Preparation method of uniformly distributed ink for color printing

A technology for color printing and uniform distribution, applied in mixing methods, chemical instruments and methods, mixers with rotary stirring devices, etc. , Affect the ink color and other problems, to ensure the color uniformity, avoid uneven mixing, ensure uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

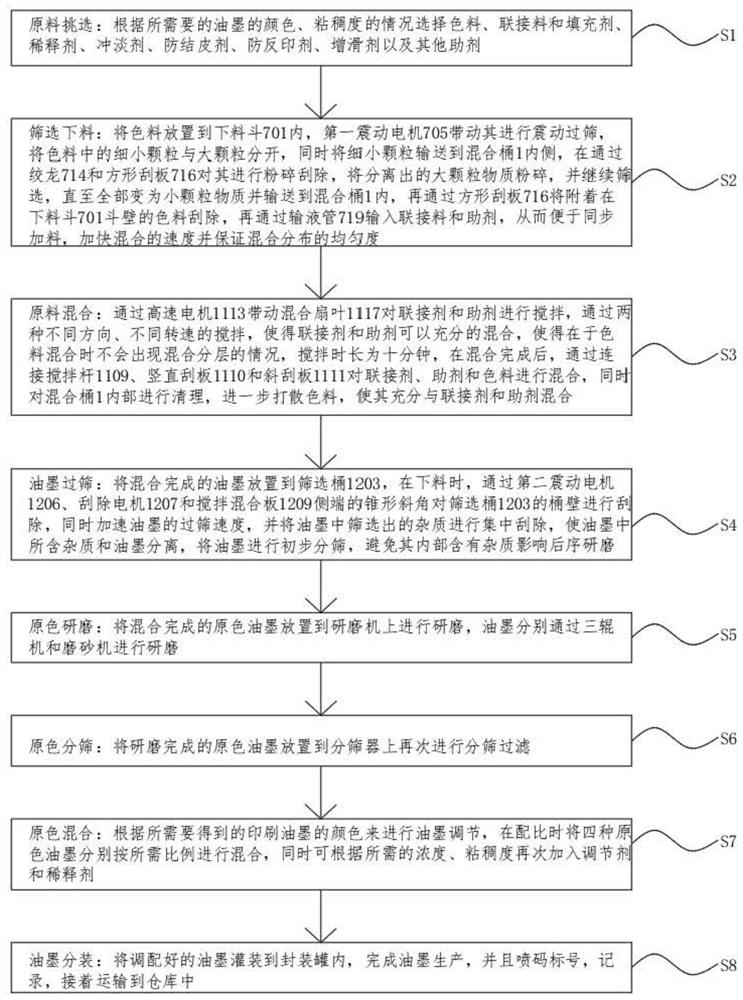

[0047] Embodiment 1: as figure 1 As shown, the present invention provides the technical scheme of the ink preparation method for uniformly distributed color printing, a method for preparing the ink for uniformly distributed color printing, comprising the steps of:

[0048] S1: Selection of raw materials: Select colorants, binders and fillers, diluents, thinners, anti-skinning agents, anti-offset agents, slip agents and other additives according to the color and viscosity of the ink required. agent;

