Rotary vacuum heat treatment device

A vacuum heat treatment and rotary technology, which is applied in pressure vessels/vacuum vessels, chemical/physical/physicochemical mobile reactors, pressure vessels used in chemical processes, etc., can solve problems such as air leakage and difficult design of vacuum sealing structures , to achieve the effect of continuous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

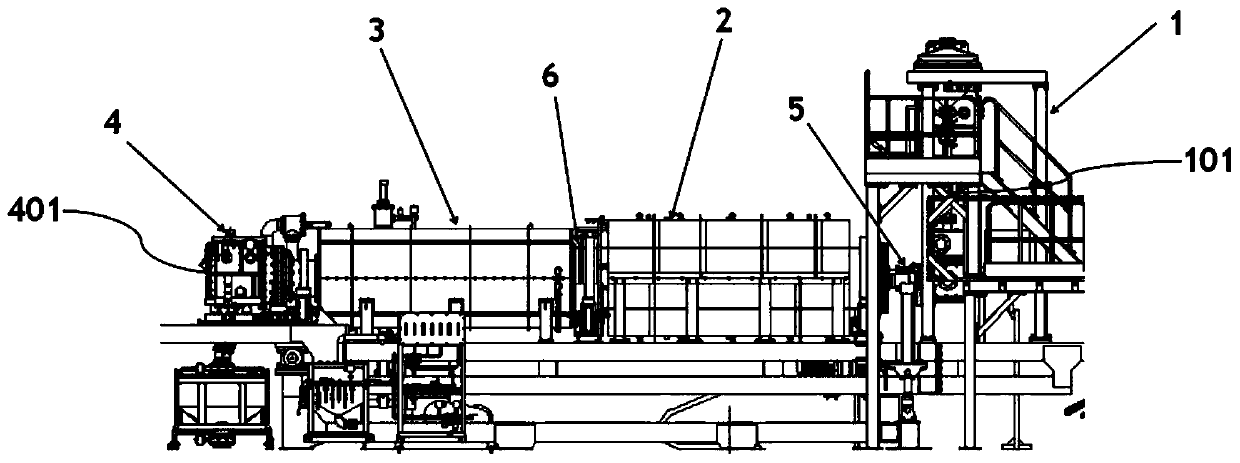

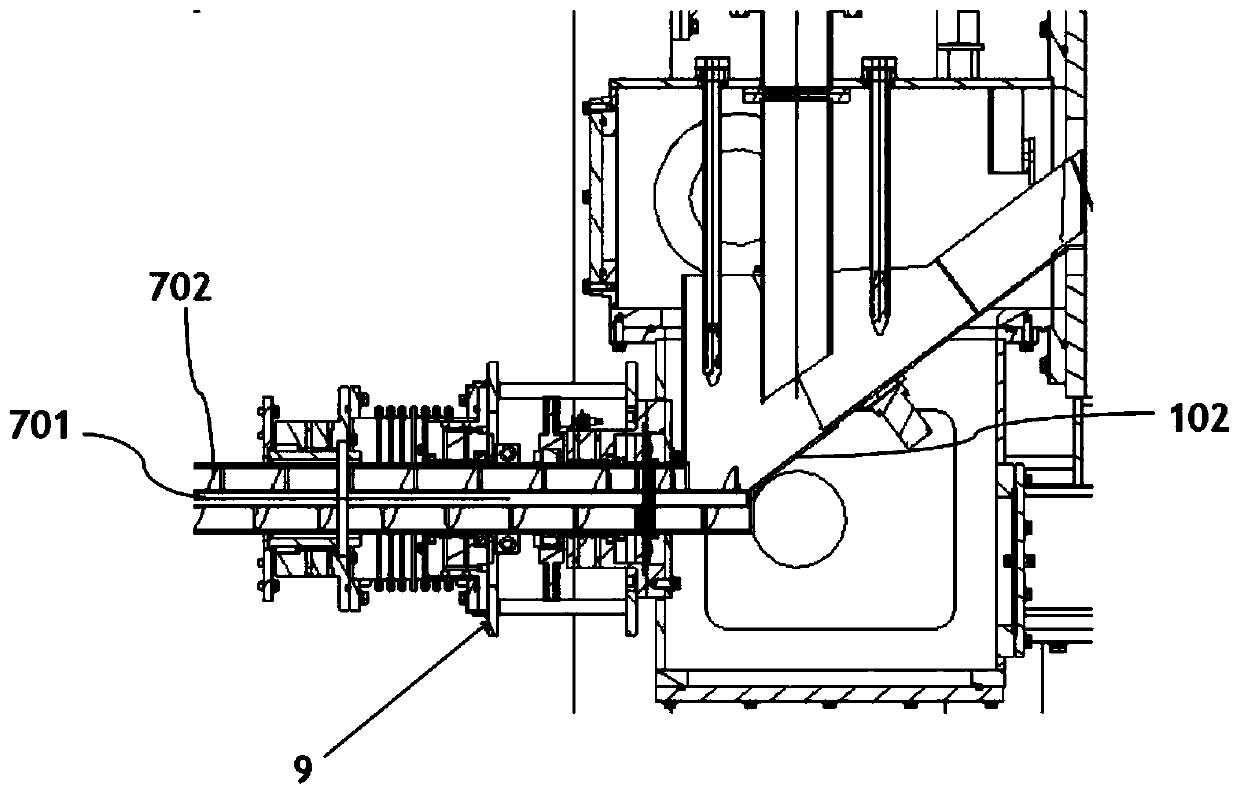

[0038] like figure 1 As shown, a rotary vacuum heat treatment device includes a feeding chamber 1, a rotating heating cylinder 2, a rotating cooling cylinder 3 and a discharge chamber 4; A vacuum butterfly valve; the rotating heating cylinder 2 is connected with the feeding cylinder 101 through the screw feeding shaft 5, and the material conveying mechanism 7 is arranged inside the rotating heating cylinder 2; the rotating cooling cylinder 3 is connected with the rotating heating cylinder 2 through the flange 6, and the rotating Another material conveying mechanism 7 is arranged in the cooling cylinder 3; the discharge chamber 4 is connected with the rotating cooling cylinder 3, and the discharge chamber 4 includes a discharge cylinder 401 and a second vacuum set at the outlet of the discharge cylinder 401. Butterfly valve.

[0039] A rotary vacuum heat treatment device according to the embodiment of the present invention, by connecting the feeding chamber 1, the rotating hea...

Embodiment 2

[0051] A rotary vacuum heat treatment device provided with reference to Example 1 provided with reference to Example 1 is different in that, as Figure 4 As shown, the material conveying mechanism 7 includes a rotating thread groove 703 arranged on the inner wall of the rotating heating cylinder 2 or the rotating cooling cylinder 3, and the rotating thread groove 703 is used for forward or reverse rotation of the rotating heating cylinder 2 or the rotating cooling cylinder 3 Next, the material in the rotating heating cylinder 2 or the rotating cooling cylinder 3 is transferred between the end near the feeding chamber 1 and the end near the discharging chamber 2.

[0052] When the material to be processed is lumpy, if the material is conveyed by rotating blades, the material is easily stuck between the bushing of the screw feed shaft and the screw blade during the transfer process, and the screw feed shaft will stop rotating at this time. In order to eliminate this phenomenon, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com