Patents

Literature

32results about How to "Change working position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

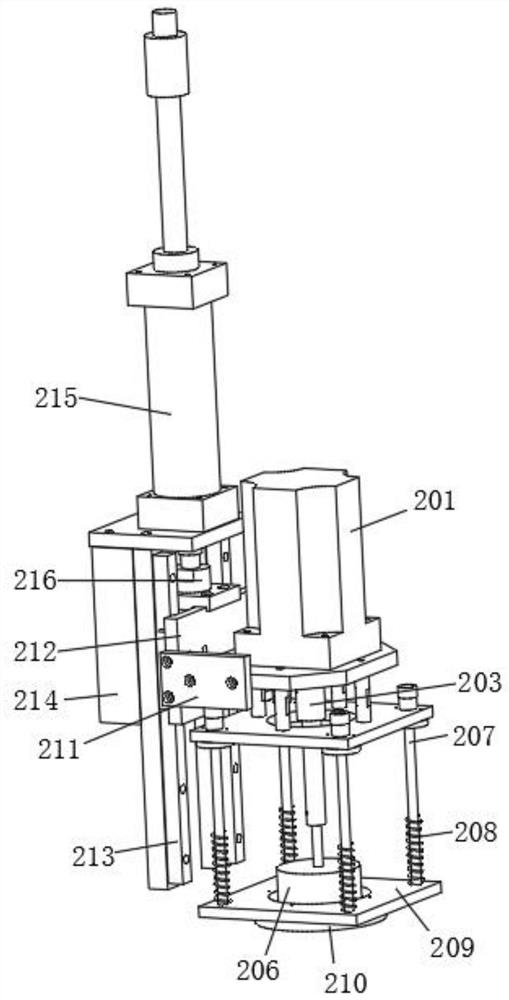

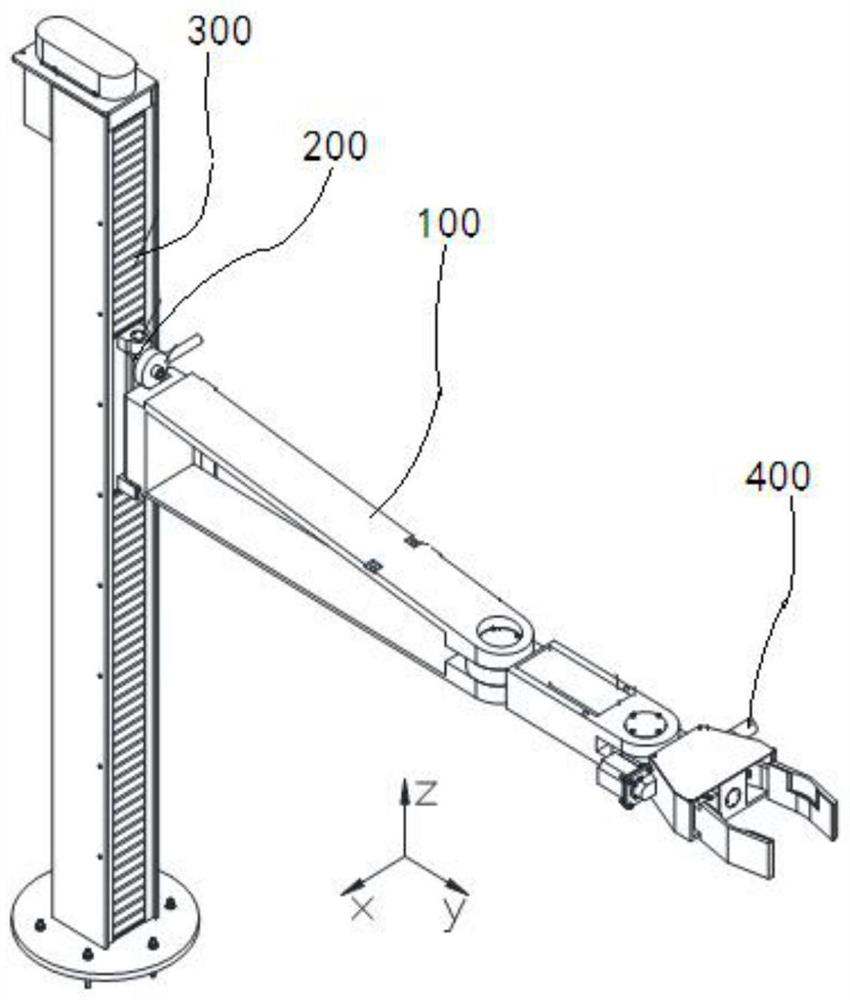

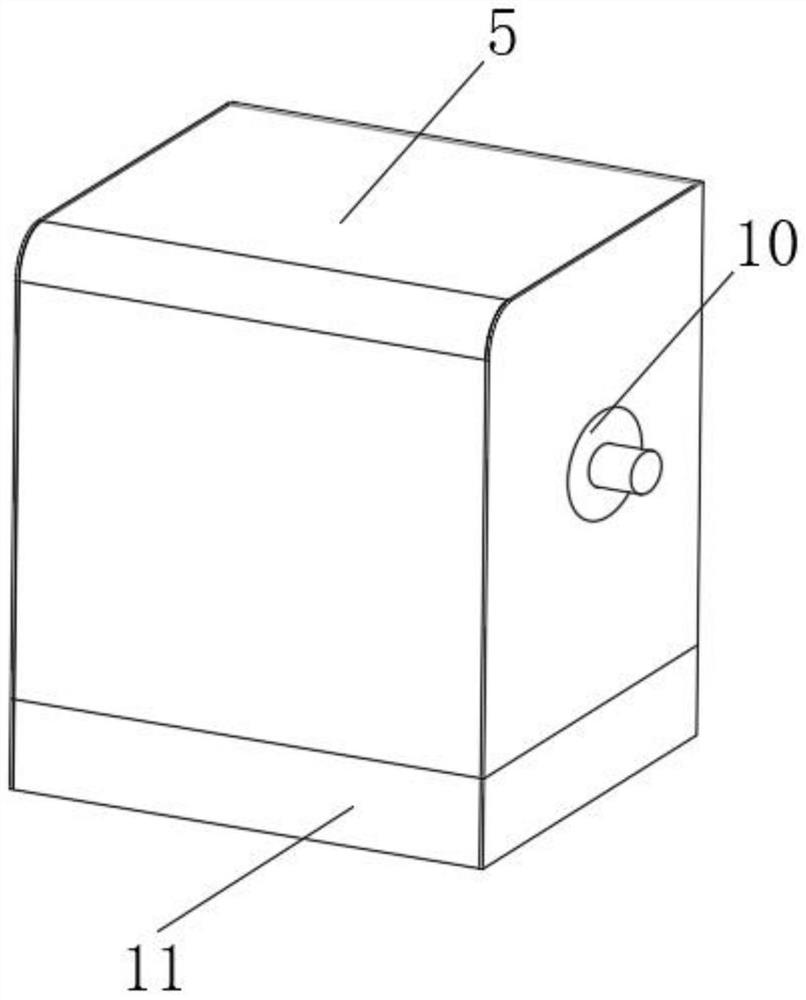

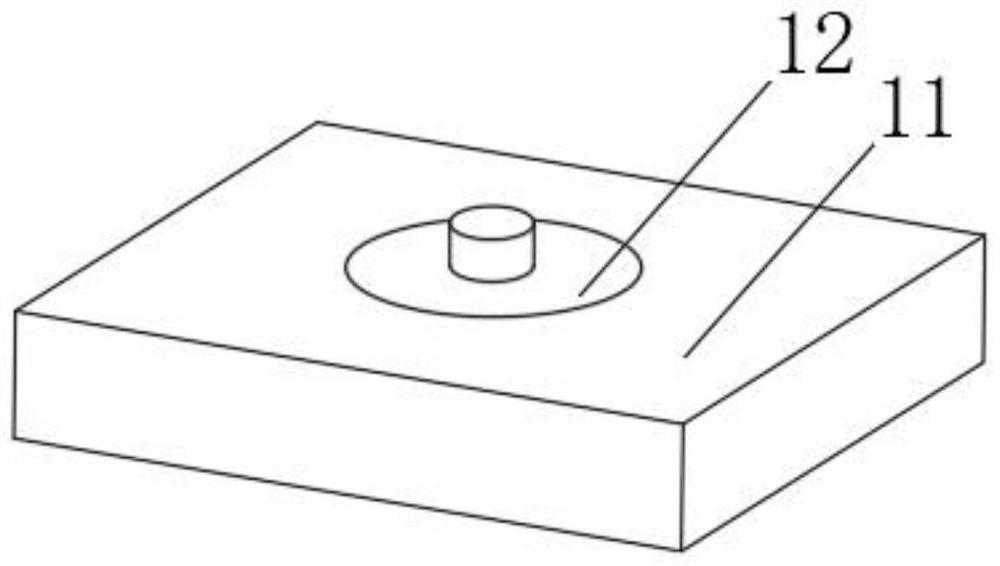

Power-assisted manipulator

InactiveCN108406747AIncrease or decrease movement speedExpand the scope of useProgramme-controlled manipulatorJointsManipulatorHinge angle