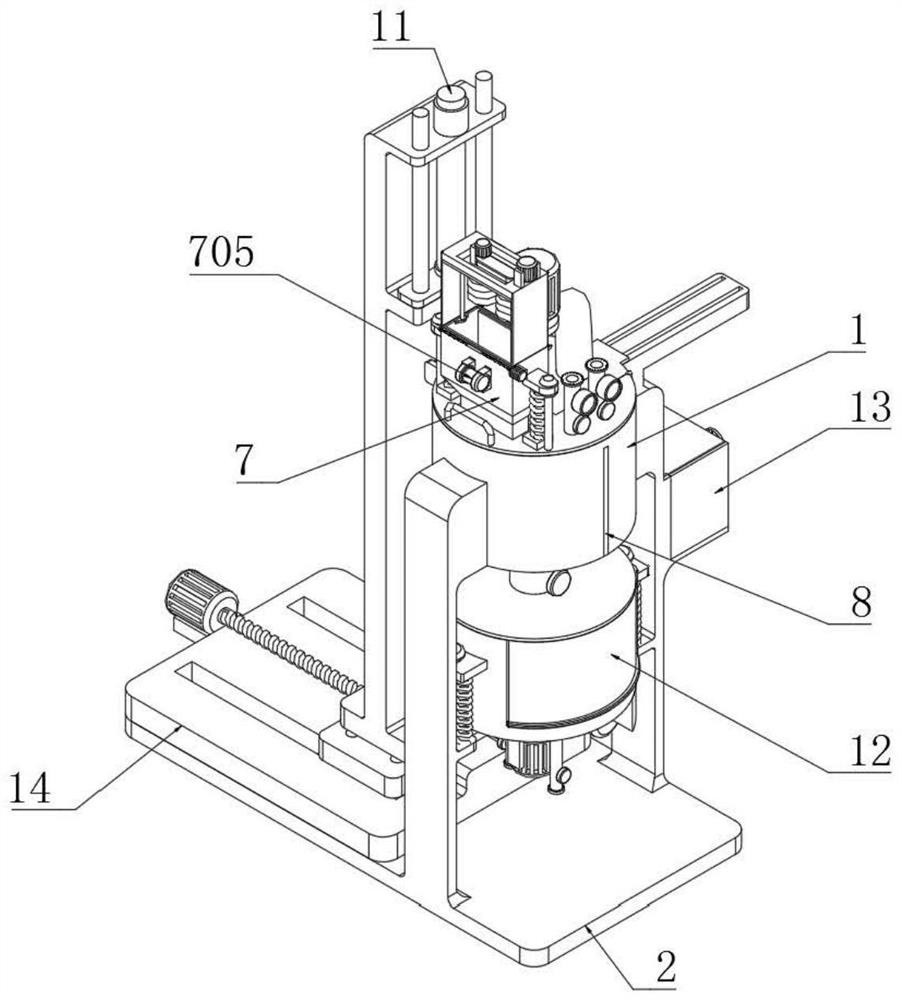

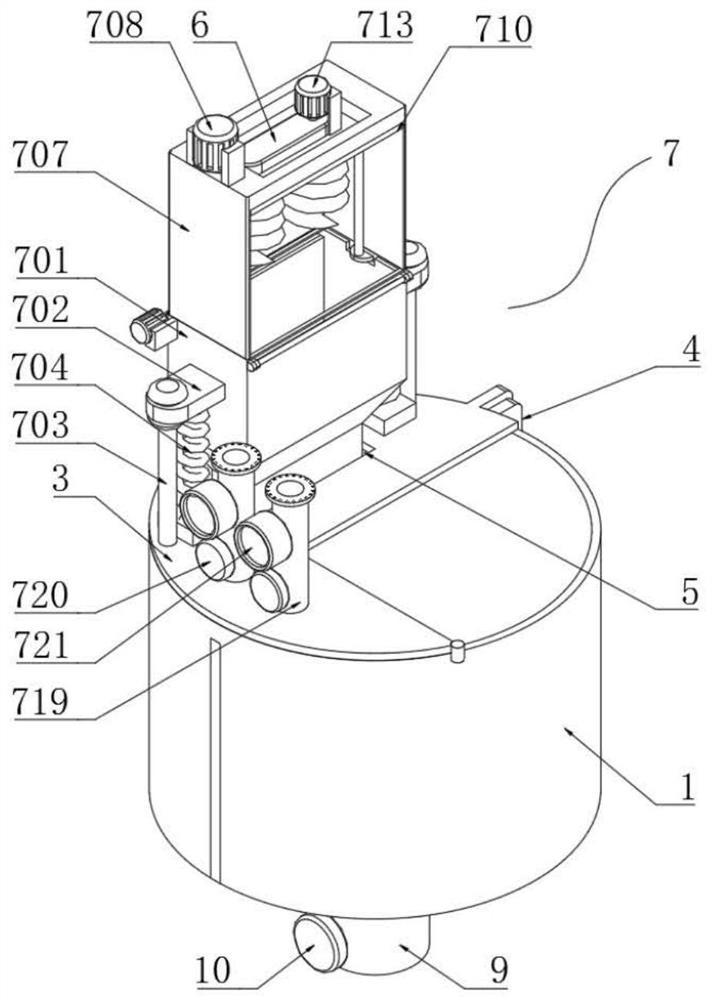

[0049] S2: Screening and discharging: put the color material in the lower hopper 701, and the first vibration motor 705 drives it to vibrate and sieve, separate the fine particles from the large particles in the color material, and transport the fine particles to the inside of the mixing tank 1 at the same time After crushing and scraping it through the auger 714 and the square scraper 716, the separated large particles are crushed, and continue to screen until all of them become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com