Sliding block pin device for die-casting

A pin and slider technology, which is applied in the field of die-casting slider pin devices, can solve problems such as unfavorable molding, difficult control, and increased costs, and achieve the effect of achieving continuity and reducing the probability of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

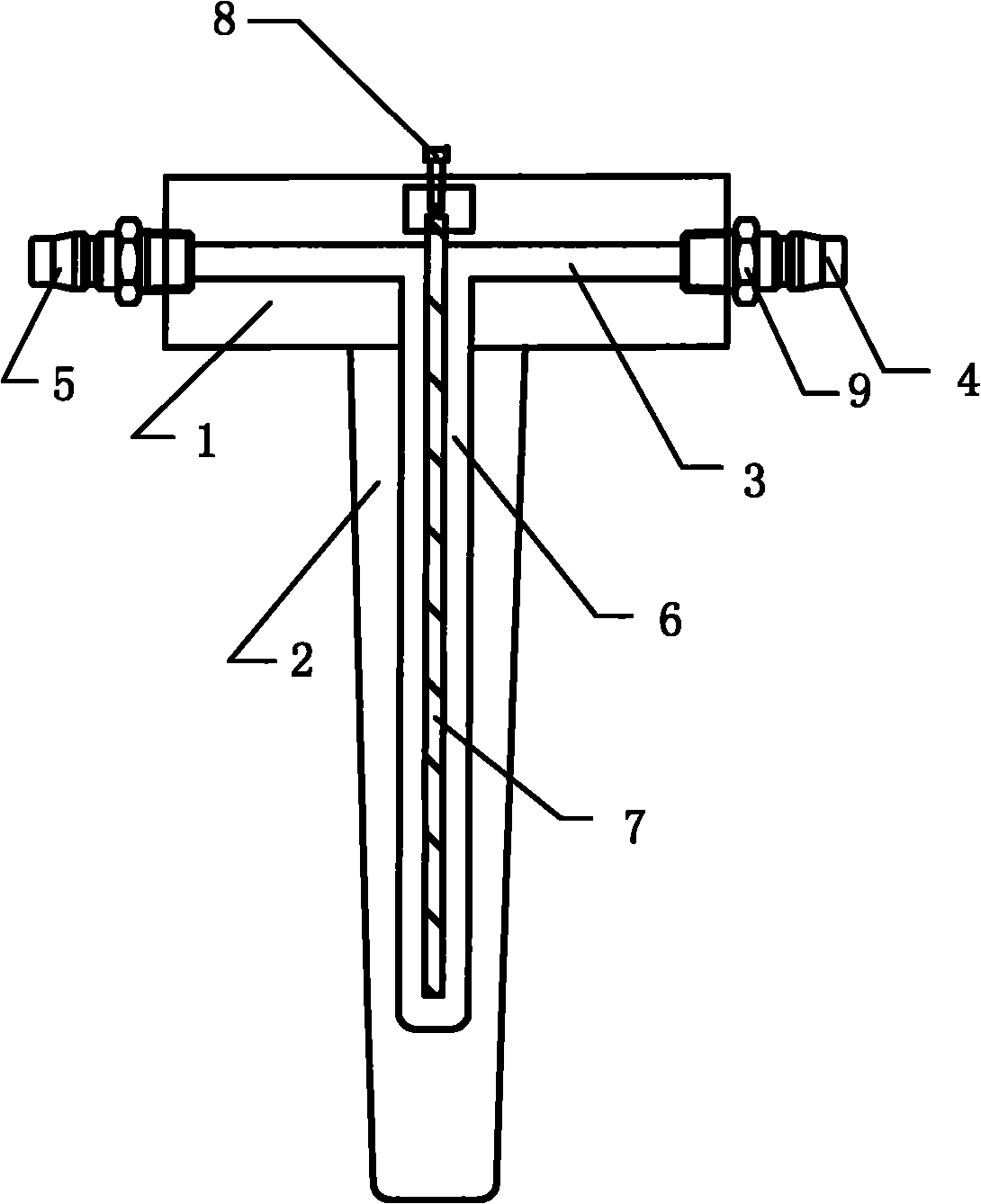

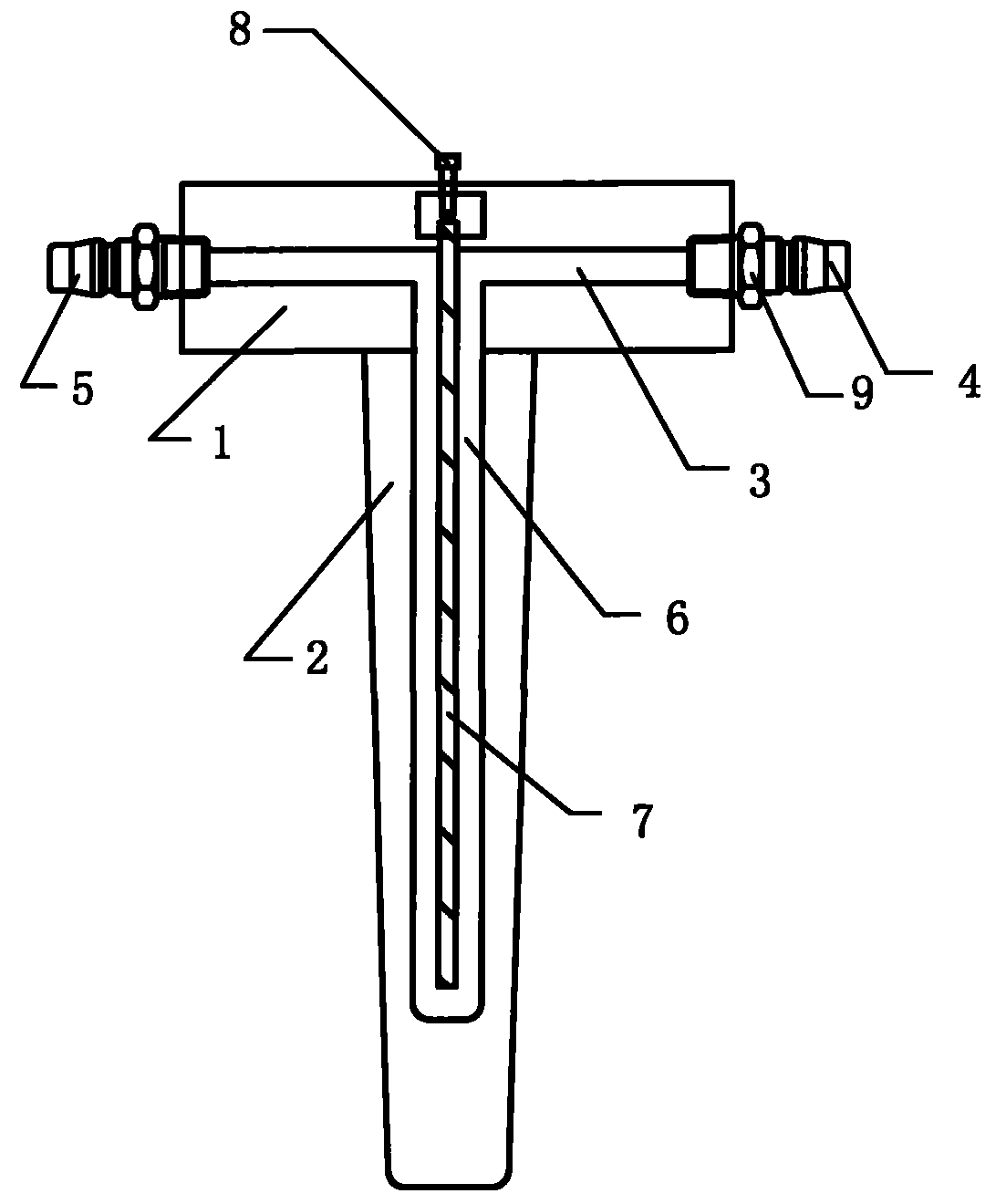

[0020] Such as figure 1 The shown die-casting slider pin 2 device includes an insert 1, and the pin 2 is arranged on the insert 1. Its special feature is that the main water channel 3 is arranged inside the insert 1, and the water channel Water outlet 4 and water inlet 5 are respectively provided at both ends of the pin 2; auxiliary water channel 6 is provided in the pin 2, and the main water channel 3 is connected.

[0021] Looking further, in order to better control the water flow in the main waterway channel 3 and the auxiliary waterway channel 6, that is to control the water inlet and outlet methods, so that the water flow can be fully and smoothly in the main waterway channel 3 and the auxiliary waterway channel 6 orderly flow, the auxiliary water channel 6 is provided with a water barrier 7, one end of the water barrier 7 is fixed on the insert 1, and the other end is not in contact with the inner wall of the auxiliary water channel 6.

[0022] At the same time, in view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com