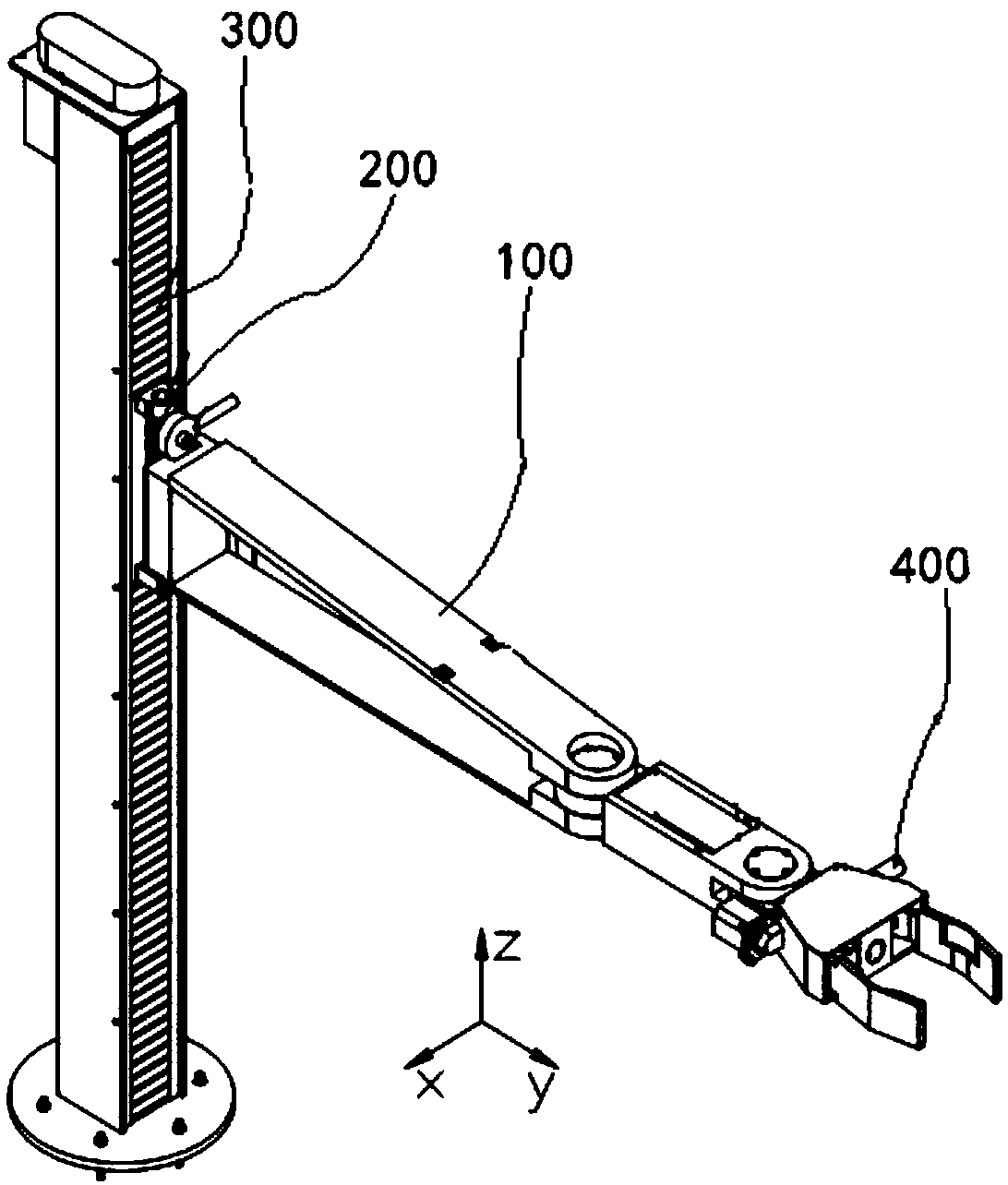

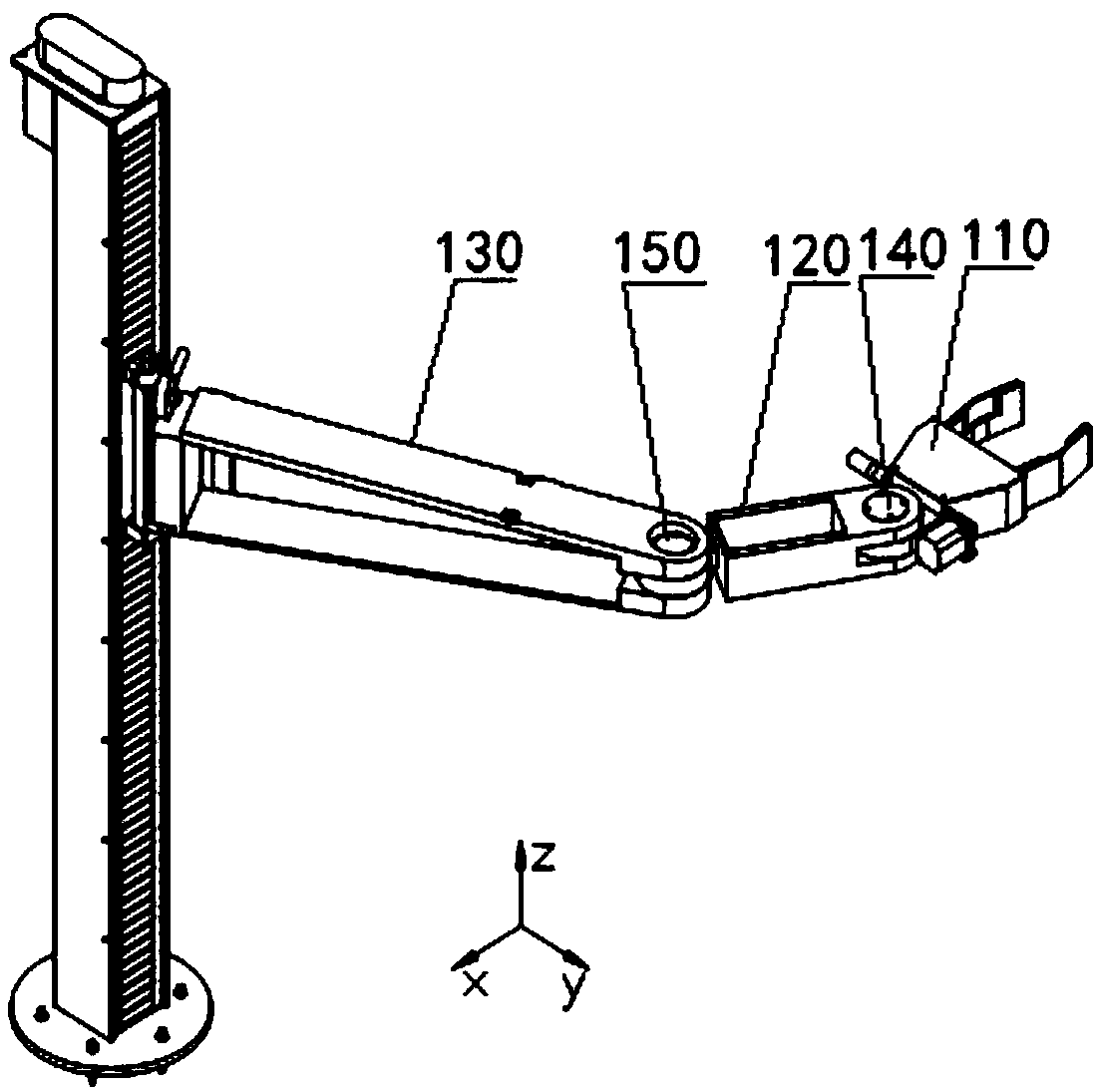

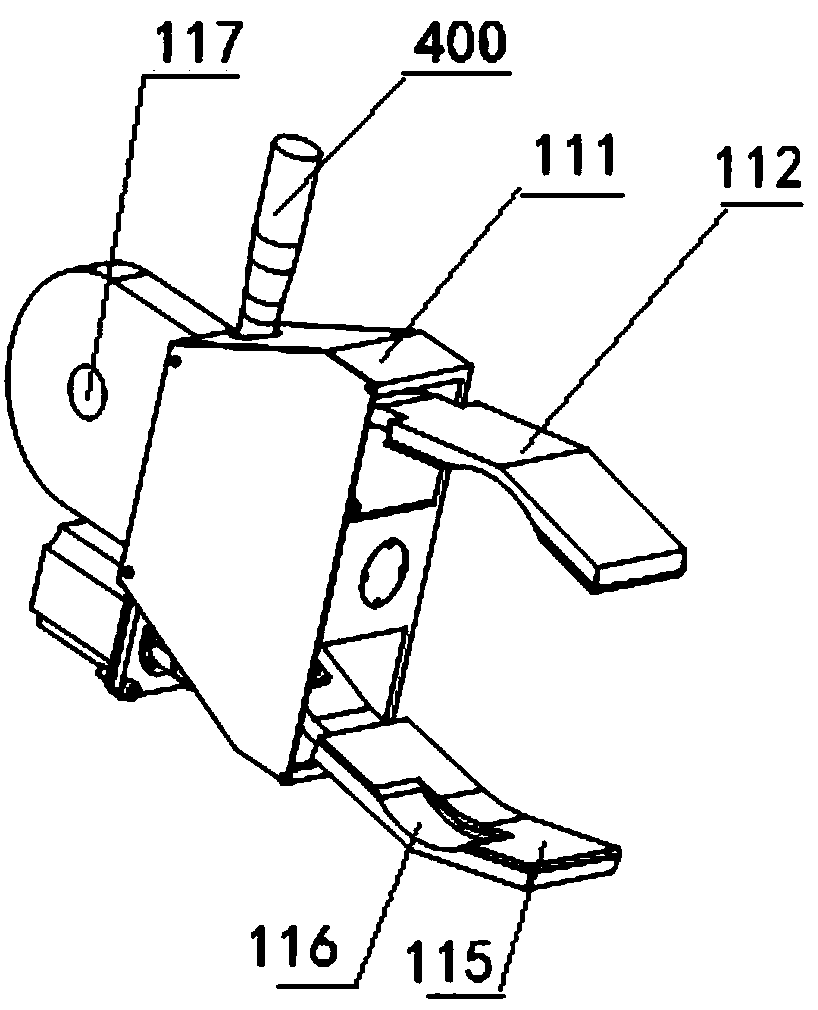

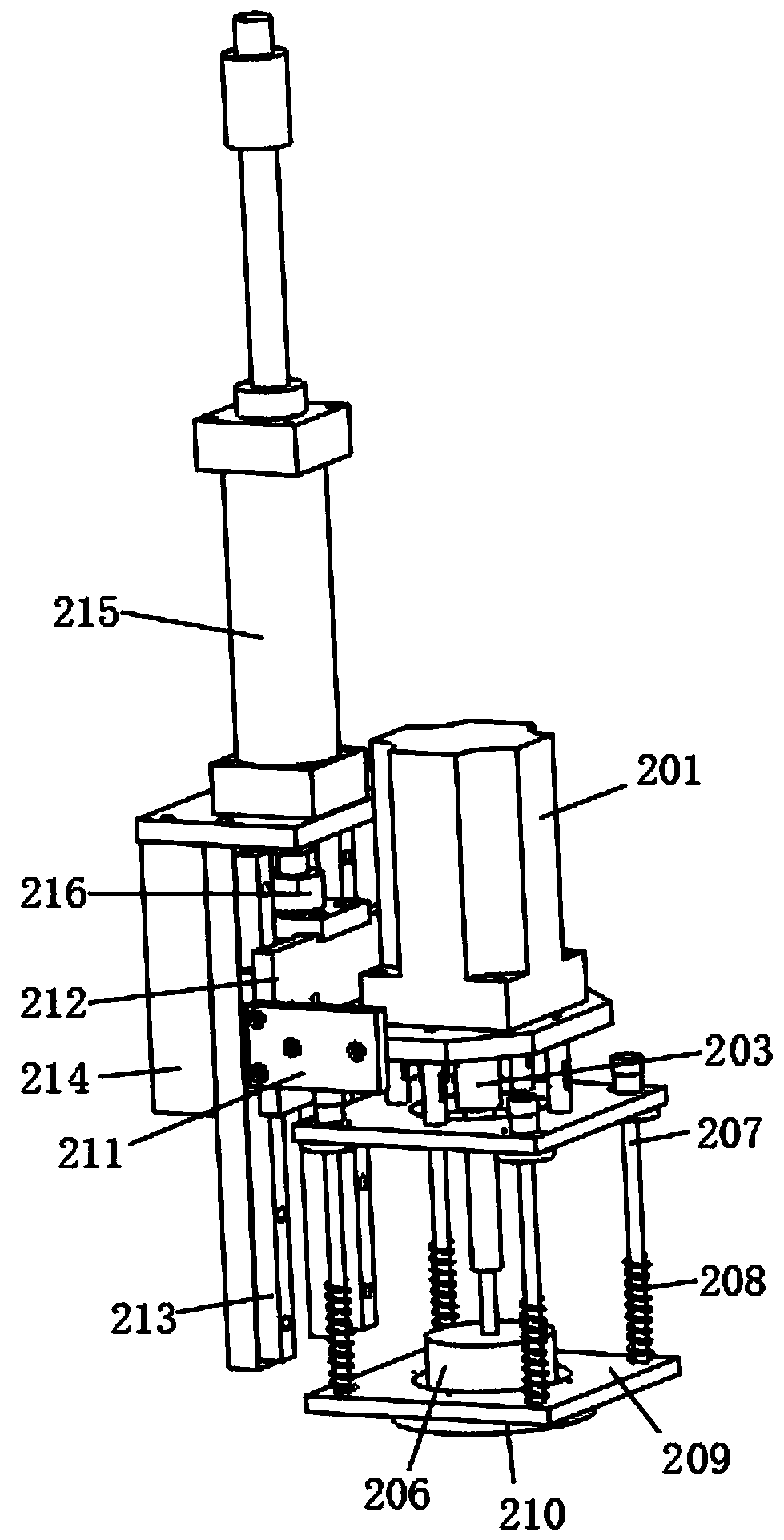

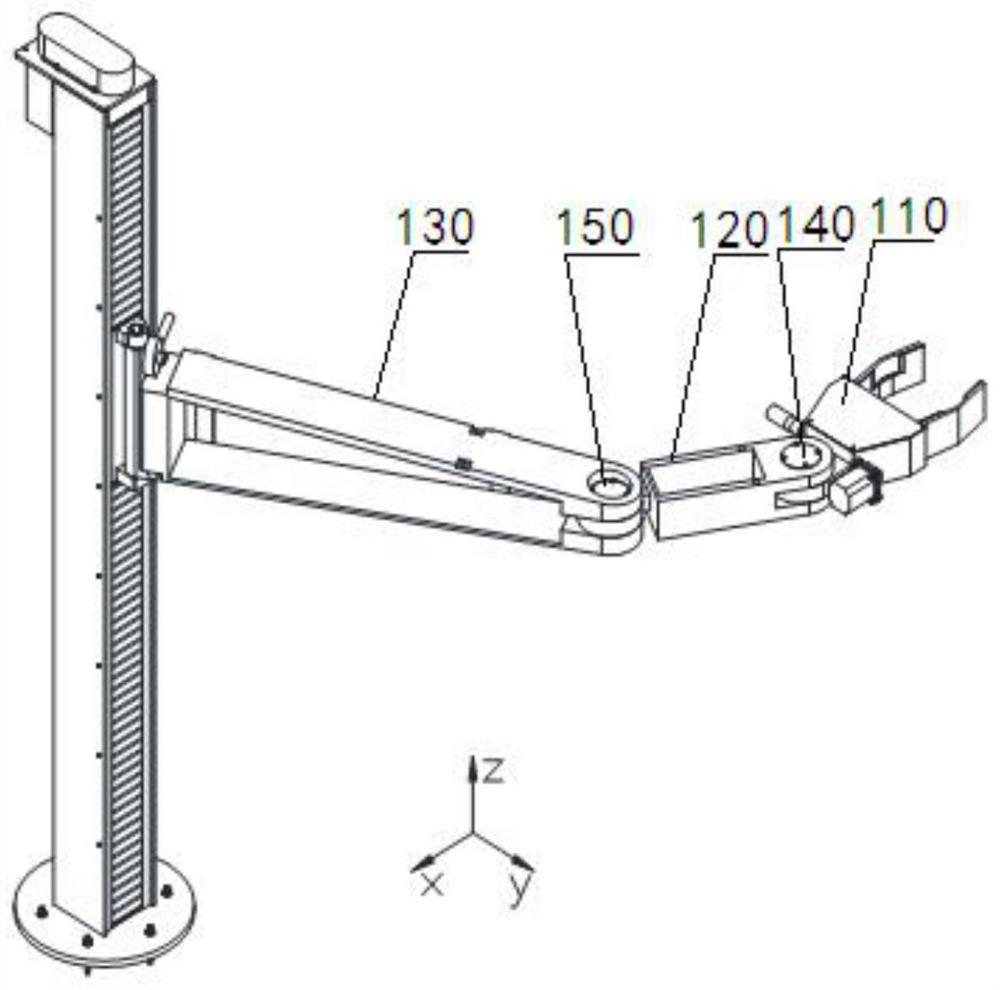

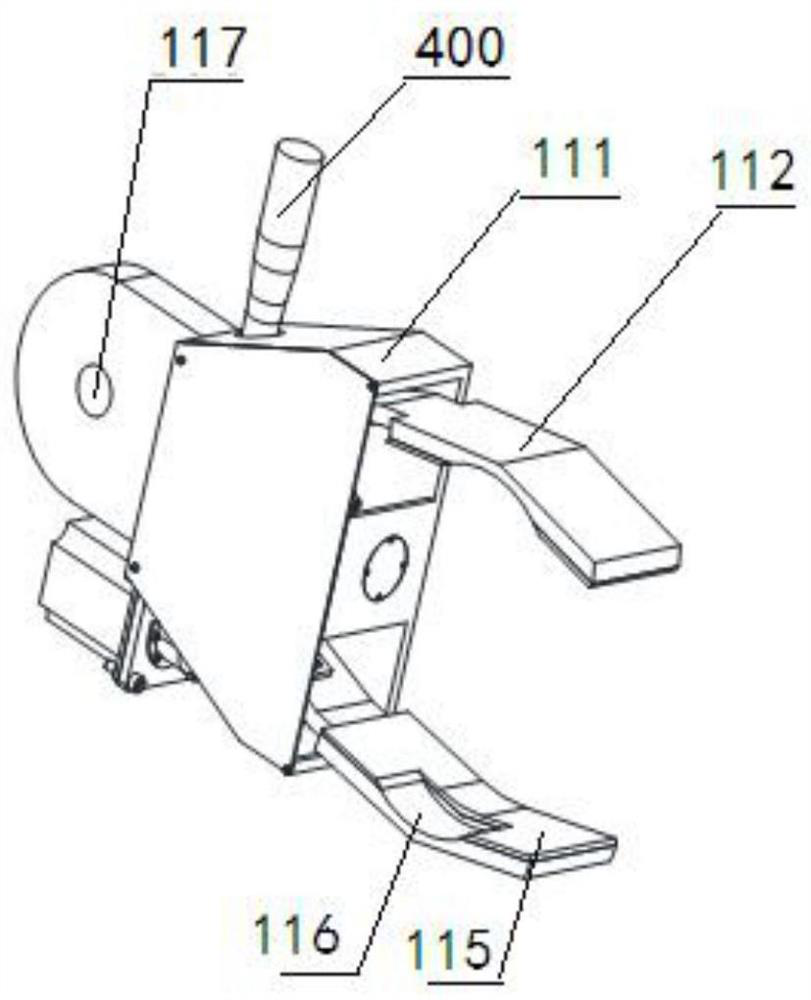

The invention discloses a power-assisted manipulator and belongs to the field of mechanical engineering. The problems that the carrying speed and strength of manipulators cannot be controlled manually, and workpieces with high mass and different sizes are difficult to dismount and mount are solved. The power-assisted manipulator comprises an arm provided with a first locking part, an adapter partwhich is hinged to the arm through an X-direction hinge shaft so that the arm can rotate around the X-direction hinge shaft, a locking mechanism detachably fixed to the adapter part, a connecting partwhich is hinged to the adapter part through a Z-direction hinge shaft so that the adapter and the arm which are connected fixedly can rotate around the Z-direction hinge shaft simultaneously, and a lifting driving mechanism which is connected with the connecting part and used for driving the connecting part, the adapter part and the arm to move in the Z direction, wherein the arm rotate around the X-direction hinge shaft to attach to the adapter part, the locking mechanism is locked with the first locking part so that the arm and the adapter part can be fixedly connected. The manipulator is simple in structure, convenient to operate and powerful in function, and the effect of carrying weights like light objects is achieved.

Owner:JILIN UNIV

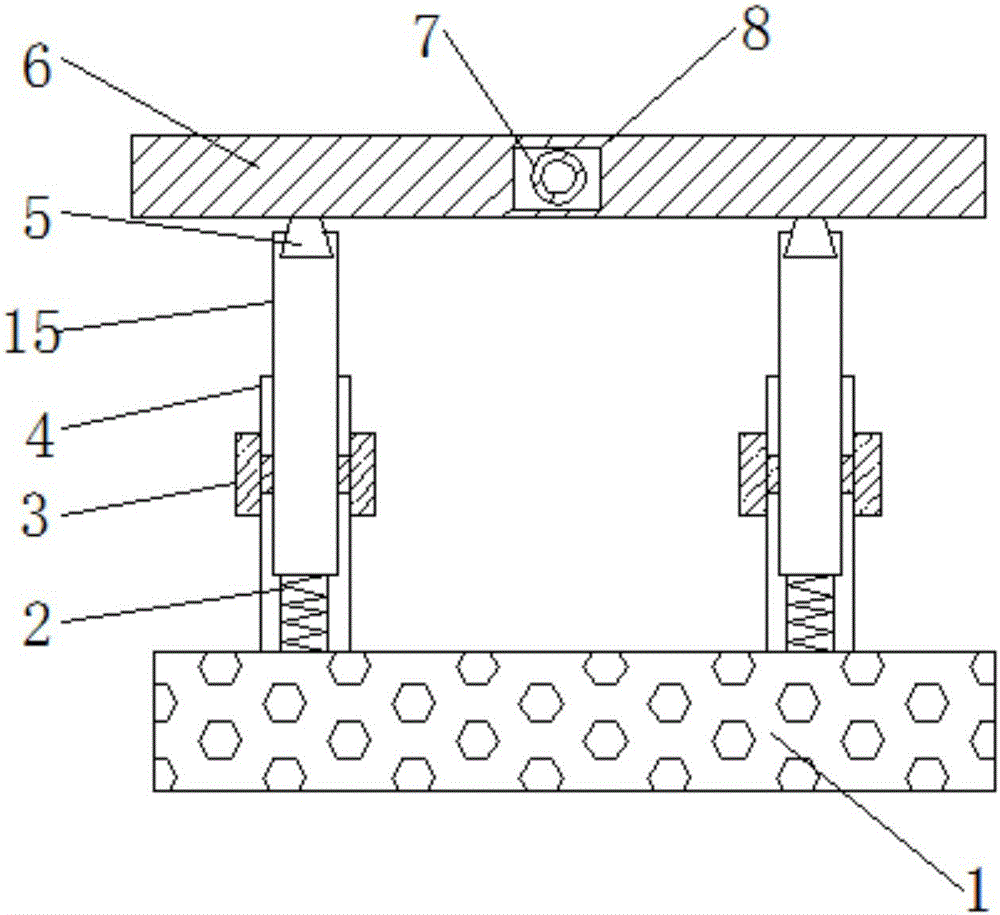

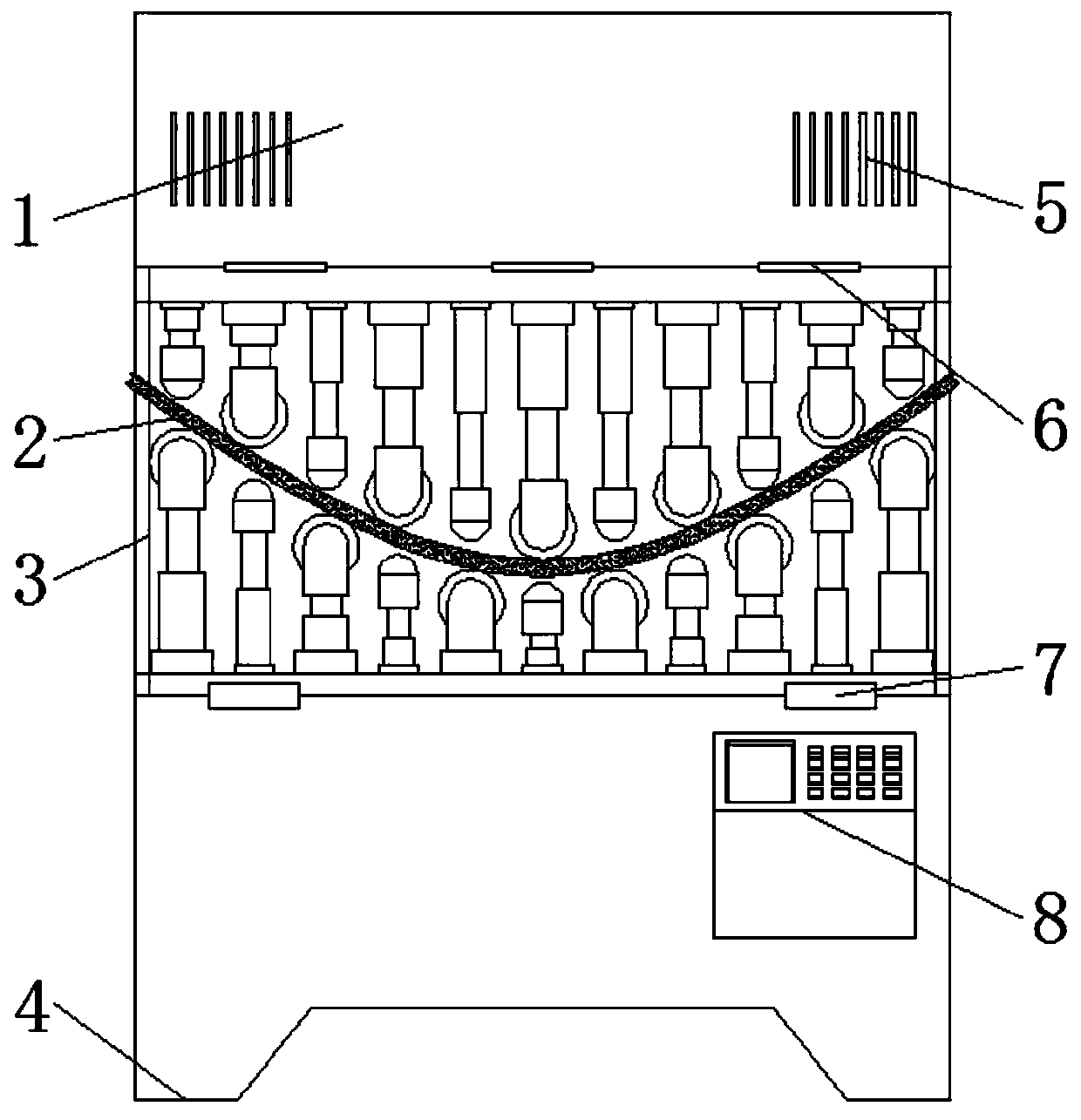

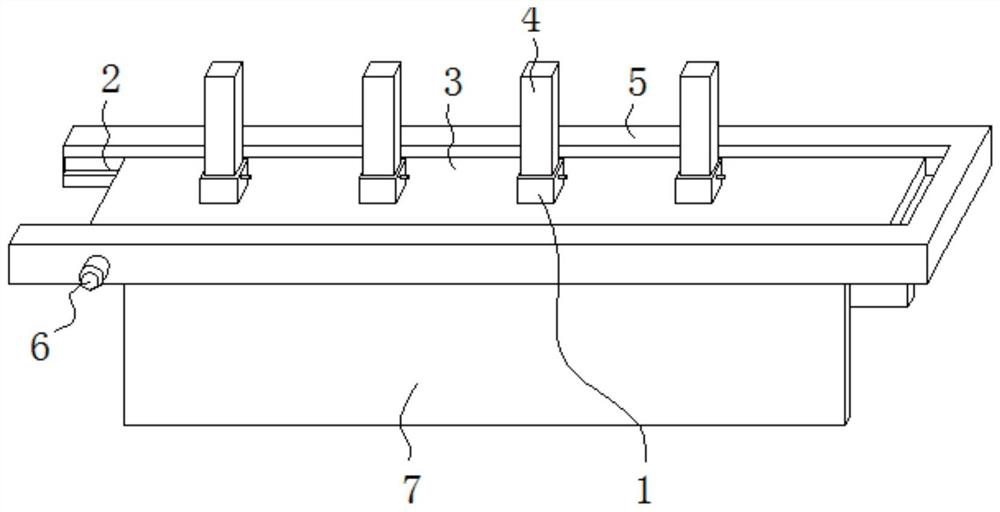

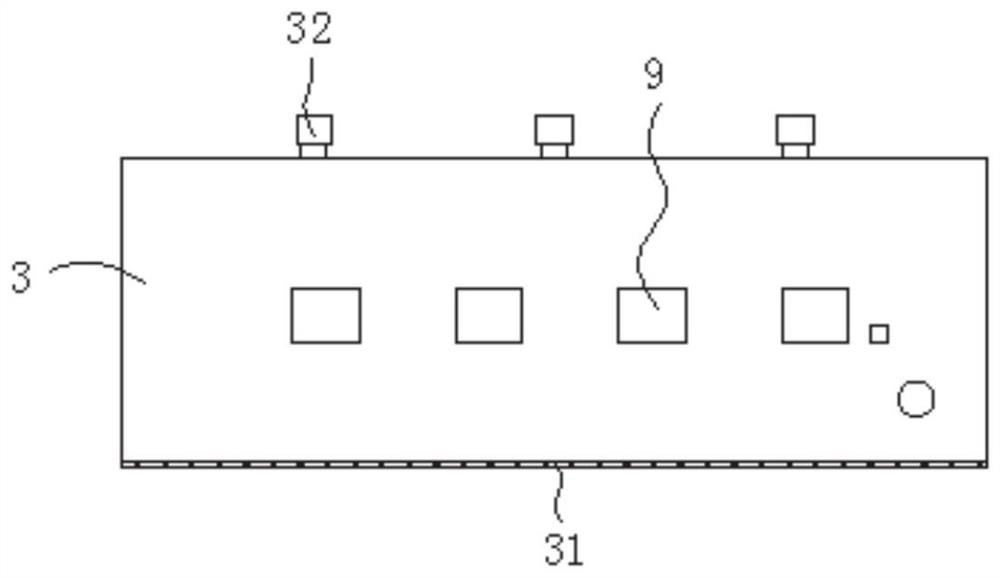

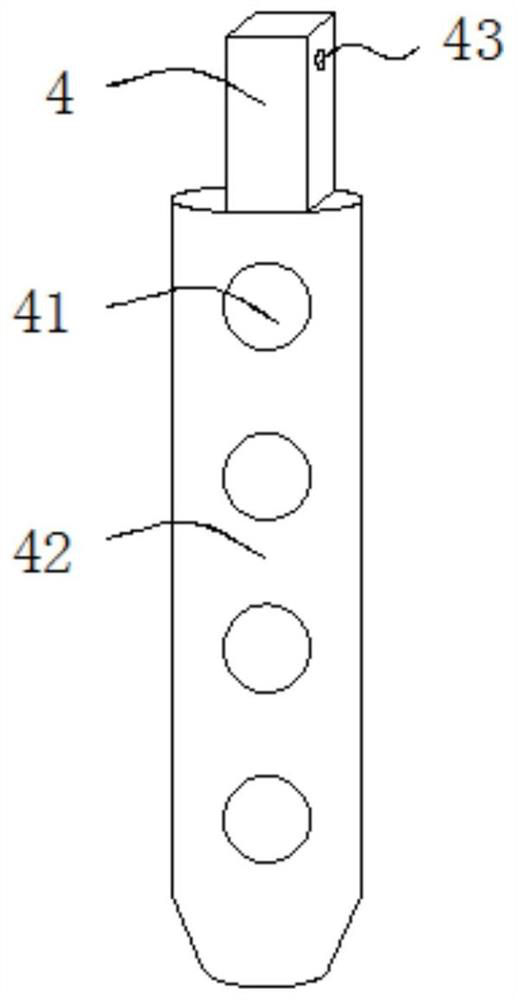

Test tube rack capable of regulating aperture and height for chemical engineering experiment

ActiveCN106423352AHeight adjustableChange heightTest tube stands/holdersCompound (substance)Test tube

The invention discloses a test tube rack capable of regulating an aperture and a height for a chemical engineering experiment. Set bolts adapting to threaded holes are arranged in the threaded holes; sliding chutes are arranged in the upper part of sliding chute plates; a test tube rack is arranged above the sliding chute plates; a left side and a right side below the test tube rack are both provided with sliding blocks; the sliding blocks are located in the sliding chutes; the front end surface of the test tube rack is provided with a motor; the motor is provided with a first screw rod; the first screw rod runs through the test tube rack from front to back; a test tube rack body consists of a first tube wall clamping block and a second tube wall clamping block. According to the test tube rack capable of regulating the aperture and the height for the chemical engineering experiment, the positions, in sleeve plates, of the sliding chute plates are regulated; afterwards, the sliding chute plates and the sleeve plates are connected through the set bolts; thus, the height of the test tube rack is changed; secondly, through utilizing the cooperation between a second screw rod and a nut, the positions of the first tube wall clamping block and the second tube wall clamping block are regulated, so as to clamp test tubes with different diameters.

