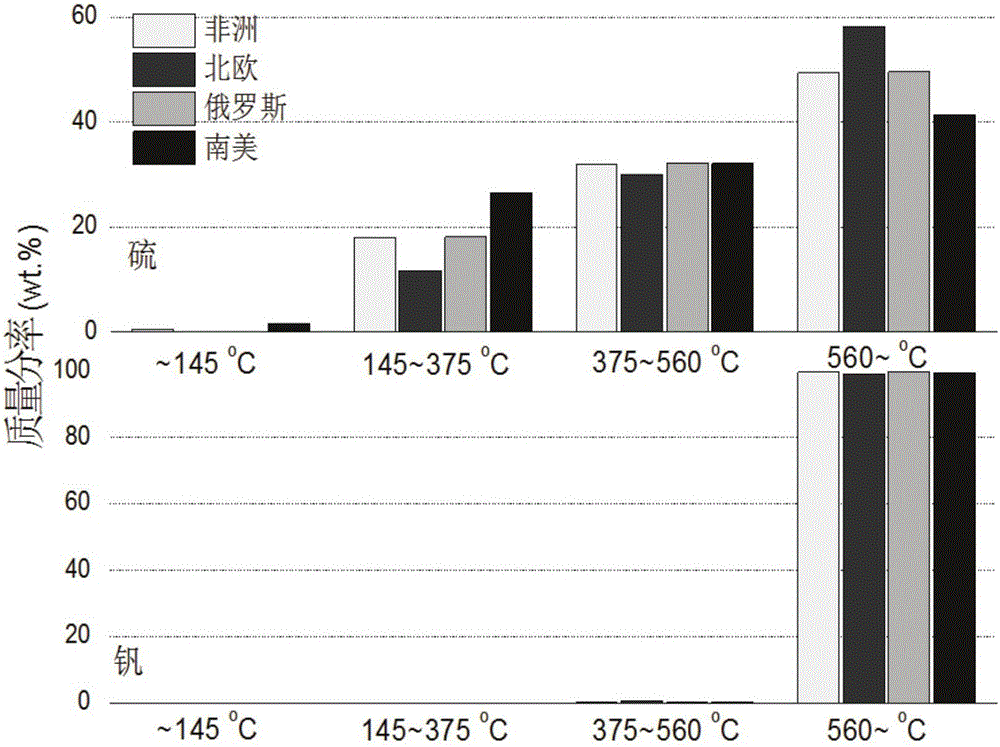

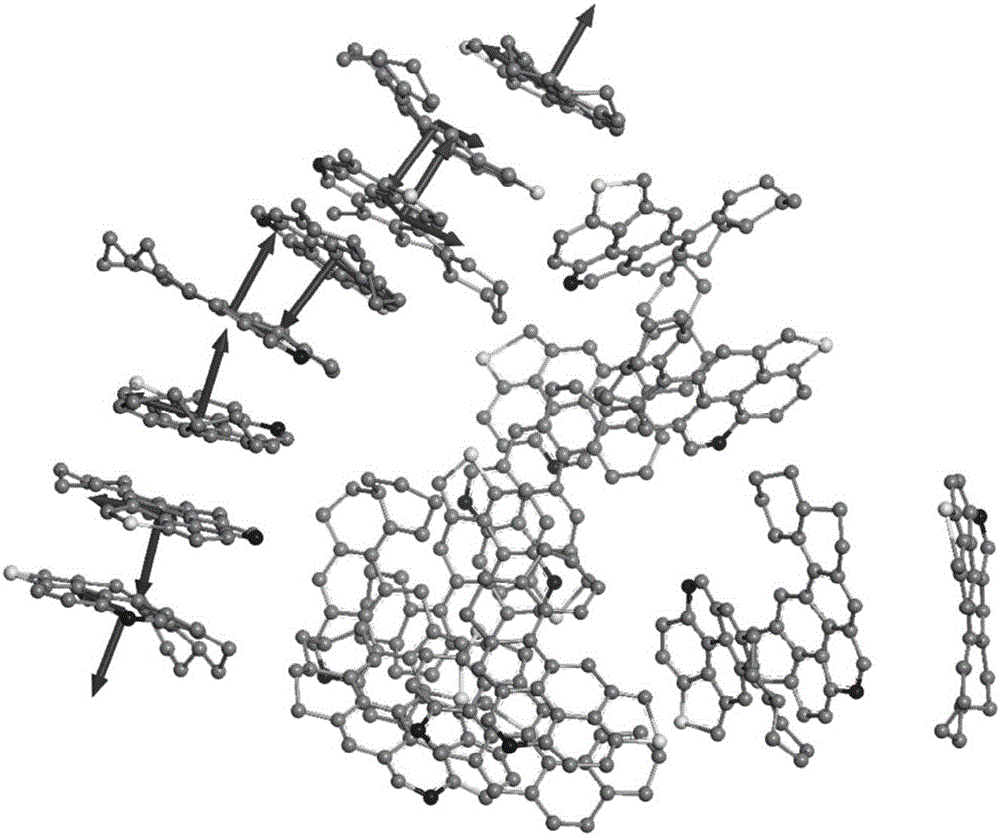

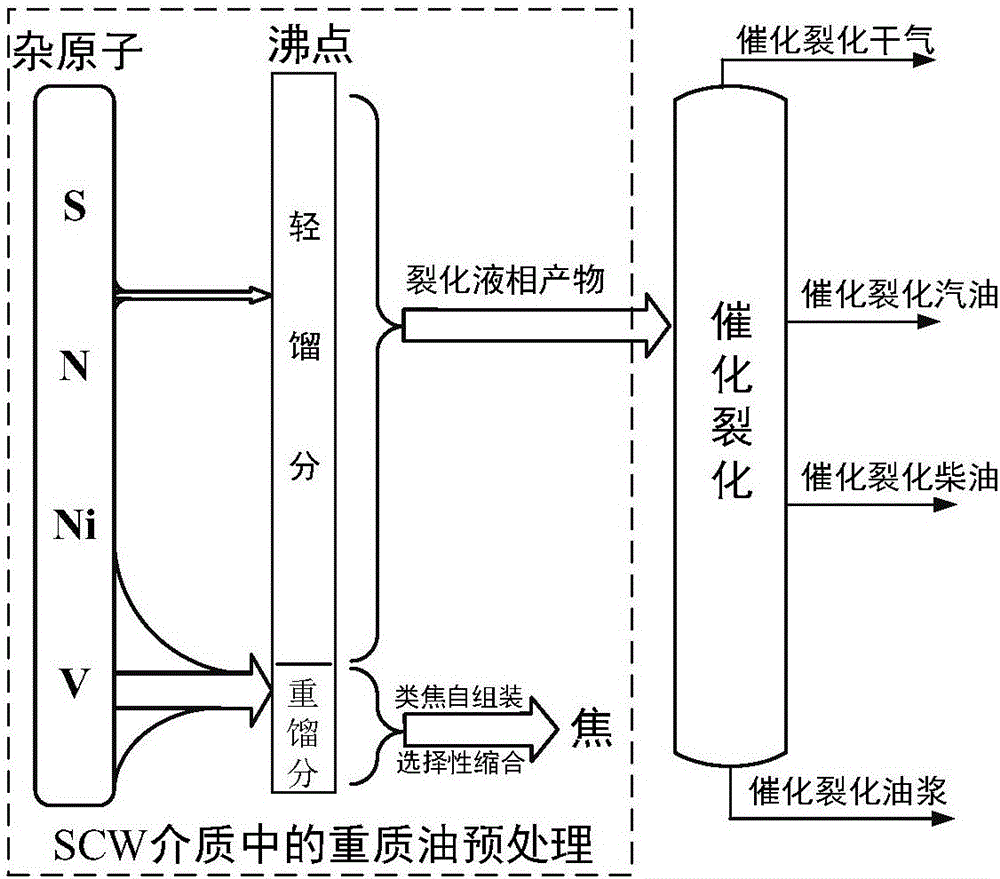

Method for pretreating heavy oil based on self-assembling effect of heavy aromatics in subcritical/supercritical water and application

