Trace precision injection molding glue injection device

A technology of injection molding and glue injection device, which is applied in the field of injection molding, and can solve problems such as difficulty in barrel feeding, difficulty in processing parts, and inability to feed materials, and achieves the effects of small error, small total capacity, and small inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

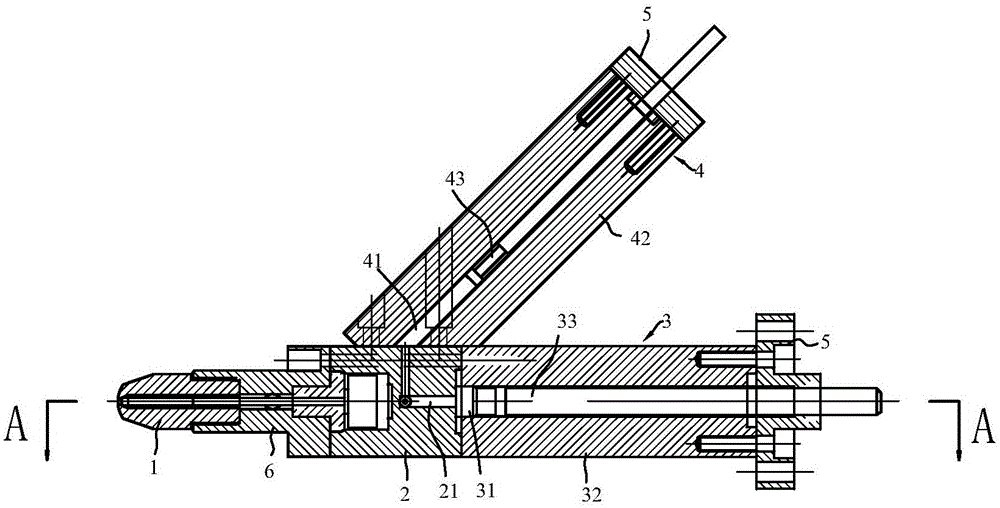

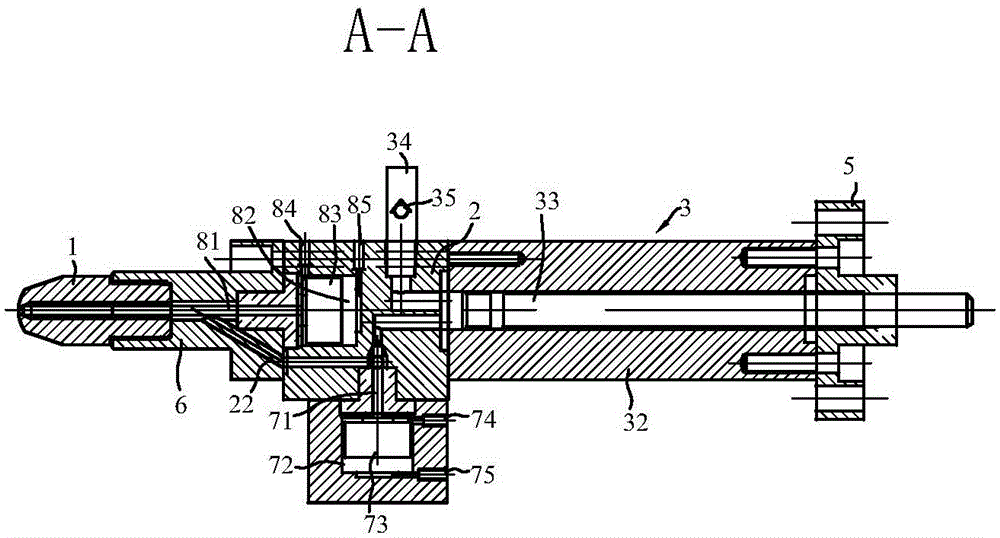

[0018] refer to figure 1 , figure 2 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0019] The invention provides a micro-precision injection molding glue injection device, which includes a nozzle 1, a connecting block 2, a first-stage glue injection barrel 3 and a precision barrel 4, and the first-stage glue injection barrel 3 and the precision barrel 4 are both Fixedly installed on the connecting block 2, the ends of the first-stage glue injection barrel 3 and the precision barrel 4 are equipped with rear flanges 5 . The nozzle 1 is fixedly installed on the front end of the connection block 2 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com