Owner:JIANGSU NARI YINLONG CABLE

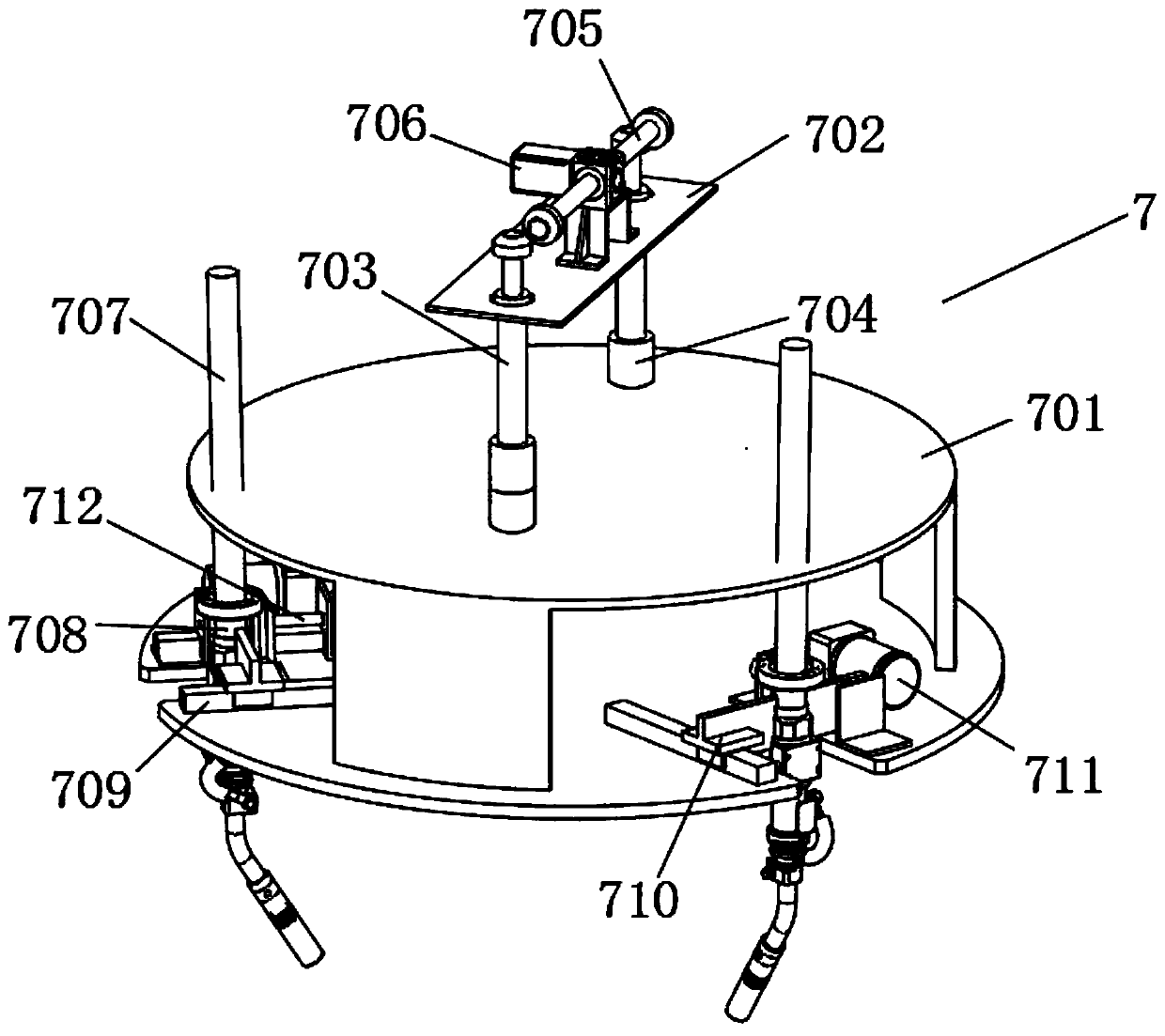

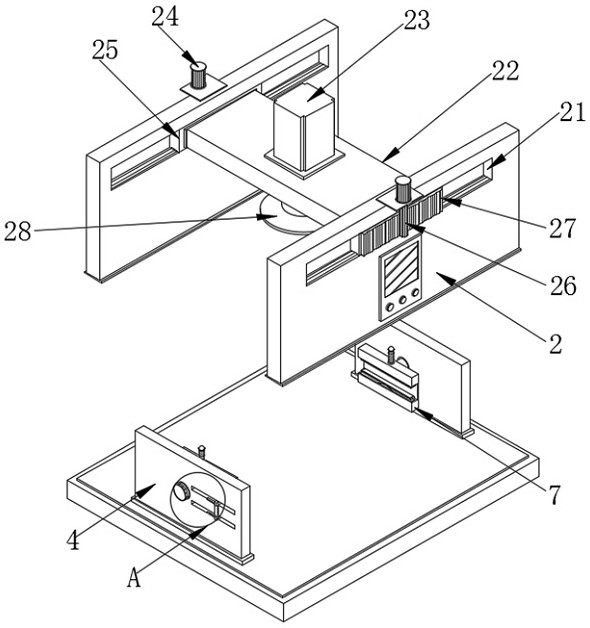

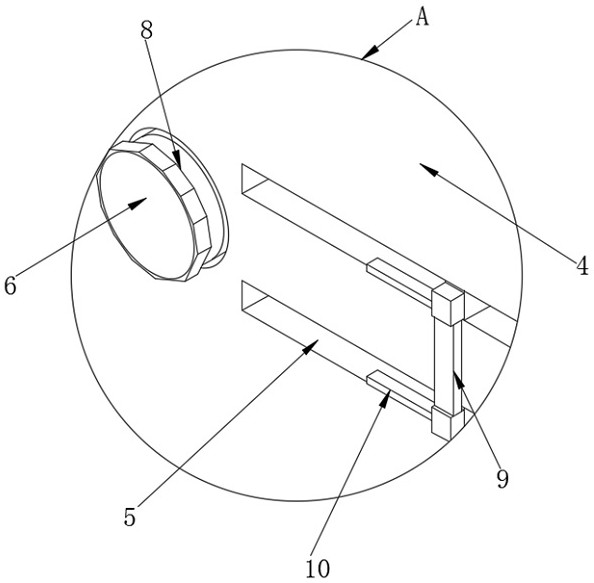

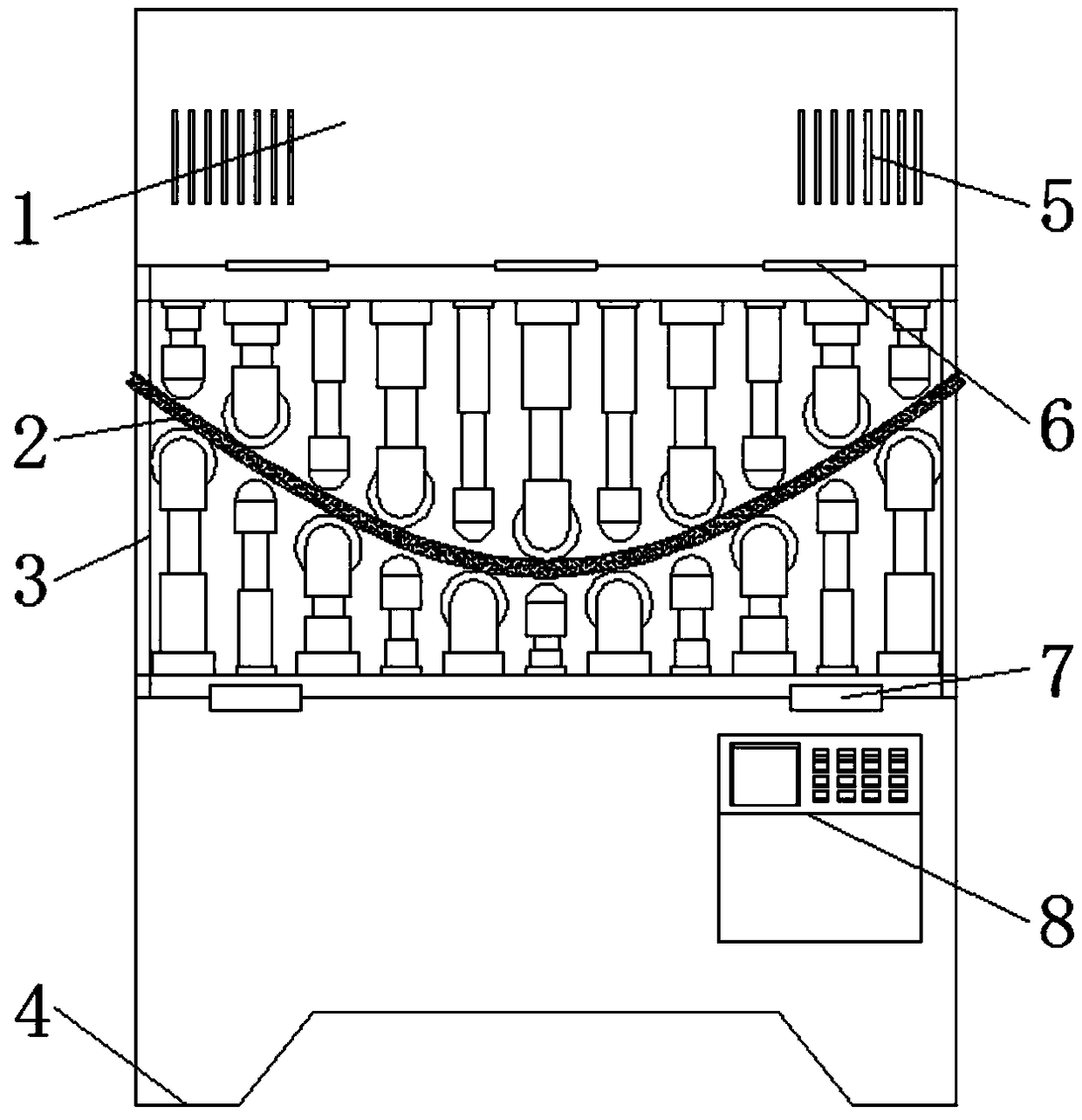

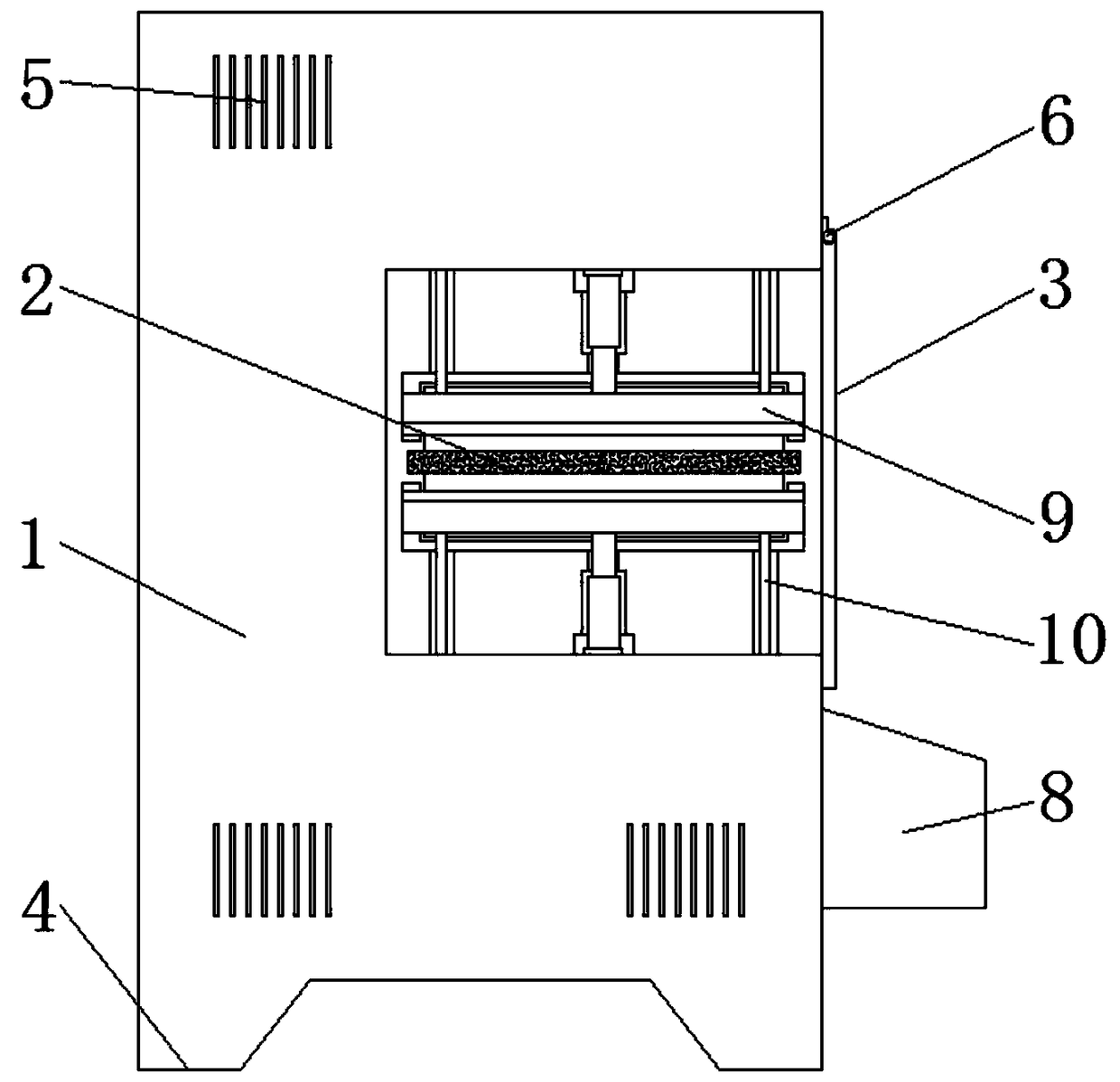

Dust removing device for electric automation equipment

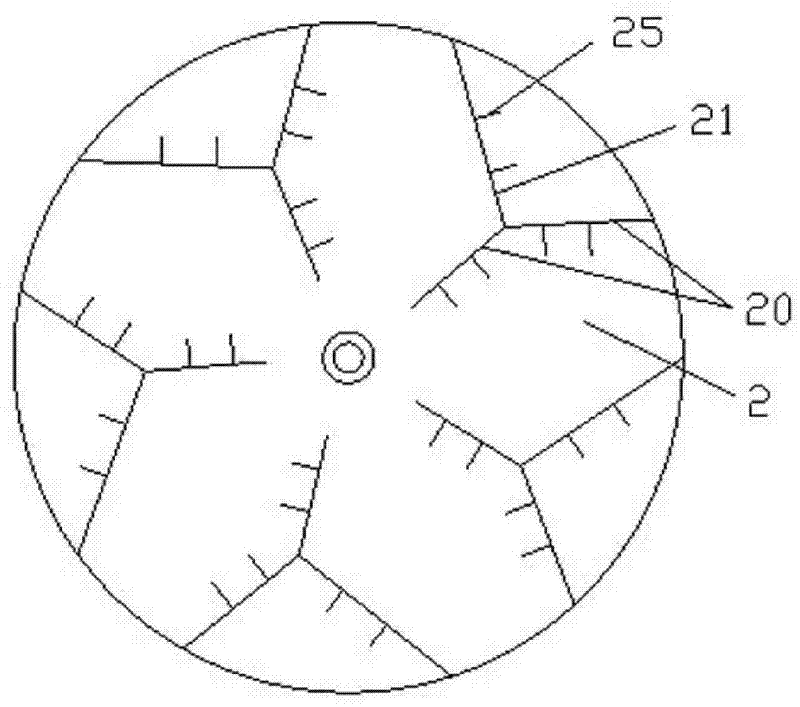

ActiveCN110756519AChange the blowing rangeDust blowing range can be changed flexiblyDirt cleaningCleaning using toolsCircular discThermodynamics

The invention discloses a dust removing device for electric automation equipment. A rotating rod is driven to rotate by a second motor, and a supporting disc is driven to move in the length directionof a screw rod, so that guide pipes move in the vertical direction to perform dust blowing treatment on different areas of the electric automation equipment, and the dust removing efficiency is improved; and when a third cylinder is started, and the third cylinder pushes a third push rod to move, so that the guide pipes move back and forth in a movable groove and are contracted or extended in thediameter direction of a supporting plate, and then the dust blowing range of the guide pipes is changed; and the working positions of the guide pipes can be flexibly changed according to different shapes of the electric automation equipment, so that the guide pipes carry out comprehensive dust removing treatment on the electric automation equipment, and the conditions that heat dissipation holes distributed on a heat dissipation plate are prone to be blocked caused by accumulation of a large amount of dust for a long time, then blockage is not favorable for timely heat dissipation of electricelements, and therefore, the internal part of the electric automation equipment is prone to overheating to influence the service life of the equipment are avoided.

Owner:ZHUHAI HENGQIN KUNPENG NEW ENERGY ENVIRONMENTAL PROTECTION TECH CO LTD

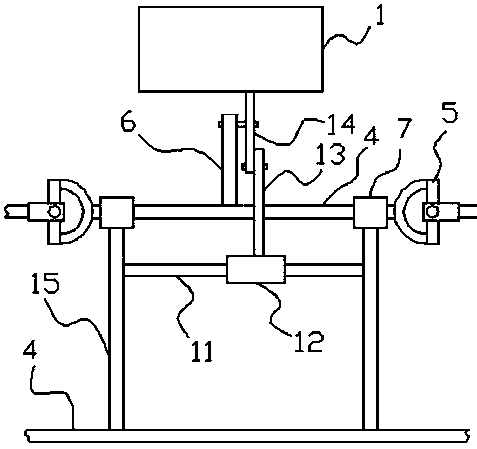

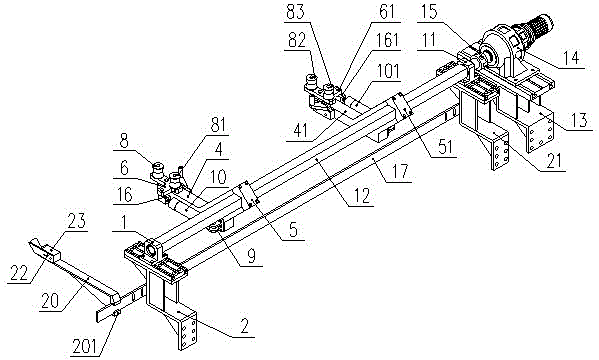

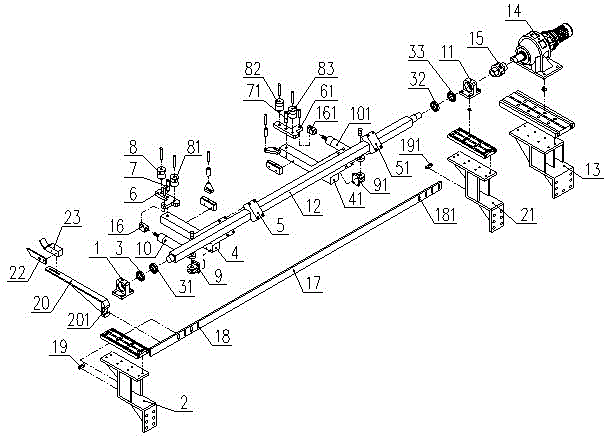

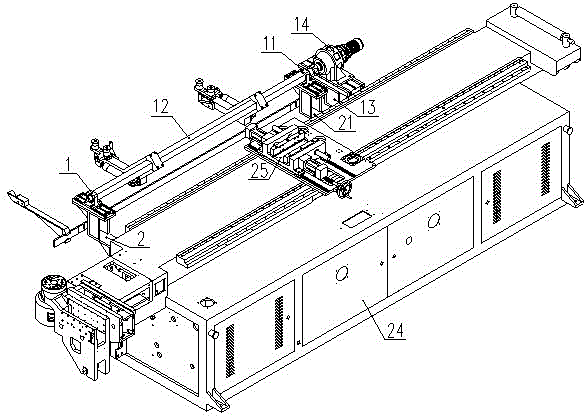

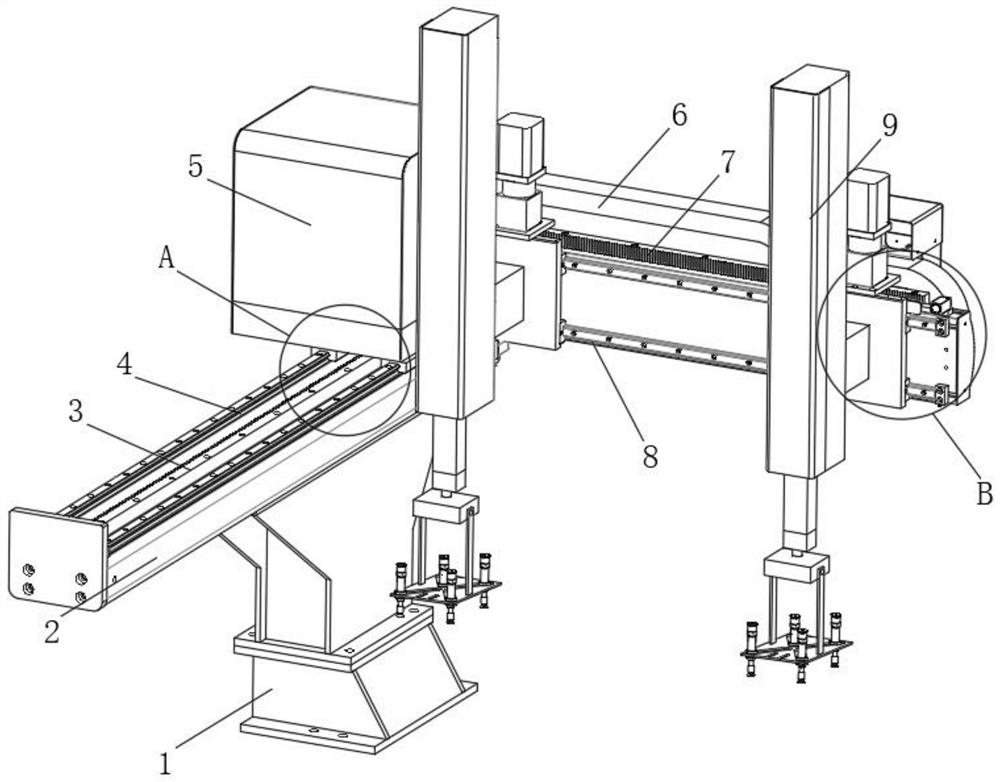

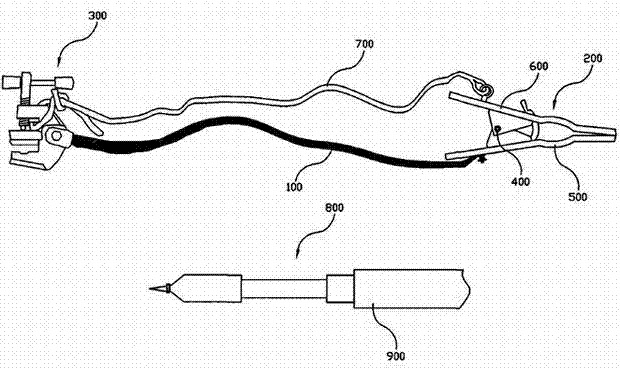

Manual feeding device used in full-automatic numerical control hydraulic pipe bender

ActiveCN102773361AReduce the burden onChange working positionMetal-working feeding devicesPositioning devicesNumerical controlPipe fitting

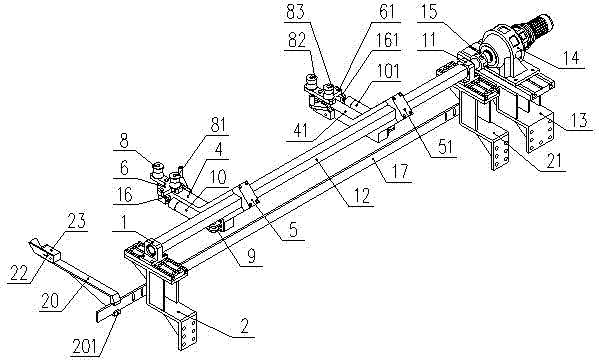

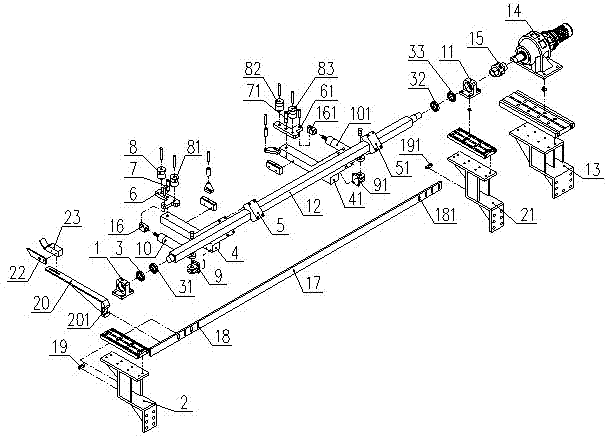

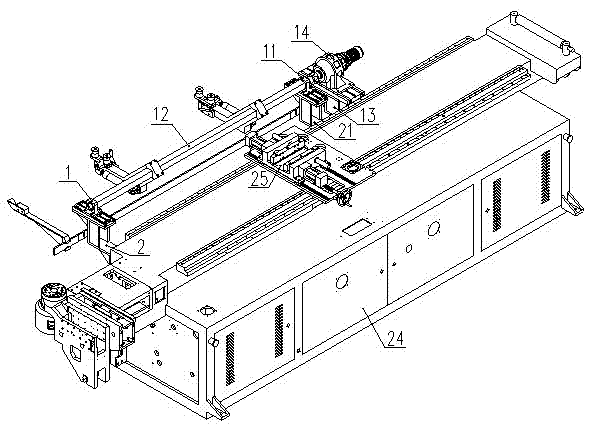

The invention discloses a manual feeding device used in a full-automatic numerical control hydraulic pipe bender; the manual feeding device comprises a motor support seat and a pair of bearing seat support seats which are fixed at the side of a large vertical seat, wherein a speed-reducing motor is fixedly arranged on the motor support seat; the bearing seat support seats are respectively provided with a bearing seat; two rotating shafts are respectively and movably arranged in the pair of bearing seats; the rotating shafts are connected with the speed-reducing motor; a pair of rotating arms which are respectively articulated with a movable plate are respectively fixed on the rotating shafts; the movable plates are respectively articulated with a pair of trip holders; two material clamp cylinders are respectively articulated at the ends of the rotating arms close to the rotating shafts; two piston rods of the material clamp cylinders are respectively connected with a connecting seat; the two connecting seats are respectively articulated with the movable plate; the two movable plates are respectively driven to make rotation along the opposite directions by the two material clamp cylinders connected with the movable plates; and a locating check block capable of moving up and down as well as left and right is arranged at the side of the large vertical seat by a locating adjustment mechanism. The manual feeding device can be conveniently used for feeding a long and heavy pipe fitting.

