Patents

Literature

73results about How to "Solve feeding difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/carbon black thermoplastic resin master batch with high dispersibility and preparation method thereof

The invention discloses a graphene / carbon black thermoplastic resin master batch with high dispersibility and a preparation method thereof. The graphene / carbon black compound in the master batch is formed in an electrostatic self-assembly manner, and comprises 10-50% of graphene, 5-20% of carbon black, 0.5-10% of surfactant, 10-65% of carrier resin and 2-10% of assistant. The preparation method comprises the following steps: (1) compounding and dispersing graphene by adopting the surfactant to control the positive electricity of the graphene surface; (2) forming a stable graphene / carbon black compound from the modified graphene and carbon black with positive electricity through electrostatic incorporation in a self-assembly manner; (3) preparing the graphene / carbon black thermoplastic resin master batch with high dispersibility by matching with a solution blended process, a melt-blending method and an in-situ polymerization method; (4) adding the assistant to extrude and pelletize, so as to prepare the graphene / carbon black / thermoplastic resin master batch particles after processing the master batch. By adopting the obtained master batch, the problems of difficult charging of graphene powder, uneven dispersion, dust pollution, unstable product performance and the like are solved.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

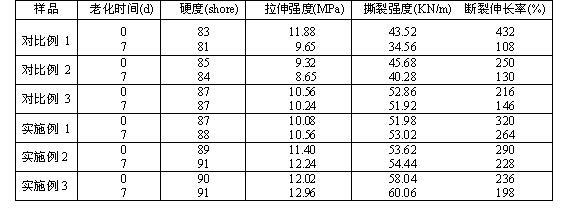

High-performance EPDM (ethylene-propylene-diene monomer)/PPTA (poly (p-phenylene terephthalamide))-pulp composite material and preparation method thereof

The invention relates to the technical field of polymer materials, in particular to a high-performance EPDM (ethylene-propylene-diene monomer) / PPTA (poly (p-phenylene terephthalamide))-pulp composite material and a preparation method thereof. The composite material takes EPDM as a cross-linked elastomer of a base material, an aramid pulp composite matrix containing zinc methacrylate with appropriate amount is added in the base material for improving mechanical properties and thermal aging performance of vulcanized rubber, and the EPDM / PPTA-pulp composite material comprises the following raw materials by weight percent: 50%-80% of ethylene-propylene-diene rubber, 10-30% of the aramid pulp composite matrix, 10%-30% of inorganic filler, 2%-6% of vulcanizing agent, 0.5%-1% of anti-aging agentand 1%-2% of promoter. The prepared high-performance EPDM / PPTA-pulp composite material not only has high strength and high hardness of the traditional short fiber-reinforced composite material, but also has the characteristic that the mechanical properties are not reduced, but even improved after high-temperature aging, and the range of applications of the EPDM / PPTA-pulp composite material can begreatly expanded.

Owner:溧阳常大技术转移中心有限公司

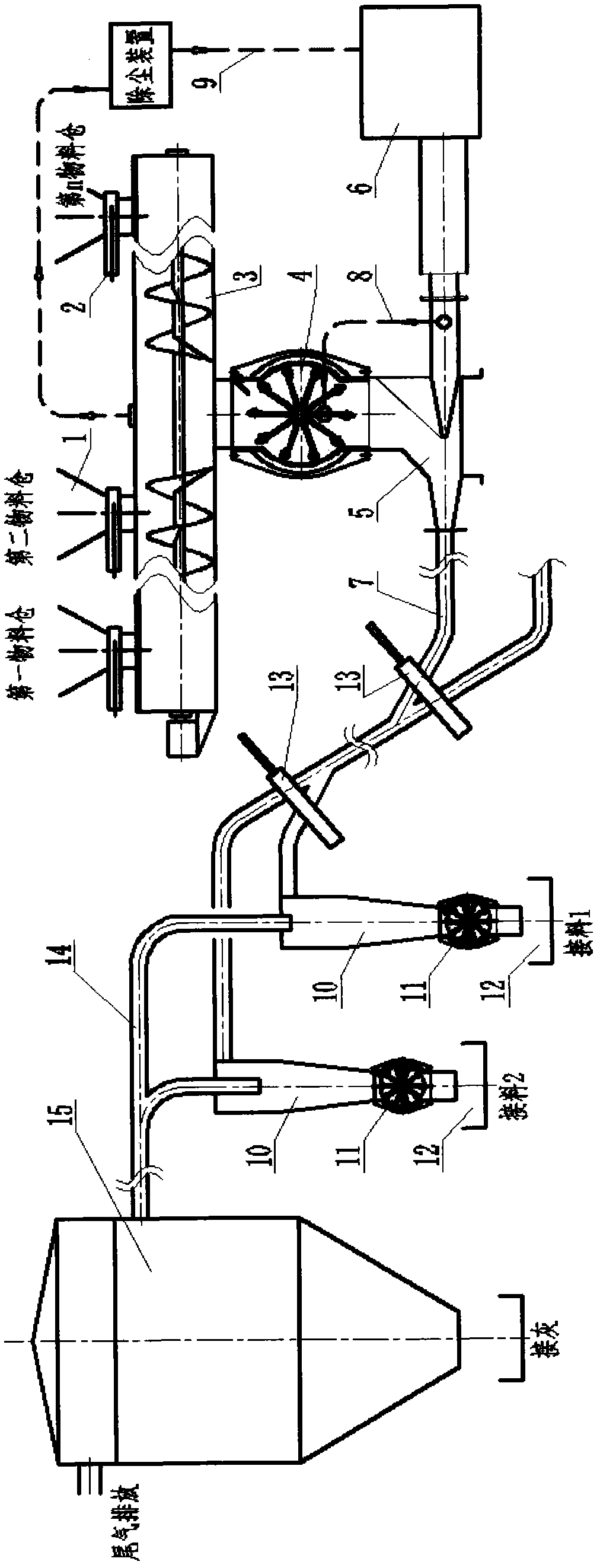

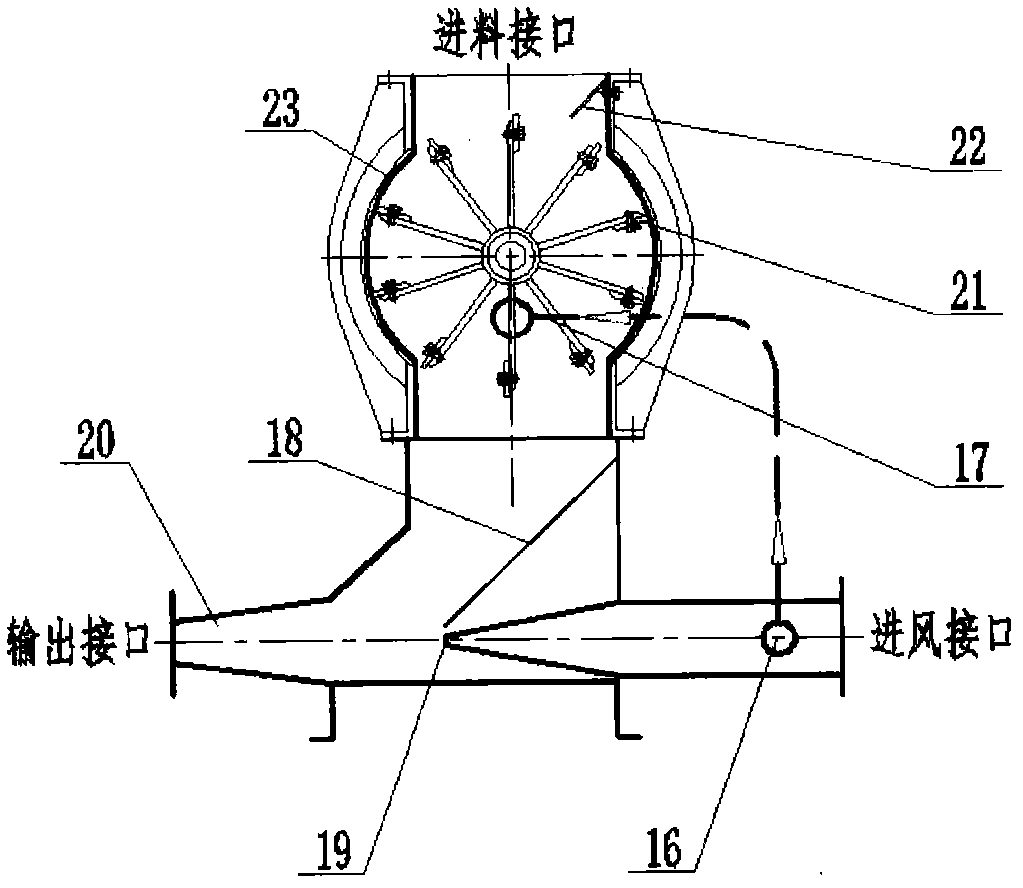

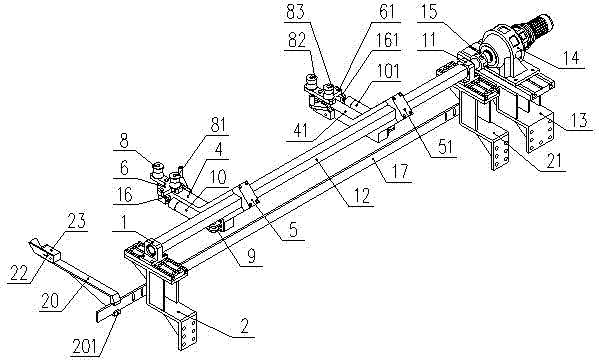

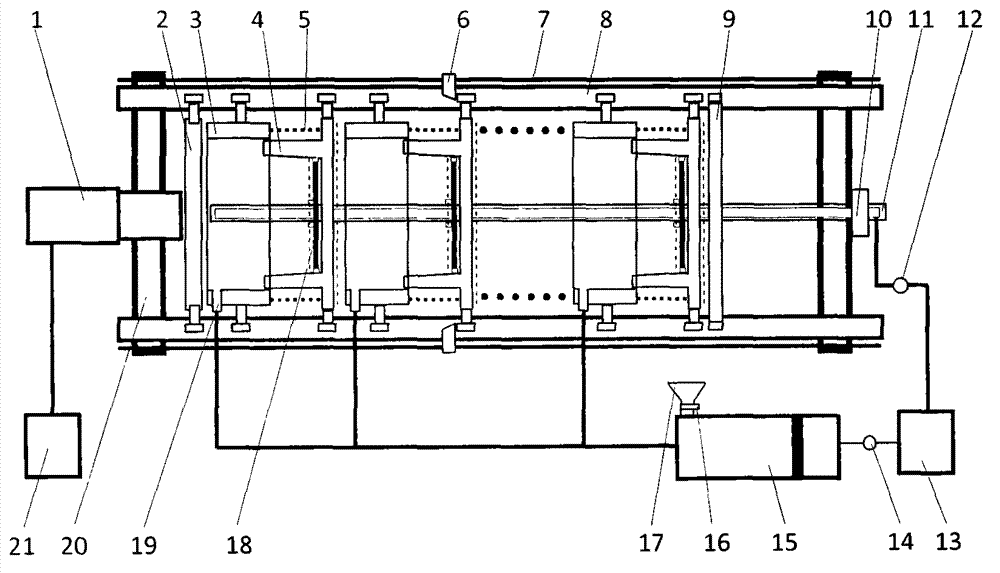

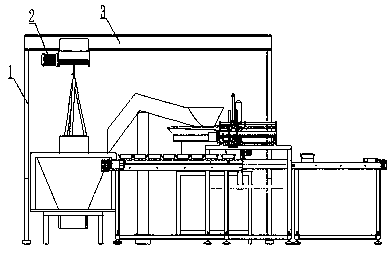

Biomass micro-positive-pressure pneumatic transmission system

InactiveCN103287857ASolve feeding difficultiesSmooth feedingBulk conveyorsHigh concentrationAutomatic control

The invention discloses a biomass micro-positive-pressure pneumatic transmission system which comprises a feeding system, a fan, a conveying pipeline system, a discharging system, a tail gas treatment system and an automatic control system, wherein the feeding system comprises a quantitative feeding device, a collecting device, a positive-pressure air sealing device, an accelerator, an air guide pipe and a return air treatment pipeline; the conveying pipeline system comprises a straight pipeline, a connecting flange and a plurality of quick-operating doors distributed on the pipeline as well as a transparent observation window. The biomass micro-positive-pressure pneumatic transmission system has the advantages that smooth feeding with higher concentration ratio can be achieved, the power consumption is low, the service life of the air sealing device is prolonged, the applicability and the pipeline durability of the conveying system are improved, the convenience is provided for pipeline smoothening and repairing, the environmental pollution can be avoided, and the automation level is high.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