ActiveCN106350101AMeet the feed requirementsCatalytic naphtha reformingHydrocarbon oils treatmentPretreatment methodReaction temperature

The invention relates to a method for pretreating heavy oil based on a self-assembling effect of heavy aromatics in subcritical / supercritical water and application. The method comprises the following steps: placing the heavy oil in a subcritical / supercritical water environment in a specific thermodynamic state, and enabling cracking reaction of the heavy oil to be transferred into a subcritical / supercritical water phase from an oil phase; and preferably forming similar coke gathered supermolecular structure by using heteroatoms which are rich in the heavy oil and heavy components of carbon residues according to a differentiated self-assembling tendency, and removing the heavy components from a reaction system in a condensation coking mode. The method for pretreating the heavy oil based on the self-assembling effect of the heavy aromatics in the subcritical / supercritical water comprises the following steps: adding the heavy oil and water; purging with high-purity N2; heating and stirring; insulating after heating to reaction temperature; and finishing reaction. The invention further relates to application of the method. By the method provided by the invention, removal of the heteroatoms from the heavy oil and pretreatment of the carbon residues can be carried out synchronously.

Owner:EAST CHINA UNIV OF SCI & TECH

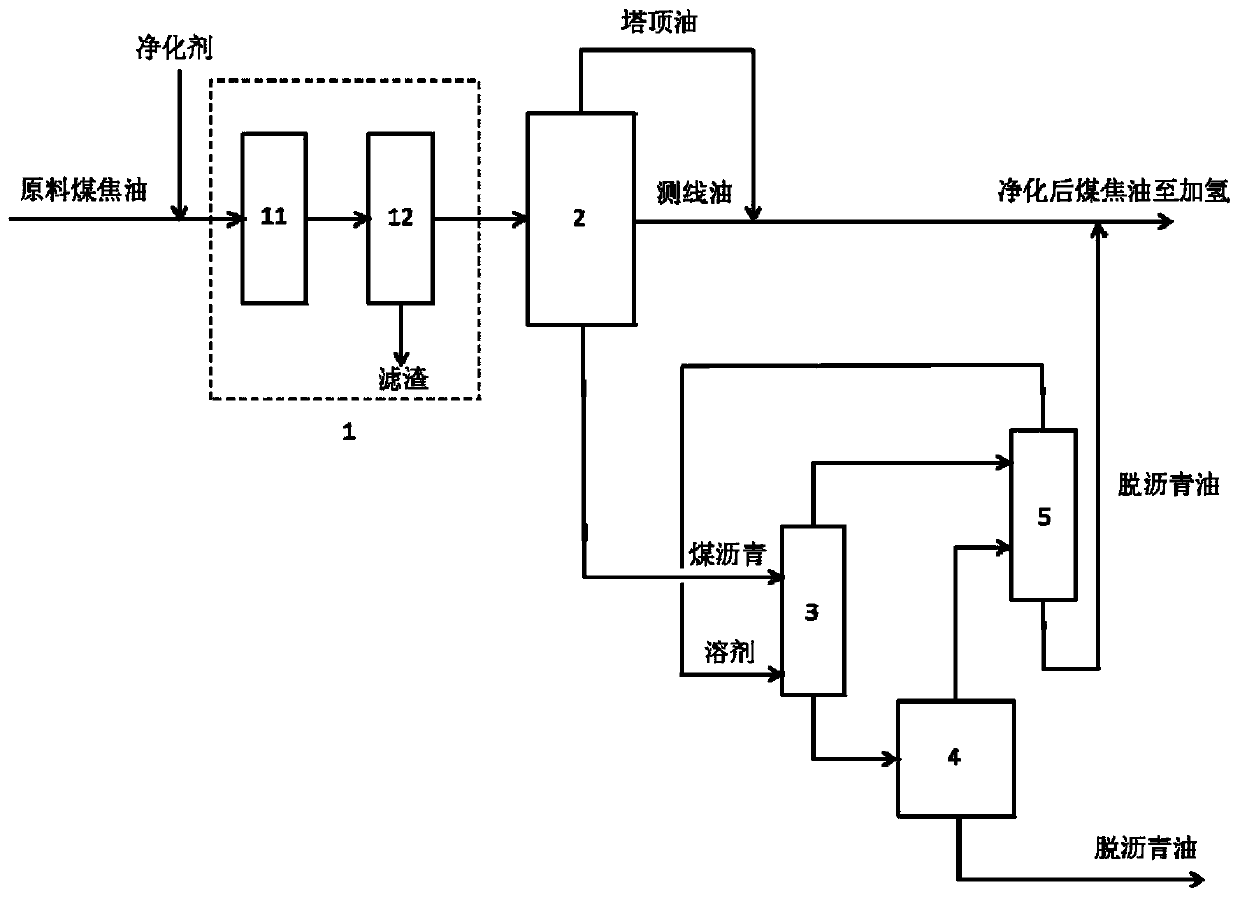

Coal tar pretreatment purification method and system

PendingCN111592905AHigh oil yieldIncrease profitWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionSolventAsphalt

The invention provides a coal tar pretreatment purification method and system. The method comprises adding a purifying agent into coal tar, carrying out dehydration and solid removal treatment on thecoal tar, carrying out solid-liquid separation on the dehydrated and solid-removed coal tar, and then carrying out fractionation cutting to obtain column top oil, side line oil and column bottom coalpitch; carrying out solvent extraction on the obtained column bottom coal pitch, and carrying out solvent recovery treatment on an extract phase to obtain a solvent and deasphalted oil; recycling thesolvent for solvent extraction; mixing the deasphalted oil with the column top oil and the side line oil to carry out hydrotreatment; carrying out asphalt steam stripping on a raffinate phase obtainedby solvent extraction, carrying out solvent recovery on an obtained solvent and an oil product, and discharging deoiled asphalt obtained by asphalt steam stripping as a product. The method can improve the utilization rate of coal tar to the maximum extent, the purified coal tar directly enters a fixed bed hydrogenation reaction system, the process is mature and stable, and the process and investment are far lower than those of fluidized beds, slurry beds and other hydrogenation reaction systems.