Owner:和和机械(张家港)有限公司

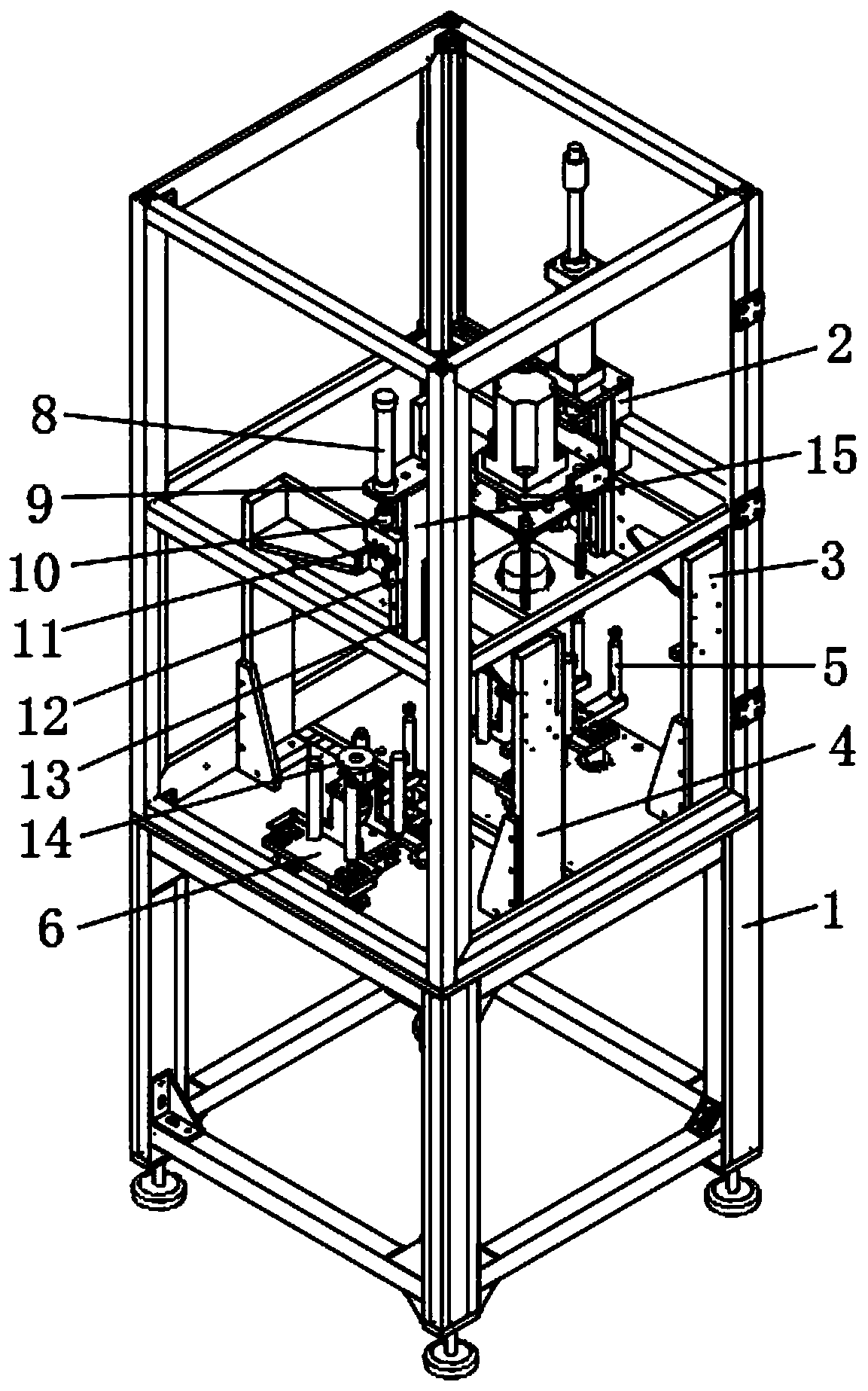

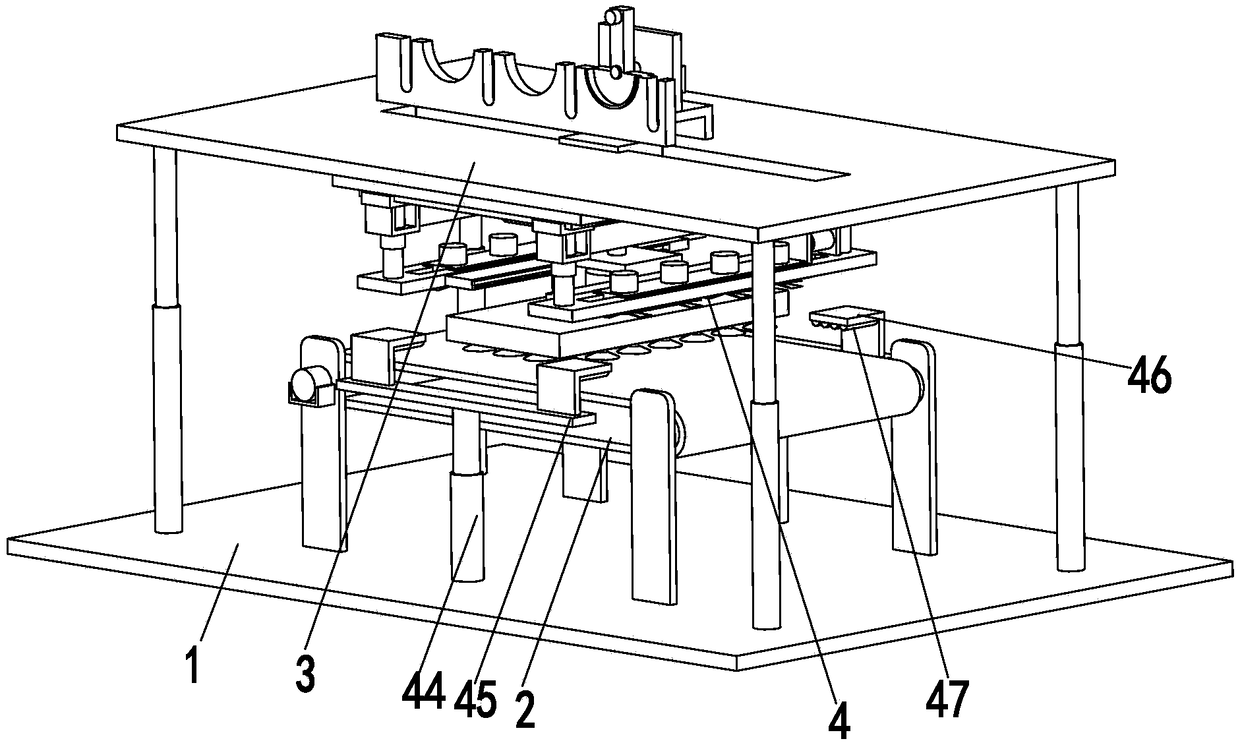

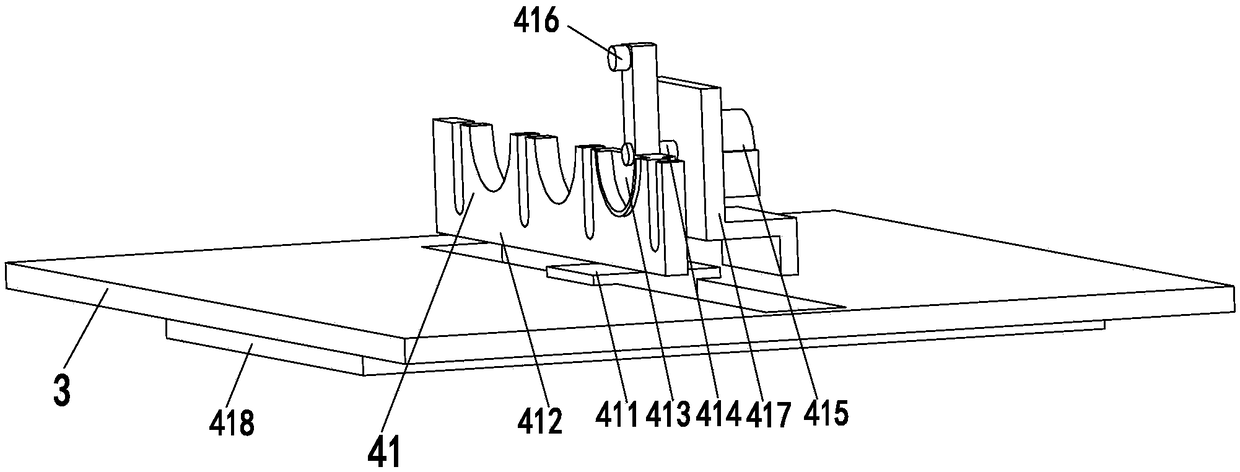

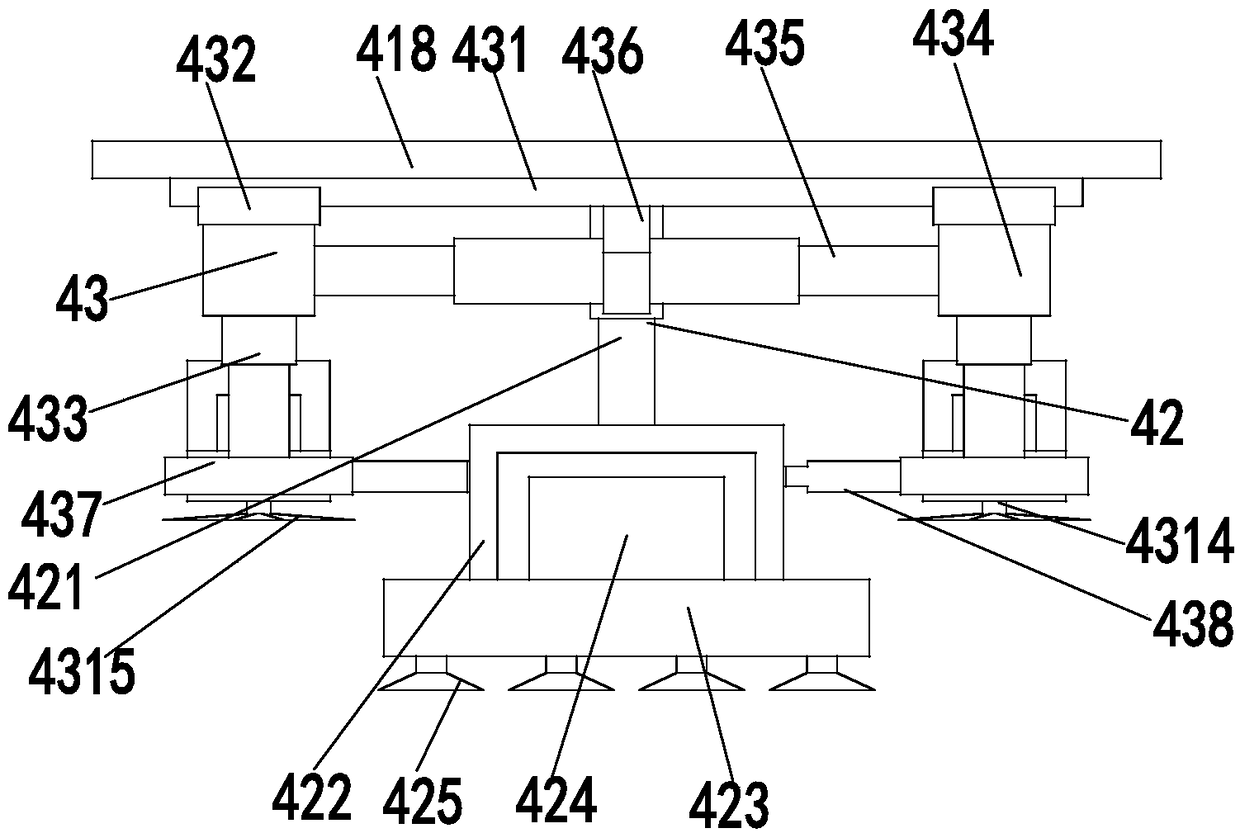

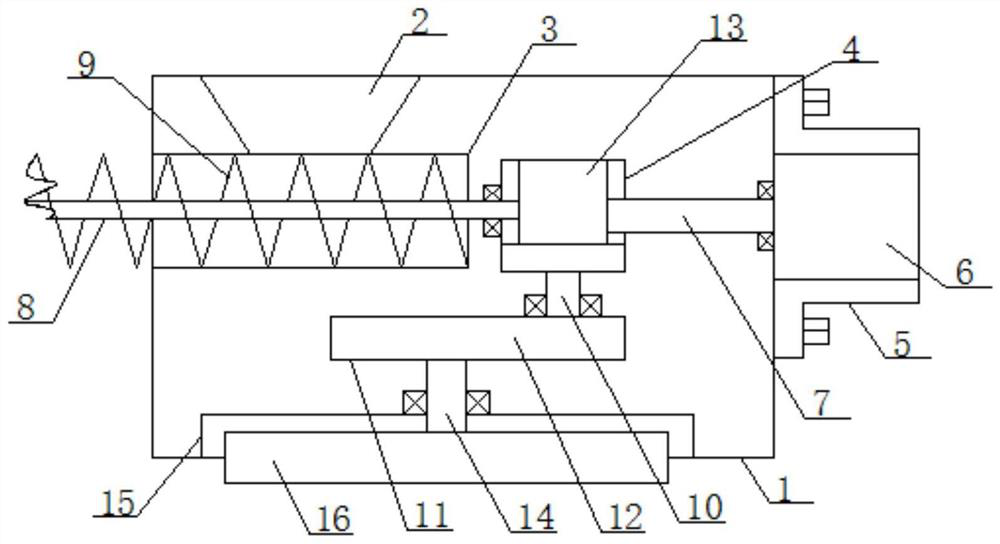

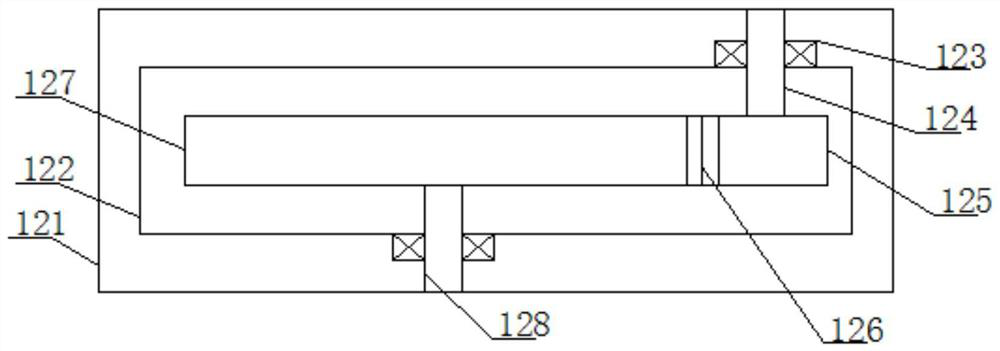

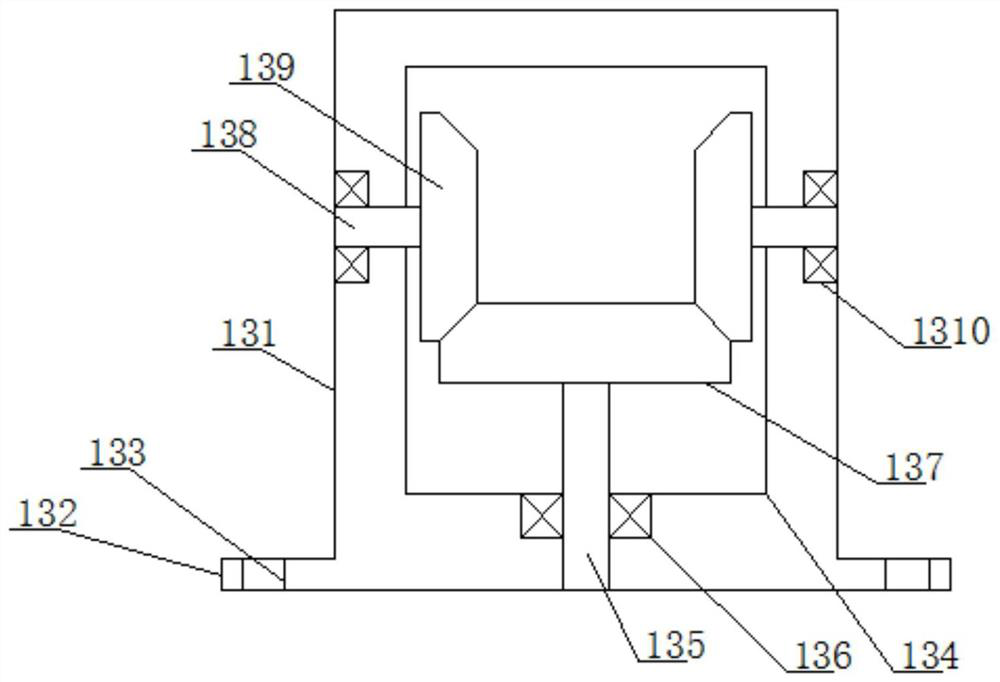

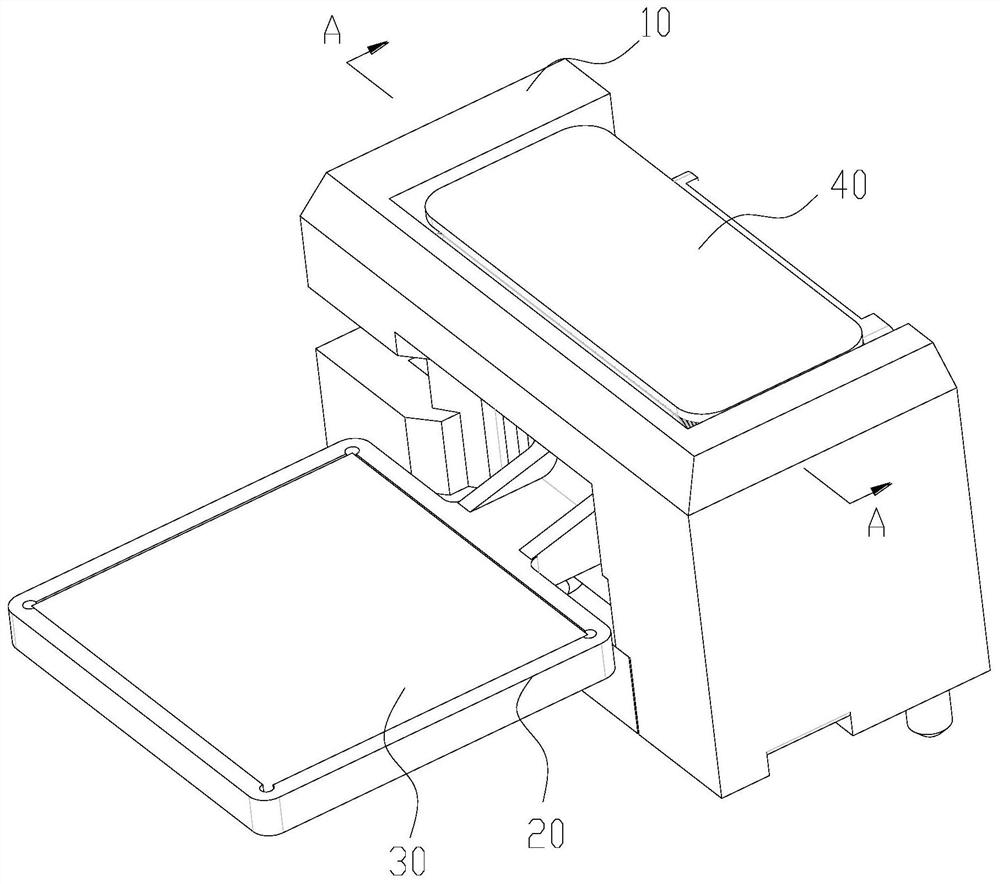

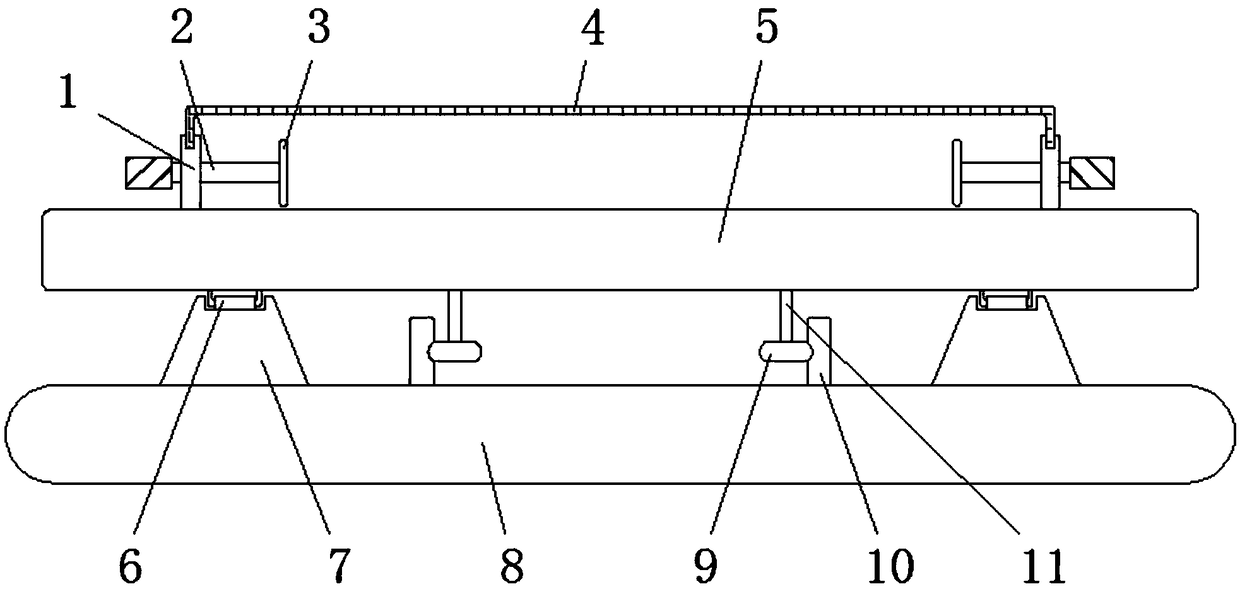

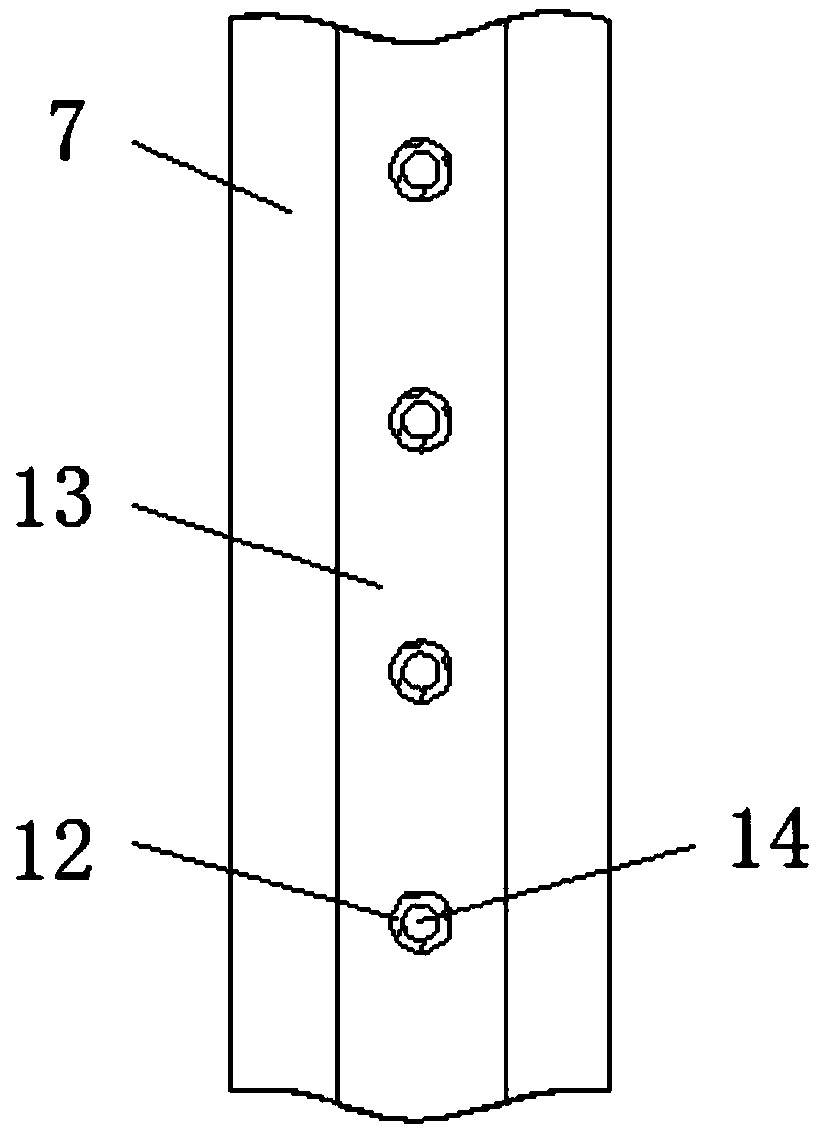

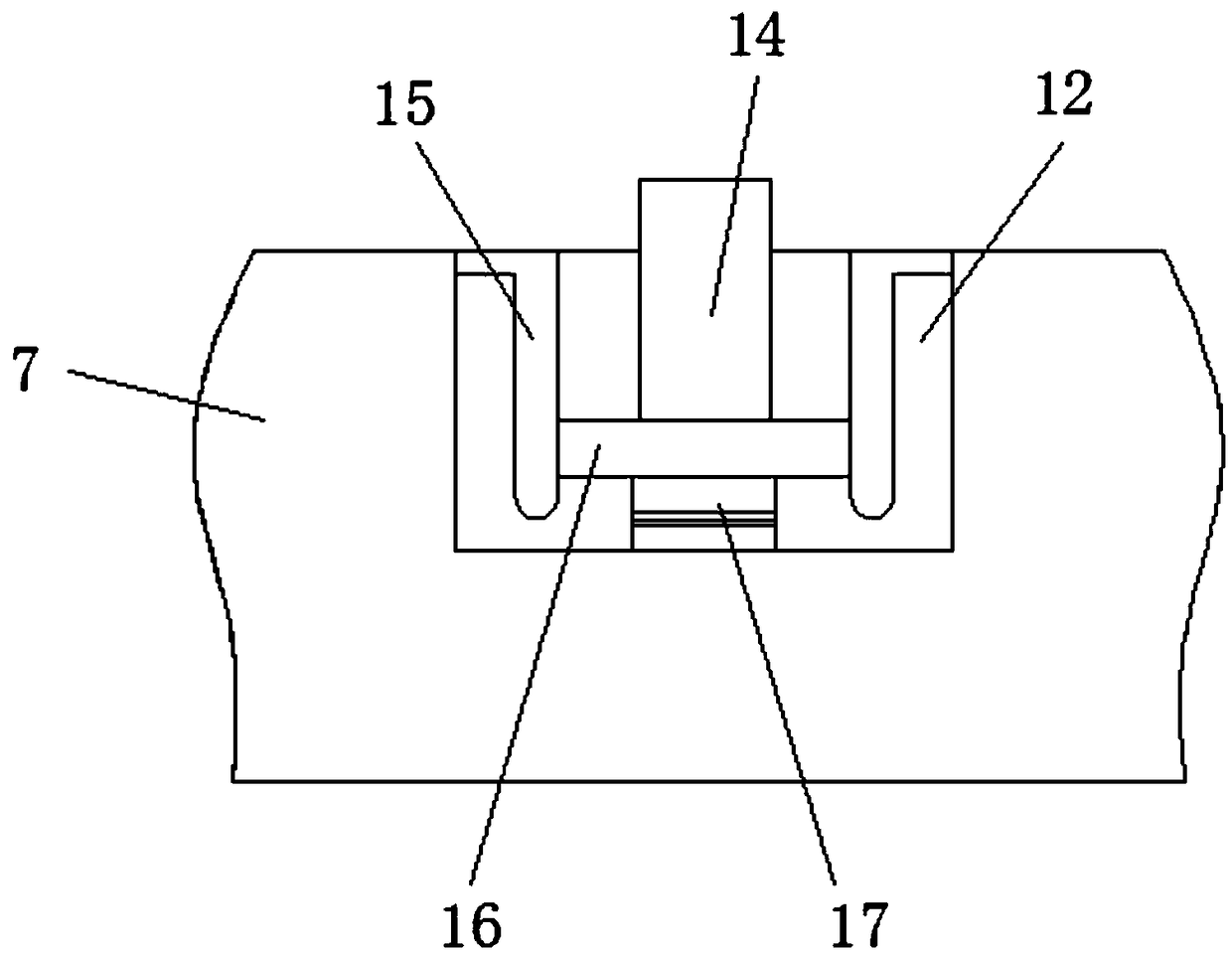

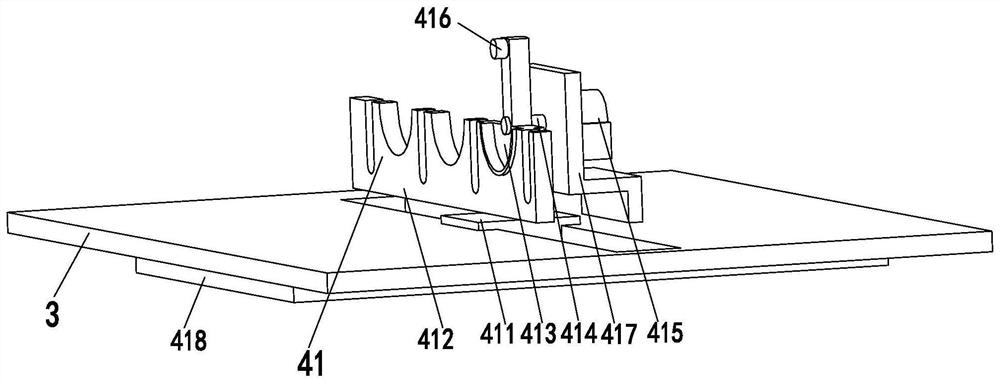

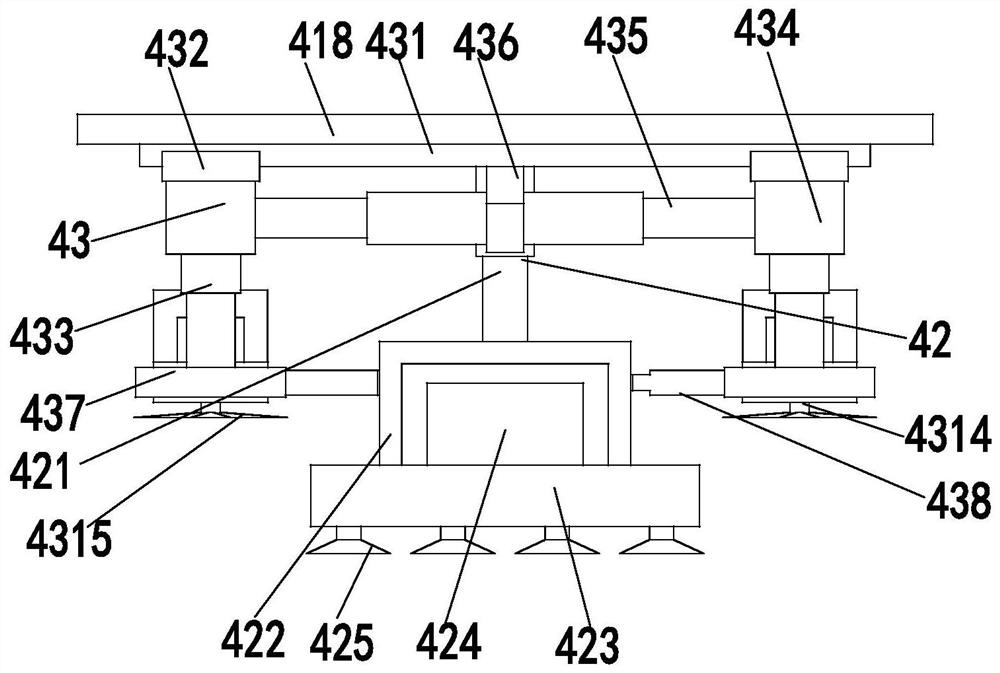

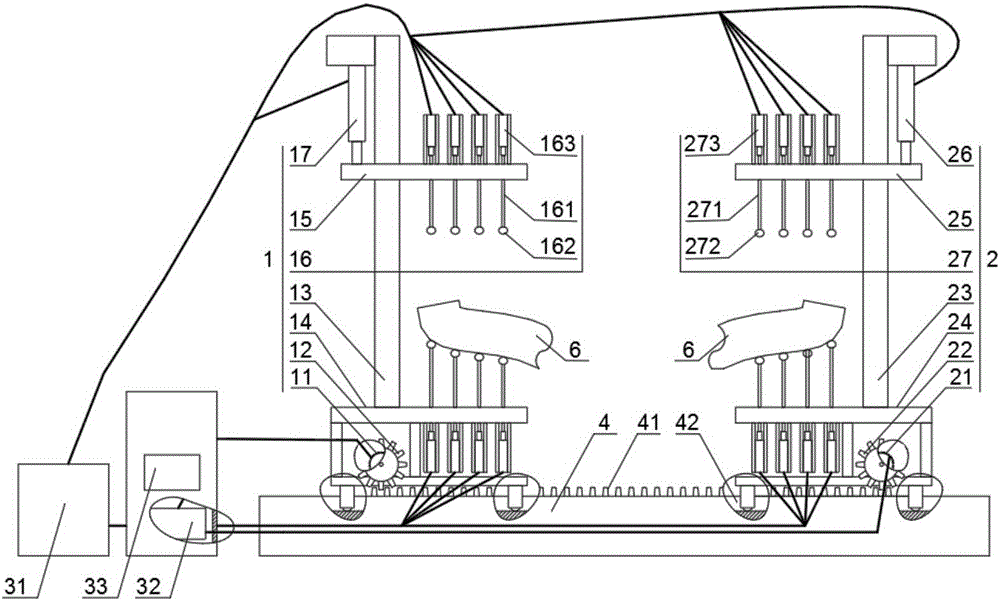

Automatic wool shearing system for textile fabric and wool shearing processing method

The invention relates to an automatic wool shearing system for textile fabric and a wool shearing processing method. The automatic wool shearing system comprises a bottom plate, a conveying table, a lifting mount and a wool shearing device, the conveying table is mounted on the bottom plate, the lifting mount is arranged at the upper end of the conveying table on the bottom plate, a sliding grooveis formed in the lifting mount, the wool shearing device is mounted in the sliding groove, the wool shearing device comprises a moving mechanism, an auxiliary mechanism, a wool shearing mechanism, alifting cylinder, a lifting plate, a workbench and rotating pillars, and the wool shearing mechanism comprises linear slides, sliders, lifting cylinders, connection fixing frames, two-way adjustment cylinders, a mounting ring, working plates, auxiliary support plates, sliding frames, adjusting plates, electric adjusting push rods, fixed support plates, working motors, rotating shafts and a rotating cutters. By the arrangement, problems about difficulty of wool cutting and incompleteness of wool cutting existing in the process of wool cutting of the existing textile fabric can be solved, and the automatic wool cutting function can be realized for the textile fabric.

