Low-cost microwave- and millimeter-wave polarized antenna of multi-layer PCB (Printed circuit board) process

A circularly polarized antenna, low-cost technology, applied in the direction of antenna, slot antenna, radiating element structure, etc., can solve the problems of narrow bandwidth, only 0.7%-7%, large size and weight of circularly polarized microstrip antenna , to achieve the effect of small structure size, easy processing, and widening of the axial ratio bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

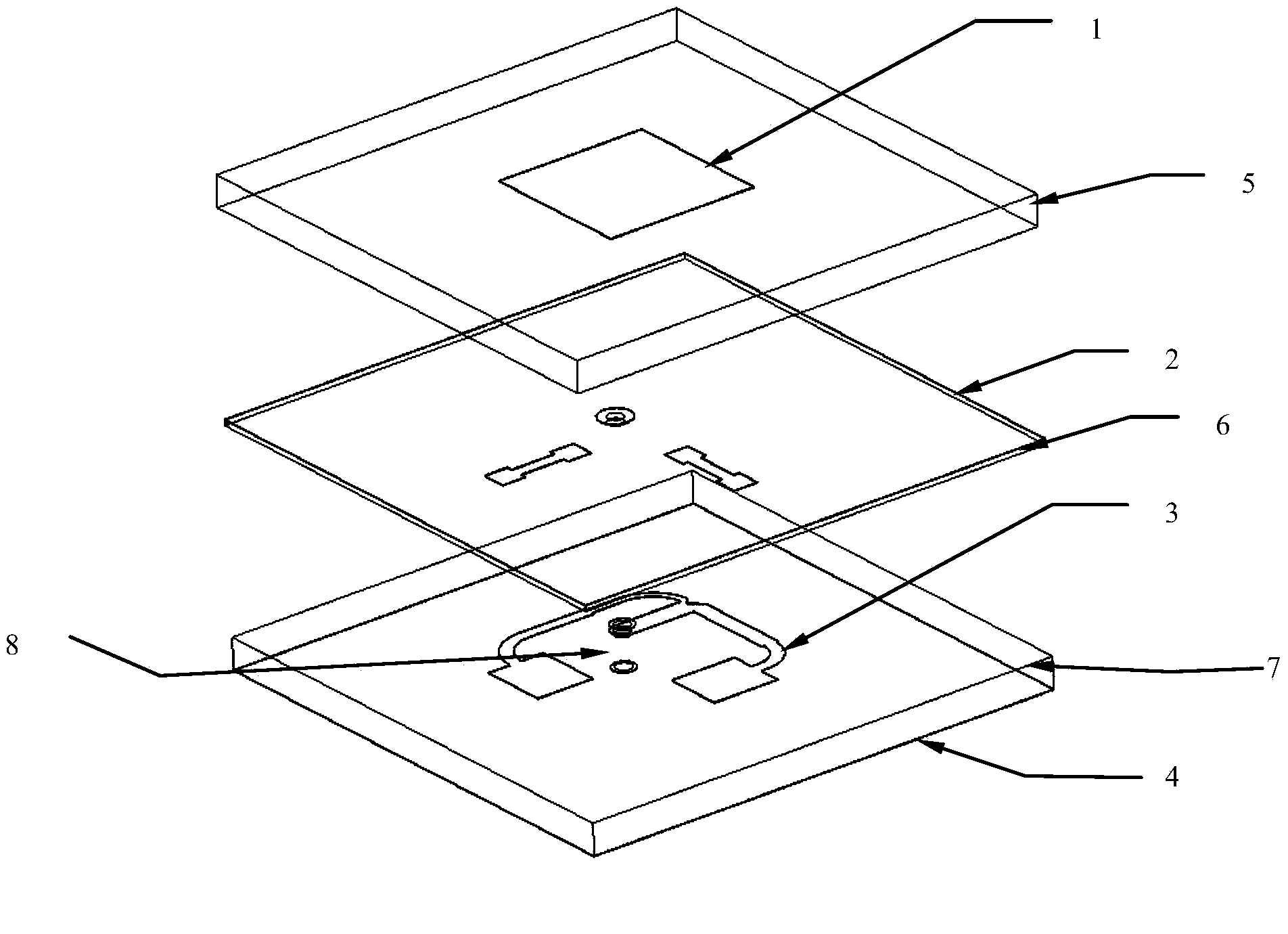

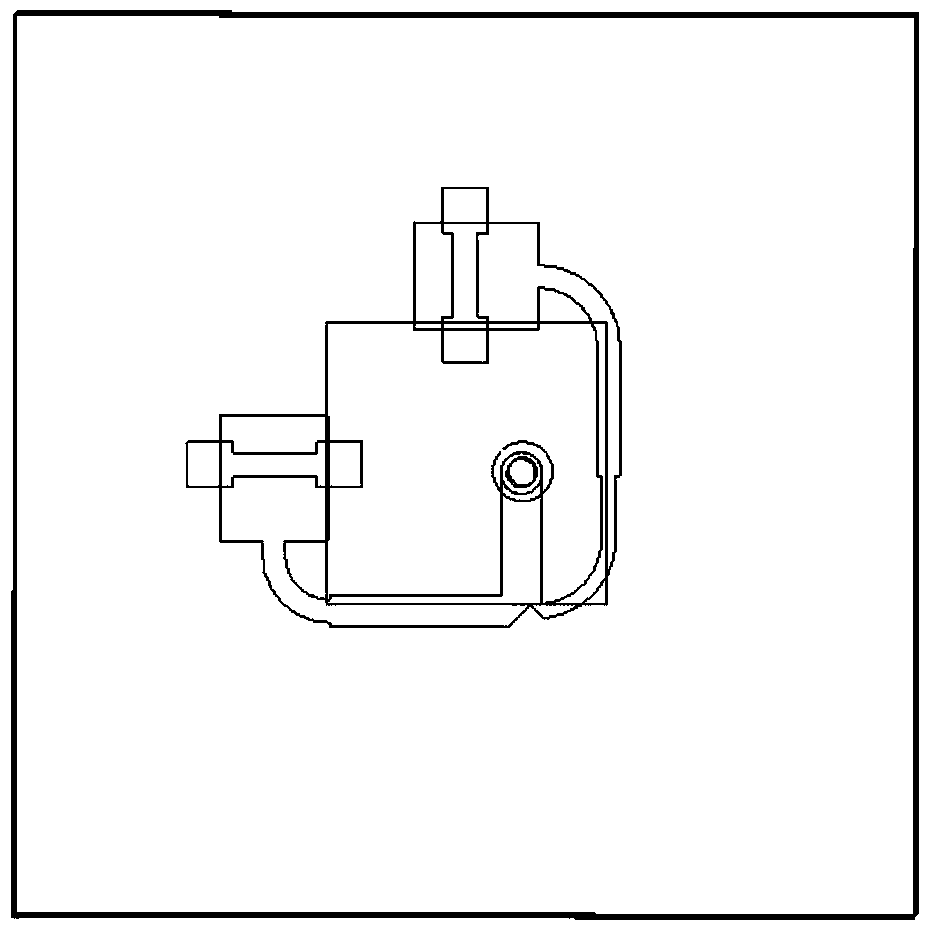

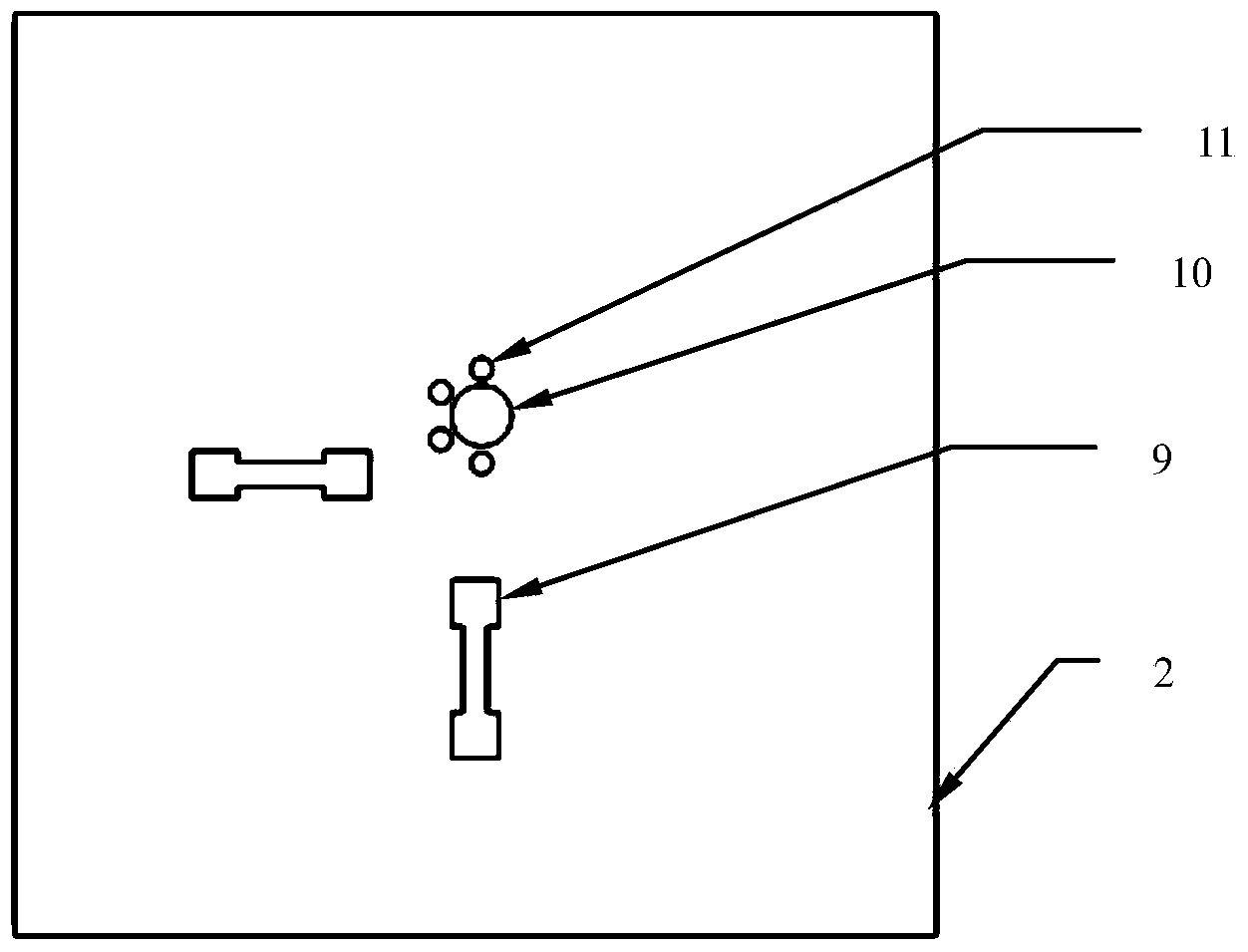

[0026] Such as figure 1 , 2 As shown, the specific multilayer structure of the low-cost microwave and millimeter wave circularly polarized antenna of the multilayer PCB process of the present invention is as follows, a square radiation metal patch 1 and an upper dielectric substrate 5, a metal floor 2 with an H-shaped coupling gap and The middle dielectric substrate 6 , the feed metal plate 3 with a power distribution network, the lower dielectric substrate 7 , and the bottom metal floor 4 . It also includes the grounding metal through hole connecting the metal floor 2 with the H-shaped coupling gap and the bottom metal floor 4, and the coaxial connection between the feed metal plate 3 with the power dividing network and the feed input port on the bottom metal floor 4. Microstrip Transition Structure8.

[0027] The radiation metal patch 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com