Ceramic shell structure member and preparation method thereof, and mobile phone

A technology for ceramic shells and structural parts, which is applied to telephone structures, accessories, electrical components, etc., and can solve the problems of ceramic shells being brittle and easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The second aspect of the embodiment of the present invention provides a method for preparing a ceramic shell structure, including the following steps: taking ceramic powder, preparing ceramic slurry, drying, granulating, and filling the granulated particles into the ceramic shell The corresponding groove of the ceramic flat plate and the corresponding groove of the ceramic protruding part of the body mold are molded to obtain a ceramic embryo, and then sintered to obtain a ceramic shell. A ceramic protruding part, the surface of the ceramic protruding part is provided with holes with a diameter of 1-10 mm, and then holes with a diameter of 1-1000 μm are formed on the surface of the ceramic shell, and the raw material of the frame and the ceramic shell with the holes provided are taken, and passed through The ceramic shell structure is made by integral molding, and the ceramic protruding part is sleeved in the concave part of the frame so that the ceramic plate is closely...

Embodiment 1

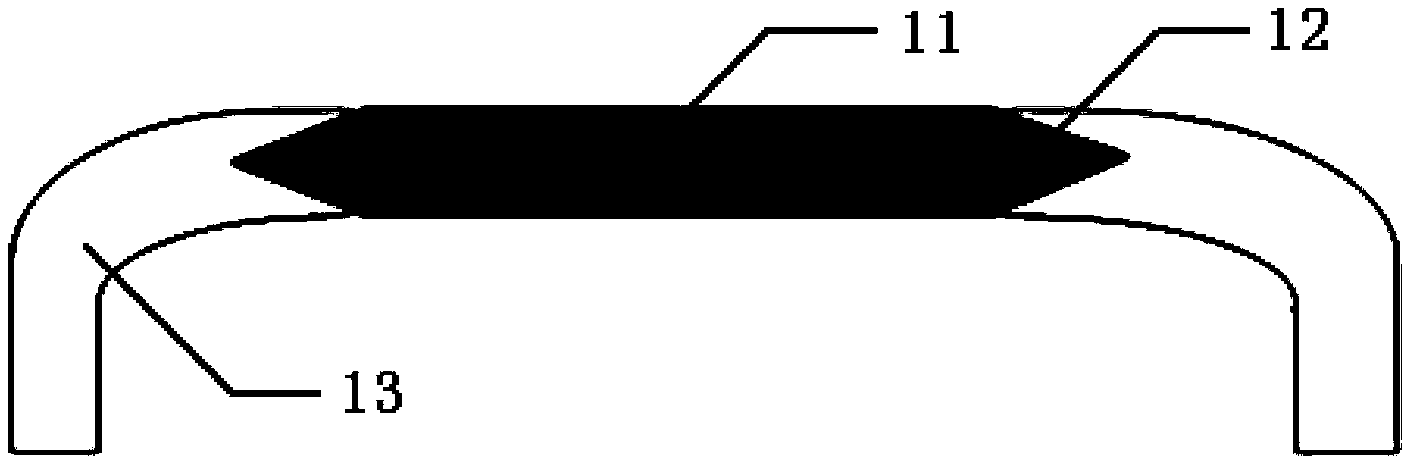

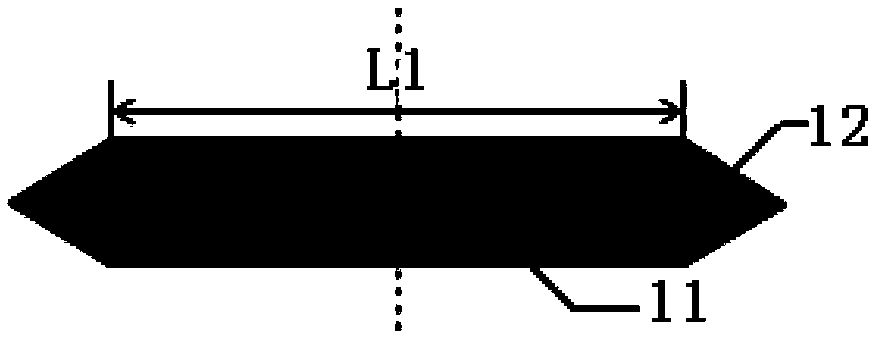

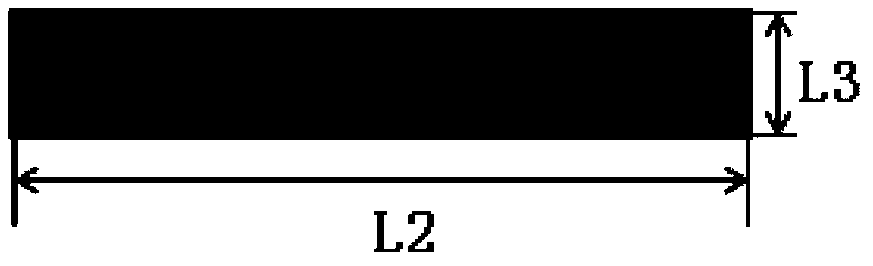

[0059] A ceramic shell structural part, comprising a ceramic shell and a frame. figure 1 It is a structural schematic diagram of the ceramic shell structure prepared in Example 1 of the present invention, figure 2 It is the front view of the ceramic housing made in Example 1 of the present invention, image 3 It is the right side view of the ceramic shell made in Example 1 of the present invention, Figure 4 It is a top view of the ceramic shell manufactured in Example 1 of the present invention. combine Figure 1~4 It can be seen that the ceramic housing includes a ceramic plate 11 and two ceramic protrusions 12 protruding outward from two opposite sides of the ceramic plate 11 . The ceramic plate 11 is a rectangular plate with a length L1 equal to 60 mm, a width L2 equal to 100 mm, and a height L3 equal to 0.8 mm. The two ceramic protruding parts 12 are three-dimensional structures with sharp angles, and the lengths L4 and L5 in the L1 direction of the ceramic plate 11 ...

Embodiment 2

[0061] A ceramic shell structural part, comprising a ceramic shell and a frame. Figure 5 It is a schematic diagram of the structure of the ceramic shell structure prepared in Example 2 of the present invention, Image 6 It is the front view of the ceramic housing made in Example 2 of the present invention, Figure 7 It is the right side view of the ceramic housing made in Example 2 of the present invention, Figure 8 It is a top view of the ceramic shell prepared in Example 2 of the present invention. combine Figure 5-8 It can be seen that the ceramic housing includes a ceramic plate 21 and 10 ceramic protrusions 22 protruding symmetrically from two opposite sides of the ceramic plate 21 , and each side is provided with 5 independent ceramic protrusions 22 . The ceramic plate 21 is a rectangular plate with a length L1' equal to 60mm, a width L2' equal to 100mm, and a height L3' equal to 0.8mm. The 10 ceramic protrusions 22 are all pointed three-dimensional structures, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com