Owner:海宁巨龙新材料股份有限公司

Hardware polishing equipment capable of improving polishing degree

ActiveCN112497033AGood processing effectEasy to disassemble and handlePolishing machinesGrinding drivesPolishingStructural engineering

The invention discloses hardware polishing equipment capable of improving the polishing degree, and relates to the technical field of hardware polishing. The hardware polishing equipment comprises a frame body, wherein edge plates are fixed to the corners of the two sides of the upper end face of the frame body, and limiting clamping plates are fixed to the positions, on the two sides between thetwo corresponding edge plates, of the upper end face of the frame body. Control panels are fixed to the middles of the front end faces of the edge plates, a clamping concave block is rotationally arranged between the two corresponding limiting clamping plates, movable rotating shafts are rotationally arranged between the clamping concave block and the limiting clamping plates, and multi-face blocks are fixedly installed on the annular outer surfaces of the movable rotating shafts. By means of the polishing equipment, clamping and fixing work of a hardware part can be well completed, the machining angle of the hardware part can be changed, operation and treatment work of external personnel is facilitated, the working position of a polishing disc can be well changed, thus, the good machiningeffect is achieved, and polishing treatment work of the external personnel is also facilitated.

Owner:吉林省新慧汽车零部件科技有限公司

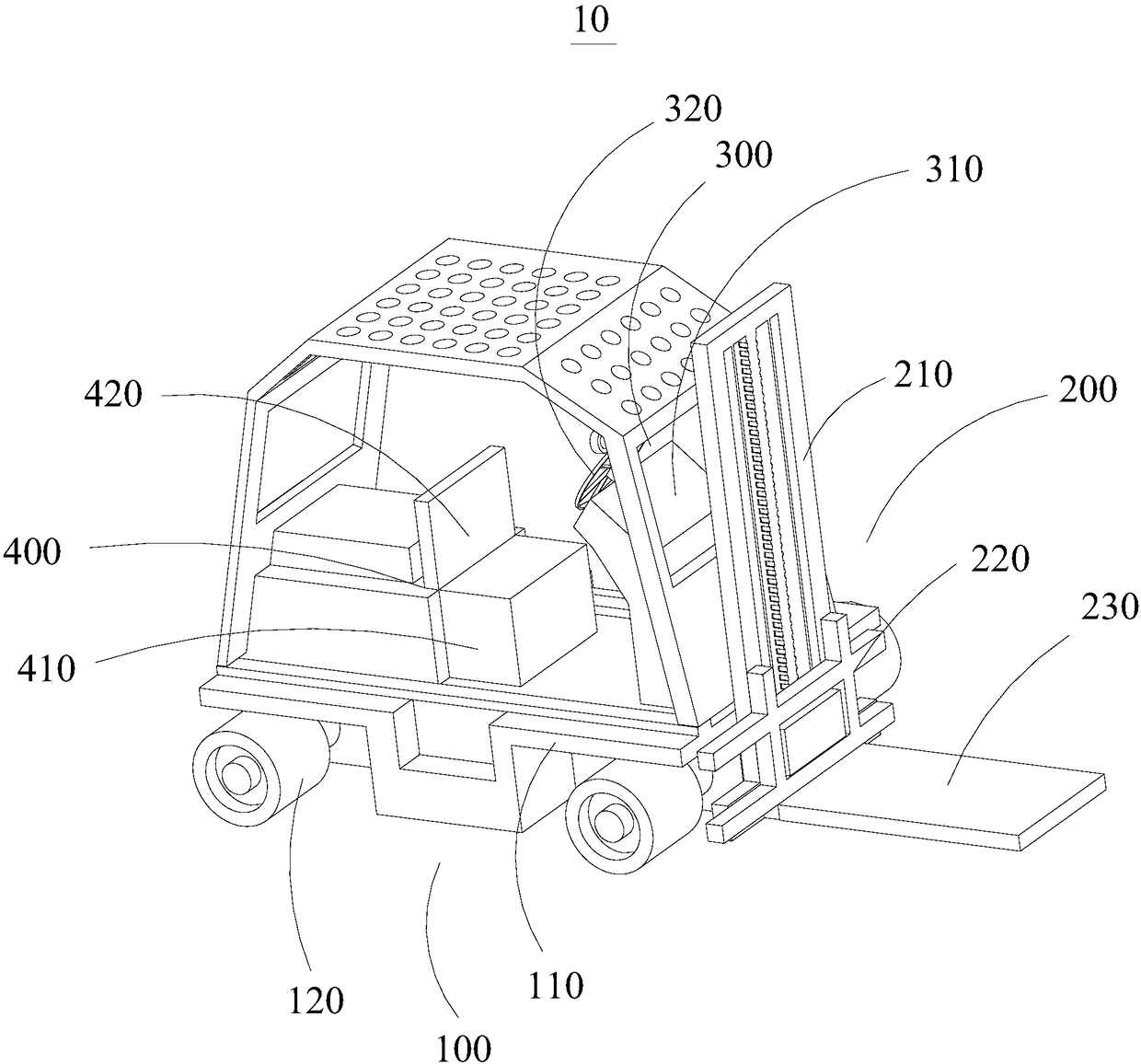

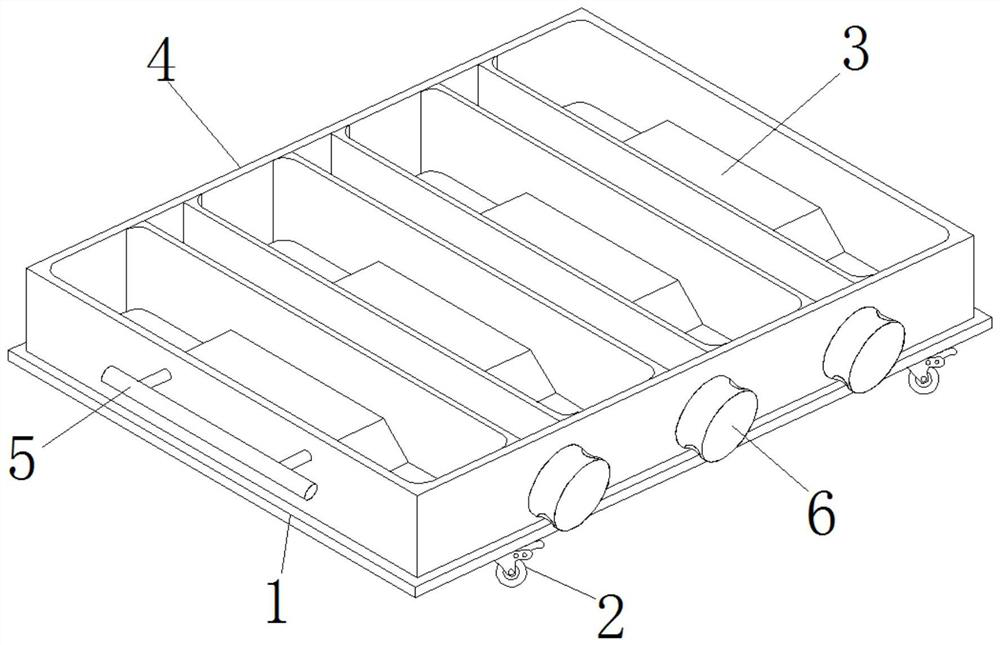

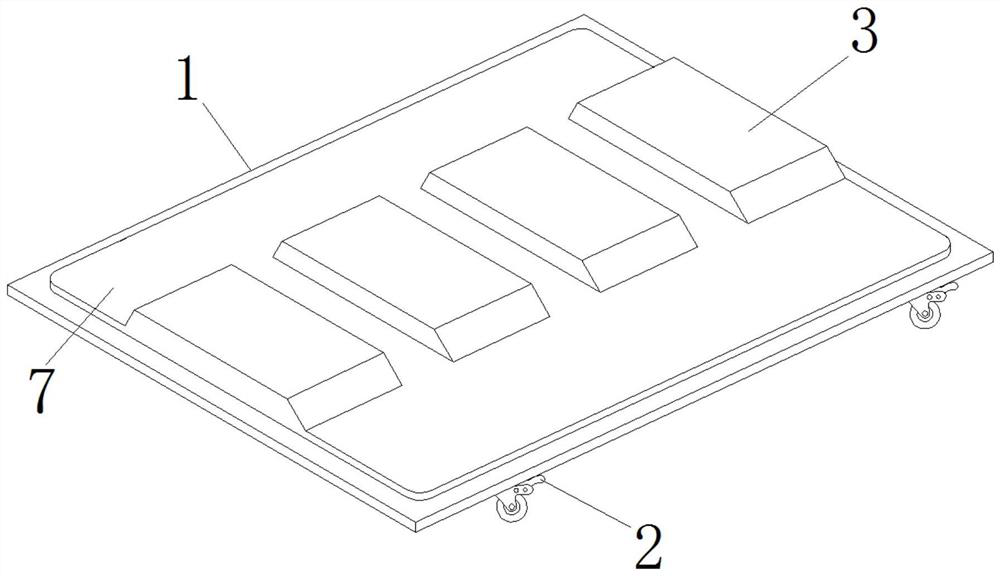

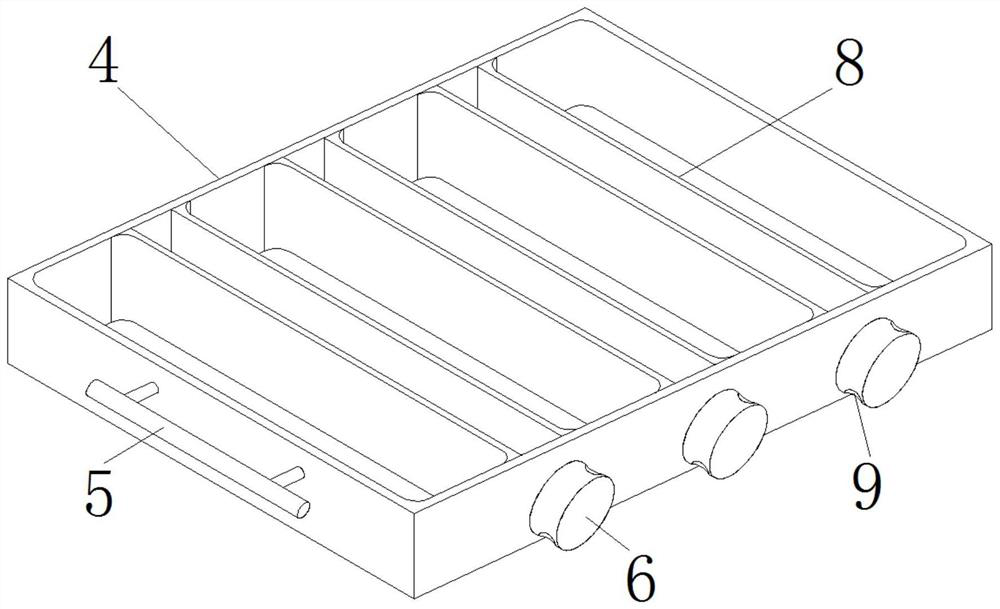

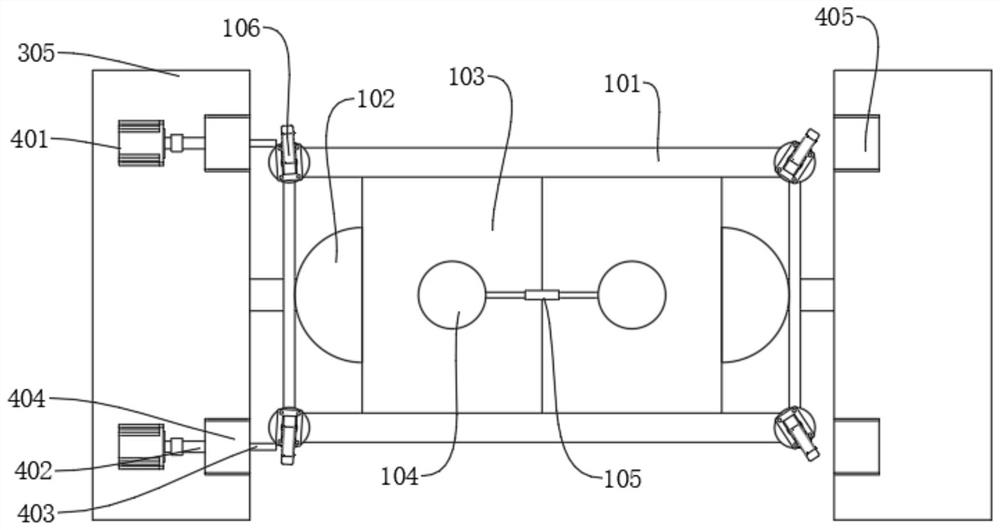

Transportation device for workshop

InactiveCN108249345AEasy to pullEasy to pushSafety devices for lifting equipmentsBatteries circuit arrangementsSteering wheelFixed frame

The invention discloses a transportation device for a workshop. The transportation device comprises a transportation assembly, a lifting assembly and a seat assembly. The transportation assembly comprises a transportation base and rotating wheels arranged on the transportation base. The lifting assembly comprises a lifting fixing frame, a lifting moving bracket and a lifting moving plate. The lifting fixing frame is fixed on the transportation base. The lifting moving plate and the lifting moving bracket are fixed. The lifting moving bracket is arranged on the lifting fixing frame in a liftingand moving manner. The rotating assembly comprises a steering table and a steering wheel arranged on the steering table, wherein the steering wheel is in driving connection with the rotating wheels.The seat assembly comprises a fixing block and a backup plate arranged on the fixing block. The transportation device for the workshop can provide greater lifting force and can lift more goods.

Owner:惠州市睿嶝光电照明有限公司

Building site leveling device

InactiveCN111778956AImprove efficiencyReduce combination rateSoil preservationGear wheelArchitectural engineering

The invention discloses a building site leveling device. The building site leveling device comprises a main case, and a conical space is formed in the center of the top of the main case. The device isof a multi-purpose type, so that the use efficiency of parts is effectively improved, and the combination rate of the parts and the manufacturing cost of the device are reduced; due to the fact thatthe device is multi-purpose, on the premise of one driving motor, the device can achieve the effects of automatically rotating and changing the working position and can also achieve the effect of driving and leveling sandy soil; moreover, the device is provided with a transverse gear set meshing gear difference increasing type speed reducing mechanism, and the speed can be reduced by utilizing different gear differences so that the device can perform a rotary driving effect on the premise of meeting the requirements, and all-dimensional coverage is realized; and in addition, the device is provided with a one-to-multiple mechanism with a gear meshing type vertical rotating function, vertical multi-purpose driving can be achieved, and therefore multiple purposes are achieved through one machine.

Owner:WEIFANG ENG VOCATIONAL COLLEGE

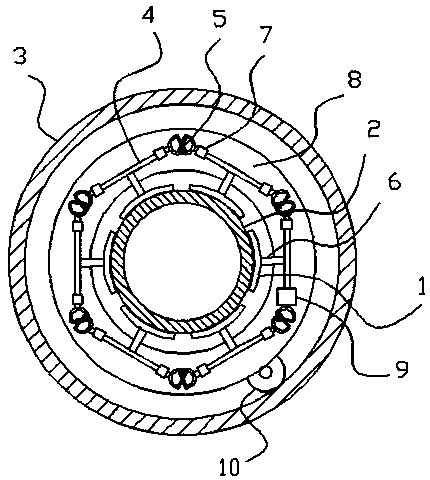

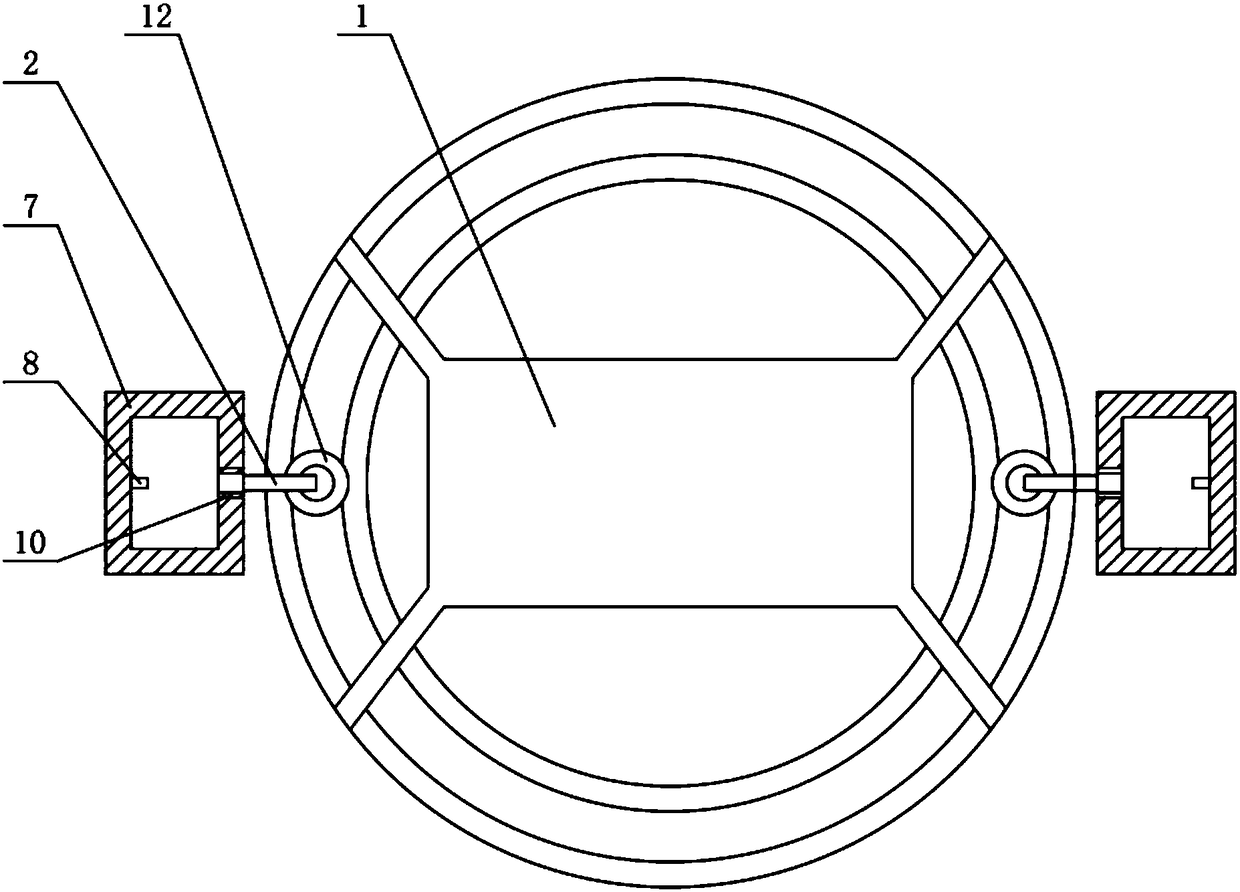

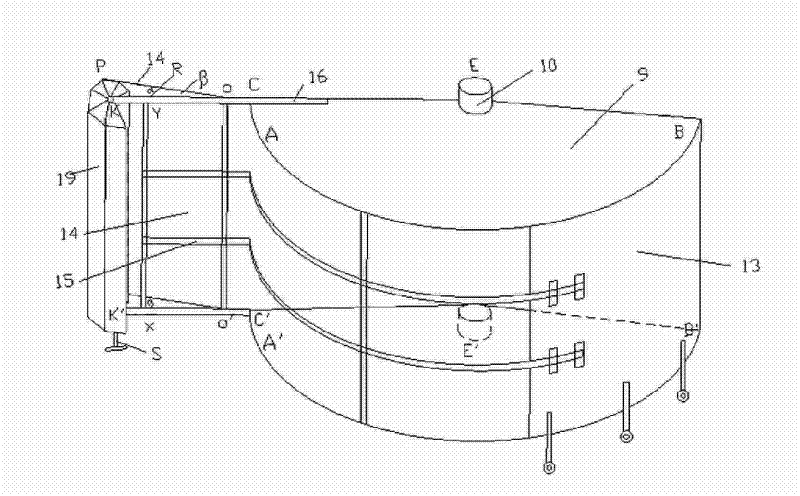

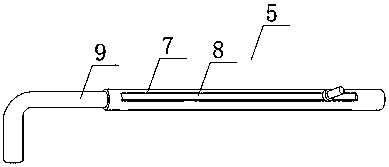

A marine diesel engine tail gas waste heat temperature difference energy utilization device

ActiveCN106545391BChange working positionEfficient use ofInternal combustion piston enginesExhaust apparatusThermal energyCoupling

The invention provides a marine diesel engine tail gas afterheat temperature difference energy utilization device, which belongs to the technical field of afterheat energy utilization, and relates to a tail gas afterheat temperature difference energy utilization device. The marine diesel engine tail gas afterheat temperature difference energy utilization device solves the problems that in the prior art, the tail gas temperature is higher, and a great amount of heat energy is not utilized and is wasted. The marine diesel engine tail gas afterheat temperature difference energy utilization device comprises a semiconductor temperature difference power generating sheet, and is characterized by also comprising a cooling sleeve, wherein the cooling sleeve coaxially sleeves an engine tail gas exhaust pipe; a cooling water pipe is coiled outside the cooling sleeve; a framework body is arranged between the tail gas exhaust pipe and the cooling sleeve; the framework body is an orthohexagonal framework body formed by connecting rotating shafts end to end; the rotating shafts are mutually connected through a universal shaft coupler; a crank rod vertical to the rotating shaft is arranged on each rotating shaft; the end part of each crank rod is provided with the semiconductor temperature difference power generating sheet; a bearing is arranged on each rotating shaft. The marine diesel engine tail gas afterheat temperature difference energy utilization device has the advantages that the work temperature of refrigeration sheets is regulated, and the cold energy and the heat energy are integrally utilized.