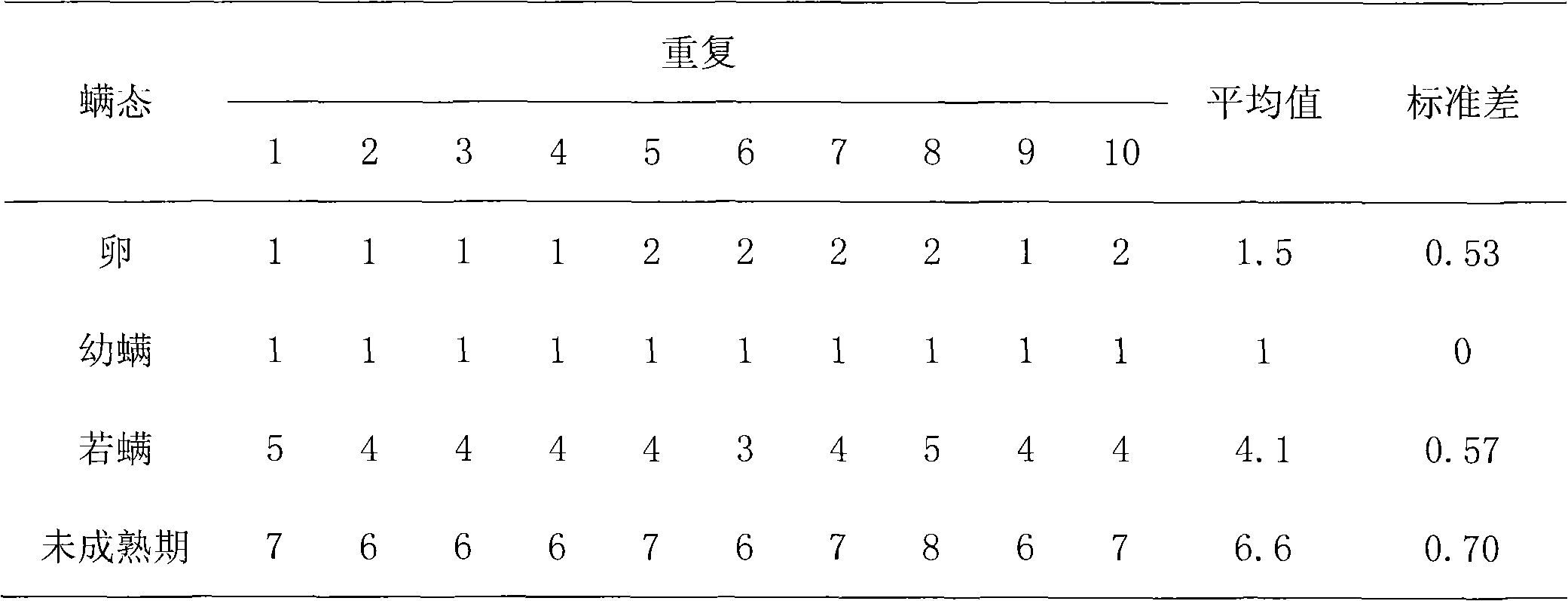

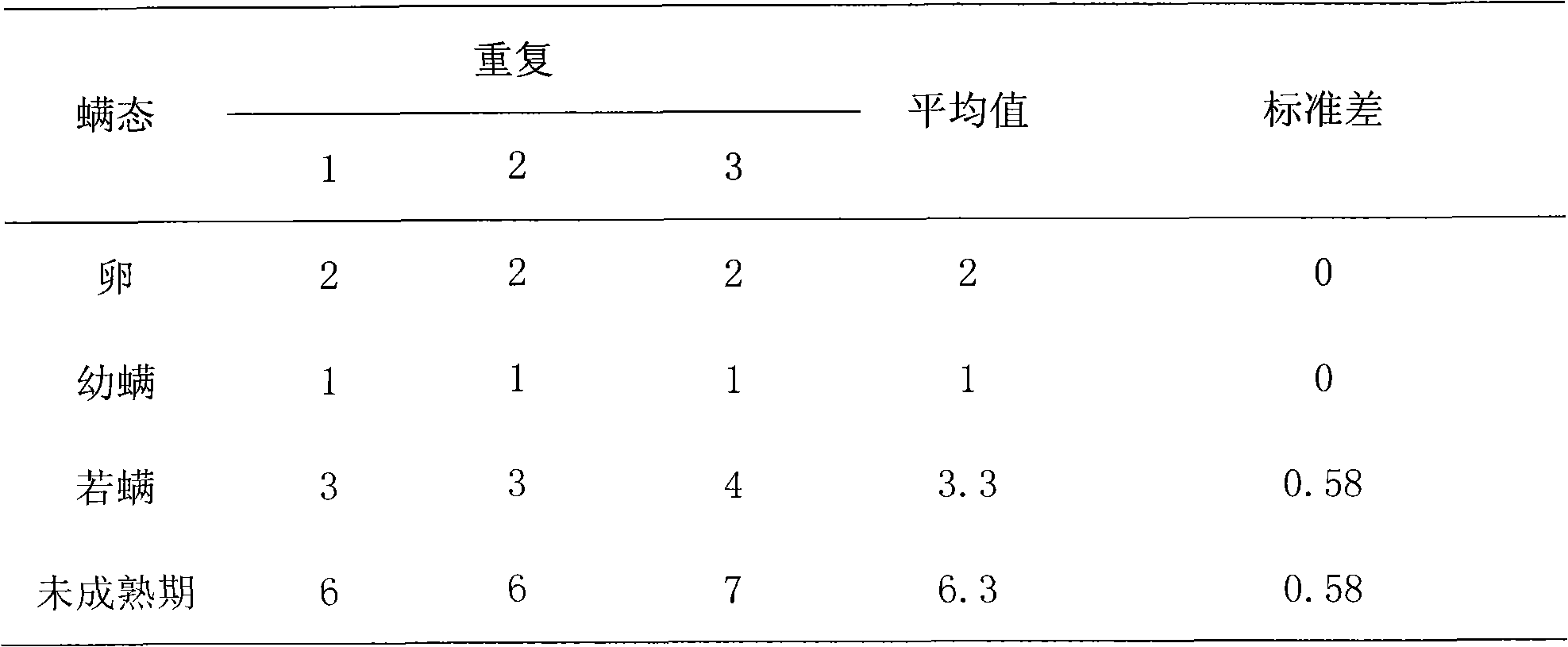

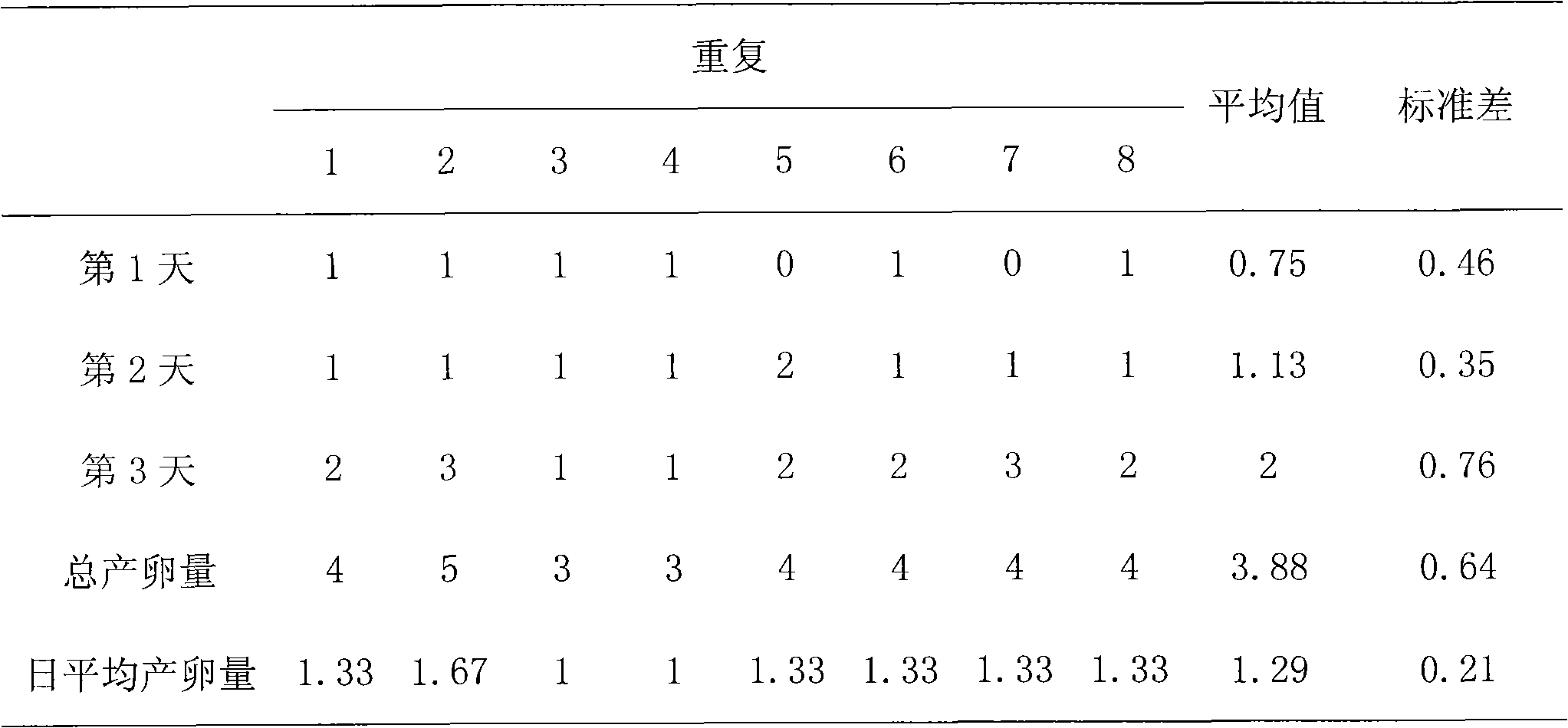

Novel method for artificial mass rearing of Amblyseius orientalis

The invention relates to a novel method for artificial mass rearing of Amblyseius orientalis, which is a method for artificial mass rearing of Amblyseius orientalis using Carpoglyphus lactis or composition of the Carpoglyphus lactis with other food. The other food, exclusive of the Carpoglyphus lactis, includes mites in reverse materials, eggs of insects, pollen, sugar, honey, yeast and the like. Using the method solves the problem that Amblyseius orientalis is difficult to rear and high in rearing cost and can only be reared with mites, pollen and honey water for long. The method has the advantages that the method breaks through predecessors' misconception that Amblyseius orientalis is a type of strict predatory mites, unpredicted technical effects are achieved, using the brand-new rearing scheme achieves simple, low-cost and efficient mass rearing of Amblyseius orientalis, a new era of development and utilization of Amblyseius orientalis is started, more and more efficient native natural enemies can be provided for safety production of agriculture and forestry products, and positive contribution is made to environmental safety.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI +1

Multistage continuous large deformation part internal high-pressure forming method and device

The invention discloses a multistage continuous large deformation part internal high-pressure forming method and device. The multistage continuous large deformation part internal high-pressure forming device comprises a preforming mold, at least one subsequent forming mold, a left feeding plunger chip, a right feeding plunger chip, a left liquid inlet and a right liquid inlet. The multistage continuous large deformation part internal high-pressure forming method comprises the following steps of: firstly putting an initial pipe billet in the preforming mold, filling high-pressure liquid into the metal pipe billet through a port sealing device, and pushing the left feeding plunger chip and the right feeding plunger chip under the effect of a horizontal cylinder; carrying out preliminary bulging on a material located in the middle under the coordination effect of axial thrust and liquid pressure, wherein the bulging height of the material is 85%-95% of the bulging height of a forming part, and taking out a middle blank after unloading; secondly, putting the middle blank in the subsequent forming mold, and bulging bulged adjacent positions of the middle blank; and carrying out bulging in sequence from the middle to two ends till obtaining a final forming part.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

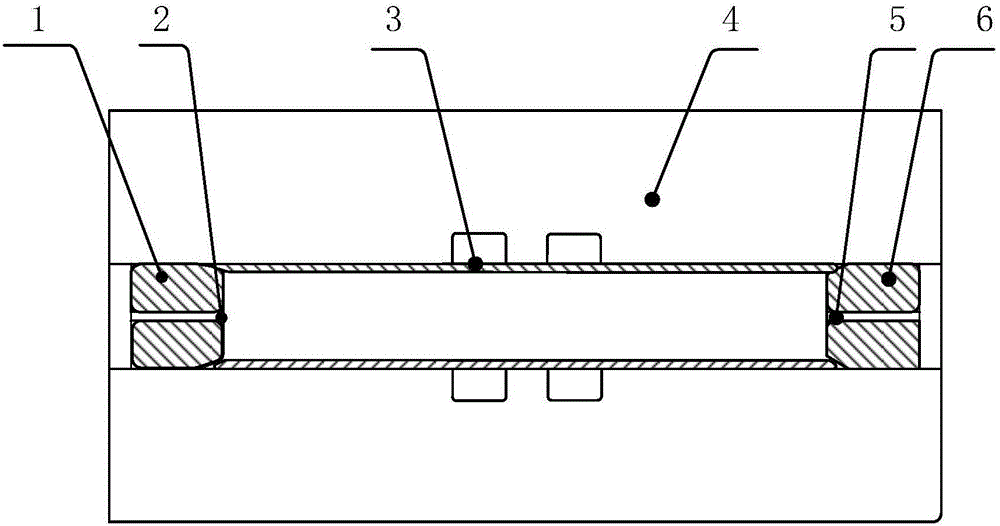

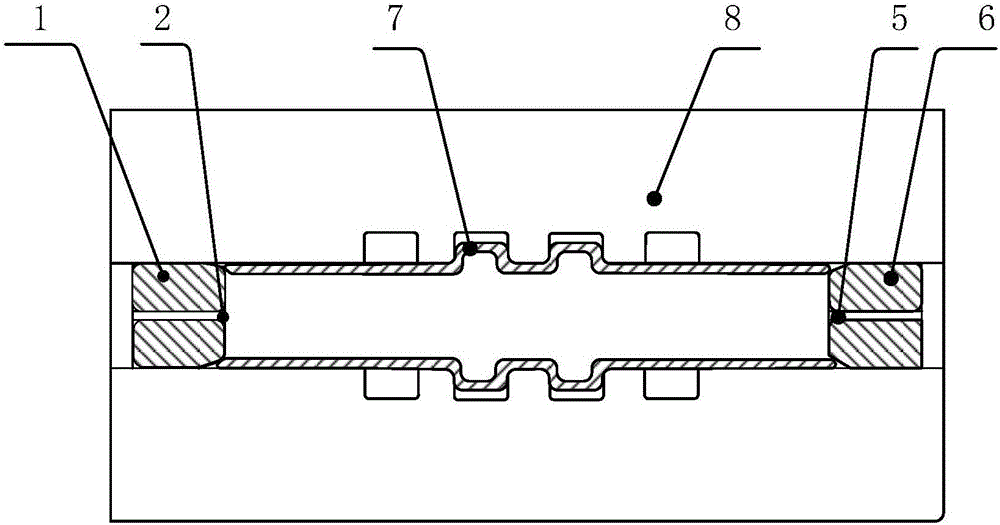

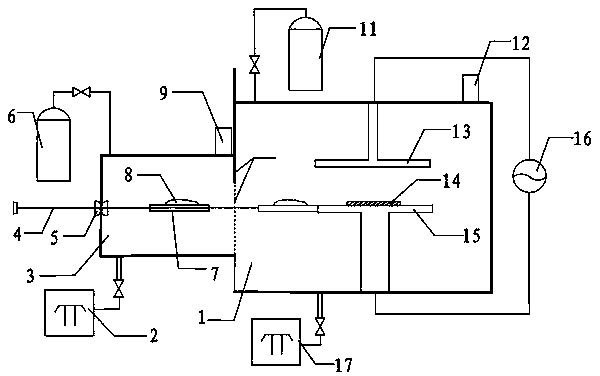

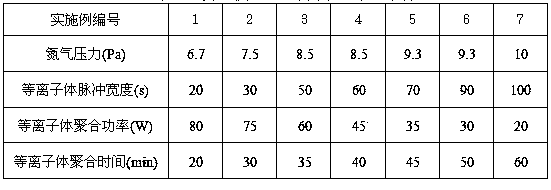

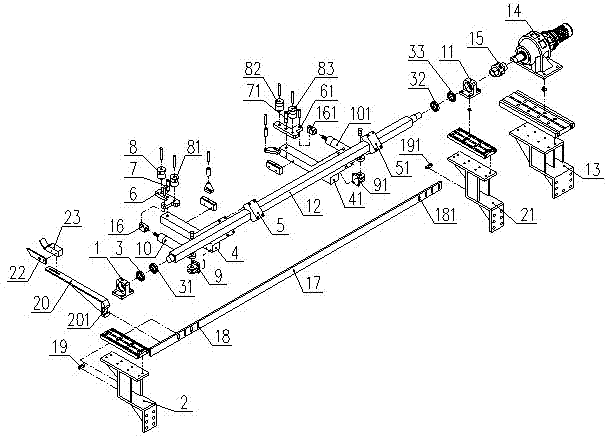

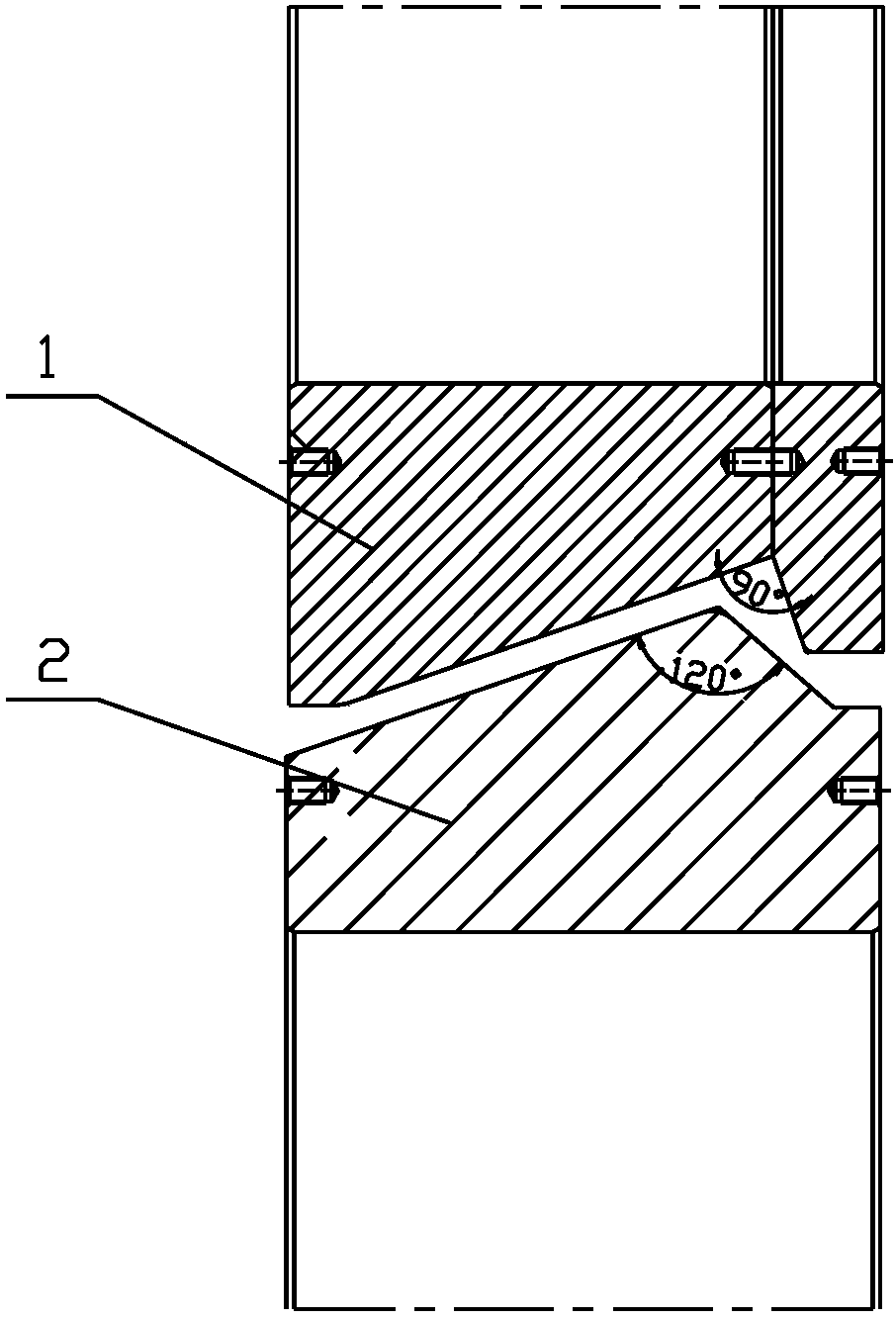

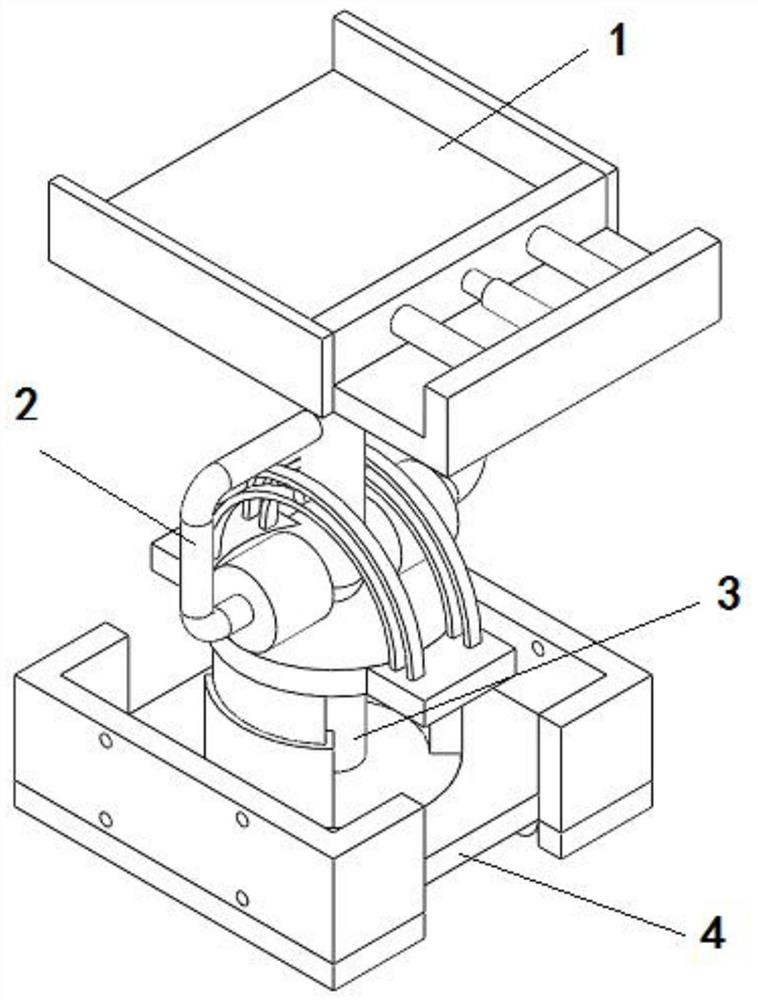

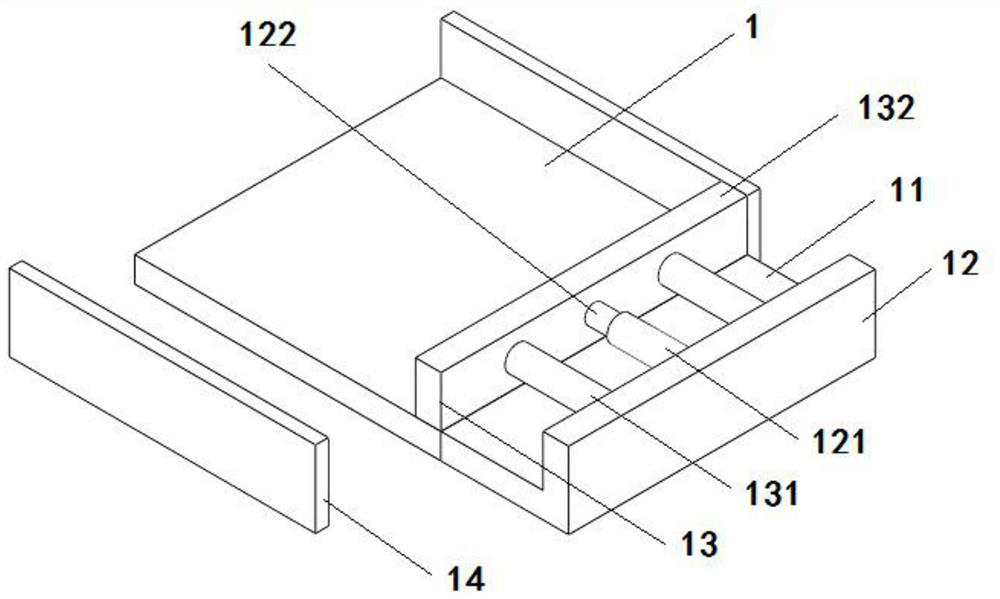

Preparation method of cyanate ester resin thin film as well as reaction equipment thereof

ActiveCN103469174ALow dielectric constantFlawlessChemical vapor deposition coatingOrganic synthesisPre treatment

The invention discloses a preparation method of a cyanate ester resin thin film as well as reaction equipment thereof, belonging to the technical field of organic synthesis of cyanate ester resin ultrathin films. The cyanate ester resin ultrathin film is generated by carrying out plasma polymerization on a cyanate ester resin monomer. The preparation method mainly comprises the following steps of substrate pre-treatment, monomer pre-treatment and plasma polymerization. The plasma polymerization condition is as follows: the pressure is 5-20Pa, the pulse width of plasmas is 20-100 seconds, the plasma polymerization power is 15-85W, and the plasma polymerization time is 20-100 minutes. The reaction equipment comprises a main reaction chamber and an assistant reaction chamber. A solid phase monomer is led into the main reaction chamber through on-off conversion of the two chambers and movement on the left and right sides of a push rod, so that the problem that the solid phase monomer is hard to feed is solved. The thin film prepared by the preparation method is low in dielectric constant, free from defect and high in quality. The preparation method is simple in preparation process, easy to implement, free from environmental pollution and low in cost.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of composite phosphate leather fatliquor without carbon-carbon unsaturated double bonds

InactiveCN105002313AImprove the lubrication effectImprove waterproof performanceLeather impregnationFiberPhosphorylation

The invention relates to a preparation method of composite phosphate leather fatliquor without carbon-carbon unsaturated double bonds. The preparation method is characterized in that a phosphorylated hydroxyl substrate of the composite phosphate fatliquor is composed of polyoxypropylene ether and high alcohol. The polyoxypropylene ether is in a liquid state at normal temperature. P2O5 can be effectively dispersed, various defects caused when the P2O5 absorbs moisture and cakes during a phosphorylation reaction are prevented, and adding of organic solvents is eradicated. The fatliquor composited mainly through the polyoxypropylene ether is low in solidifying point and can well permeate into leather fibers. The fatliquor is combined with the high alcohol, a good fatliquoring effect is achieved, the oil spill phenomenon can be effectively avoided, and meanwhile leather can have a certain waterproof effect. Because the hydroxyl substrate used by the composite phosphate leather fatliquor does not contain the carbon-carbon unsaturated double bonds, it is guaranteed that the obtained composite phosphate fatliquor has good stability, oxidation resistance and light resistance.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

