Manufacturing method of bipolar electrode and battery

A technology of bipolar electrodes and manufacturing methods, applied in bipolar electrodes, electrode manufacturing, active material electrodes, etc., can solve problems such as overvoltage and waste of volume energy density, achieve continuity, avoid overvoltage and volume energy The wasteful effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

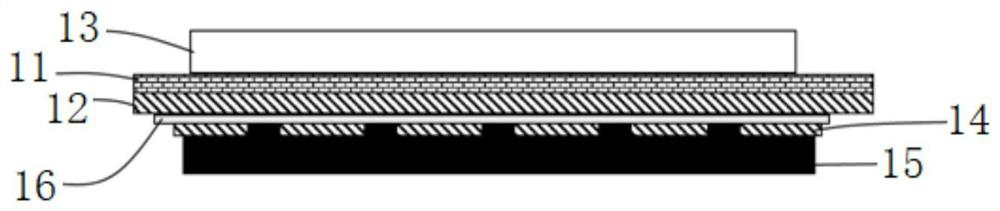

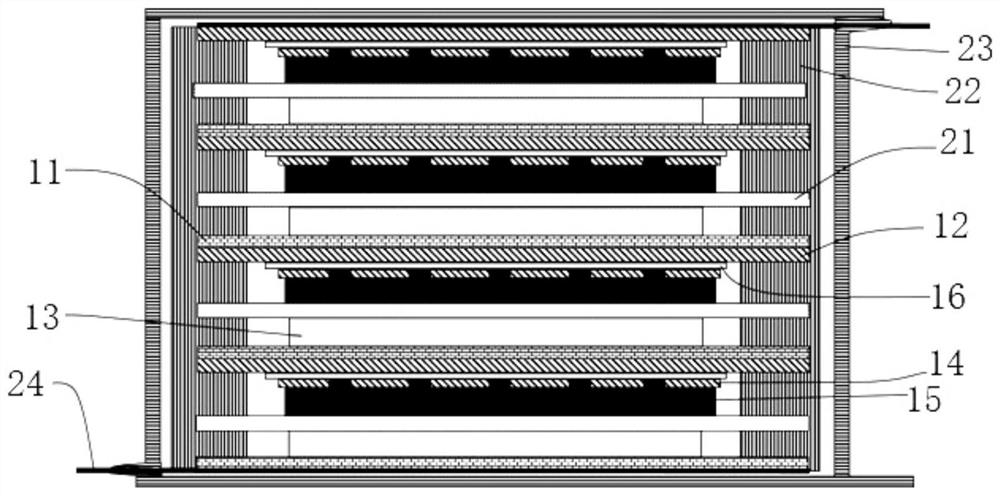

[0025] See figure 1 , a method for making bipolar electrodes, which specifically includes the following steps:

[0026] (1) The copper-aluminum composite tape is used as the bipolar current collector, the thickness of the positive electrode conductive layer 11 aluminum is 10um, the thickness of the negative electrode conductive layer 12 copper is 4.5um, and the positive electrode is coated on the Al side surface of the bipolar current collector. NCM slurry 13 with a mass percentage of 96% active material and a solid content of 73% was dried at 100°C and then rolled, with a compacted density of 3.4g / cm 3 ;

[0027] (2), using a copper mesh as the auxiliary current collector 14, coating one side of the auxiliary current collector 14 with a graphite slurry 15 with a negative active material mass percentage of 95% and a solid content of 53%, and then drying at 100 ° C Rolled after drying, compacted density 1.7g / cm 3 ;

[0028] (3), coat the conductive adhesive layer 16 on the ...

Embodiment 2

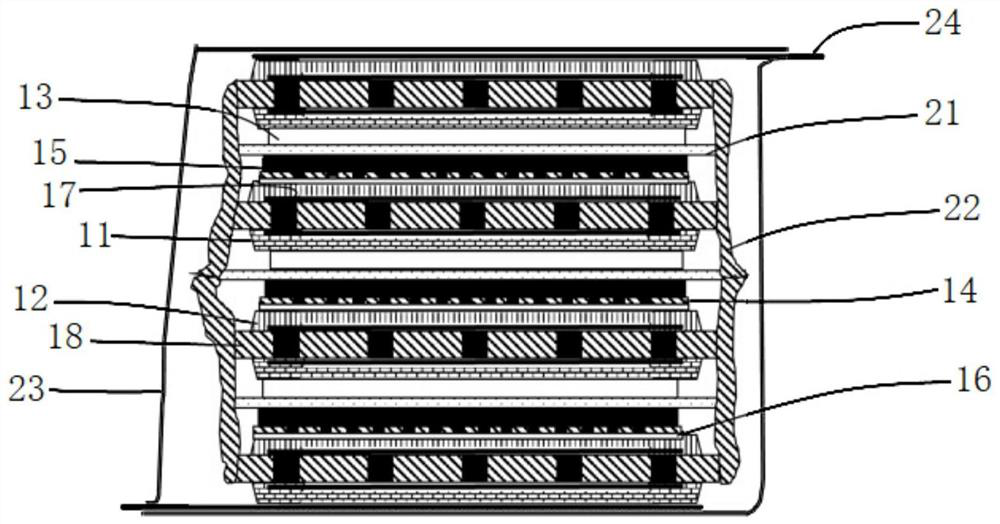

[0032] See image 3 , a method for making bipolar electrodes, which specifically includes the following steps:

[0033] (1) The porous vapor-deposited composite current collector that is conducted by the conductive filling layer is used as a bipolar current collector, wherein 0.5um of conductive carbon black 17 conducts 500nm copper (negative electrode conductive layer 12) and 700nm aluminum (positive electrode conductive layer 11) ), between the negative electrode conductive layer 12 and the positive electrode conductive layer 11 is a porous support layer 18, and the Al side surface of the bipolar current collector is coated with a positive electrode active material mass percentage of 96% and a solid content of 73% NCM slurry 13 , and then dried at 100°C and then rolled, with a compacted density of 3.4g / cm 3 ;

[0034] (2), using a copper mesh as the auxiliary current collector 14, coating one side of the auxiliary current collector 14 with a graphite slurry 15 with a negat...

Embodiment 3

[0038] See figure 1 , a method for making bipolar electrodes, which specifically includes the following steps:

[0039] (1) The copper-aluminum composite tape is used as the bipolar current collector, the thickness of the positive electrode conductive layer 11 aluminum is 10um, the thickness of the negative electrode conductive layer 12 copper is 4.5um, and the positive electrode is coated on the Al side surface of the bipolar current collector. NCM slurry 13 with a mass percentage of 96% active material and a solid content of 73% was dried at 100°C and then rolled, with a compacted density of 3.4g / cm3 ;

[0040] (2) Using porous PET as the auxiliary current collector 14, coating one side of the auxiliary current collector 14 with a graphite slurry 15 with a negative active material mass percentage of 95% and a solid content of 53%, and then baked at 100°C Rolled after drying, compacted density 1.7g / cm 3 ;

[0041] (3), coat the conductive adhesive layer 16 on the Cu side s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com