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

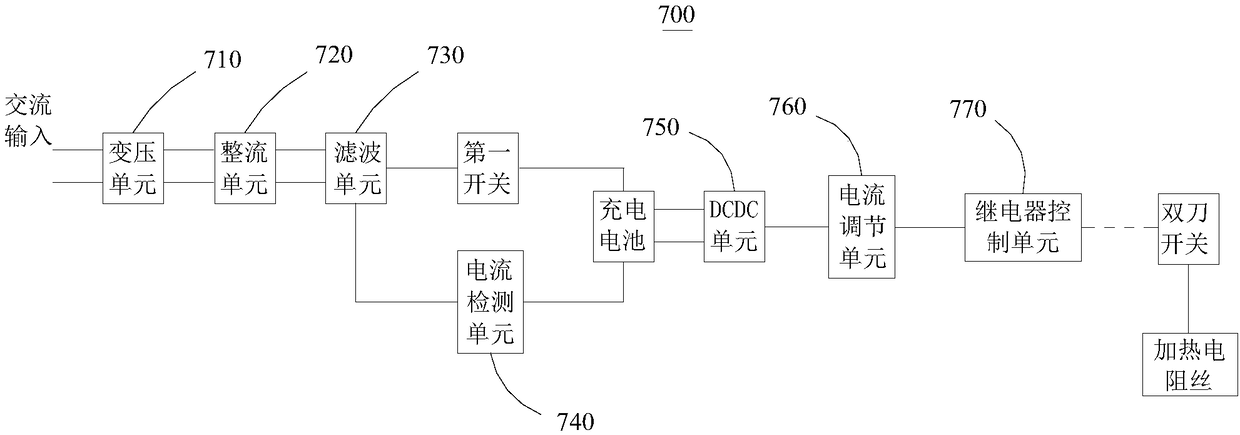

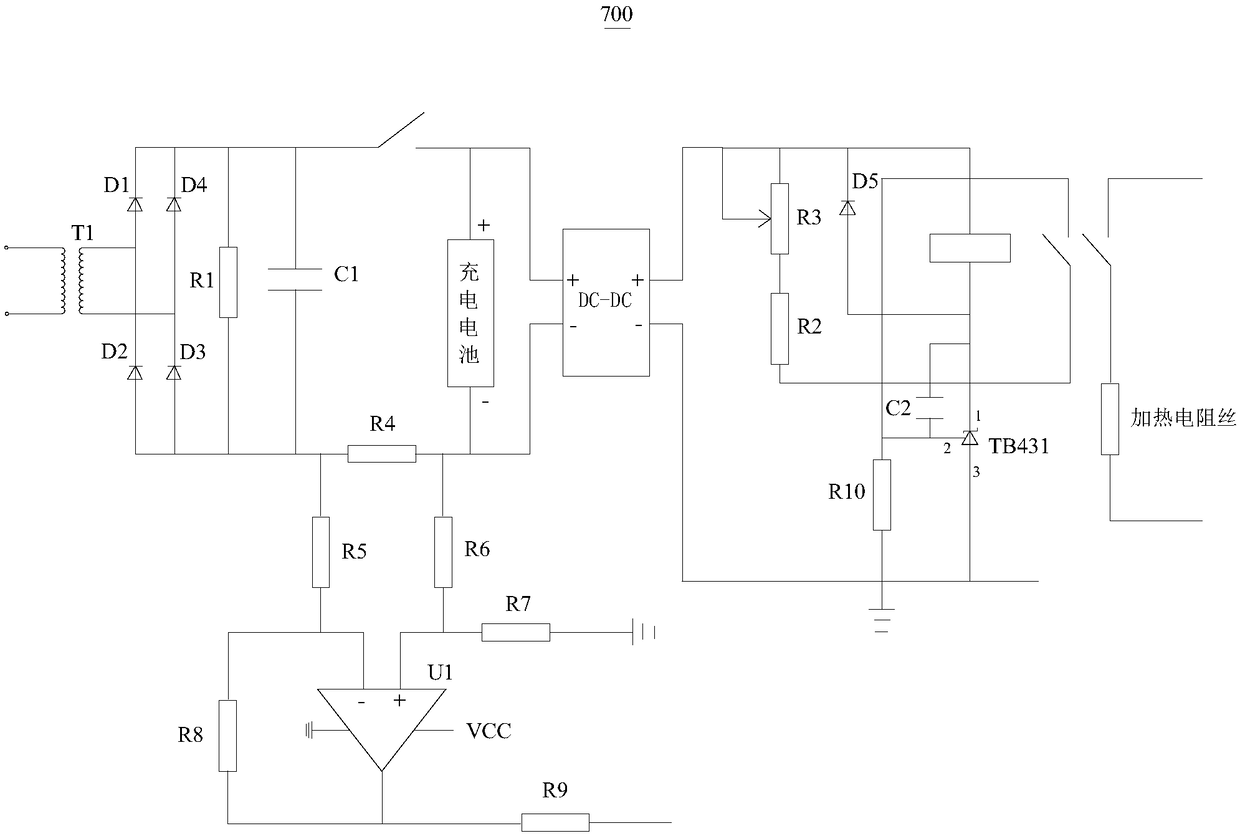

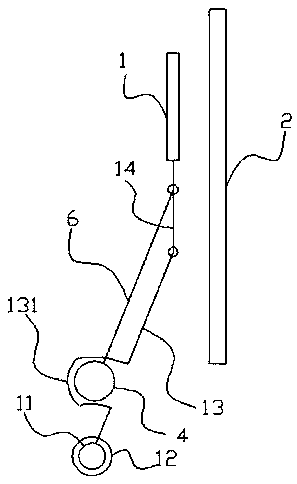

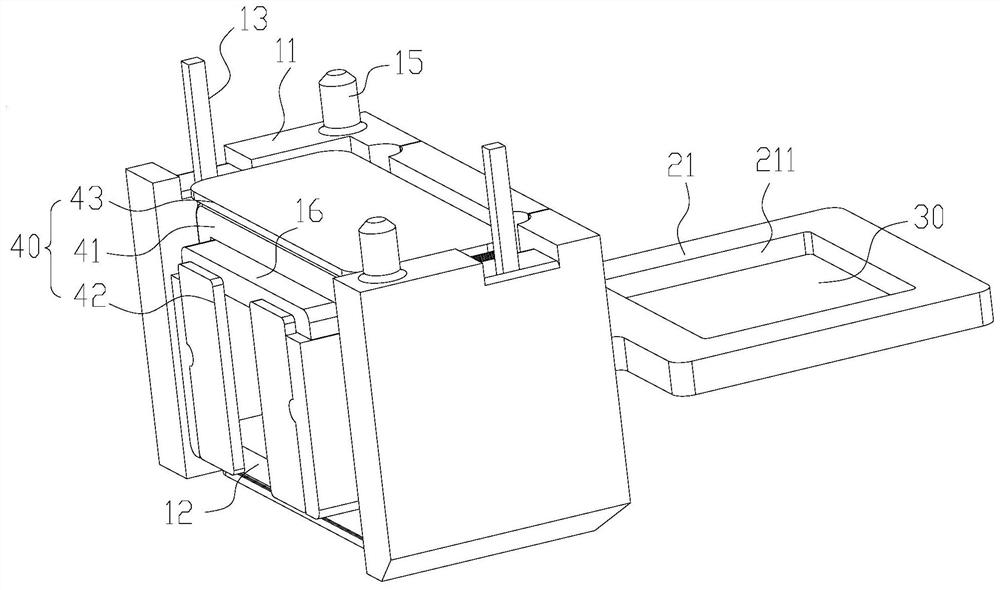

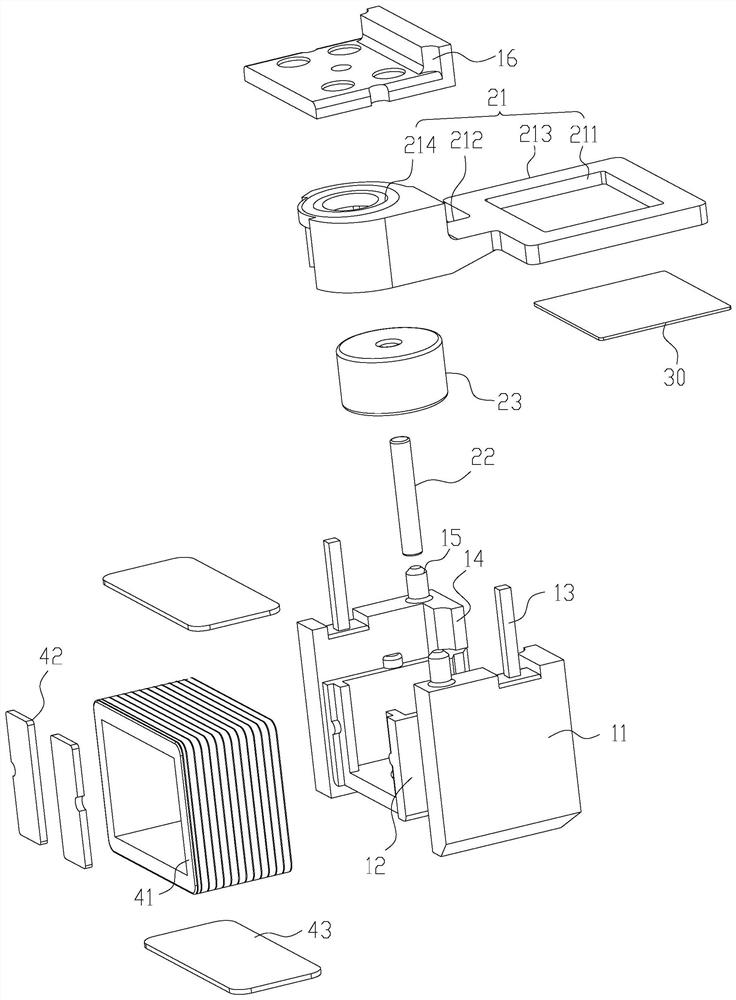

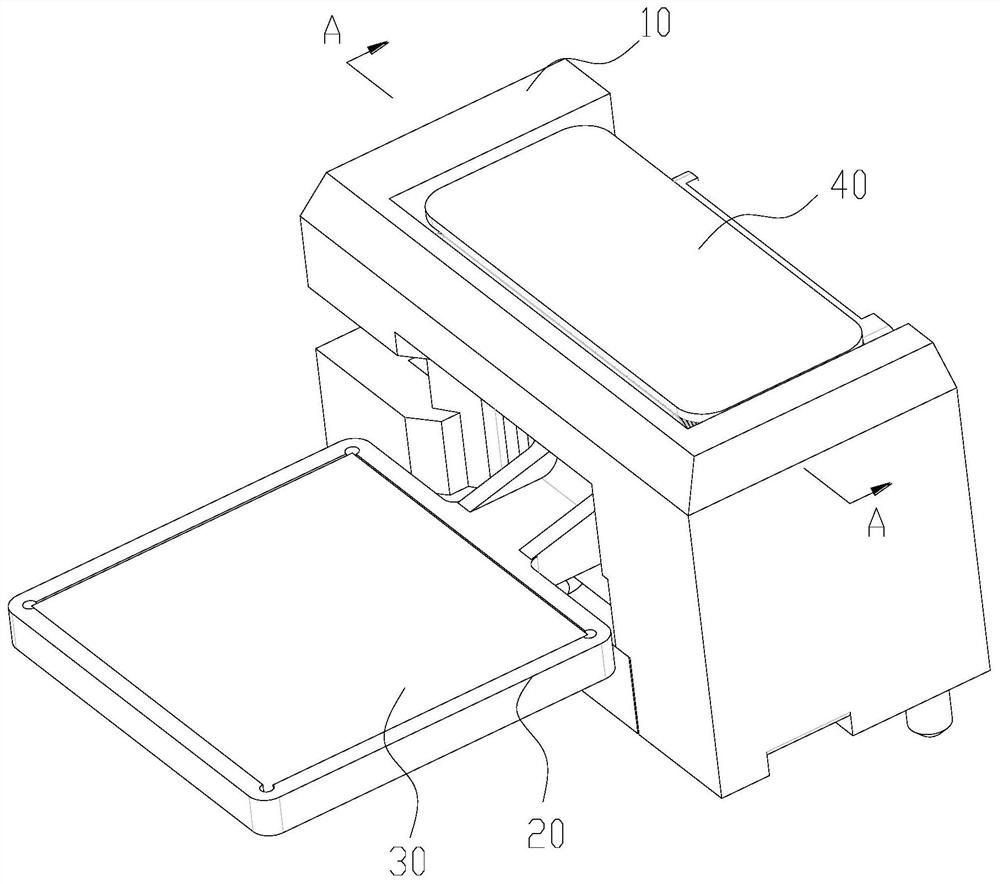

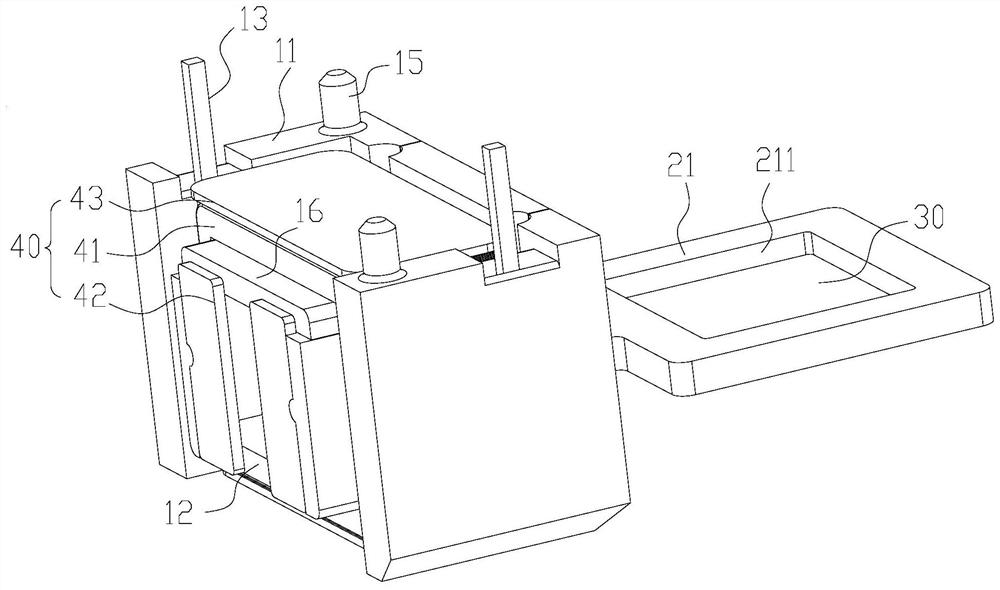

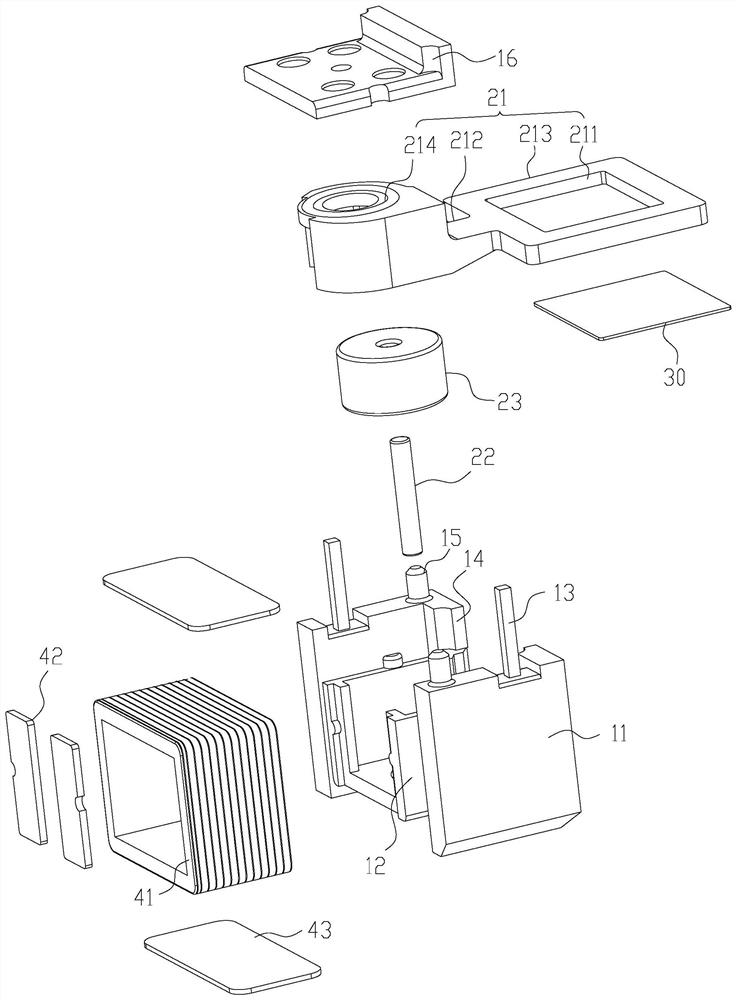

Thermal imaging image attenuation device, control module and thermal imaging equipment

ActiveCN112985618BChange working positionEasy to adjustRadiation thermographyImaging equipmentMechanical engineering

The present application provides a thermal imaging image attenuation device, a control module and a thermal imaging device. The thermal imaging image attenuation device includes a base, a driving component mounted on the base, a cantilever assembly movably connected to the base, and an attenuation sheet mounted on the cantilever assembly, the attenuation sheet is located outside the base , the driving component is drivingly connected with the cantilever assembly, and the cantilever component moves relative to the base under the driving of the driving component to adjust the working position of the damping sheet. The damping sheet is installed on the cantilever assembly and moves with the cantilever assembly. By adjusting the relative position between the cantilever assembly and the base, the working position of the damping sheet can be changed, and the position adjustment is convenient.

Owner:HANGZHOU HIKMICRO SENSING TECH CO LTD

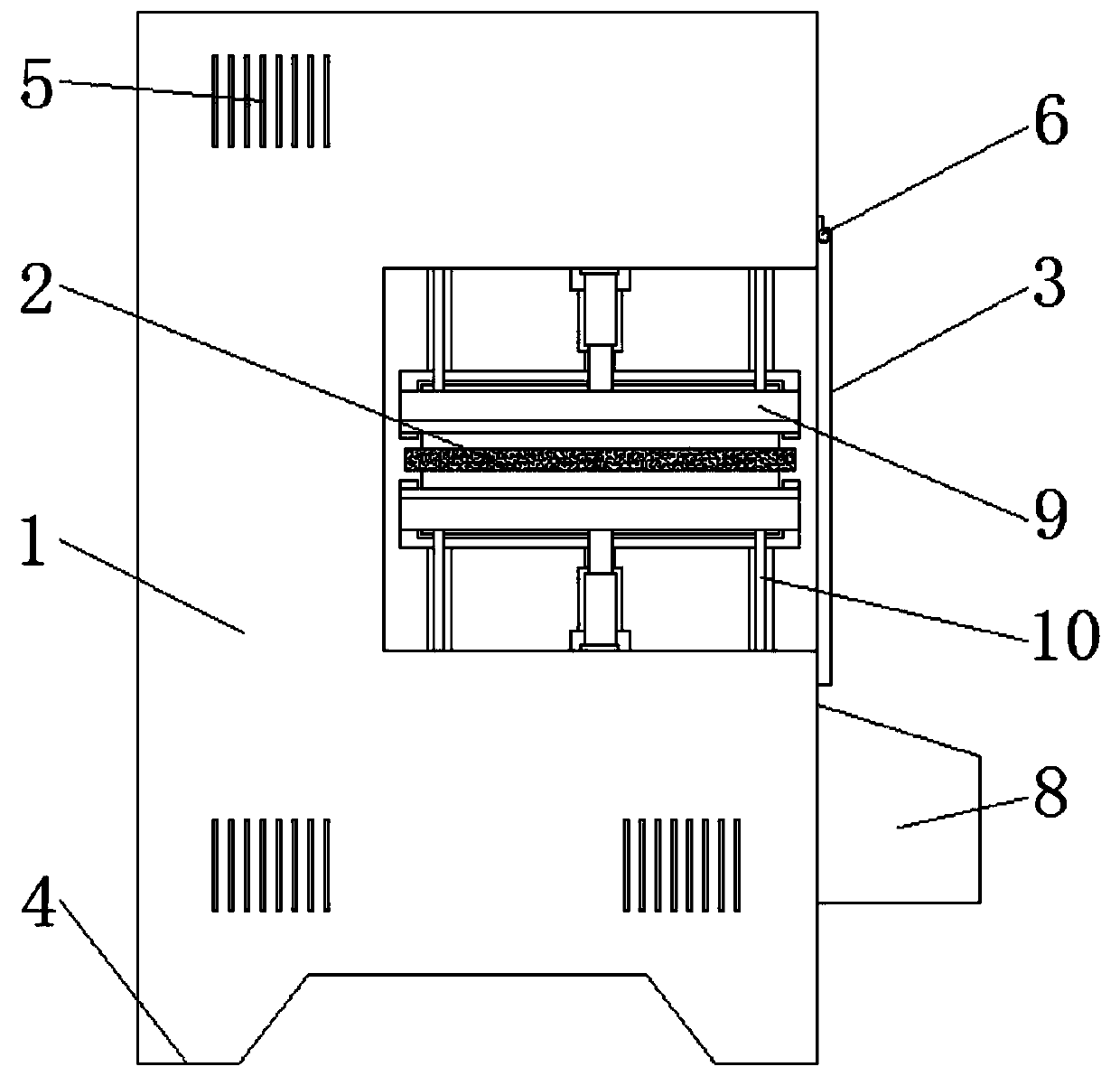

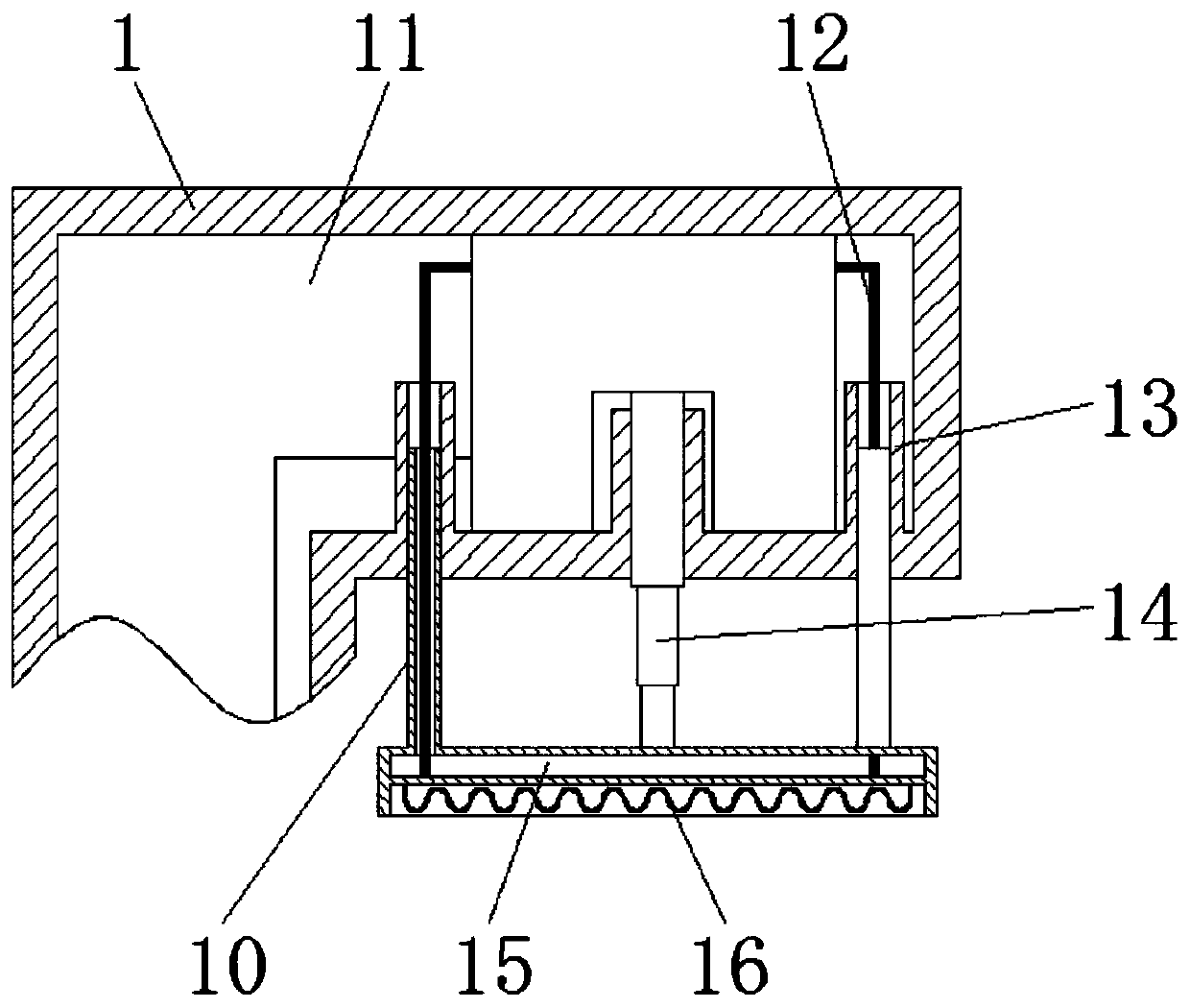

Bending processing device and method for boron-magnesium alloy deep processing

ActiveCN108637057AFacilitate different kinds of bending workImprove efficiencyShaping toolsShaping safety devicesBoronDeep processing

The invention discloses a bending processing device and method for boron-magnesium alloy deep processing. The bending processing device comprises a device body and supporting legs; a boron-magnesium alloy is arranged on the inner side of the device body; protective baffles are installed on the outer side of the boron-magnesium alloy; electric heating ovens are arranged on the upper side and the lower side of the boron-magnesium alloy; the outer sides of the electric heating ovens are connected with the device body through first sliding rods; first limiting sleeves are arranged inside the device body, and the inner sides of the first limiting sleeves are connected with the first sliding rods; and second limiting sleeves are fixed inside the device body, the inner sides of the second limiting sleeves are connected with second sliding rods, and movable bases are fixed to the lower ends of the second sliding rods. According to the bending processing device and method for boron-magnesium alloy deep processing, through the arrangement of the electric heating ovens and electric telescopic rods, high efficiency of the boron-magnesium alloy in the deformation process can be ensured, the boron-magnesium alloy is also prevented from being damaged in the deformation process, and the using value of the whole bending processing device is improved.