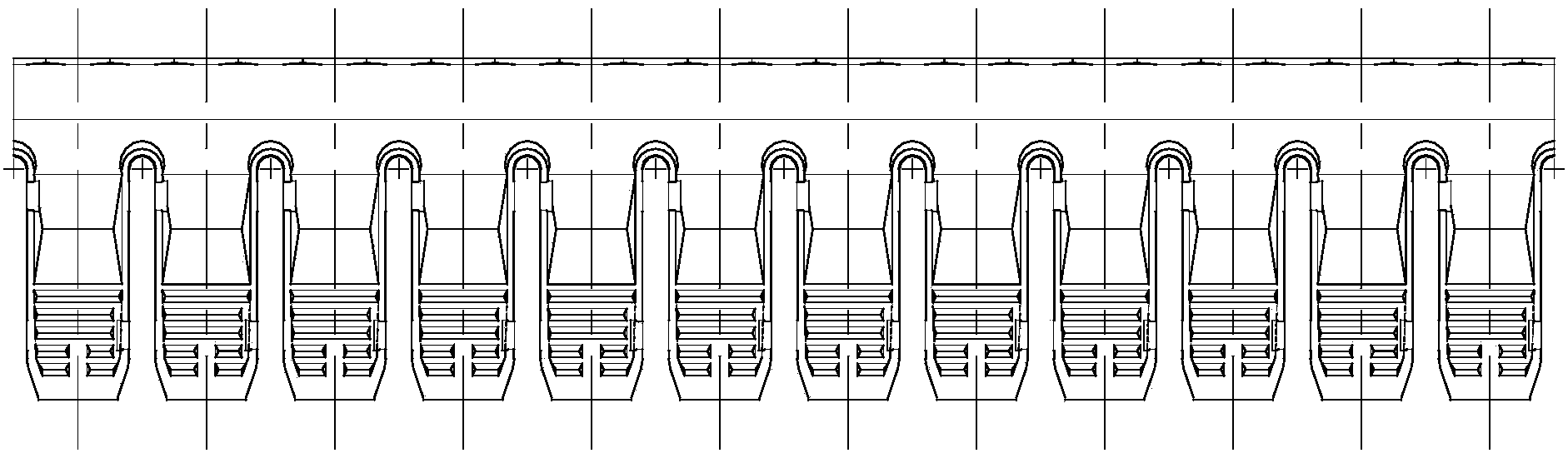

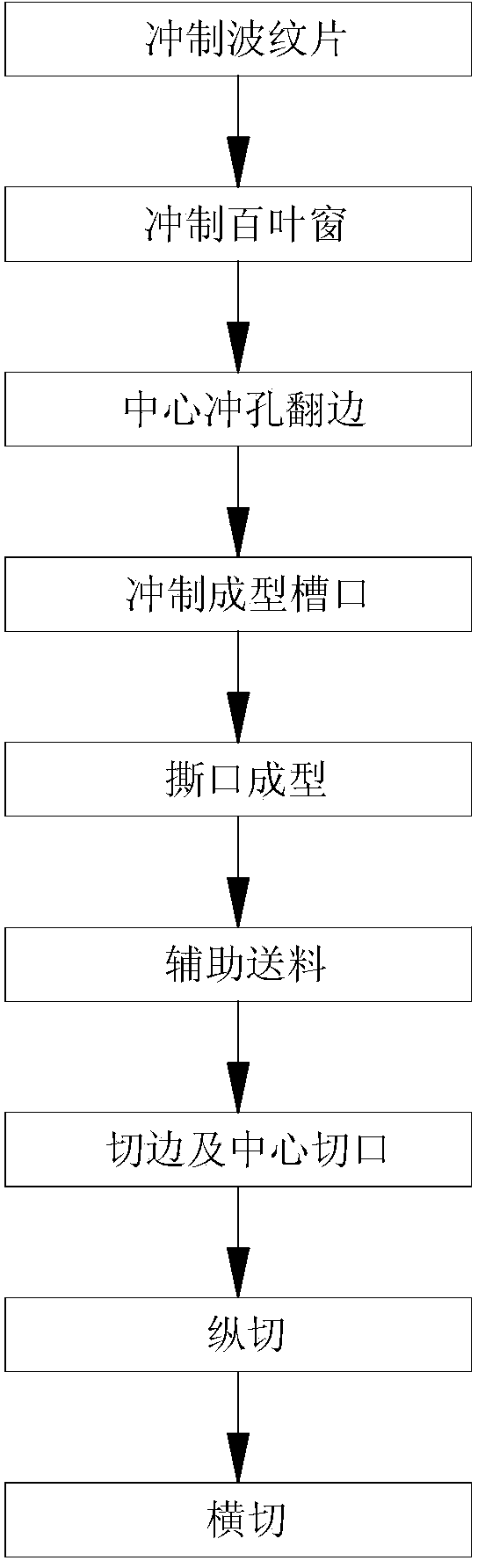

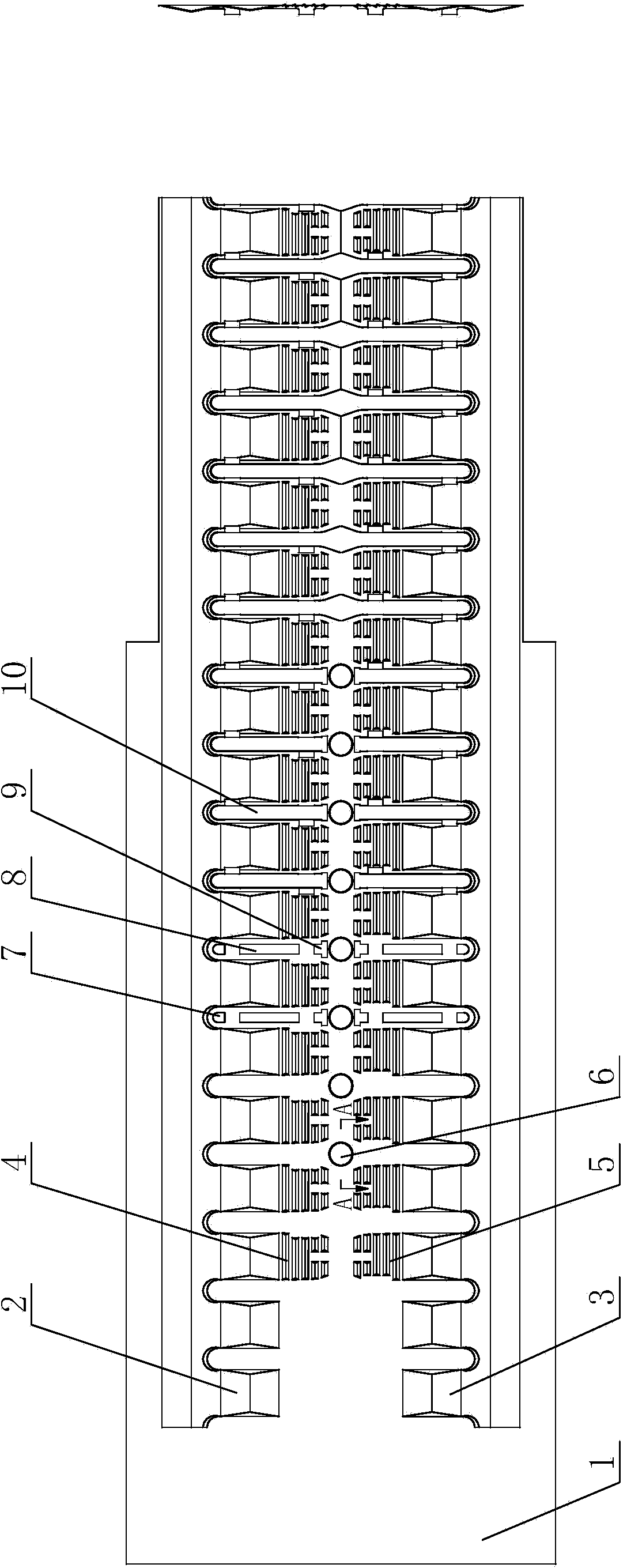

Production process of air-conditioner fin

The invention discloses a production process of an air-conditioner fin. After beltings of a strip-shaped structure are transported into a stamping die through a feeder step-by-step to be subjected to continuous blanking, and are sequentially and continuously subjected to the following working procedures of a, corrugated sheet coining, b, shutter coining, c, centre punching flanging, d, molding notch coining, e, tearing molding, f, assistant feeding, g, edge cutting and center notching, h, lengthwise cutting, and i, crosscutting. By means of the production process of the air-conditioner fin, the air-conditioner fin is coined after the beltings are subjected to corrugated sheet coining, shutter coining, centre punching flanging, molding notch coining, tearing molding, assistant feeding, edge cutting and center notching, lengthwise cutting and crosscutting, so that production of the air-conditioner fin is convenient and simple, and the production is high in efficiency; the operation of the beltings in a mould is more stable and precise due to positioning and guiding conducted through the center hole coining; the center hole is of a circular structure, the strength is high, assistant feeding can be achieved with the cooperation of a kidney-shaped groove, and the problem of difficult feeding of air-conditioner fins in the prior art is solved.

Owner:江苏科菱库精工科技有限公司

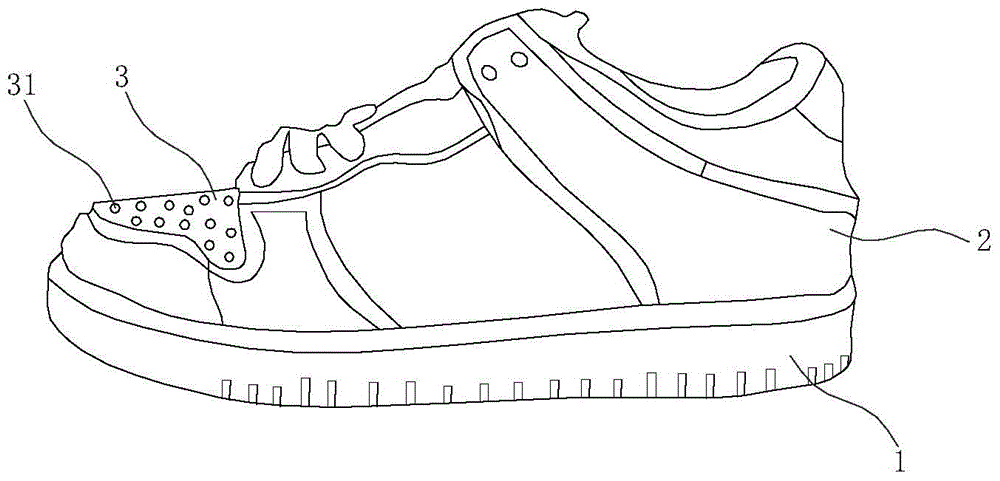

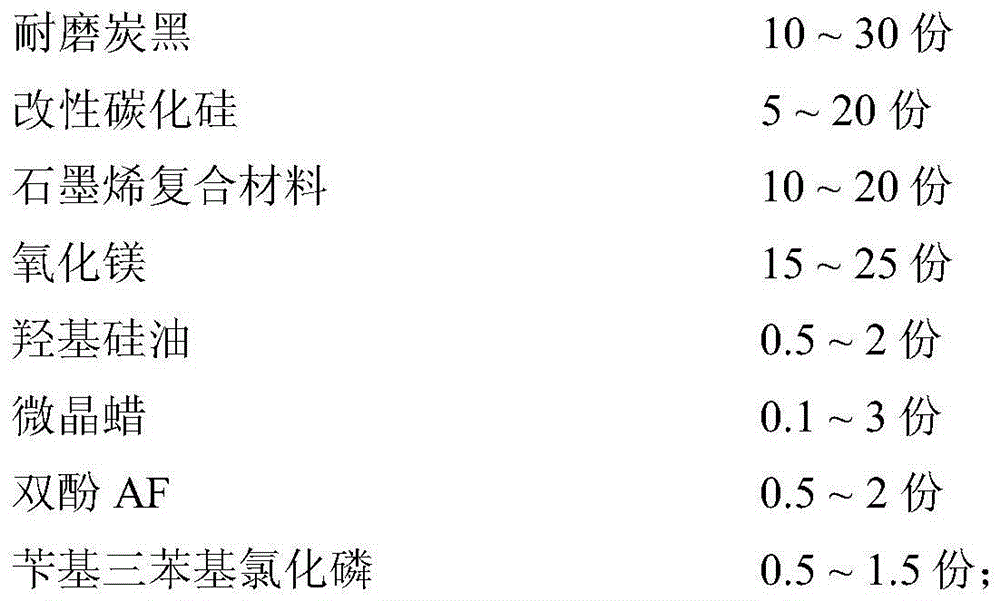

Wear-resisting climbing boot

The invention relates to a wear-resisting climbing boot. The wear-resisting climbing boot comprises a sole, an upper and a vamp, wherein the upper and the vamp are arranged on the sole, and a plurality of air-permeable holes are formed in the vamp at intervals. The wear-resisting climbing boot is characterized in that the materials of the sole comprise, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. Fluororubber rubber serves as the main materials, graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the sole materials, the function of the graphene is fully played, and the wear resistance of the sole materials is effectively improved.

Owner:NINGBO ZHONGDI SHOES

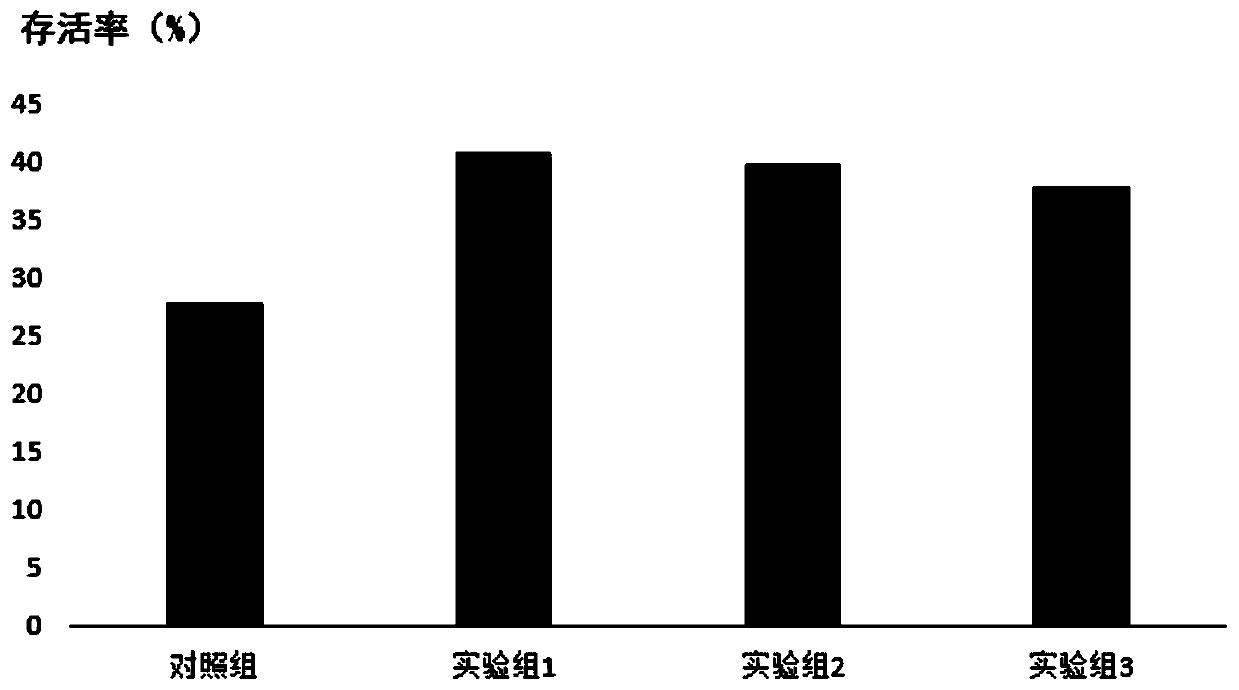

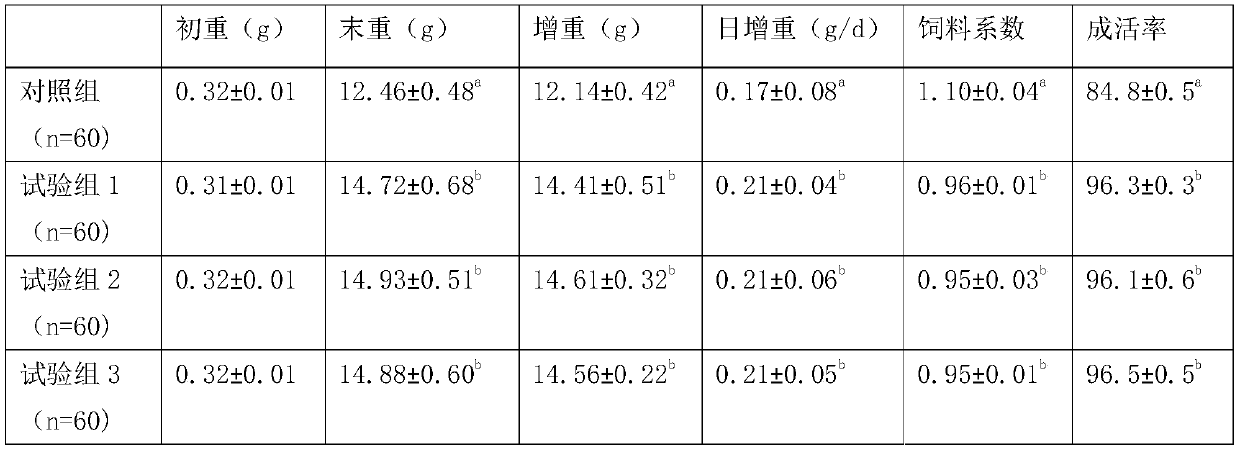

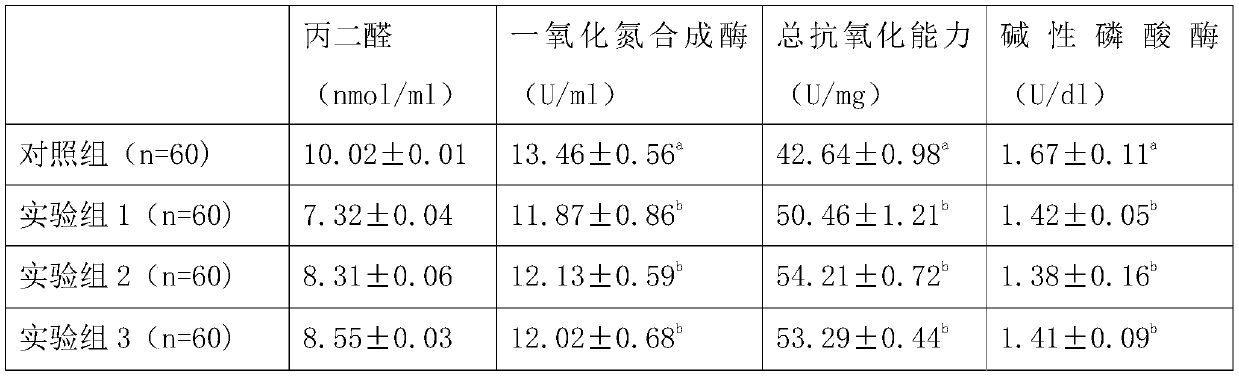

Fish meal-free litopenaeus vannamei feed containing clostridium ethanolum protein and preparation method of feed

InactiveCN111466497AReduce the bait coefficientIncrease appetiteFood processingClimate change adaptationAnimal scienceFish oil

The invention provides fish meal-free litopenaeus vannamei feed containing clostridium ethanolum protein. The feed is characterized in that the feed includes, by weight percentage, 5-8% of clostridiumethanolum protein, 5-6% of hermetia illucens powder, 8-12% of chicken meal, 2-5% of spray-dried animal blood cells, 8-12% of fermented soybean meal, 8-12% of soybean protein concentrate, 5-8% of corngluten meal, 8-12% of dephenolized cottonseed protein, 12-16% of strong flour, 6-10% of enzymatic hydrolysis fish dissolved pulp, 8-10% of rice bran, 1.5-2.5% of fish oil, 1.5-2.5% of soya-bean oil,1.5-2% of calcium dihydrogen phosphate and 1.5-2.5% of vitamin mineral salt premix, wherein the sum of the weight percentage of components are 100%. The feed is good in attractiveness, high in digestion rate, strong in antiviral ability, green and environment-friendly; and the fed litopenaeus vannamei has the advantages of being natural in body color and strong in disease resistance.

