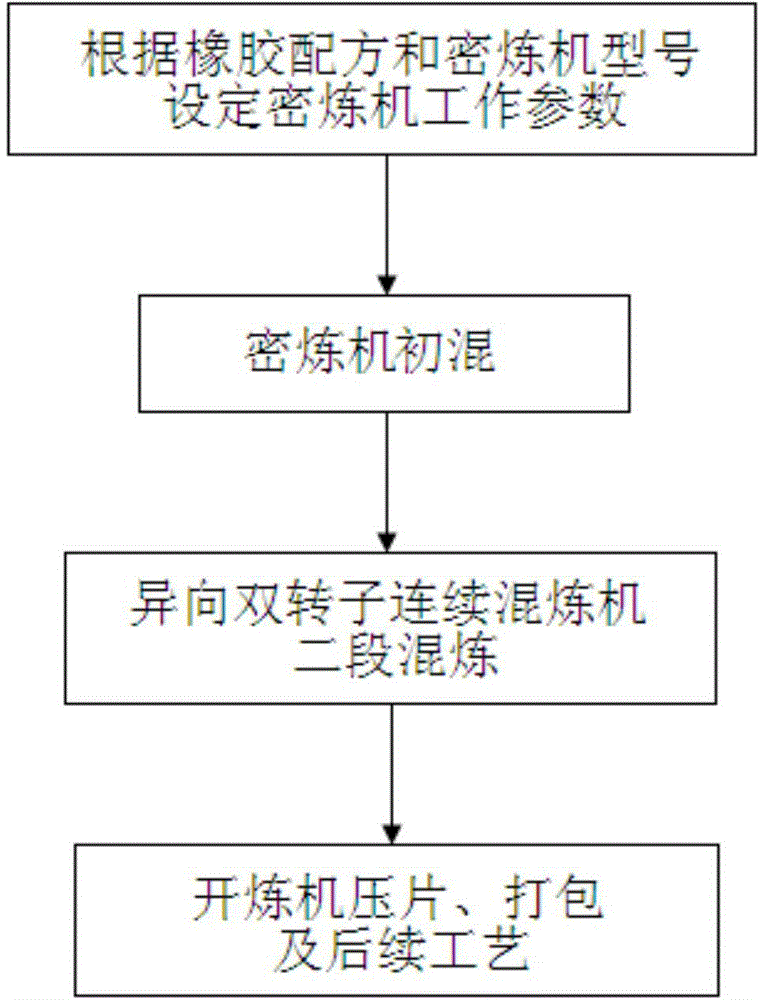

Continuous serial-type rubber mixing method

A tandem, mixing technology, applied in the processing field of rubber molding, can solve the problems of uneven mixing of compounding agent and base rubber, complicated equipment and process, and low quality of rubber materials, so as to avoid uneven mixing and increase Temperature control range, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