Owner:EASTERN LIAONING UNIV

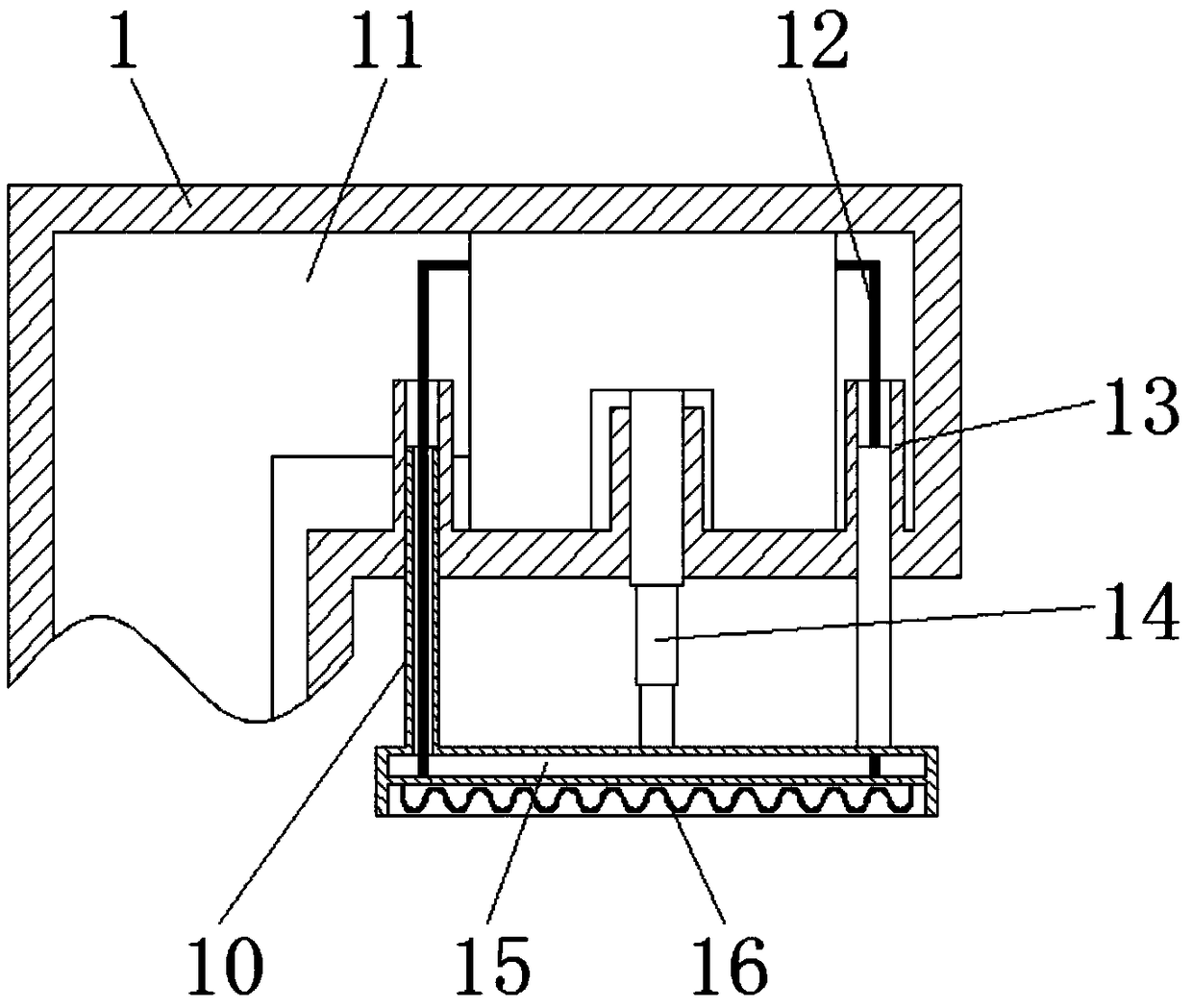

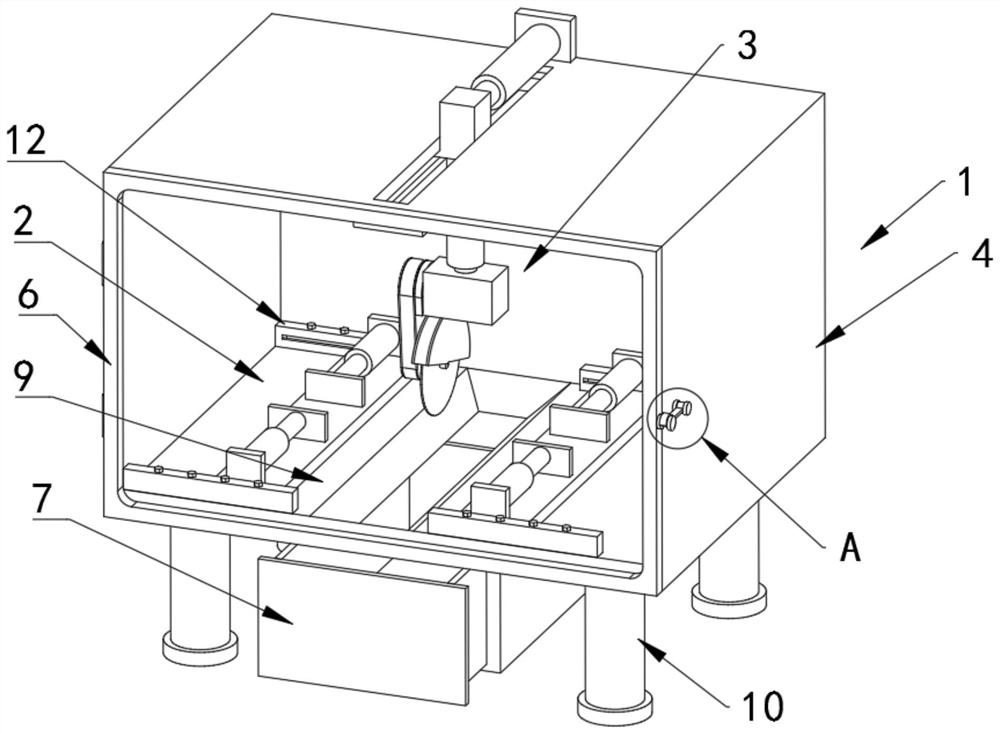

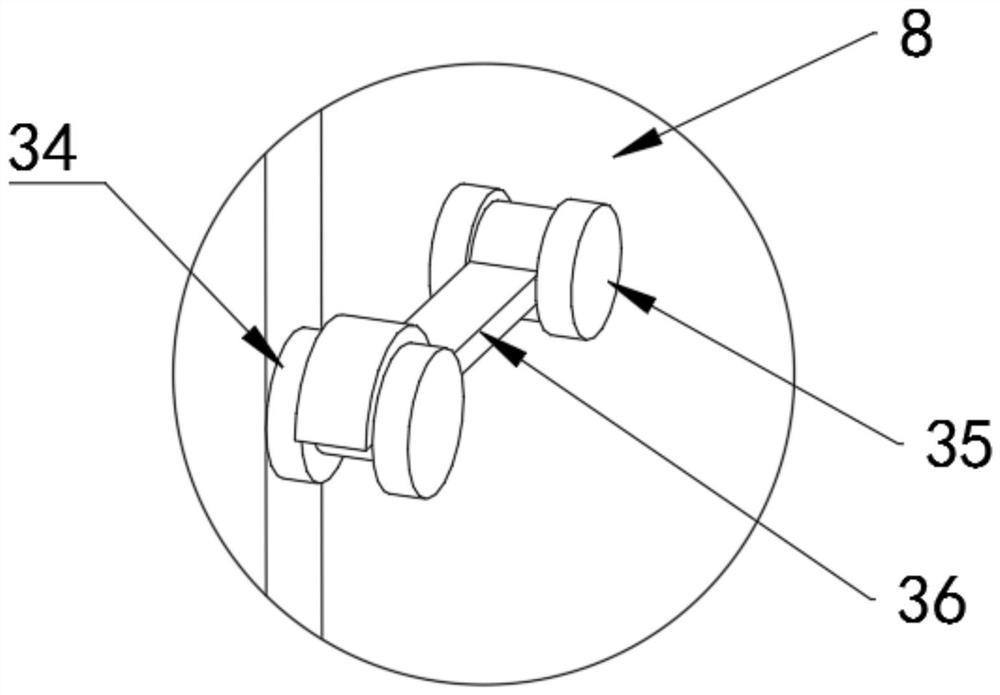

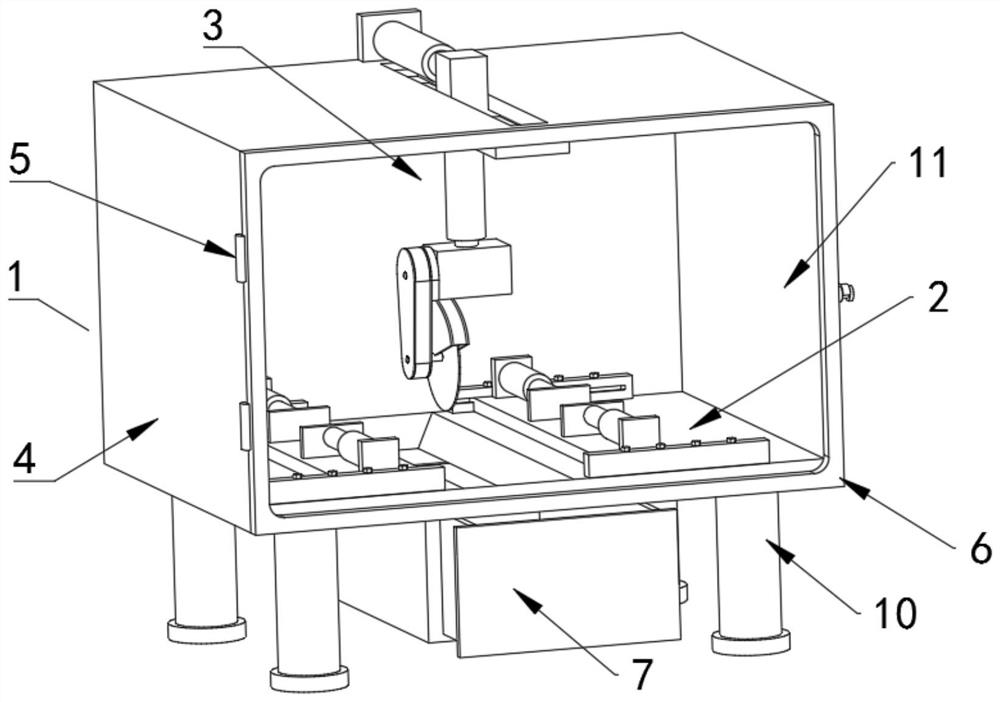

Environment-friendly building material cutting equipment

PendingCN112828972AImprove securityEasy to collect and processDirt cleaningSound producing devicesMotor protectionBuilding material

The invention discloses environment-friendly building material cutting equipment in the technical field of building material cutting equipment. The environment-friendly building material cutting equipment comprises an equipment cavity, a clamping device and a cutting device; a shell comprises an equipment cavity, a rotating shaft, an observation door, a hasp, a storage box, supporting legs and a sound insulation plate; the clamping device comprises a lower sliding groove, a working plate, a first hydraulic rod, a first fixing block, a second hydraulic rod, a second fixing block and a clamping plate; and the cutting device comprises a third hydraulic rod, a third fixing block, a sliding block, an upper sliding groove, a fourth hydraulic rod, a motor protection box, a rotating motor, a rotating belt protection box, a rotating shaft, an upper rotating gear, a lower rotating gear, a rotating belt, a cutting disc and a cutting protection cover. The environment-friendly building material cutting equipment can move flexible during cutting, the sound insulation plate can greatly reduce the noise generated during cutting building materials, the device is closed in the cutting process, so that the influence of chippings and dust on workers in the cutting process is avoided, the damage of noise to the hearing of the workers is reduced, and the effect of conveniently collecting the chippings and dust is achieved.

Owner:苏州伏柯山建设有限公司

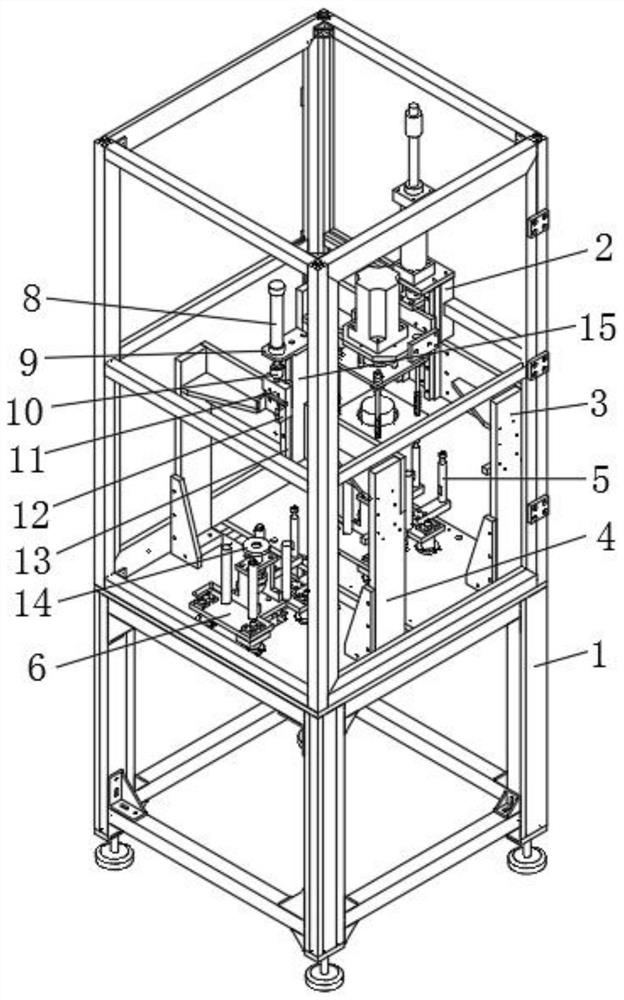

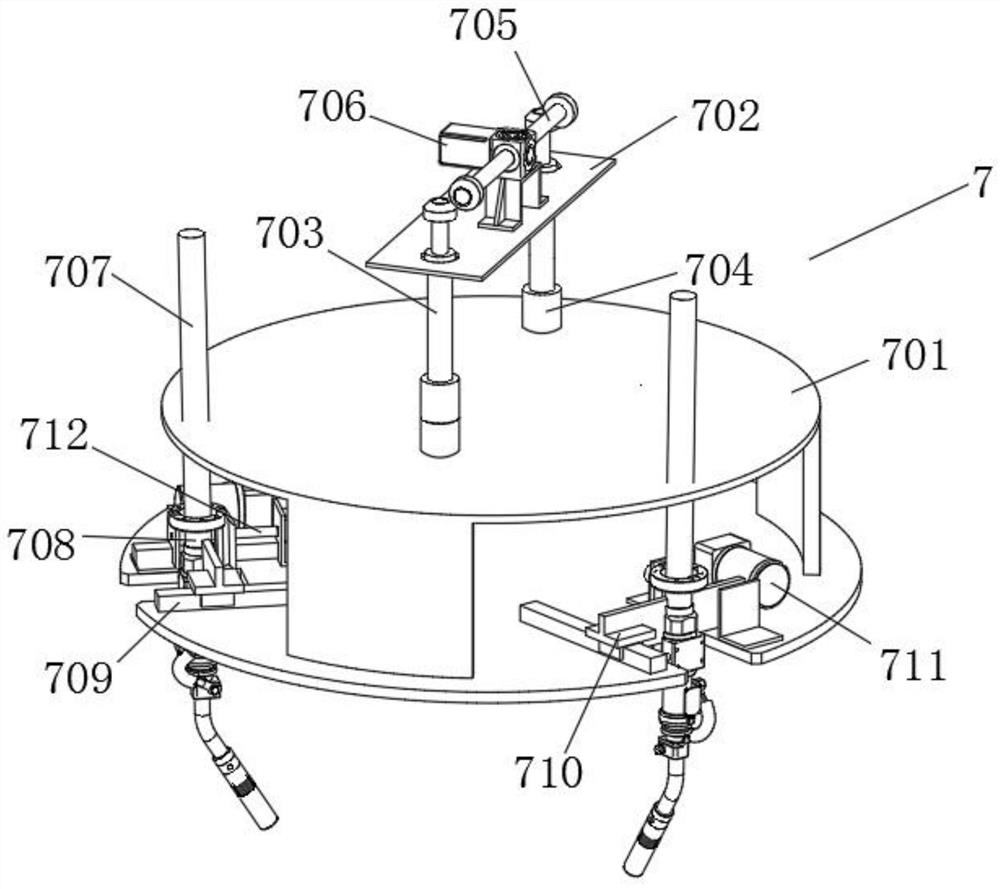

Rail horizontal-moving type lifting stacking robot control platform

PendingCN109335710AChange working positionAvoid inconvenienceStacking articlesDe-stacking articlesEngineeringRobot control

The invention discloses a rail horizontal-moving type lifting stacking robot control platform. The platform comprises a platform mounting plate and a seat, positioning plates are symmetrically connected to two sides of the upper surface of the platform mounting plate in a welded mode, and transmission rods are connected to the inner center of the positioning plates in a threaded mode. Pushing plates are connected to the inner sides of the transmission rods in a welded mode, guiding rails are symmetrically connected with two sides of the upper surface of the seat in a welded mode, sliding grooves are formed in the middle positions of the upper surfaces of the guiding rails, the inner surface walls of the sliding grooves are connected with the platform mounting plate through moving rollers in a rolling mode, and lateral position plates are arranged at the upper surface of the seat and located on the inner sides of the guiding rails in a welded mode. According to the rail horizontal-moving type lifting stacking robot control platform, through the arranged structure of the moving rollers and the guiding rails, the platform mounting plate is enabled to perform a horizontal-moving type sliding and adjusting in the sliding grooves of surfaces of the guiding rails under the rolling action of the moving rollers to change working positions of the control platform, inconvenience caused bylabors manually moving the control platform is avoided, and the operation flexibility of the control platform is improved.

Owner:江苏派远软件开发有限公司

An automatic shearing system for textiles and a shearing processing method thereof

ActiveCN108754975BSolve difficultyLess difficult to shearTextile shapingElectric machineryStructural engineering

The invention relates to an automatic wool shearing system for textile fabric and a wool shearing processing method. The automatic wool shearing system comprises a bottom plate, a conveying table, a lifting mount and a wool shearing device, the conveying table is mounted on the bottom plate, the lifting mount is arranged at the upper end of the conveying table on the bottom plate, a sliding grooveis formed in the lifting mount, the wool shearing device is mounted in the sliding groove, the wool shearing device comprises a moving mechanism, an auxiliary mechanism, a wool shearing mechanism, alifting cylinder, a lifting plate, a workbench and rotating pillars, and the wool shearing mechanism comprises linear slides, sliders, lifting cylinders, connection fixing frames, two-way adjustment cylinders, a mounting ring, working plates, auxiliary support plates, sliding frames, adjusting plates, electric adjusting push rods, fixed support plates, working motors, rotating shafts and a rotating cutters. By the arrangement, problems about difficulty of wool cutting and incompleteness of wool cutting existing in the process of wool cutting of the existing textile fabric can be solved, and the automatic wool cutting function can be realized for the textile fabric.

Owner:海宁巨龙新材料股份有限公司

Manual feeding device used in full-automatic numerical control hydraulic pipe bender

ActiveCN102773361BReduce the burden onChange working positionMetal-working feeding devicesPositioning devicesNumerical controlPipe fitting

The invention discloses a manual feeding device used in a full-automatic numerical control hydraulic pipe bender; the manual feeding device comprises a motor support seat and a pair of bearing seat support seats which are fixed at the side of a large vertical seat, wherein a speed-reducing motor is fixedly arranged on the motor support seat; the bearing seat support seats are respectively provided with a bearing seat; two rotating shafts are respectively and movably arranged in the pair of bearing seats; the rotating shafts are connected with the speed-reducing motor; a pair of rotating arms which are respectively articulated with a movable plate are respectively fixed on the rotating shafts; the movable plates are respectively articulated with a pair of trip holders; two material clamp cylinders are respectively articulated at the ends of the rotating arms close to the rotating shafts; two piston rods of the material clamp cylinders are respectively connected with a connecting seat; the two connecting seats are respectively articulated with the movable plate; the two movable plates are respectively driven to make rotation along the opposite directions by the two material clamp cylinders connected with the movable plates; and a locating check block capable of moving up and down as well as left and right is arranged at the side of the large vertical seat by a locating adjustment mechanism. The manual feeding device can be conveniently used for feeding a long and heavy pipe fitting.

Owner:和和机械(张家港)有限公司

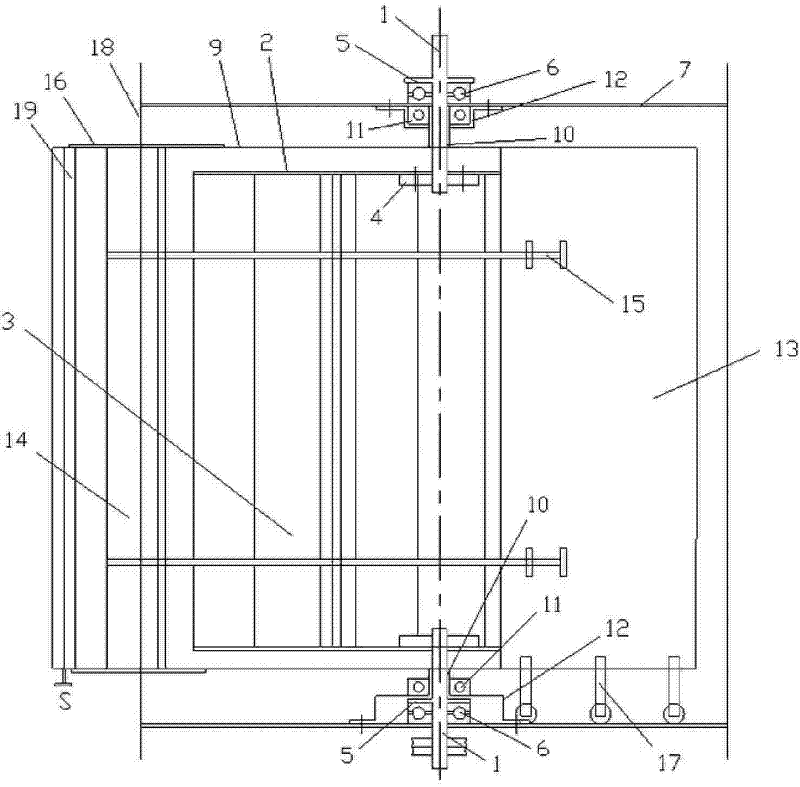

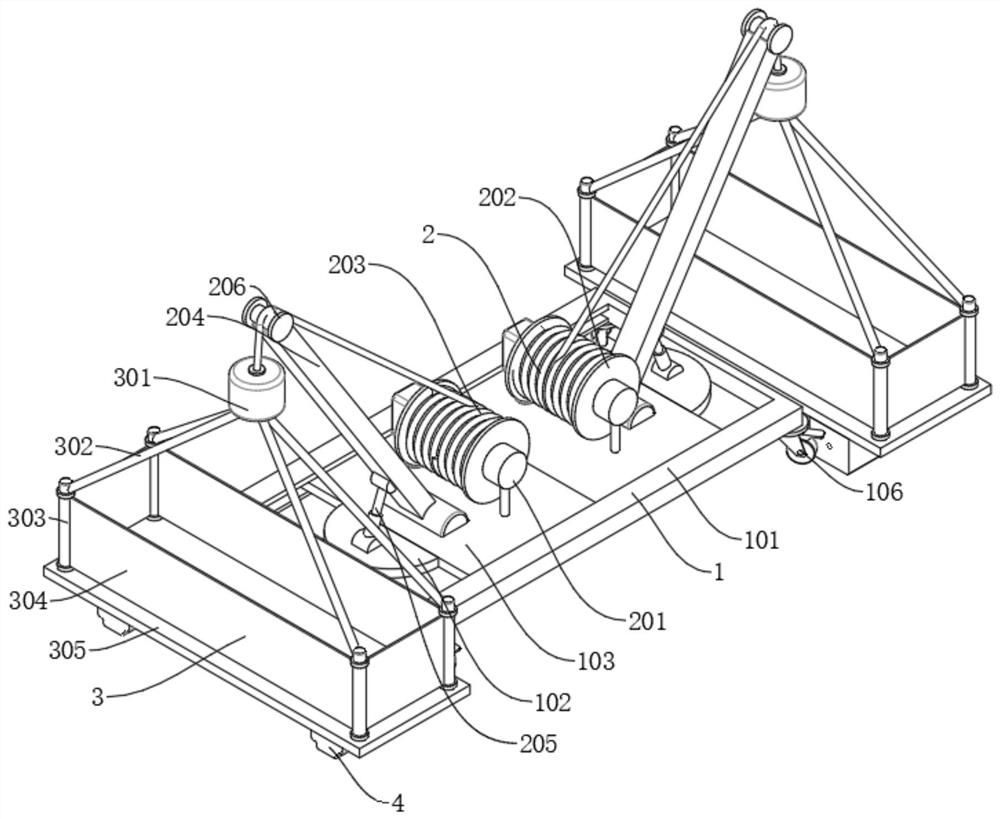

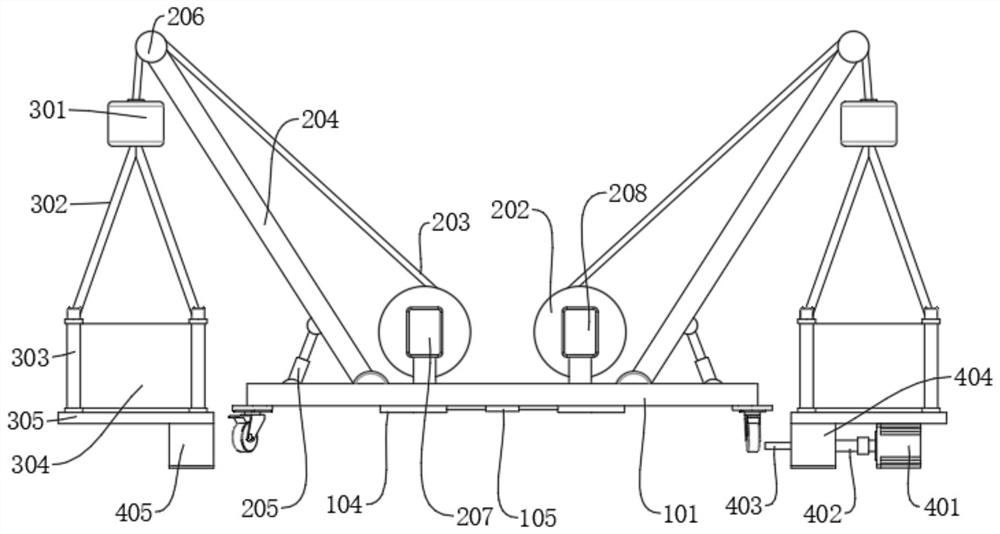

Novel mounting tool for railway bridge pier hanging basket

InactiveCN108505455AChange working positionEnsure personal safetyBridge erection/assemblyEconomic benefitsEngineering

The invention relates to the technical field of railway construction, in particular to a mounting tool for a railway bridge pier hanging basket. The mounting tool comprises a supporting bracket and afirst fixing frame. The bottom end of the supporting bracket is fixedly connected with the first fixing frame and a second fixing frame. The inner side of the middle end of the second fixing frame isslidably connected with a first pulley. The inner side of the bottom end of the second fixing frame is slidably connected with a second pulley. The left ends of a first connecting rod and a second connecting rod are fixedly connected with a working table. The inner side of the right end of the working table is fixedly connected with a hinge. The inner side of the left end of the working table is fixedly connected with a supporting block. The right end of the first pulley is slidably connected with a first arc guide rail. The mounting tool can rotate by 360 degrees, the work space is enlarged,the height can also be adjusted according to the need of a user, the great economic benefits and wide market prospects are achieved, and the mounting tool is worth using and promoting.