Owner:湛江恒兴特种饲料有限公司

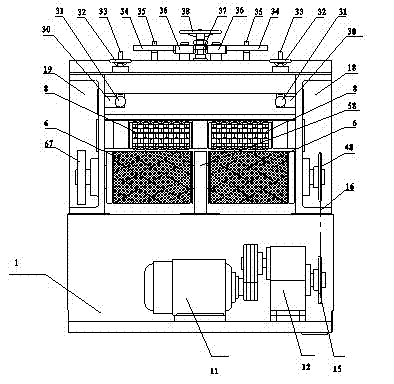

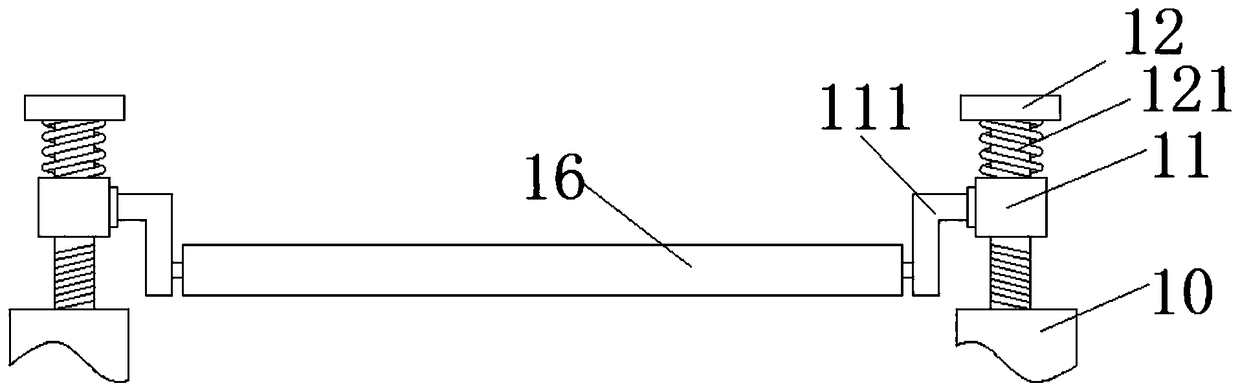

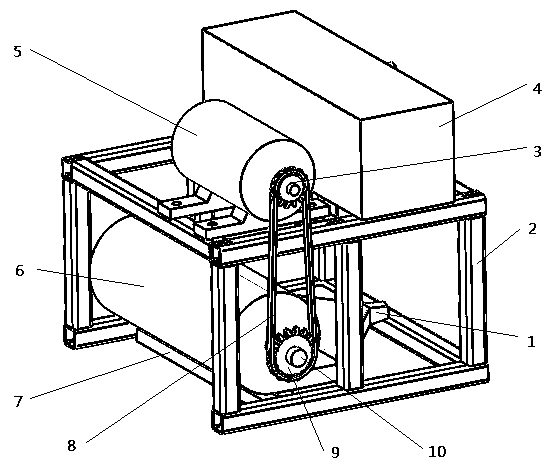

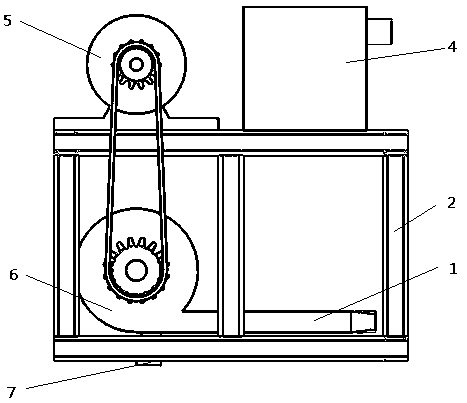

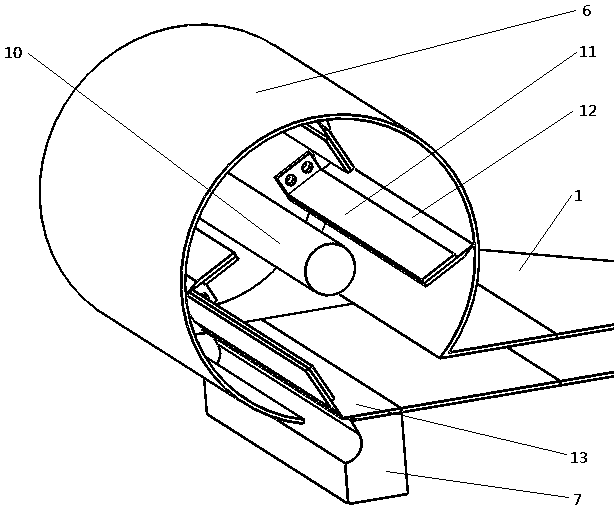

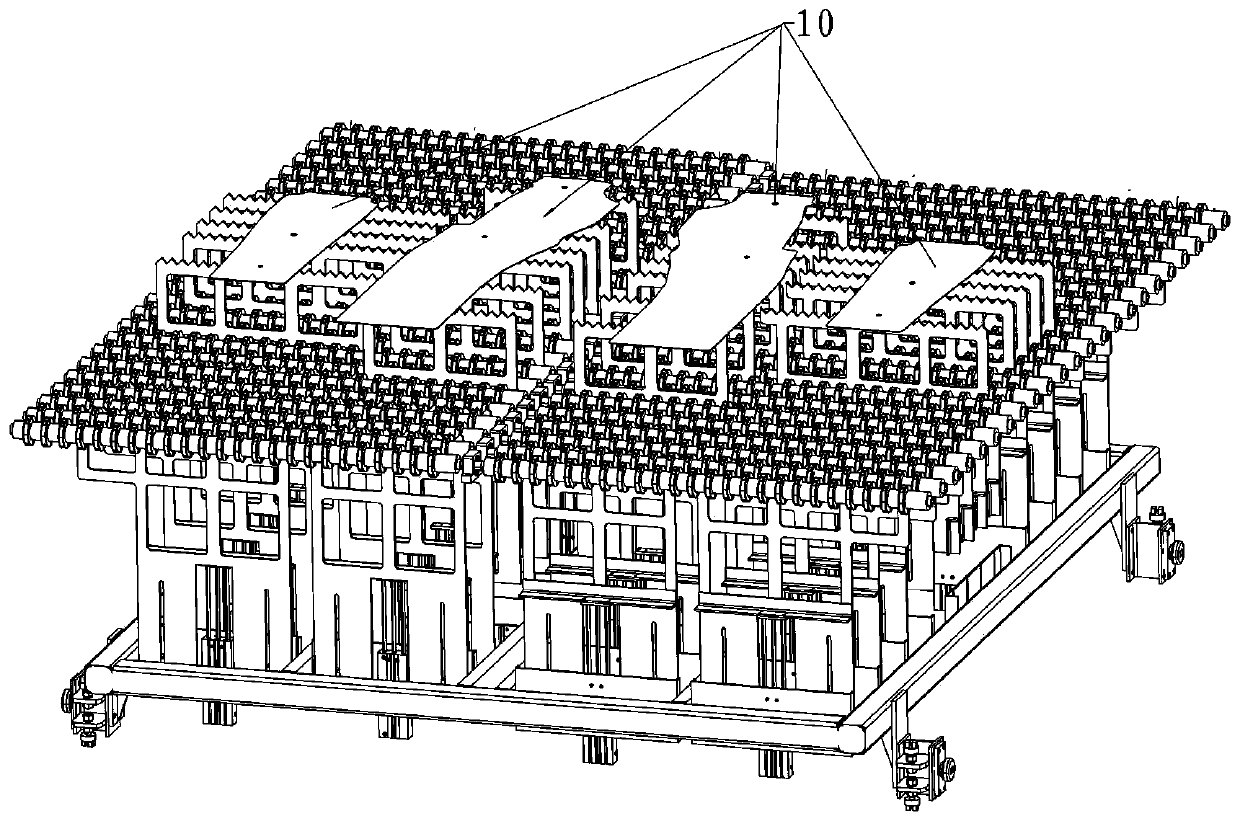

Compact feeding skid steel receiving device

InactiveCN101671775ASmall footprintSolve feeding difficultiesFurnace typesHeat treatment furnacesEngineeringSprocket

The invention discloses a compact feeding skid steel receiving device comprising a steel removing machine and a steel sending machine, wherein the steel removing machine comprises a chain, a chain wheel and an electric motor, the chain is surrounded on the chain wheel, and the chain wheel is connected with the electric motor; the steel sending machine comprises a steel sending skid and an air cylinder, and the rotating shaft of the steel sending skid is connected with the air cylinder; one end of the chain is arranged at a steel billet feeding part, and the other end is matched with a materialreceiving end of the steel sending skid; and a material sending end of the steel sending skid is arranged at the mouth of a heating furnace. The invention has compact structure, effectively saves site areas for factories, and has fewer devices and smooth steel receiving compared with the traditional feeding system.

Owner:NANJING IRON & STEEL CO LTD

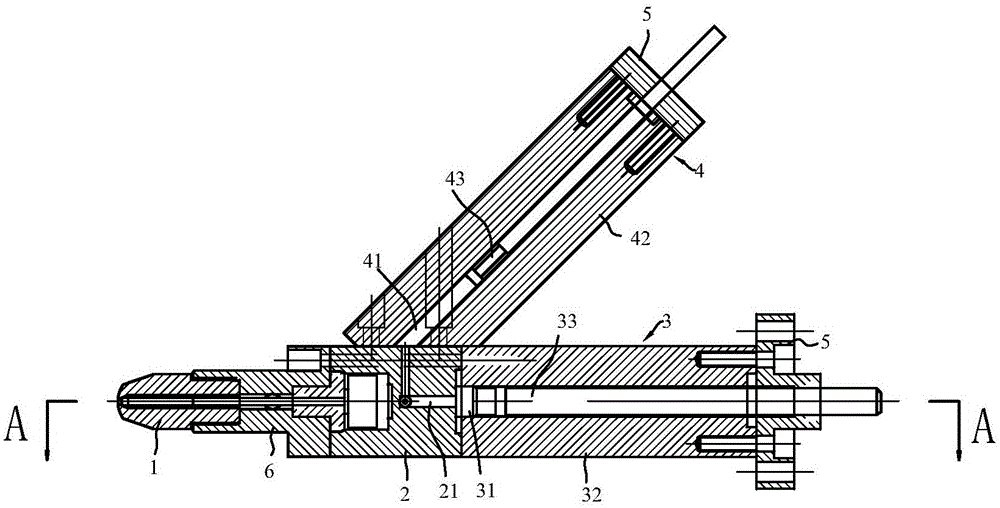

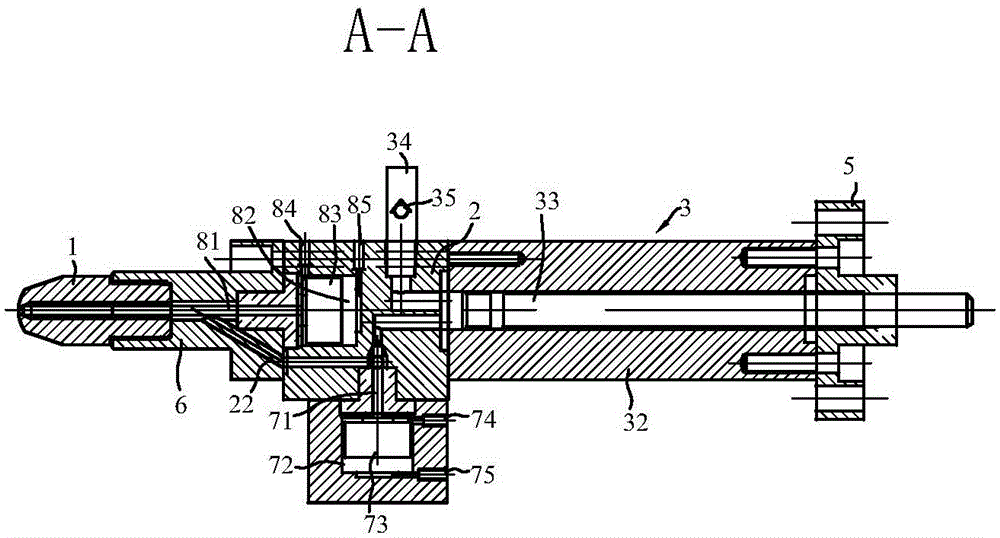

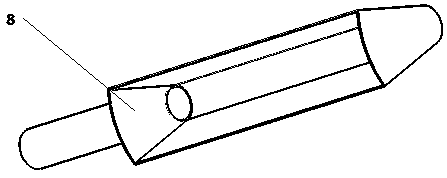

Trace precision injection molding glue injection device

The invention discloses a trace precision injection molding glue injection device. The trace precision injection molding glue injection device comprises a spray nozzle, a primary glue injection gun barrel and a precision gun barrel. The primary glue injection gun barrel comprises a primary gun barrel body internally provided with a primary glue injection cavity and a primary glue injection gun barrel piston rod capable of reciprocating in the primary glue injection cavity. The precision gun barrel comprises a precision gun barrel body internally provided with a precision glue injection cavity and a precision gun barrel piston rod capable of reciprocating in the precision glue injection cavity. The internal diameter of the primary glue injection cavity is larger than that of the precision glue injection cavity. A raw material inlet passageway is communicated with the primary glue injection cavity. The primary glue injection cavity and the precision glue injection cavity are connected through a material supply passageway. A glue inflow valve is arranged on the material supply passageway. The precision glue injection cavity is connected with the spray nozzle through the glue injection passageway. A glue injection valve is arranged on the glue injection passageway. The primary glue injection gun barrel and the precision gun barrel which are different in internal diameter are combined for glue injection, material supply is easy due to the characteristics and the beneficial effects of the primary glue injection gun barrel and the precision gun barrel, the errors generated by outputting the glue amount are small, and the output precision is higher.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