Owner:胜帮科技股份有限公司

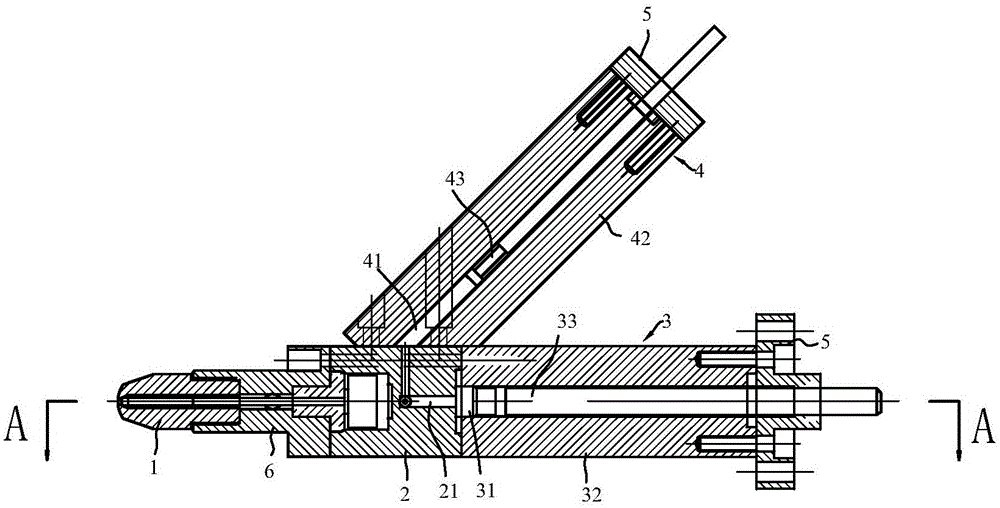

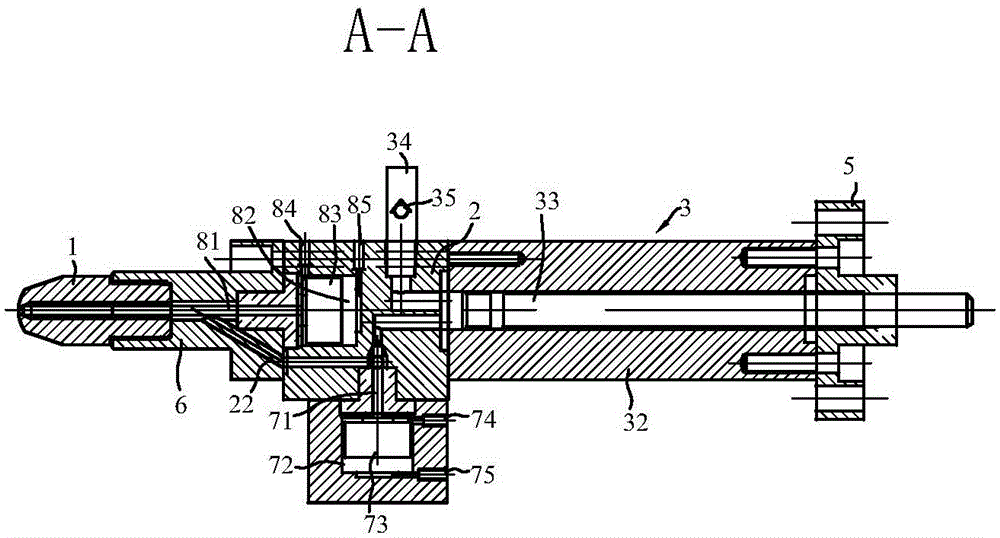

Trace precision injection molding glue injection device

The invention discloses a trace precision injection molding glue injection device. The trace precision injection molding glue injection device comprises a spray nozzle, a primary glue injection gun barrel and a precision gun barrel. The primary glue injection gun barrel comprises a primary gun barrel body internally provided with a primary glue injection cavity and a primary glue injection gun barrel piston rod capable of reciprocating in the primary glue injection cavity. The precision gun barrel comprises a precision gun barrel body internally provided with a precision glue injection cavity and a precision gun barrel piston rod capable of reciprocating in the precision glue injection cavity. The internal diameter of the primary glue injection cavity is larger than that of the precision glue injection cavity. A raw material inlet passageway is communicated with the primary glue injection cavity. The primary glue injection cavity and the precision glue injection cavity are connected through a material supply passageway. A glue inflow valve is arranged on the material supply passageway. The precision glue injection cavity is connected with the spray nozzle through the glue injection passageway. A glue injection valve is arranged on the glue injection passageway. The primary glue injection gun barrel and the precision gun barrel which are different in internal diameter are combined for glue injection, material supply is easy due to the characteristics and the beneficial effects of the primary glue injection gun barrel and the precision gun barrel, the errors generated by outputting the glue amount are small, and the output precision is higher.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

Novel composite riser heating agent and preparation method thereof

ActiveCN103949593AImprove heating effectImprove insulation effectFoundry mouldsFoundry coresSlagSodium nitrate

The invention discloses a novel composite riser heating agent. The novel composite riser heating agent is prepared from the following raw material components in parts by weight: 25-35 parts of aluminum powder, 5-15 parts of magnesium powder, 3-7 parts of fluorite powder, 3-7 parts of silicon carbide powder, 5-10 parts of iron oxide powder, 3-7 parts of silicon calcium powder, 12-16 parts of aluminum slag, 8-12 parts of modified fly ash, 6-9 parts of sodium nitrate and 6-9 parts of sodium fluosilicate, wherein the modified fly ash is obtained by sequentially putting burnt fly ash into a 20-25 percent sulfuric acid solution and a 16-24 percent sodium hydroxide solution, stirring for 20-22h, washing the fly ash filtered from acid-base immersion liquid by using deionized water to be neutral, and filtering and drying the fly ash finally. The heating agent prepared from a raw material formula by using a method is good in heating effect and good in heat preservation effect, meets requirements for feeding of a casting, and guarantees the quality conformance of the casting.