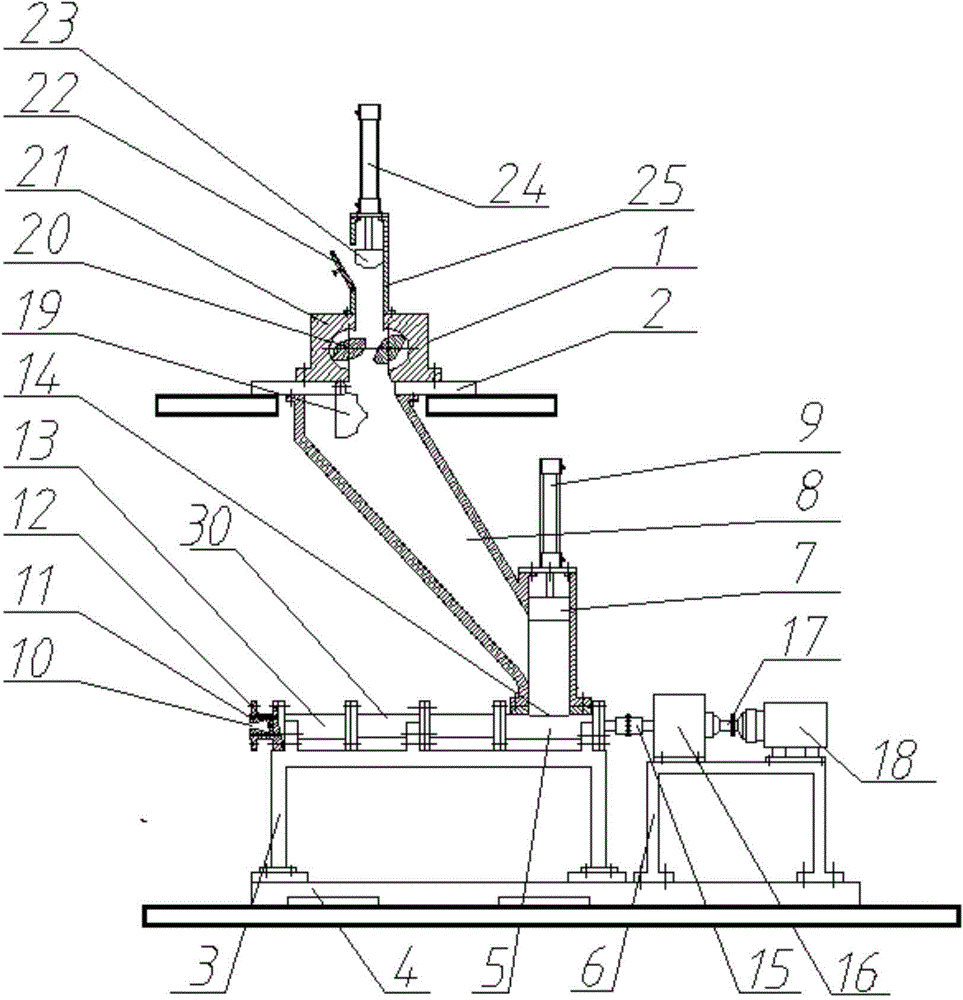

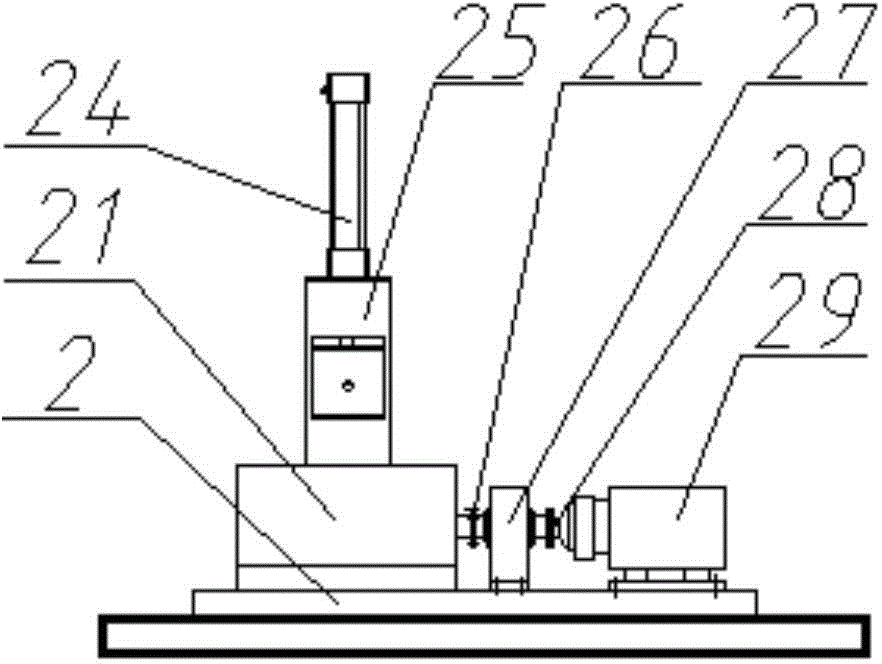

Image

Examples

Embodiment 1

[0022] In this embodiment, the formula of all-steel radial tire tread rubber is taken as an example for illustration. The tandem rubber continuous mixing method involved specifically includes the following process steps:

[0023] (1) Using a filling factor of 65±5%, based on the specific model of the upstream internal mixer 1 and the production formula of the mixed rubber, the mass of various materials is calculated and weighed for later use. The working parameters of the upstream internal mixer 1 are: the rotor speed is 60±15r / min, preferably 65±3r / min, the temperature control is 50±10°C, preferably 45±3°C, and the pressure of the top bolt is 0.6±0.05MPa; the materials include Base glue and compounding agent;

[0024](2) Put the matrix rubber weighed in step (1) into the upstream internal mixer 1 for 40 ± 10s, preferably 35 ± 3s of masticating to form masticated rubber, and then add compounding agents including carbon black N330, zinc oxide , anti-aging agent RD, plasticizer...

Embodiment 2

[0032] In this example, taking the formula of all-steel radial tire tread rubber as an example, the serial rubber continuous mixing method involved in Example 1 is compared with the traditional internal mixer mixing method.

[0033] The specific process steps of the traditional internal mixer mixing method are:

[0034] (1) adopt the filling factor of 65 ± 3%, based on the specific model of the internal mixer and the production formula of the mixed rubber described in Example 1, calculate the quality of various materials and weigh them for later use, set The working parameters of the internal mixer are: the rotor speed is 65±3r / min, the temperature control is 45±3℃, and the pressure of the top bolt is 0.6±0.05MPa;

[0035] (2) Put the natural rubber weighed in the step (1) into the internal mixer and carry out 35 ± 3s masticating, then add carbon black N330, zinc oxide, antioxidant RD, plasticizer A, stearic acid respectively SA for mixing; when the temperature of the mixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com