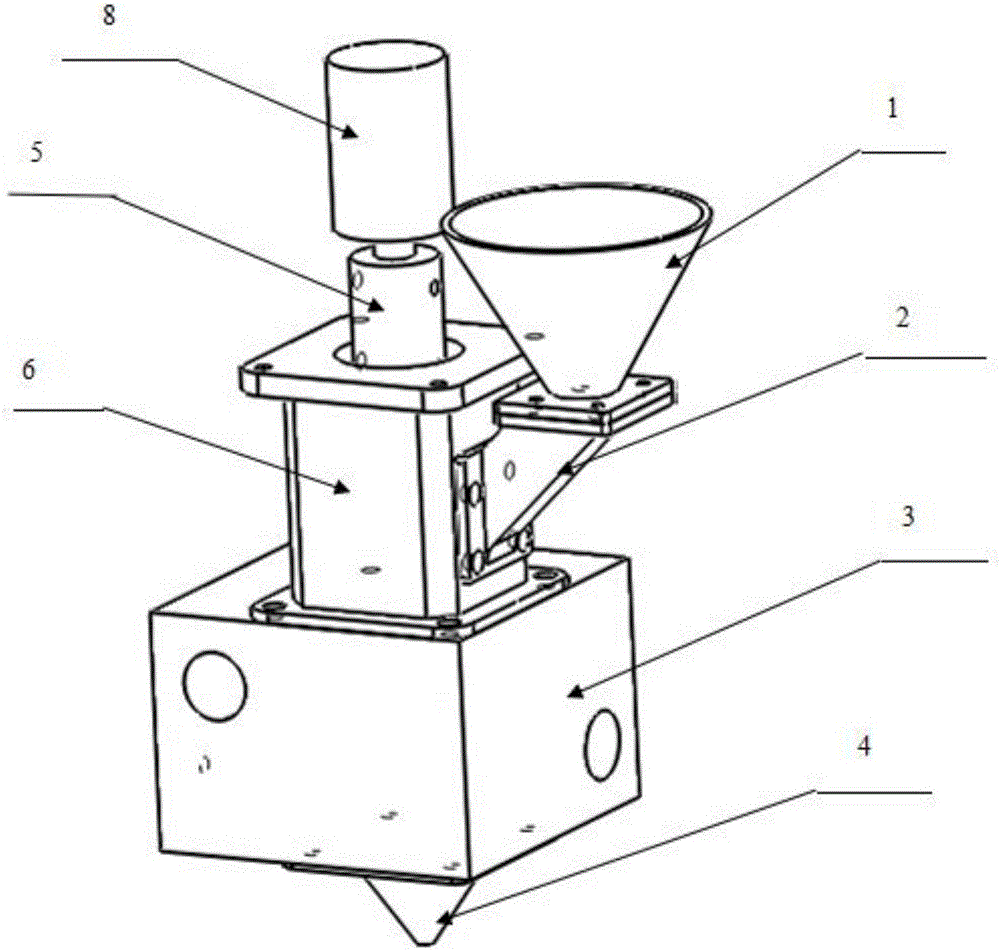

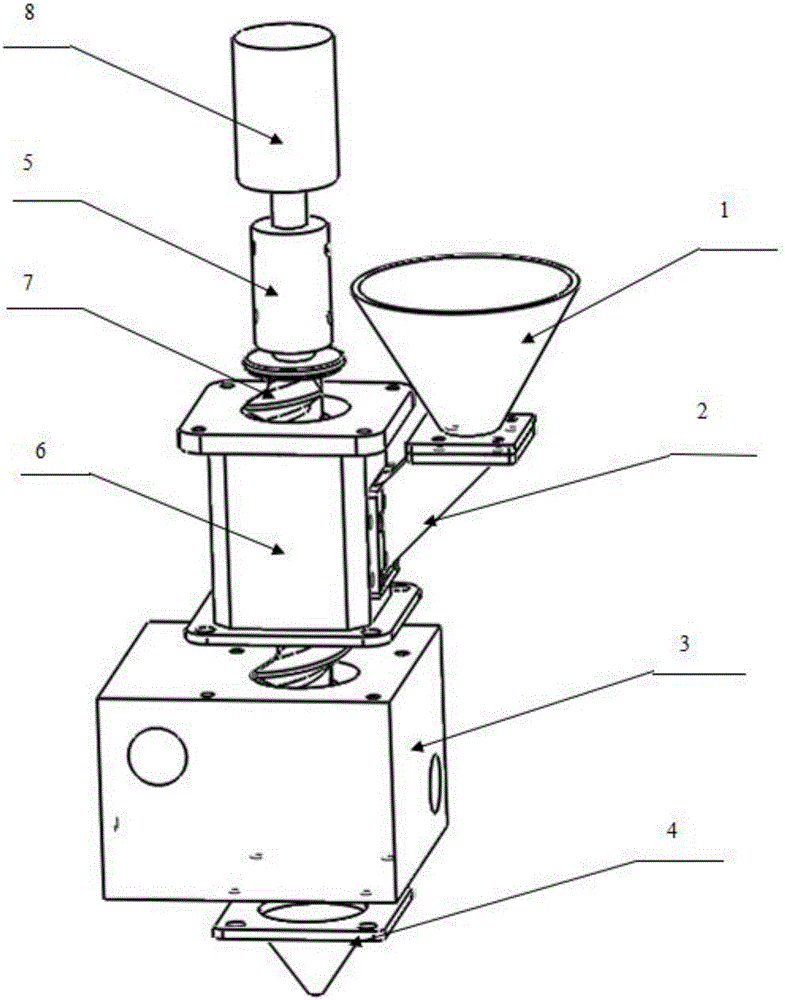

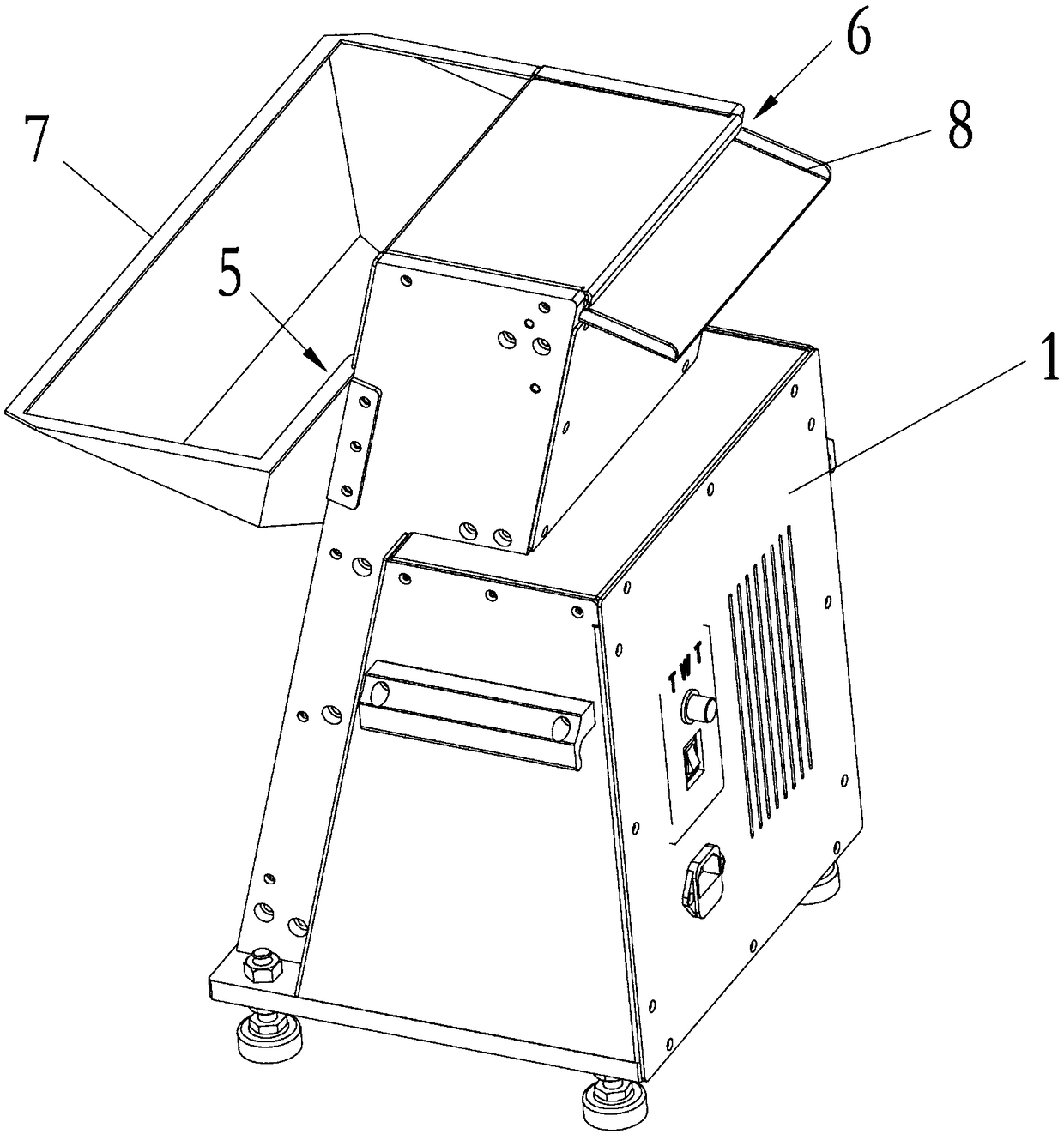

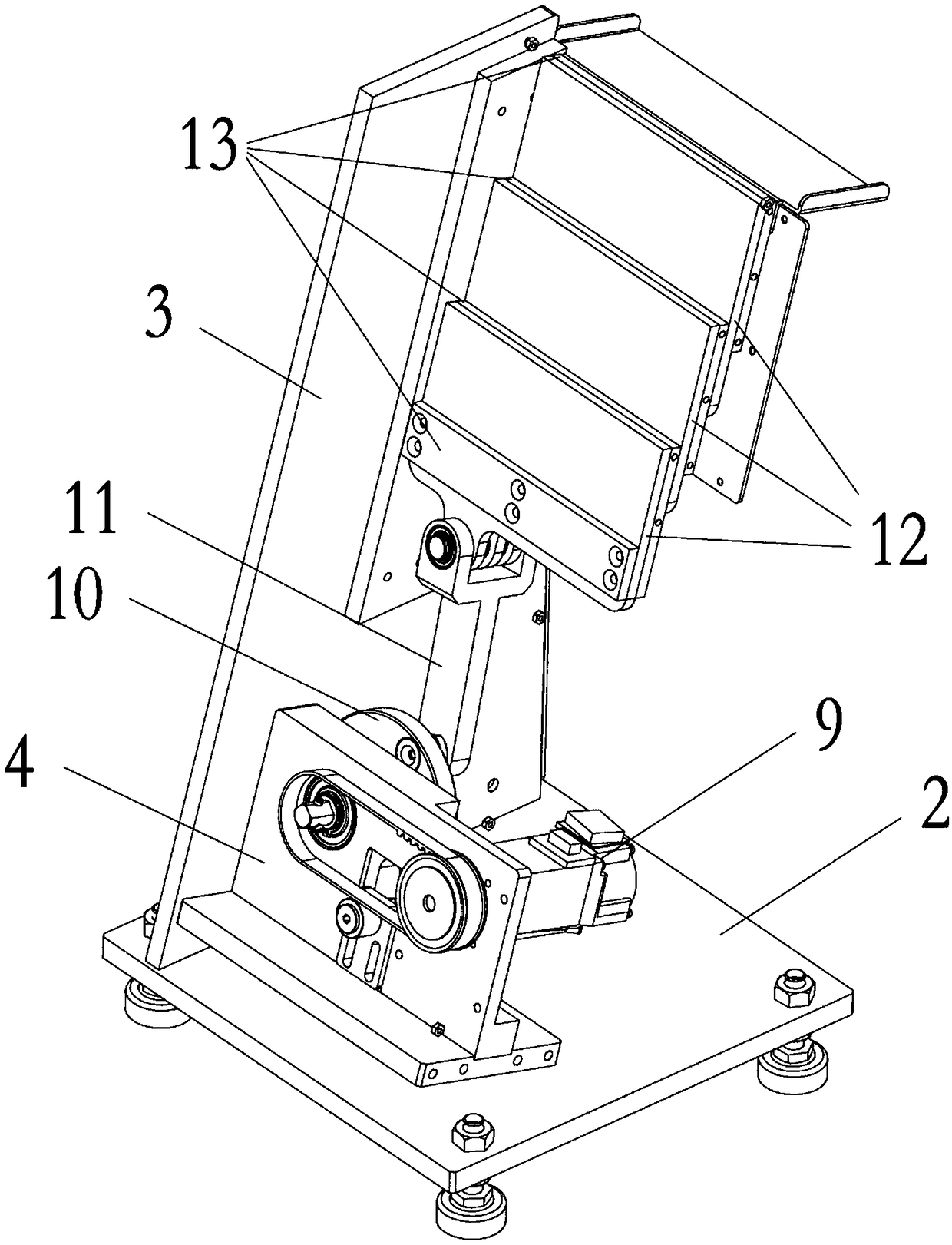

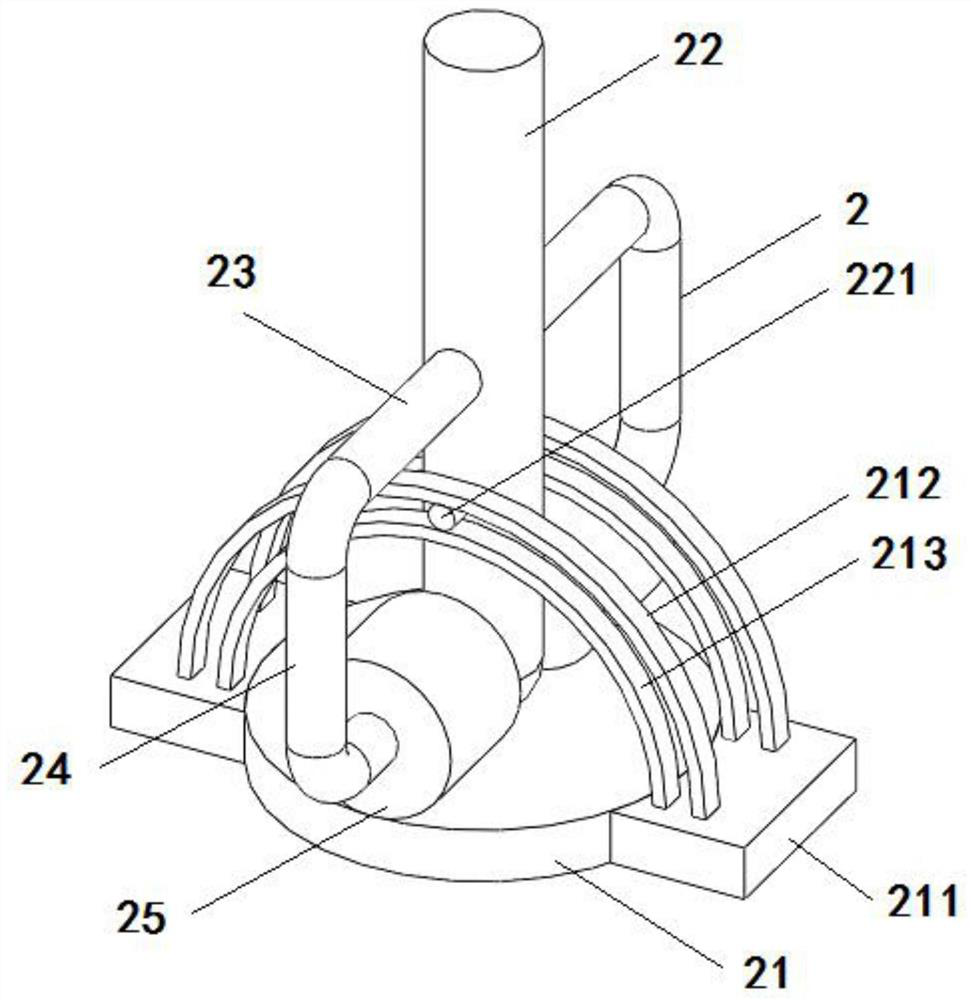

Three-dimensional waxing, supply and extrusion integrated nozzle structure

InactiveCN105058794ASimple structureSolve feeding difficultiesAdditive manufacturing apparatusWaxHeater Rod

The invention discloses a three-dimensional waxing, supply and extrusion integrated nozzle structure. The structure comprises a conveying drum fixed on the upper surface of a mobile slide block, wherein a conveying hole communicated with the conveying drum is formed in the mobile slide block; a screw rod is installed in the conveying drum, and is driven by a motor; the motor is fixed at the top of the conveying drum; the screw rod is inserted in the conveying hole of the mobile slide block; a nozzle is arranged below the conveying hole of the mobile slide block, and is fixedly connected to the lower surface of the mobile slide block; heating rods are arranged around the conveying hole of the mobile slide block, and are inserted into the mobile slide block; an inclined conveying pipe is fixed at one side of the conveying drum; and a discharge hopper is fixed at the top of the conveying pipe. The three-dimensional waxing, supply and extrusion integrated nozzle structure simplifies the structure of an extruded wax supply device of a three-dimensional waxing printer, solves the problem of feeding difficulty of molten wax, and improves the printed product precision. The three-dimensional waxing, supply and extrusion integrated nozzle structure is simple in structure, low in manufacturing cost and convenient for operation.

Owner:TIANJIN UNIV

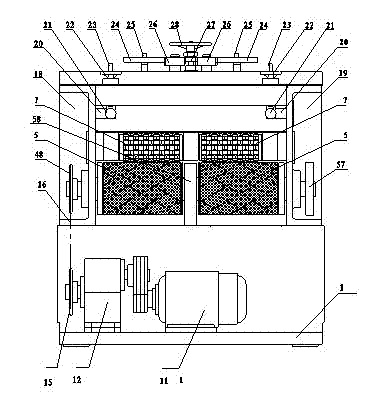

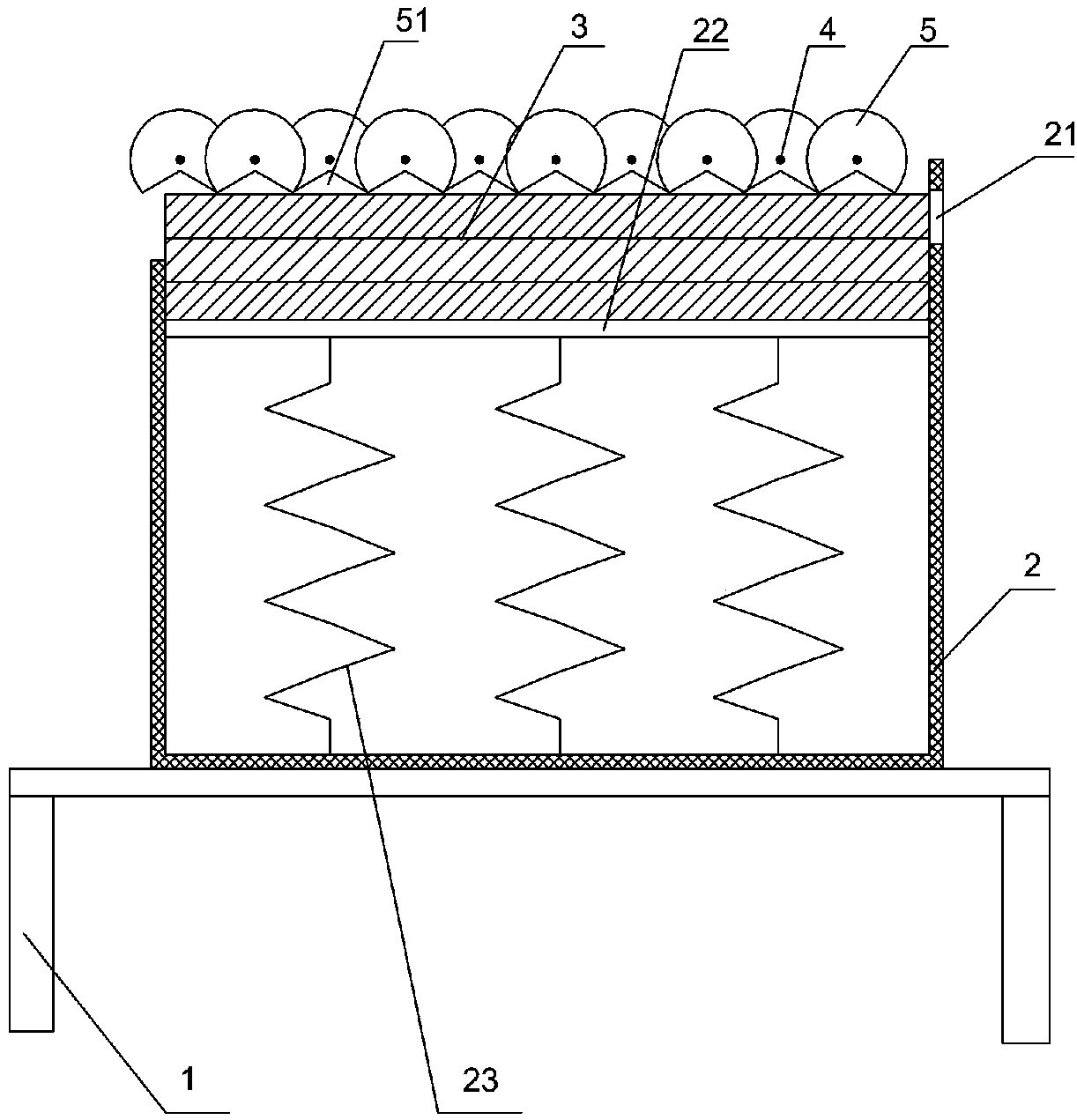

Joint-eliminating and flattening machine used in bamboo processing

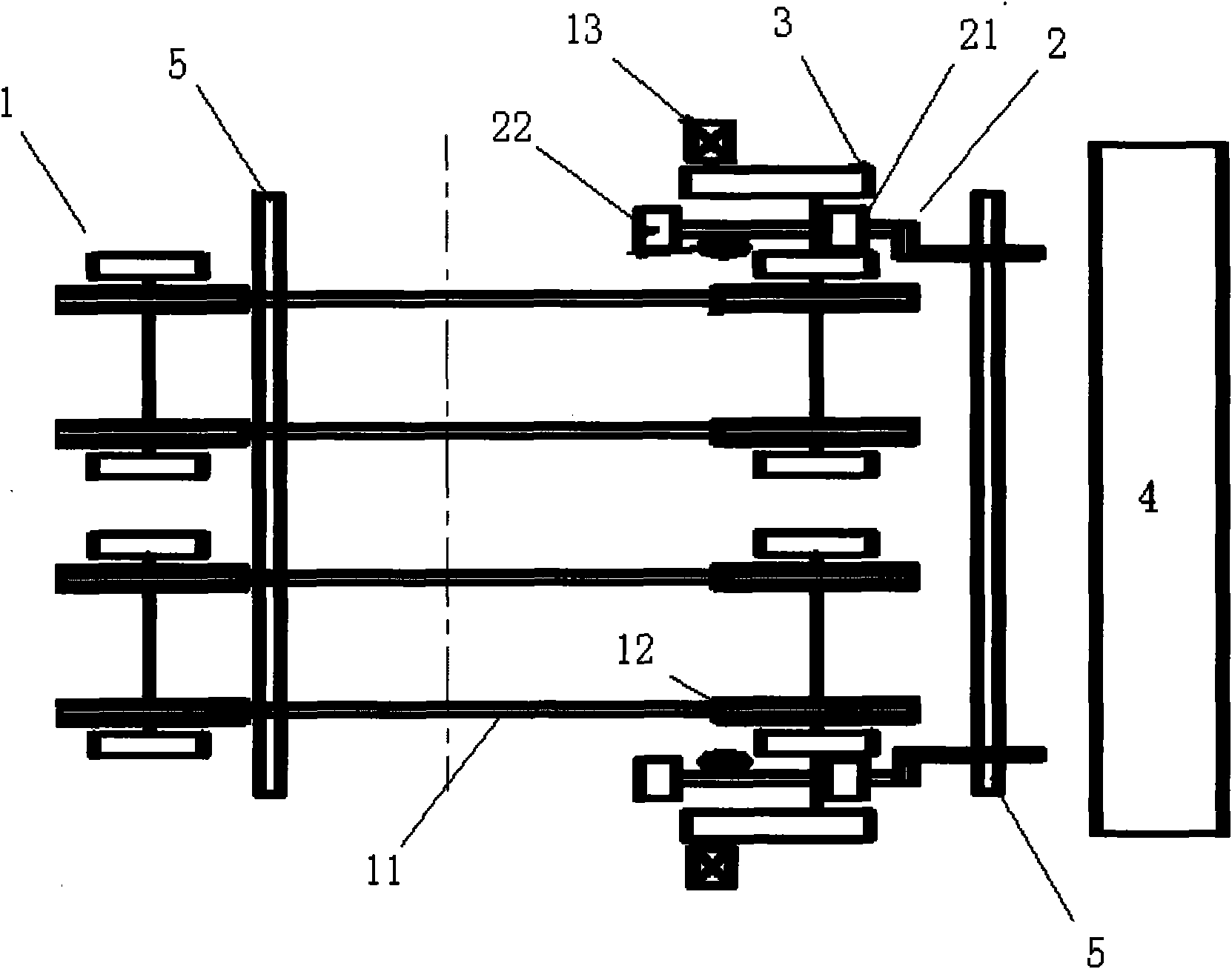

InactiveCN102896671ASolve feeding difficultiesSolve the problem that bamboo joints are easy to breakCane mechanical workingWood working apparatusPush pullEngineering

The invention discloses a joint-eliminating and flattening machine used in bamboo processing. The machine is provided with two friction roll shaft systems which actively rotate to feed and two joint eliminator shaft systems which passively rotate, wherein two groups of friction roll bodies are arranged on each friction roll shaft system, and two groups of joint-eliminating blades are arranged on each joint eliminator shaft system. According to the invention, four groups of friction roll bodies and four groups of joint-eliminating blades constitute two groups of joint-eliminating and flattening mechanisms which independently feed, so as to form a push-pull working mode, so that bamboo joints can be effectively eliminated, and bamboo is not easy to break at the bamboo joints after being flattened; and moreover, the base materials of bamboo are good in uniformity and strong in sizing permeability.