Owner:JIAOZUO GEDE NEW MATERIALS

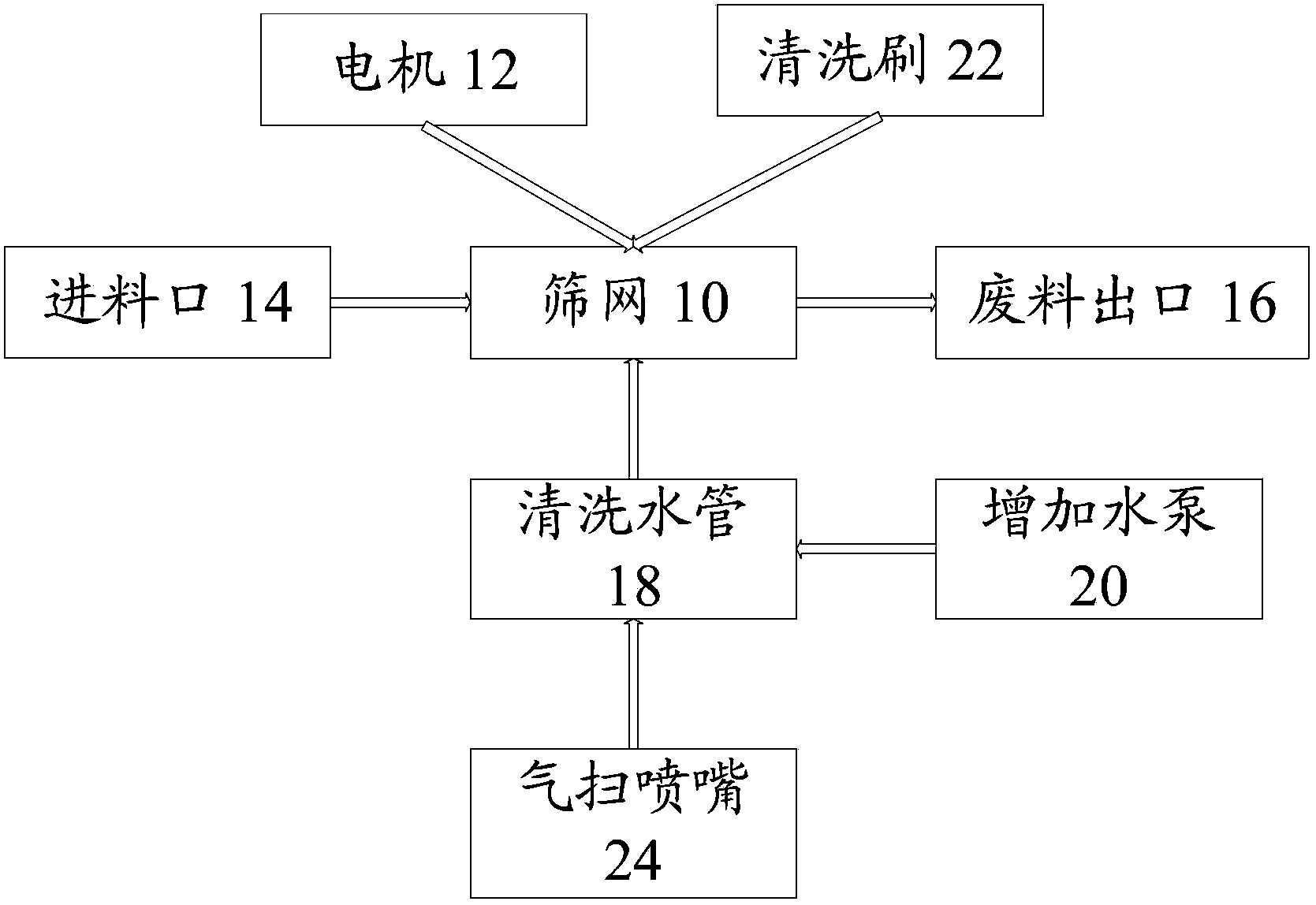

Drum screening machine

InactiveCN103449691AImprove screening efficiencyEfficient sortingWaste water treatment from quariesSievingPipingEngineering

The invention discloses a drum screening machine comprising a screen drum screen mesh, a motor for driving the screen drum screen mesh to rotate, a material inlet connected with the screen drum screen mesh, a waste material outlet connected with the screen drum screen mesh, and a pedestal for supporting the screen drum screen mesh. The drum screening machine is characterized by also comprising two cleaning water pipes and a booster water pump for pressurizing the cleaning water. The two cleaning water pipes are respectively longitudinally arranged on the inner side and the outer side of the screen mesh, the two cleaning water pipes are each provided with a plurality of holes, and cleaning water is provided for oil sludge in the screen mesh through the plurality of holes. According to the technical scheme of the invention, sundries in hardened tank bottom sludge and hardened pool bottom sludge can be effectively sorted out, and the screening efficiency is increased, so that the treated fluidization oil sludge meets feeding requirements of subsequent oil sludge treatment equipment.