Owner:廊坊市双安结构胶合板研究所

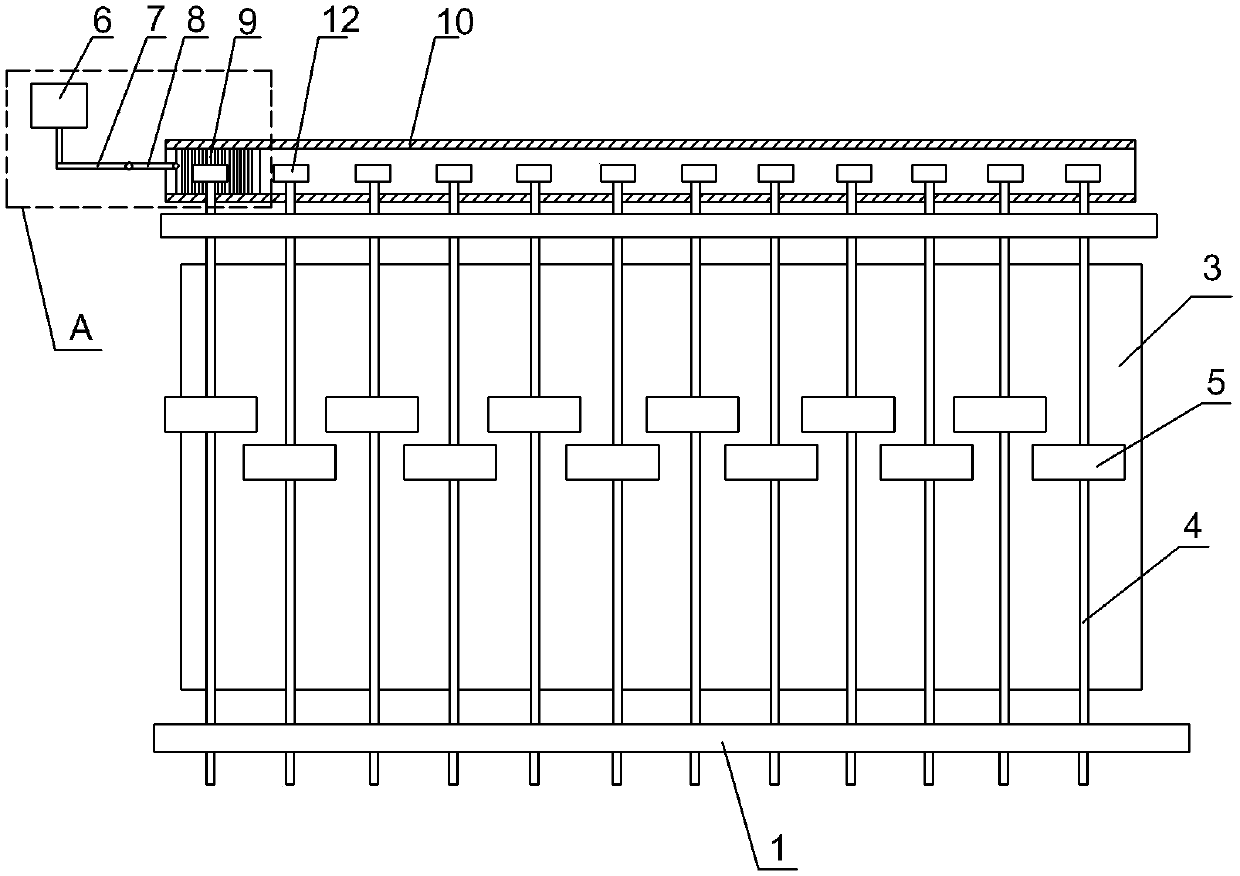

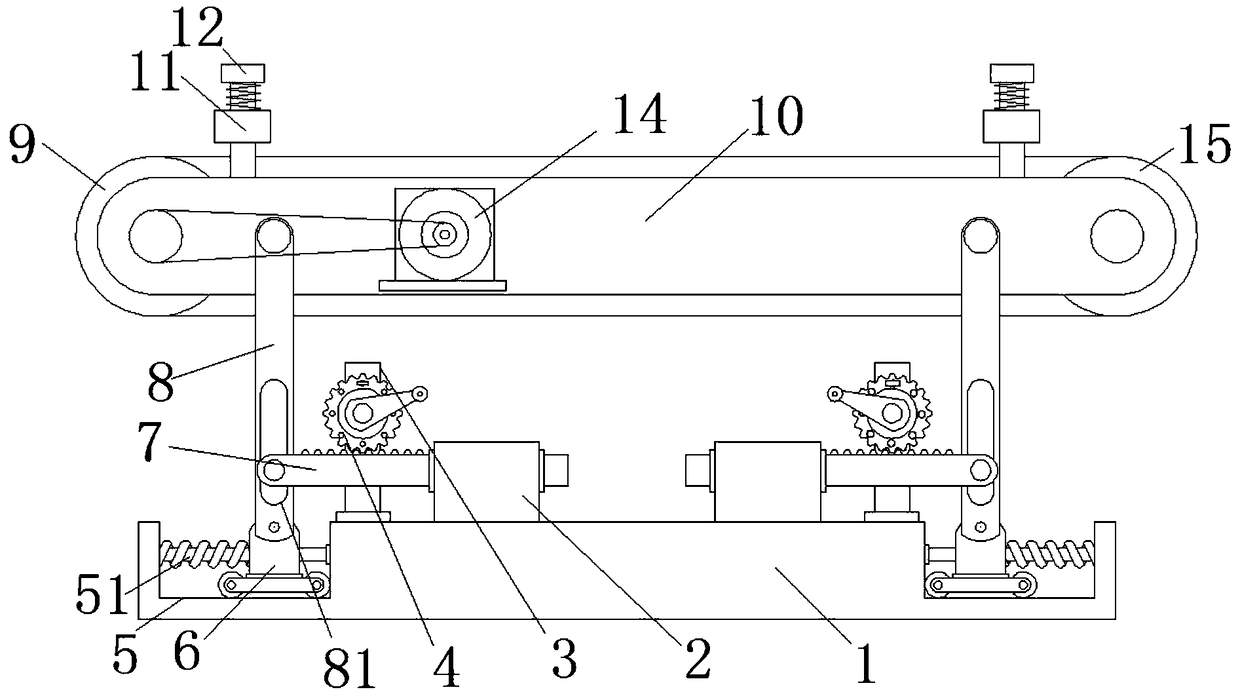

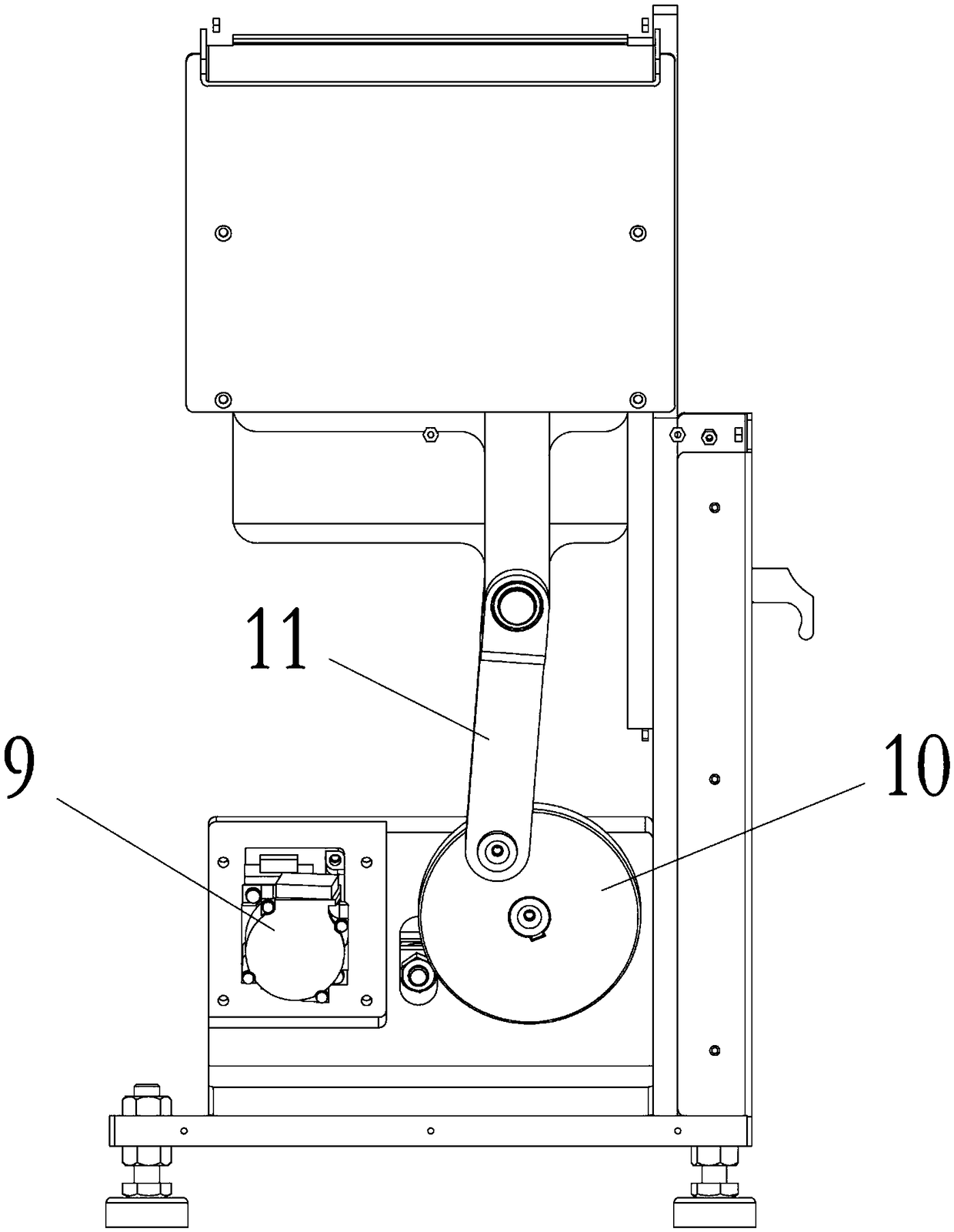

Plate feeding device

ActiveCN107755570AAvoid skiddingSolve feeding difficultiesMetal-working feeding devicesVehicle componentsMechanical componentsElectric machinery

The invention belongs to the field of mechanical part processing equipment, and specifically discloses a plate feeding device comprising a rack. The rack is fixedly provided with a storage tank of which the upper part is provided with an opening, and the storage tank is internally provided with a tray slidably; a plurality of elastic support parts are arranged between the bottom end of the tray and the storage tank, and the side wall of the storage tank is provided with a discharge port; the rack is further provided with a setting mechanism comprising a plurality of rotating shafts which are all connected to the rack rotatably, and the rotating shafts are uniformly distributed horizontally, and fixedly connected to wheels coaxially; the cross sections of the wheels are circular, and the wheels are provided with notches; the adjacent wheels are staggered and distributed, and the projections of the adjacent wheels on a plane have an overlapping part; the rack is further provided with anactuating mechanism comprising a motor, a crank, a connecting rod, a sliding block, a rack and a plurality of teeth. According to the plate feeding device disclosed by the invention, the problem thatplates are hard to feed is solved.

Owner:重庆市合川区云天机械制造有限公司

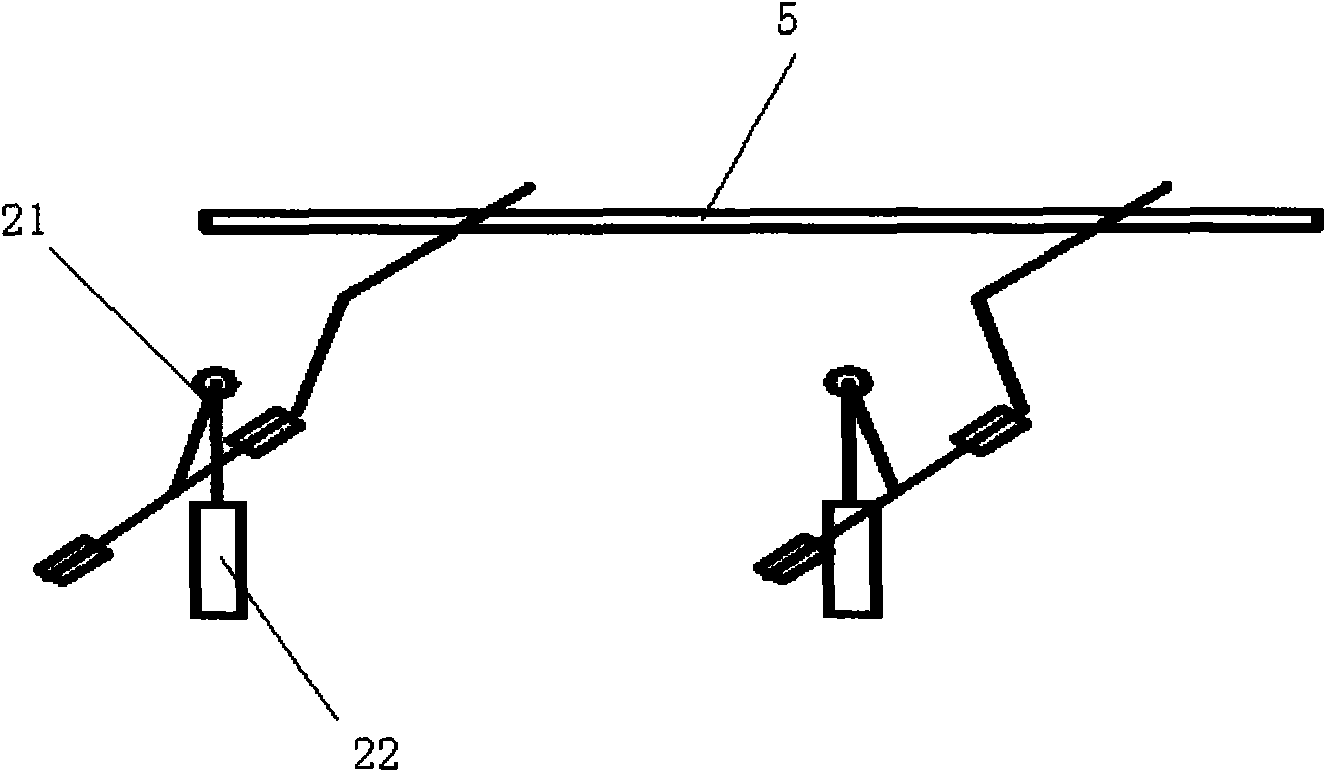

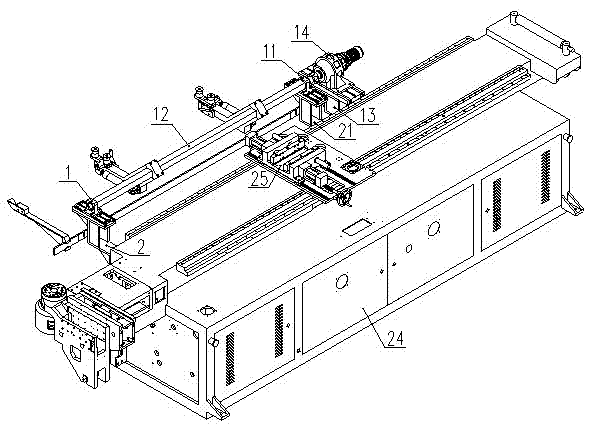

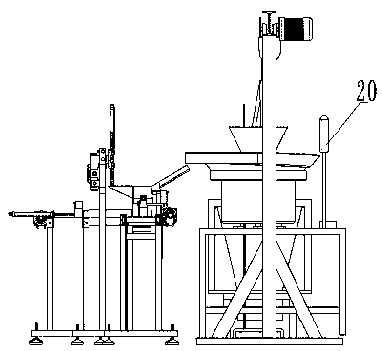

Manual feeding device used in full-automatic numerical control hydraulic pipe bender

ActiveCN102773361AReduce the burden onChange working positionMetal-working feeding devicesPositioning devicesNumerical controlPipe fitting

The invention discloses a manual feeding device used in a full-automatic numerical control hydraulic pipe bender; the manual feeding device comprises a motor support seat and a pair of bearing seat support seats which are fixed at the side of a large vertical seat, wherein a speed-reducing motor is fixedly arranged on the motor support seat; the bearing seat support seats are respectively provided with a bearing seat; two rotating shafts are respectively and movably arranged in the pair of bearing seats; the rotating shafts are connected with the speed-reducing motor; a pair of rotating arms which are respectively articulated with a movable plate are respectively fixed on the rotating shafts; the movable plates are respectively articulated with a pair of trip holders; two material clamp cylinders are respectively articulated at the ends of the rotating arms close to the rotating shafts; two piston rods of the material clamp cylinders are respectively connected with a connecting seat; the two connecting seats are respectively articulated with the movable plate; the two movable plates are respectively driven to make rotation along the opposite directions by the two material clamp cylinders connected with the movable plates; and a locating check block capable of moving up and down as well as left and right is arranged at the side of the large vertical seat by a locating adjustment mechanism. The manual feeding device can be conveniently used for feeding a long and heavy pipe fitting.

Owner:和和机械(张家港)有限公司

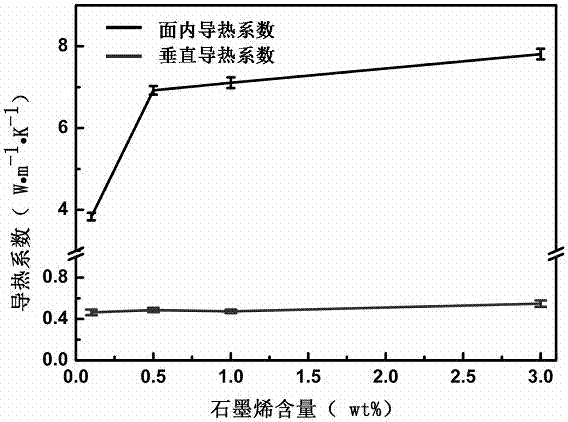

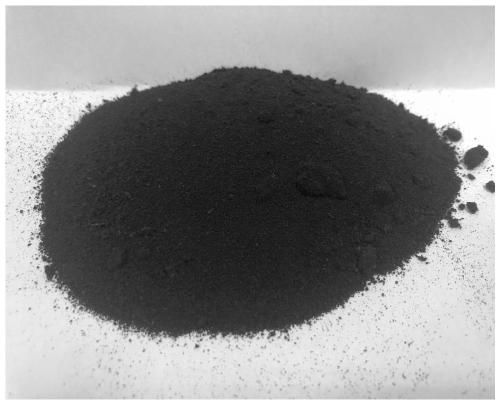

Anisotropic heat-conducting nylon 6/graphene nanocomposite material and preparation method thereof

InactiveCN107325542ASolve feeding difficultiesSolve for uniformityHeat-exchange elementsIn planeMasterbatch

The invention discloses an anisotropic heat-conducting nylon 6 / graphene nanocomposite material and a preparation method thereof. The anisotropic heat-conducting nylon 6 / graphene nanocomposite material comprises 97-99.9% of nylon 6 and 0.1-3% of graphene by mass. The preparation method comprises the following steps: (1) according to a proportion that the addition amount of the graphene is 10%, adding the nylon 6 and the graphene into a torque rheometer, performing melt mixing while heating, granulating, and drying to obtain nylon 6 / graphene masterbatch; and (2) mixing the nylon 6 / graphene masterbatch and the nylon 6 according to a proportion that the mass fraction of the graphene is 0.1-3%, adding into the torque rheometer, performing melt blending, and discharging to obtain the nylon 6 / graphene nanocomposite material. Aggregation between graphene sheets in the anisotropic heat-conducting nylon 6 / graphene nanocomposite material is avoided; the in-plane heat conductivity coefficient of the anisotropic heat-conducting nylon 6 / graphene nanocomposite material is greater than or equal to 3W.m<-1>.K<-1>, the vertical heat conductivity coefficient thereof is smaller than or equal to 0.6W.m<-1>.K<-1>, and the anisotropy ratio of the heat conductivity coefficient is greater than or equal to 5.

Owner:SHANGHAI UNIV

A load and conveying device for pap printing

A load and conveying device for pap printing including the base, A mount seat and a support seat are fixedly connected at the top of the base, A support seat is rotatably connecte with a gear througha rotating shaft, A sliding rod is slidably connecte with that inner wall of the mounting seat, A top portion of the slide bar is meshed with a gear through gear teeth, At both side of that base, grooves are arrange, A limit position light rod is fixedly connected with that inn wall of the groove, A slide block is slidably sleeved on the position limiting polish rod, A movable lever is hinged at the top end of the slider, a sliding groove is arranged on the movable lever, an end of the sliding lever far away from the mounting seat is movably connected to the inner wall of the sliding groove through a rotating shaft, and a mounting frame is rotatably connected at the top end of the movable lever through the rotating shaft, and a driven conveying roller and a driving conveying roller are rotatably installed on the mounting frame. The invention solves the problem that the feeding of the traditional paper conveying device is difficult, improves the working efficiency of the worker, facilitates the conveying of the paper, and at the same time can make the paper entering the printing press more even.

Owner:BEITANG JUNZHI PRINTING PAPER PROCESSING FACTORY

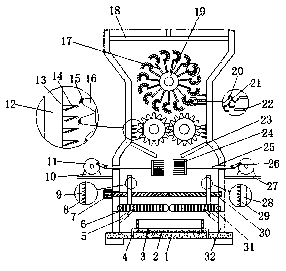

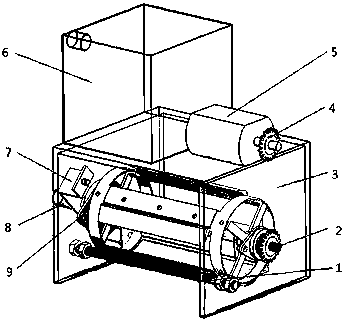

Alternanthera philoxeroides straw crushing device for river channel cleaning

ActiveCN109168640APrevent hanging onSolve feeding difficultiesFeeding-stuffCrop conditionersEngineeringAlternanthera

The invention belongs to the technical field of river channel cleaning, in particular to an alternanthera philoxeroides straw crushing device for river channel cleaning. Aiming at the problem that alternanthera philoxeroides straws are intertwined easily and difficult to feed, the following scheme is proposed: the device includes a base; the base is provided with supporting legs in the four corners of the top outer wall thereof, the same box body is arranged on the top outer walls of the four supporting legs; the box body is provided with a feeding inlet in the top outer wall thereof; the boxbody is provided with a first through hole and a first groove in two inner walls near the feeding inlet respectively; and the inner walls of the first through hole and the first groove are rotationally connected with a feeding wheel through bearings. The feeding wheel can be driven to rotate by a first rotating motor. Through a feeding hook and barbs, alternanthera philoxeroides straws can be hooked and fed to crushing rollers. Baffles can prevent the straws from being hooked to the feeding hook. Therefore, the problem that the alternanthera philoxeroides straws are intertwined easily and difficult to feed can be solved.

Owner:嘉兴麦瑞网络科技有限公司

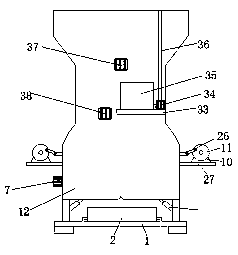

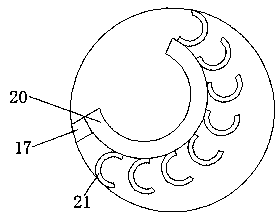

Copying drum cutting type flos carthami harvesting device

PendingCN108886961ASolve the problem of severe jitterSolve feeding difficultiesPicking devicesFlosEngineering

A copying drum cutting type flos carthami harvesting device mainly comprises a rack portion, a drum cutting portion and an air-suction collecting portion. The rack is used for fixing various components, and the drum cutting portion is mounted in an air-suction cover. During harvesting operation, flower balls enter the device from a position in front of a rack, and touch the air-suction cover at first, under the effect of negative pressure in the air-suction cover, filaments enter an opening of the wall of the air-suction cover, at the moment, the flower balls move to a copying baffle below theair-suction cover, under the effects of air suction and the copying baffle, the flower balls are fixed shortly, the fixed flower balls and filaments are cut by the cutting portion, the cut filamentsare collected to a negative-pressure collecting box under the effect of negative pressure, and thus, a harvesting process is finished. According to the device, the flower balls are fixed under the effect of the copying baffle and air suction, the problems that the flower balls shake severely, and the filaments are fed difficultly are solved effectively, by a drum knife, the filaments are cut continuously, and the picking efficiency is improved.

Owner:SHIHEZI UNIVERSITY

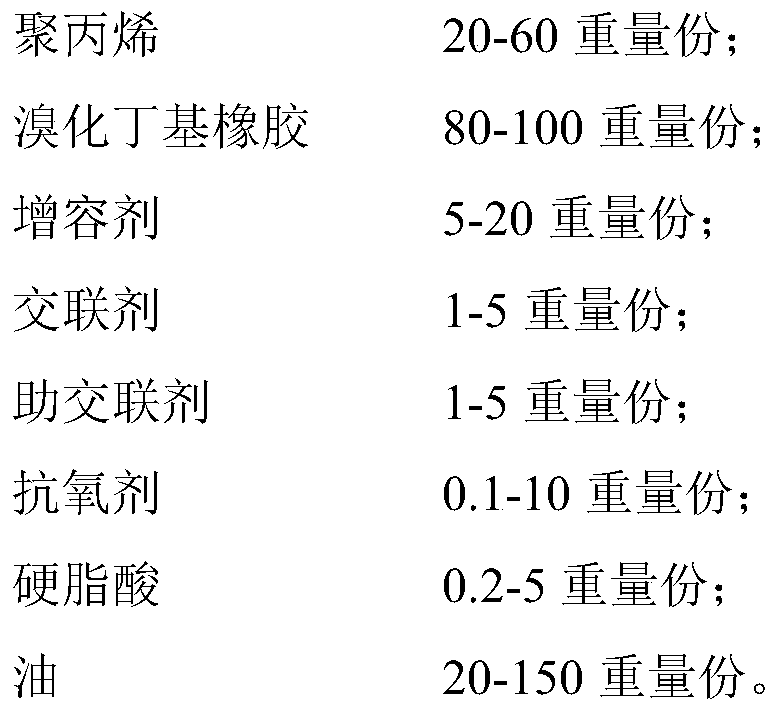

Brominated butyl rubber/polypropylene thermoplastic vulcanized rubber with low hardness and capability of 3D printing and preparation method and application thereof

PendingCN109796689AImprove mechanical propertiesImprove fluidity and self-adhesivenessAdditive manufacturing apparatusSmooth surfacePolypropylene

The embodiment of the invention relates to the field of materials, in particular to a brominated butyl rubber / polypropylene thermoplastic vulcanized rubber with low hardness and capability of 3D printing and a preparation method and application thereof. The brominated butyl rubber / polypropylene thermoplastic vulcanized rubber is prepared from a raw material comprising the following components: polypropylene, brominated butyl rubber, a compatibilizer, a cross-linking agent, an auxiliary cross-linking agent, an antioxidant, stearic acid and oil. The preparation method comprises the following steps of: granulating rubber; oil filling; granulating master batch; vulcanizing. The brominated butyl rubber / polypropylene thermoplastic vulcanized rubber prepared by a formula and the preparation method has the advantages of high mechanical property, good compatibility, good fluidity, high self-adhesion, flat and smooth surface, suitability for 3D printing, low hardness and suitability for medicalrubber plugs. In addition, the feeding mode of single-screw melt feeding solves the problem that wire feeding is difficult when the low-hardness brominated butyl rubber / polypropylene thermoplastic vulcanized rubber is used for 3D printing.

Owner:QINGDAO UNIV OF SCI & TECH

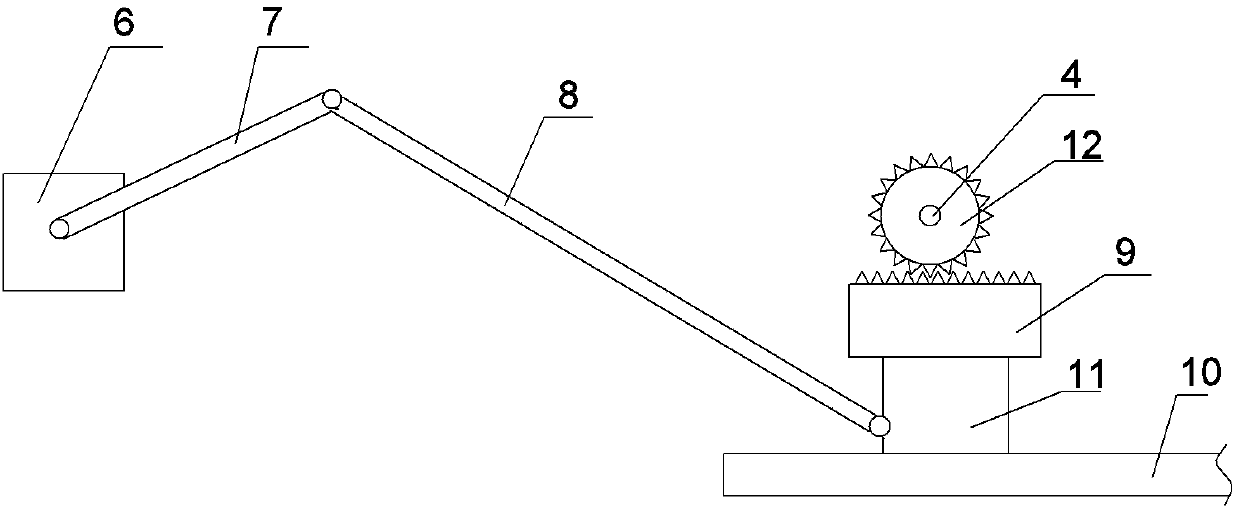

Rapid feeding mechanism of shaft workpiece

PendingCN109110404ASolve feeding difficultiesArranged in an orderly mannerConveyorsEngineeringMechanical engineering

The invention discloses a rapid feeding mechanism of a shaft workpiece. The mechanism comprises a machine frame, an outer cover is arranged on the machine frame, a feeding port and a discharging portare formed in the machine frame, the feeding port is lower than the discharging port in the vertical direction, and a stepping lifting mechanism is arranged between the feeding port and the discharging port; and the stepping lifting mechanism comprises a reciprocating driving assembly and a reciprocating push plate set, wherein the reciprocating driving assembly drives the reciprocating push plateset to move in a reciprocating mode, and the shaft type workpiece entering from the feeding port is conveyed to the discharging port in a stepping mode. The rapid feeding mechanism has the beneficialeffects that the problem of difficulty in feeding the shaft-type workpiece is effectively solved, ingenious and reliable are achieved, so that the shaft-type workpiece can be quickly and orderly arranged, and the function that the shaft workpiece is conveyed from a low position to a high position is completed.

Owner:JIANGSU XINTIMU INTELLIGENT EQUIP CO LTD

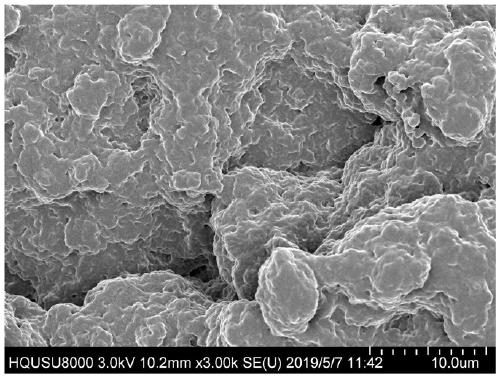

Graphene oxide master batch as well as preparation and application thereof

The invention belongs to the technical field of graphene, and particularly relates to a graphene oxide master batch as well as preparation and application thereof. According to the technical scheme, agraphene oxide aqueous solution is directly added into a waterborne polyurethane emulsion with good intermiscibility, and dispersion of graphene oxide in the waterborne polyurethane emulsion is promoted. A polypeptide condensing agent is added, so that amidation and esterification reactions between active groups such as carboxyl on the surface of the graphene oxide and active groups such as hydroxyl and amino on a waterborne polyurethane chain are promoted; the interface bonding strength of the graphene oxide and the waterborne polyurethane is enhanced, the good dispersion of the graphene oxide in the waterborne polyurethane is further promoted, and a slow demulsification process is formed. The obtained graphene oxide master batch can be directly mixed with polyester, polyamide, thermoplastic polyurethane and other high-molecular resin and then subjected to melt extrusion, thermal reduction of graphene oxide is achieved, and the problems that graphene powder is difficult to feed, large in dust amount, prone to agglomeration, weak in binding power with matrix resin and the like are solved.

Owner:FUJIAN HUACAI NEW MATERIALS CO LTD

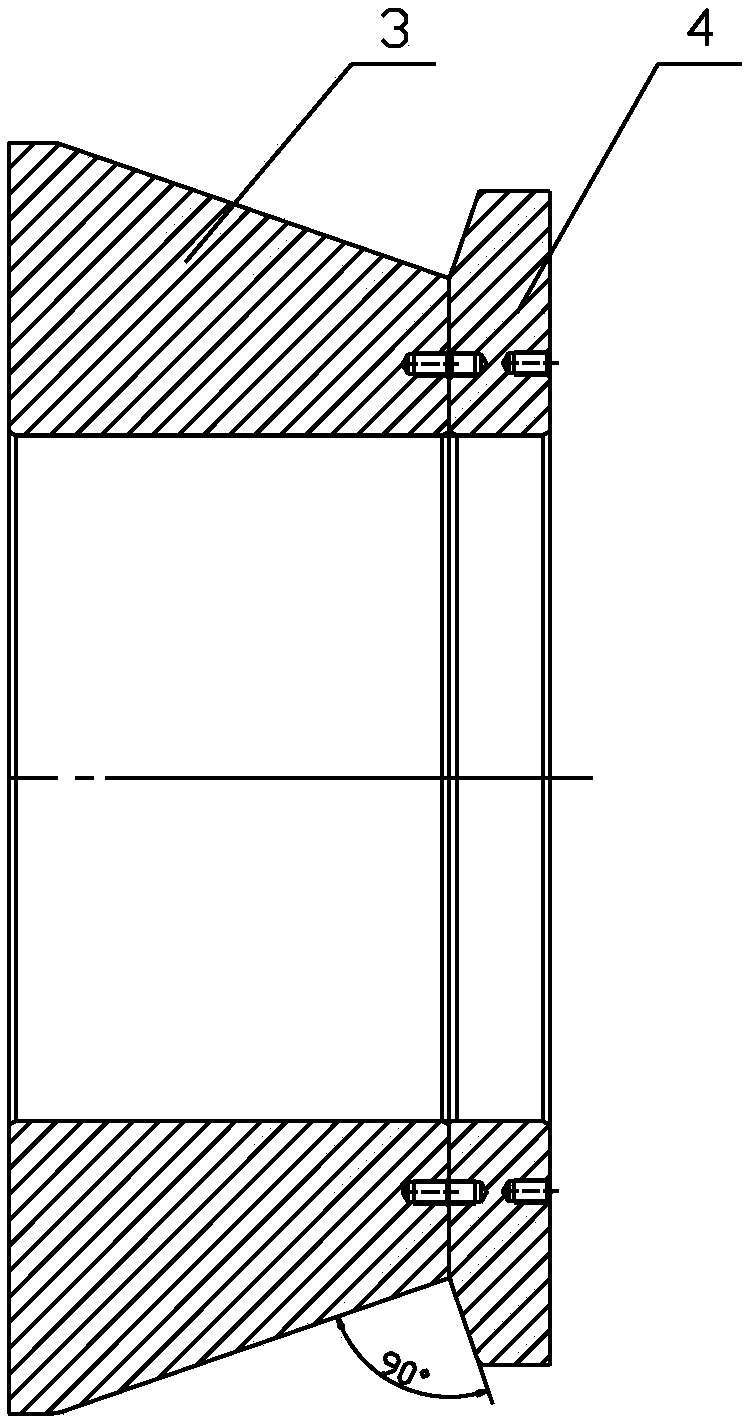

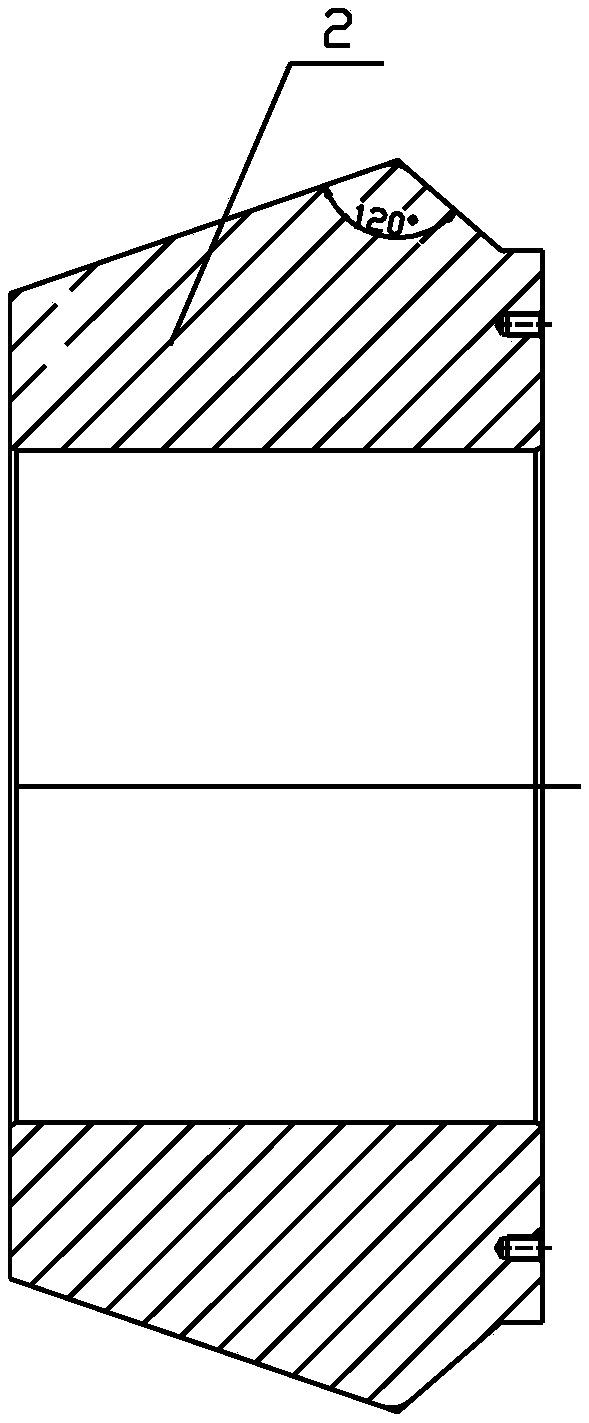

Straightening method for flat-bulb steel and straightening roll

InactiveCN108296315ASolve the difficulty of feedingReduce labor intensityShaping toolsEngineeringAxial force

The invention relates to a straightening method for flat-bulb steel. The method comprises the steps that 1) 'oblique straightening method' is adopted as the straightening method for the flat-bulb steel for shipbuilding, that is, the flat-bulb steel obliquely enters into a straightening machine at an angle of 16 degrees to 25 degrees; 2) upper and lower straightening rolls of a hole pattern adjustsvertical bending, the side wall of the end face of the hole pattern adjusts horizontal bending, the upper straightening roll is a two-piece combination type, and the lower straightening roll is an integral type; 3) straightening pressures are sequentially decreased from an entrance direction of the straightening machine, and a depressed stroke is adjusted within a range of 4 millimeters to 15 millimeters. The straightening method for the flat-bulb steel has the advantages that the flat-bulb steel is straightened by a roll type straightening machine, a cross-sectional shape is rolled by combining with an oblique rolling method, and the straightening positions are a flat-bulb steel web plane and the outer side of a bulb. The combined upper straightening roll can effectively solve the problem that the side wall is broken due to excessive axial force, and thereby roll scrap is produced, the straightening roll consumption is greatly reduced, the straightening quality and output are remarkably improved, the oblique straightening method reduces the amount of vehicle repair and improves the utilization rate of the rolls.