Owner:河北海清大地环保科技有限公司

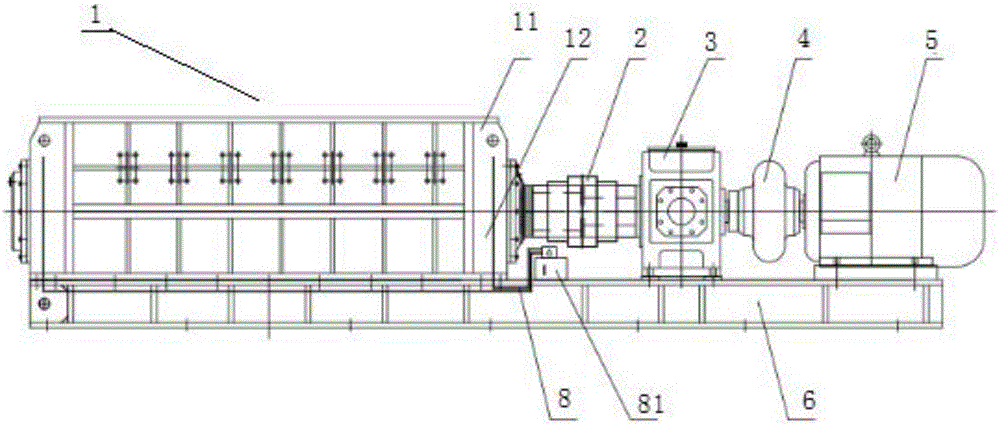

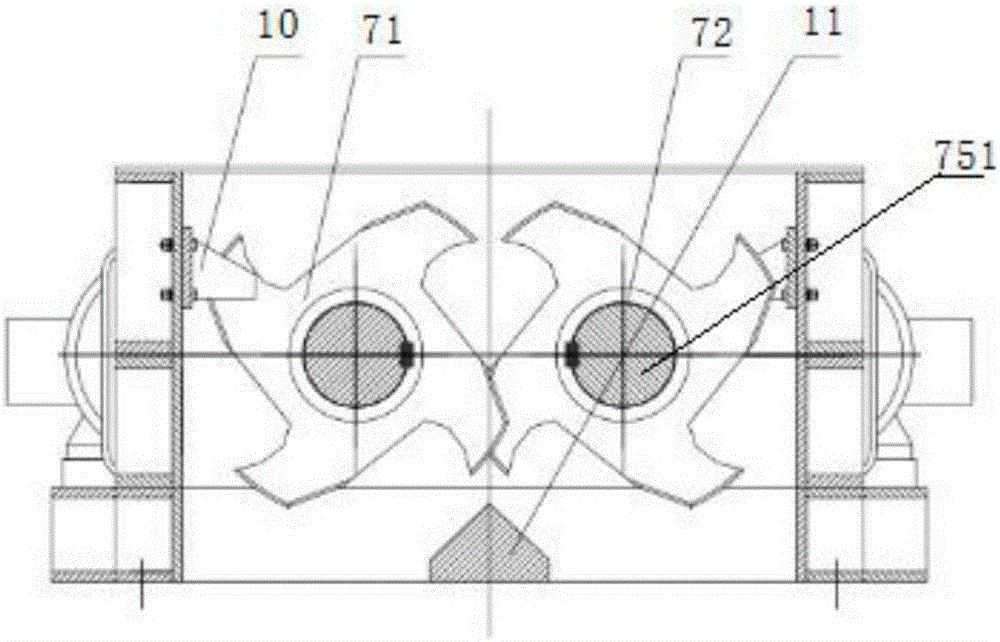

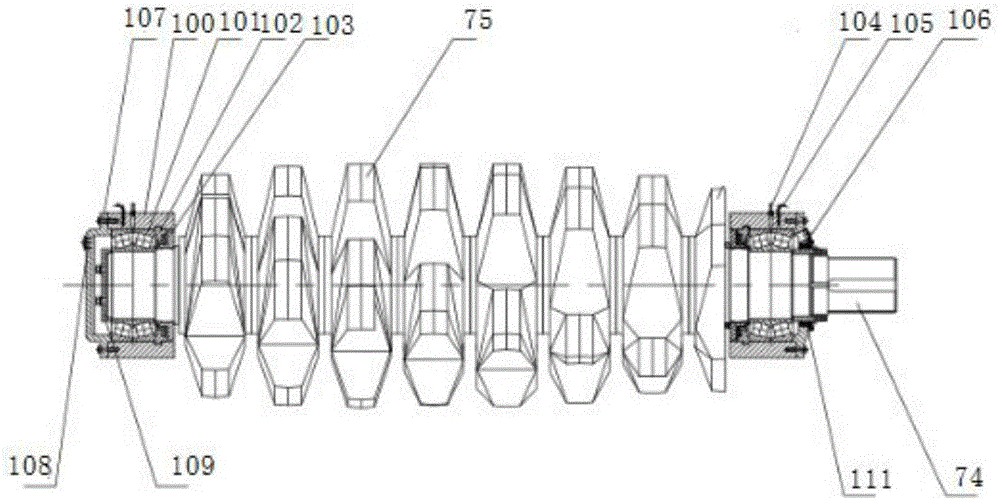

Rotary tooth type crusher

ActiveCN106111273AMeet crushing feed requirementsMeet the feed requirementsGrain treatmentsFluid couplingReducer

The invention provides a rotary tooth type crusher. The rotary tooth type crusher comprises a crushing cavity, a drum-shaped gear coupling, a speed reducer, a hydraulic coupler, a motor and a base, wherein the crushing cavity, the drum-shaped gear coupling, the speed reducer, the hydraulic coupler and the motor are sequentially connected and then are arranged on the base; the crushing cavity comprises an upper crushing cavity body and a lower crushing cavity body; the upper crushing cavity body is arranged on the lower crushing cavity body; and rotary tooth spindles are arranged inside the crushing cavity and comprise the left-handed spindle assembly and the right-handed spindle assembly which are arranged inside the crushing cavity in parallel in an overlapped mode. The main work components are the two parallel rotary tooth spindles comprising the left-handed spindle assembly and the right-handed spindle assembly, the volume compression principle is adopted, multiple supporting points generate force on materials, that is, the materials are crushed through common action of shearing, bending and partial extrusion, and high efficiency and energy conservation are achieved.

Owner:NANTONG ZHENQIANG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com