Owner:ANGANG STEEL CO LTD

Loading mechanism for automatic unpacking machine for seeds

ActiveCN111776669ASuitable for useEasy loadingArticle unpackingSupporting framesAgricultural engineeringStructural engineering

The invention discloses a loading mechanism for an automatic unpacking machine for seeds. The loading mechanism for the automatic unpacking machine for the seeds comprises a loading plate and a rotation mechanism fixedly installed below the loading plate, wherein a lifting mechanism is rotationally installed below the rotation mechanism; and a movable placement mechanism is fixedly installed belowthe lifting mechanism. According to the loading mechanism for the automatic unpacking machine for the seeds, through the arrangement for the lifting mechanism, the height of the loading plate can beadjusted according to the actual height of a conveying belt of the unpacking machine, and the loading plate is applicable to the actual use; through the arrangement for the rotation mechanism, the loading plate can be rotated to reach an angle suitable for working personnel to load through rotation, after the loading is completed, the loading plate is rotated to the conveying belt, materials are pushed onto the conveying belt through a hydraulic pushing mechanism to complete loading, and though the arrangement, the problem of difficult loading caused by a large distance between the conveying belt and the ground can be solved, and the working personnel can load more conveniently; and through the arrangement for the movable placement mechanism, movement or fixed placement is facilitated, andthe movable placement mechanism is applicable to loading on different occasions.

Owner:HEFEI YU SHENG INFORMATION TECH

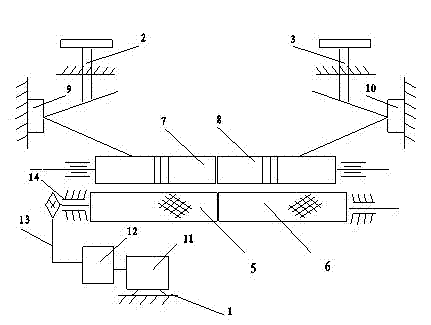

Strong pressure type sludge deep dehydration system

ActiveCN104492134AExpand follow-up treatment channelsWith contraction functionSludge treatment by de-watering/drying/thickeningFiltration separationGeotechnicsSludge

The invention relates to a strong pressure type sludge deep dehydration system, belonging to the technical field of environmental geotechnics. The strong pressure type sludge deep dehydration system is composed of a stroke support, a front top plate, a rear top plate, a shrinking steel rod, a piston grouting pump, a discharging plate and more than two arranged dehydrating units; According to the strong pressure type sludge deep dehydration system, the piston grouting pump is adopted to grout under strong pressure, so that a problem that sludge with low moisture content is difficultly fed is solved; the dehydrating units have shrinking functions and can realize sludge deep dehydration under strong pushing action of a hydraulic oil cylinder; the discharging plate can be used for discharging the dehydrated sludge automatically under the cooperative action of the shrinking steel rod and a mechanical arm; the whole system can realize continuous and automatic operation, and the time and labor costs are saved; and the strong pressure type mechanical dehydration mode is adopted, the energy consumption is low, the effect is good, the dehydration treatment cost is reduced and the follow-up sludge disposal way is expanded.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

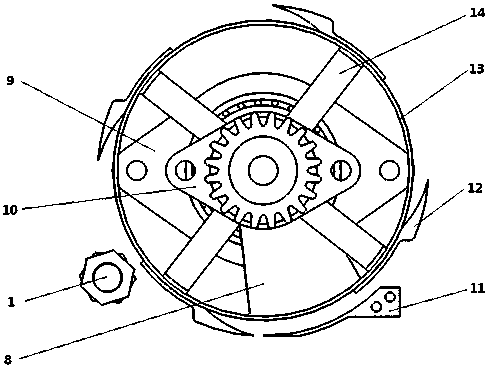

Roller cutting type flos carthami filament harvesting device

PendingCN108271511ASolve feeding difficultiesAchieve continuous cutting and harvestingHarvestersEngineering

The invention provides a roller cutting type flos carthami filament harvesting device. The roller cutting type flos carthami filament harvesting device comprises a rack part, a cutting part and a negative pressure collecting part. The rack part is used for fixing all parts, a baffle rod is installed at the front end of a rack, the cutting part is installed at the rear end of the rack, and the negative pressure collecting part is installed at the rear end of the cutting part. In the forward moving process of the whole device, plants firstly pass through the baffle rod, if the height of flower balls is lower than the mounting position of the baffle rod, the flower balls successfully pass through the baffle rod to arrive at the cutting part, a rotary cutter completes cutting, if the height ofthe flower balls is higher than the mounting position of the baffle rod, the flower balls cannot pass through the baffle rod, at this moment, the device continues to move forwards, since the absoluteposition of the plants is unchanged, the relative height of the flower balls and the baffle rod is continuously reduced till the flower balls can successfully pass through the baffle rod to arrive atthe cutting part, and cutting and harvesting are completed. Cut filament is absorbed by a negative pressure collecting opening on the inner wall of the rotary cutter and is transferred to a collecting box through a pipe, and the whole harvesting work is completed. Through the sawtooth type rotary cutter, the device conducts cutting, the problem that the filament is difficult to feed can be effectively solved, large-scale blind harvesting is achieved, and the harvesting efficiency is improved.

Owner:SHIHEZI UNIVERSITY

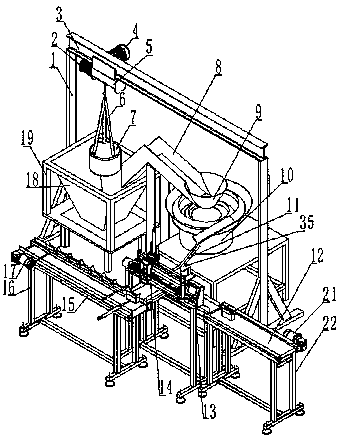

Iron nail counting, arranging and boxing system

PendingCN109367878ASolve feeding difficultiesOrderly rowsPackaging automatic controlEngineeringDrive motor

The invention discloses an iron nail counting, arranging and boxing system which comprises a lifting support, a vibrating plate, a controller, a feeding control mechanism and a box input mechanism. Asliding chute is formed in a support rod on the top part of the lifting support; a rolling and sliding device is arranged on the sliding chute; an up-and-down drive motor and a horizontal drive deviceare arranged on the rolling and sliding device; the rolling and sliding device is connected to an electromagnet through a lifting belt; a storage box is placed under the electromagnet and is connected to a storage hopper through an anti-falling guide groove; the vibrating plate is placed under the storage hopper; a slideway is arranged on one side of the vibrating plate; an optical fiber countingmodule is arranged on the slideway; the feeding control mechanism is arranged on one side of the slideway; and the controller is arranged on the feeding control mechanism. The iron nail counting, arranging and boxing system has the beneficial effects that the problems of difficulty in loading, counting and arranging and easiness in scratching fingers or skins are solved, the number of working personnel is reduced, iron nails are arranged in order, the production efficiency is improved, the iron nails are boxed and arranged, and the structure is novel.

Owner:GUANGZHOU MINGKE PACKAGING MACHINERY CO LTD

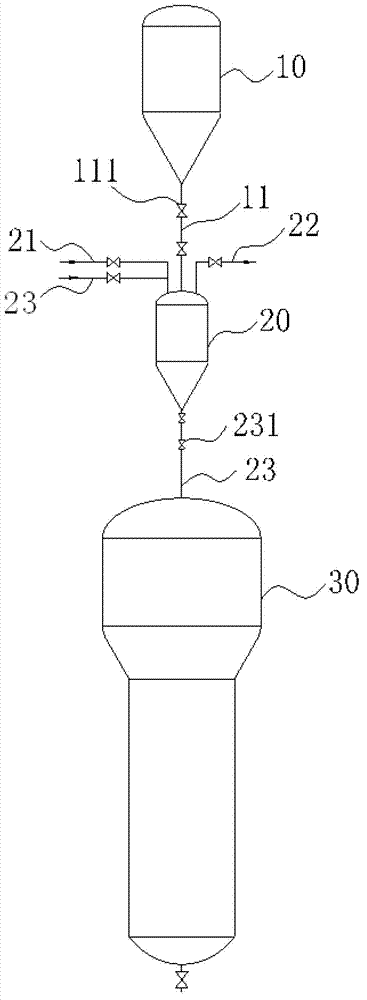

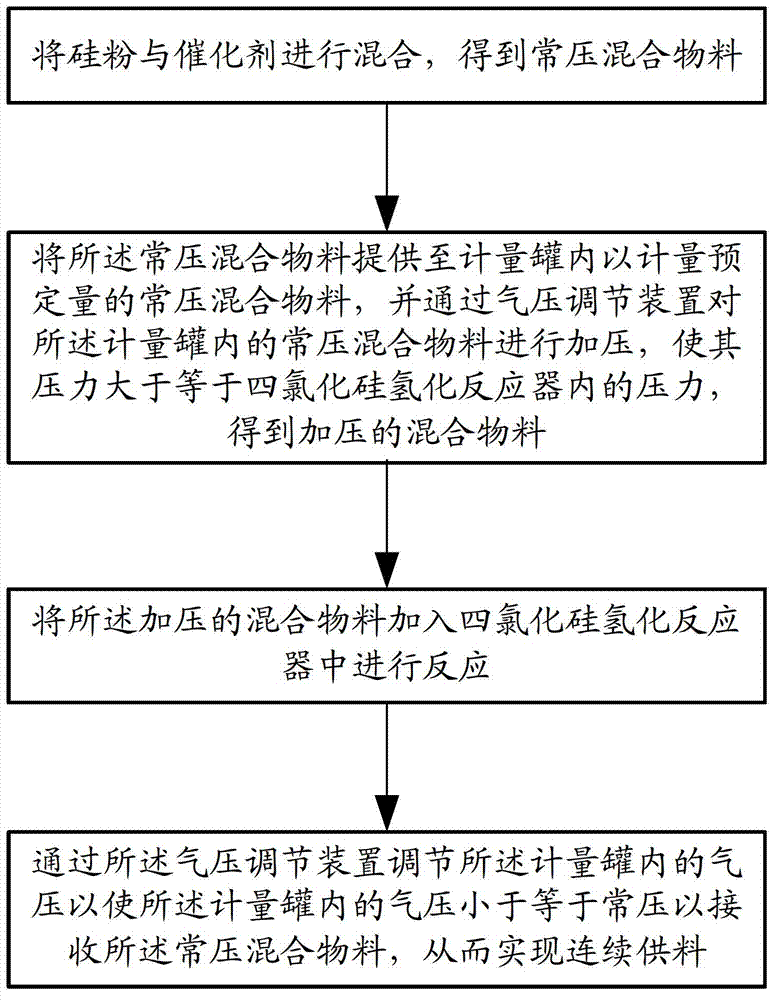

Silicon tetrachloride hydrogenation reaction device and solid raw material continuous feeding device thereof

InactiveCN102815708ASimple structureEasy to useHalogenated silanesHydrogenation reactionAtmospheric pressure

The invention discloses a silicon tetrachloride hydrogenation reaction device and a solid raw material continuous feeding device thereof. The solid raw material continuous feeding device of silicon tetrachloride hydrogenation reaction comprises a storage tank and a metering tank which communicates with each other. Solid materials for the silicon tetrachloride hydrogenation reaction are stored in the storage tank. The metering tank is provided with a material outlet used for supplying the solid raw materials to the silicon tetrachloride hydrogenation reaction device. The metering tank is provided with an atmospheric pressure adjusting device which is used for adjusting the atmospheric pressure in the metering tank. According to the silicon tetrachloride hydrogenation reaction solid raw material continuous feeding device provided by the embodiment of the invention, the atmospheric pressure adjusting device is arranged on the metering tank, such that a difficulty in feeding from the storage tank with a relatively low atmospheric pressure to the silicon tetrachloride hydrogenation reaction device with a relatively high atmospheric pressure is effectively solved. The feeding device is advantaged in simple structure, convenient application, and high safety.

Owner:CHINA ENFI ENGINEERING CORPORATION

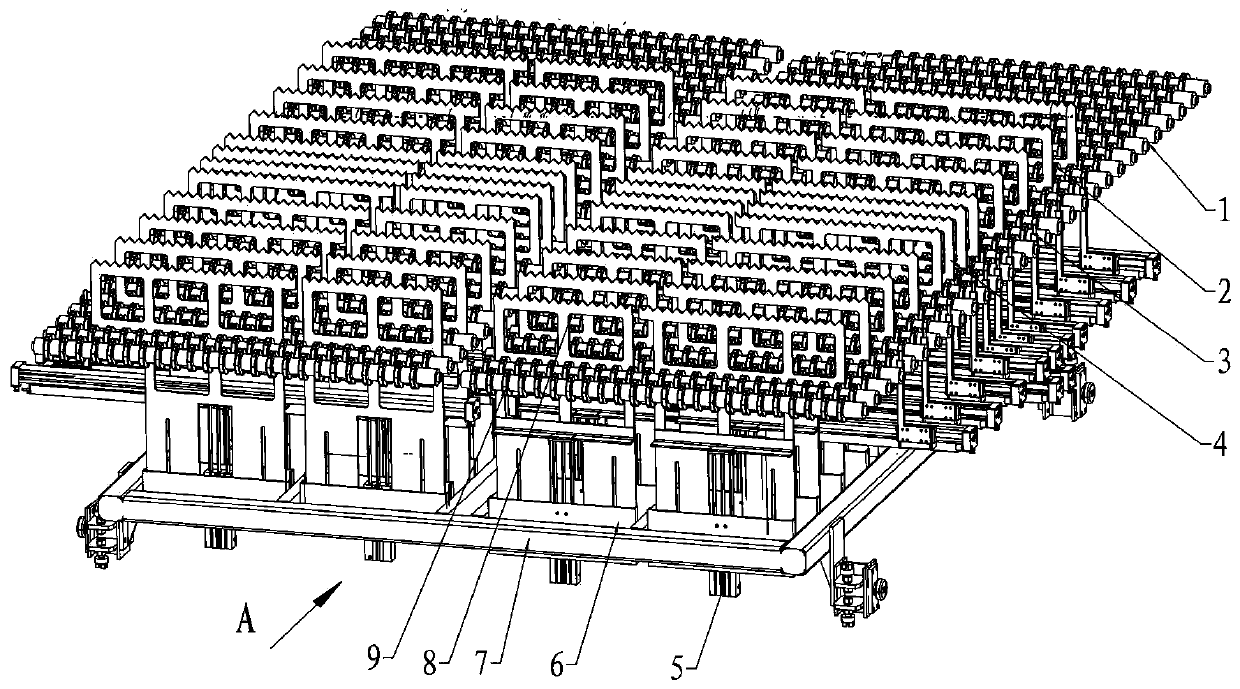

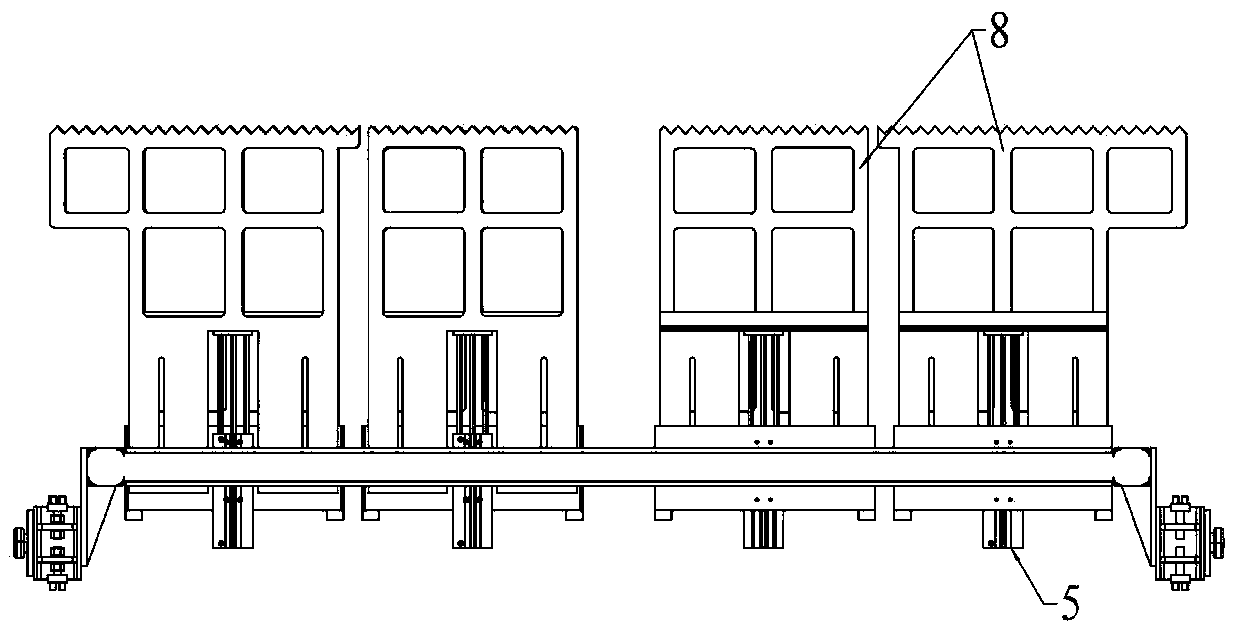

Heating furnace discharging platform system for thermoforming production line

PendingCN111504071ASolve feeding difficultiesSpeed up the debugging processShaping toolsCharge manipulationManufacturing lineProduct Part

A heating furnace discharging platform system for a thermoforming production line comprises a base, a plurality of furnace rollers and a plurality of rows of lifting tool rests, wherein each furnace roller is arranged between adjacent rows of lifting tool rests, each lifting tool rest comprises a plurality of rows of conventional lifting tool rests and a plurality of rows of adjusting lifting toolrests, the rows of conventional lifting tool rests are assembled on a conventional lifting tool rest installation frame, the conventional lifting tool rest installation frame is located in the middleof the base, the conventional lifting tool rest installation frame drives the conventional lifting tool rests to achieve uniform lifting action, the adjusting lifting tool rests are arranged on the peripheries of the conventional lifting tool rests, and the adjusting lifting tool rests respectively control the lifting action according to the specification and the quantity of conveyed product material sheets. The lifting tool rests are composed of the conventional lifting tool rests and the adjusting lifting tool rests, the use of the adjusting lifting tool rests can be selected and adjusted according to the conveying requirements of the appearance and the quantity of product parts, the feeding difficulty caused by the fact that tool rests can only be selected according to long material sheets due to different material sheet lengths is avoided, the debugging and line changing efficiency can be improved, and the application range is wide.

Owner:LINGYUN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com