Owner:WUHU RUNLAN BIOTECH CO LTD

A dust removal device for electrical automation equipment

ActiveCN110756519BChange the blowing rangeDust blowing range can be changed flexiblyDirt cleaningCleaning using toolsCircular discElectric machinery

Owner:ZHUHAI HENGQIN KUNPENG NEW ENERGY ENVIRONMENTAL PROTECTION TECH CO LTD

Assist manipulator

InactiveCN108406747BChange working positionAutomatically increase or decrease the movement speedProgramme-controlled manipulatorJointsEngineeringManipulator

The power-assisted manipulator of the present invention belongs to the field of mechanical engineering, and solves the problem that the handling speed and strength of the manipulator cannot be manually controlled, and the workpieces with large mass and different volumes are difficult to load and unload. The power-assisted manipulator includes: an arm with a first locking member; The adapter, which is hinged with the arm through the X-axis hinge, makes the arm rotate around the X-axis; the locking mechanism, which is detachably fixed on the adapter; when the arm rotates around the X-axis to close The adapter, the locking mechanism is locked with the first locking member, so that the arm is fixedly connected with the adapter; the connector, which is hinged with the adapter through the Z-direction hinge axis, makes the fixedly connected adapter and arm At the same time, it rotates around the hinge axis in the Z direction; the lifting drive mechanism is connected with the connecting piece and is used to drive the connecting piece, the adapter piece and the arm to move along the Z direction. The device has the advantages of simple structure, convenient operation and powerful function, and has the effect of lifting a heavy object as light as it is when carrying a heavy object.

Owner:JILIN UNIV

Novel fluid engine

InactiveCN101649808BChange working positionExempt from power controlFinal product manufactureReaction enginesEngineeringWind power generation

Owner:杨伦华

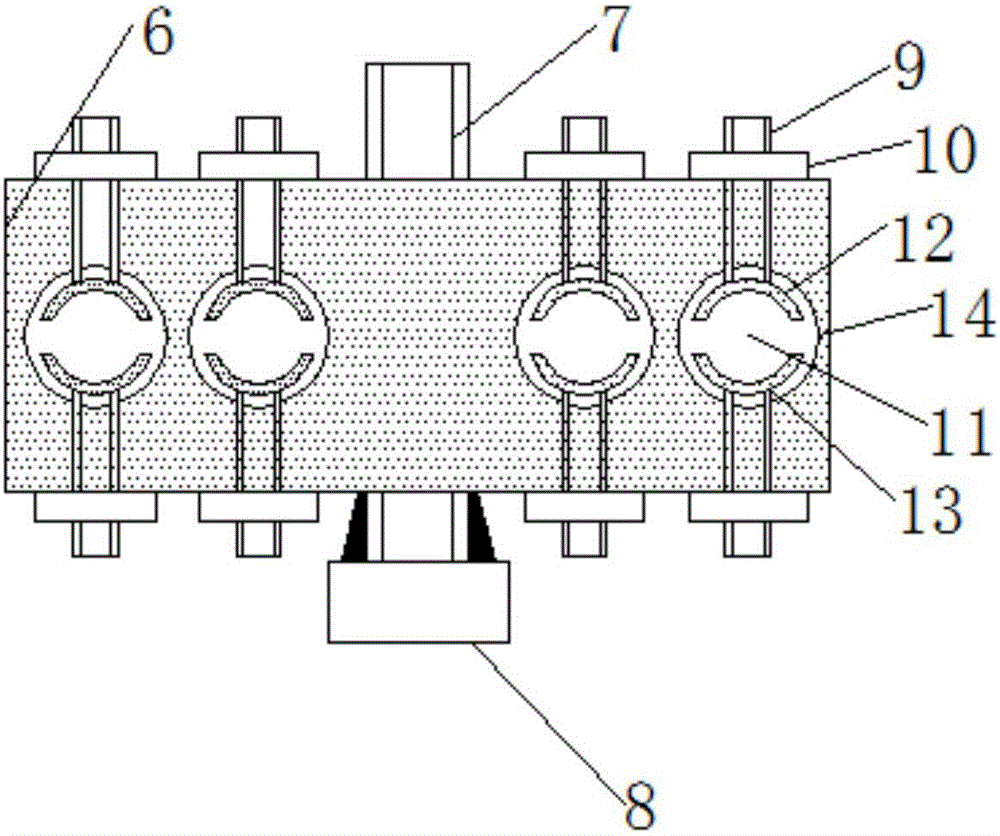

A production mold for railway sleepers that is convenient for pouring and demoulding

ActiveCN110883921BQuick release workQuickly complete the demoulding workDischarging arrangementMould auxillary partsRotational axisManufacturing engineering

Owner:武汉思力博轨道装备有限公司

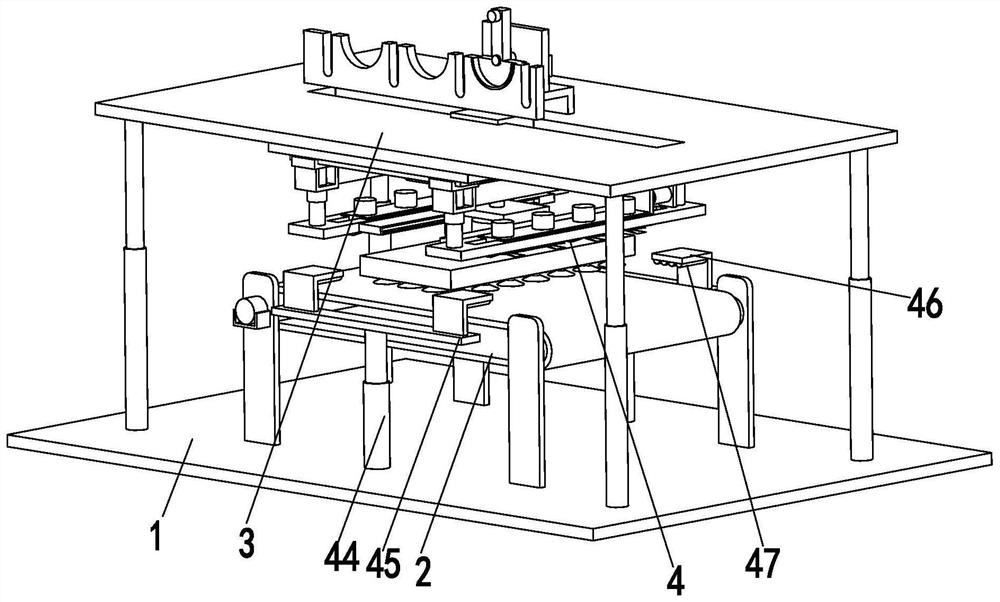

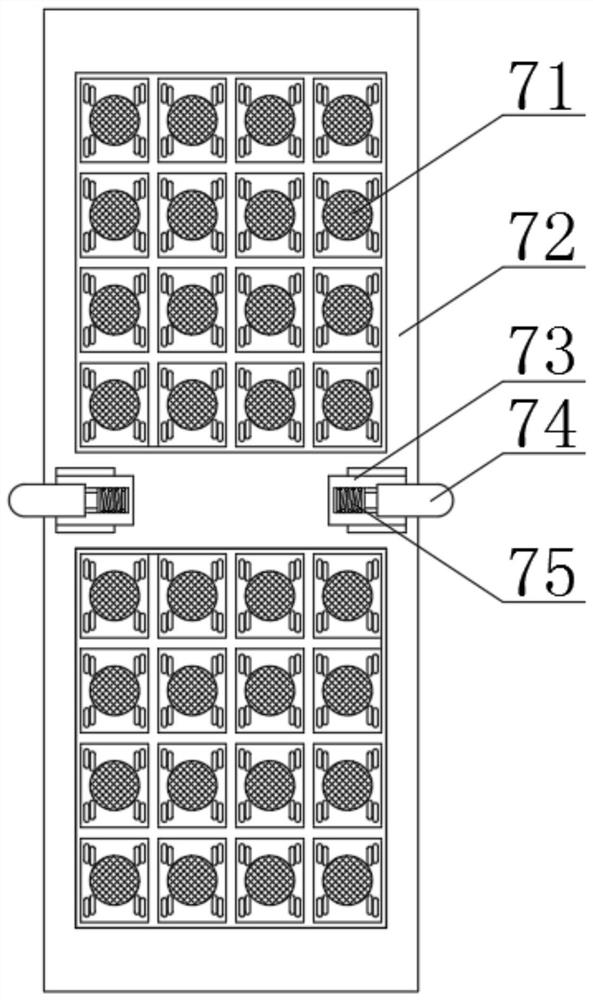

A dual-arm robot flexible grinding device

ActiveCN112139944BEasy to useEasy to disassembleGrinding carriagesGrinding drivesRobotic armEngineering

The present invention relates to the technical field of grinding tools, in particular to a flexible grinding device for a robot with dual mechanical arms, which includes a supporting platform, a horizontal sleeve plate, a rotating loading plate and two mechanical arms. The set plate, and both sides of the upper end surface of the horizontal set plate are provided with a slide rail one, and a tooth plate one is horizontally provided between the two slide rails one. Beneficial effects of the present invention: the objects are polished at the same time by the grinding components at the bottom of the two mechanical arms respectively, the device is more efficient in grinding the objects, and the grinding components are screwed and fixed in the groove by two nuts, While ensuring more convenient installation, use or disassembly of the grinding component, it is also possible to more flexibly and quickly adjust the fixed position of the grinding component in the sleeve groove, and adjust the loading and grinding on the mounting plate according to the needs of grinding different objects. The number of components ensures that the grinding device has higher precision and faster efficiency in grinding different objects.

Owner:ANHUI XINJINGJIE AUTOMATION TECH

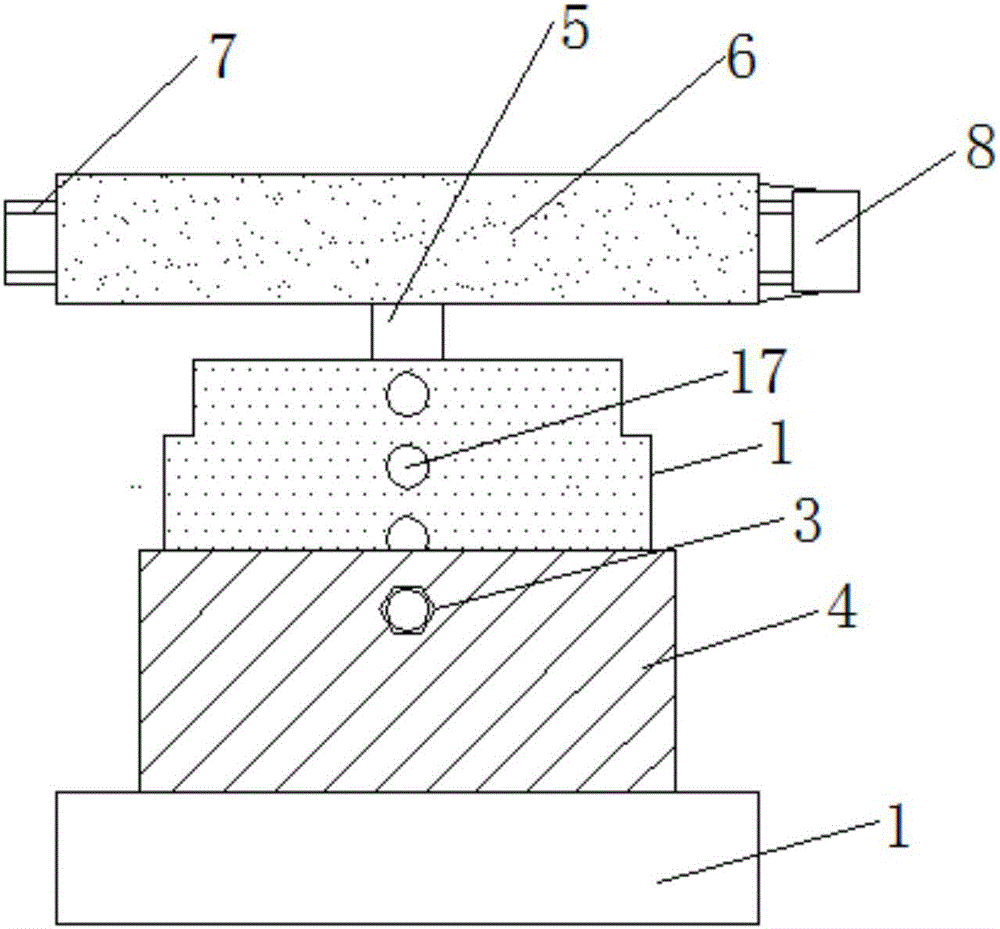

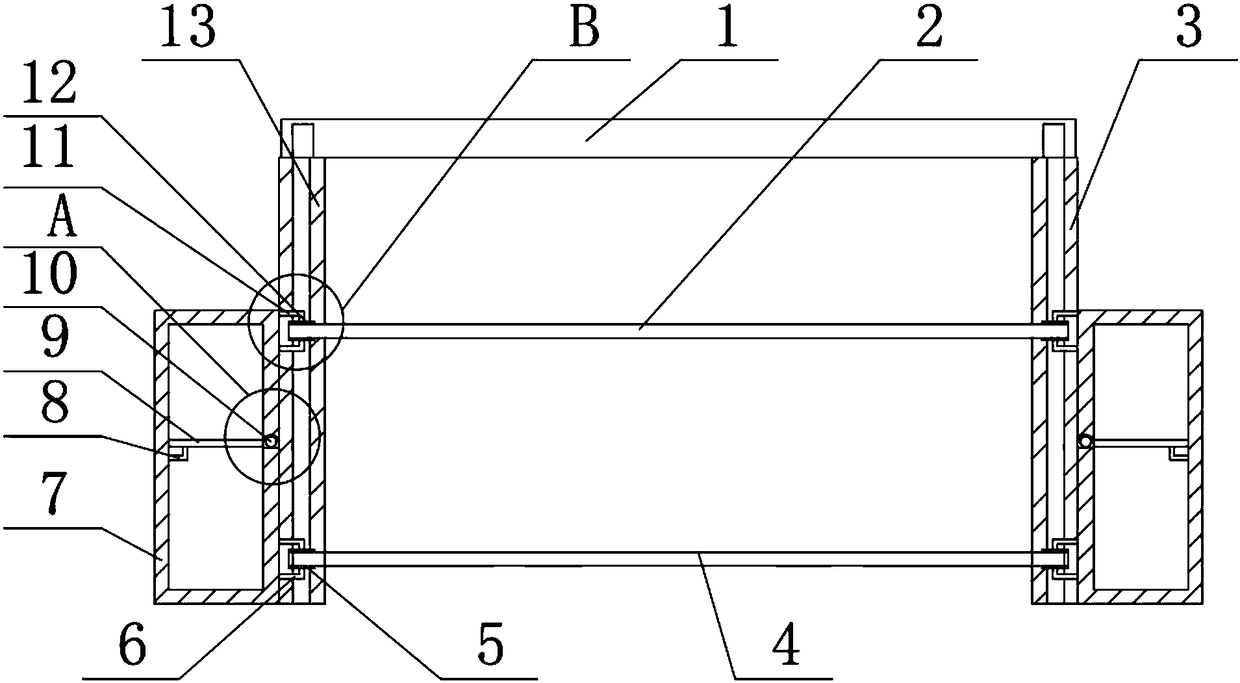

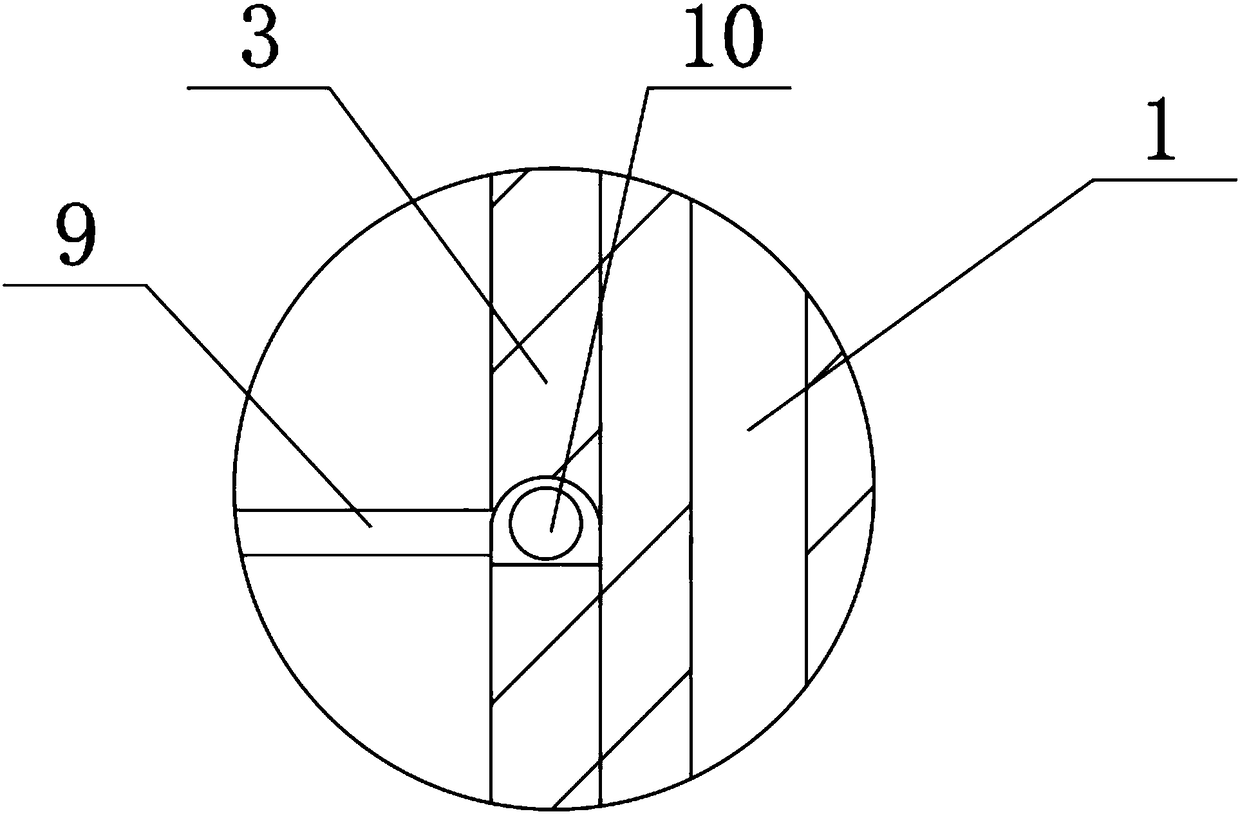

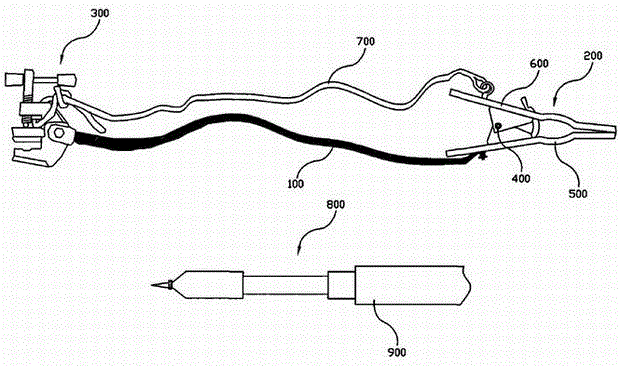

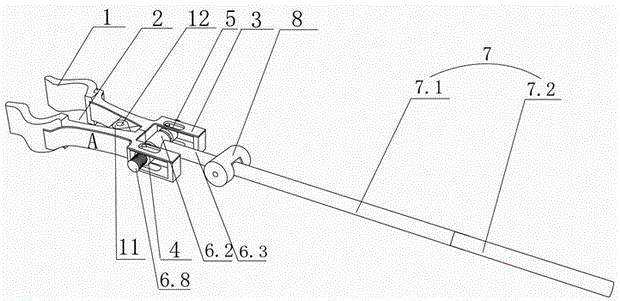

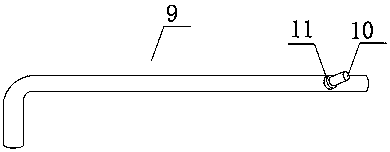

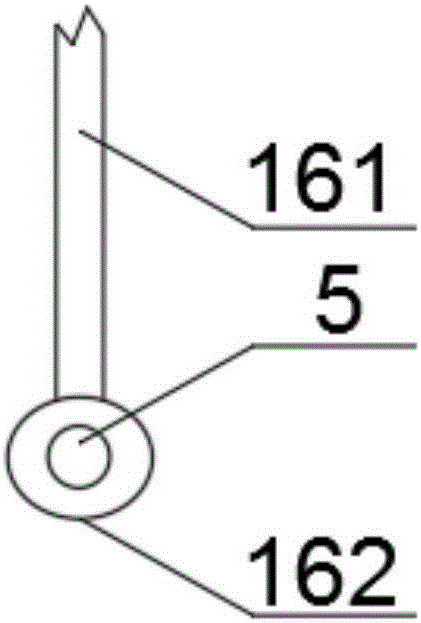

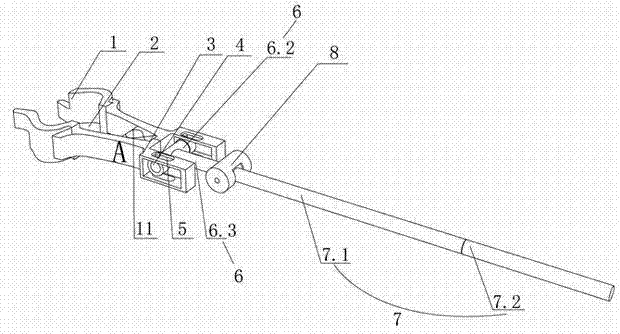

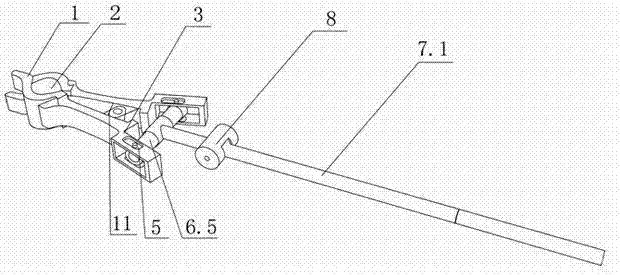

Clutch straight rod short-circuit grounding device

InactiveCN103036080BChange working positionEasy to useLine/current collector detailsElectric connection structural associationsComputer moduleEngineering

The invention discloses a clutch straight pole type short circuit grounding device which comprises a wire end cable cleat (A) and a holding rod (7), wherein the wire end cable cleat (A) comprises a pair of clamping plates (1), the clamping plates (1) rotate with the help of a revolving shaft, and arc-shaped occlusions (2) are arranged on the upper portions of the clamping plates (1). The clutch straight pole type short circuit grounding device is characterized in that opposite die blocks (3) are arranged on the tail portion of the wire end cable cleat (A), moving nuts (4) are arranged in the opposite die blocks (3), the moving nuts (4) are movably connected with the opposite die blocks (3), and the moving nuts (4) can horizontally rotate and slide in the opposite die blocks (3). A telescoping mechanism (6) is fixedly connected with the moving nuts (4), the telescoping mechanism (6) is connected with the holding rod (7), and the holding rod (7) is provided with a control mechanism which can control the telescoping mechanism (6) to stretch out and draw back. The clutch straight pole type short circuit grounding device has the advantages of being good in safety performance. Due to the fact that the wire end cable cleat is controlled by people to clamp or loosen wires, the condition that the wire end cable cleat automatically fall off is not enabled to emerge.

Owner:何国飞

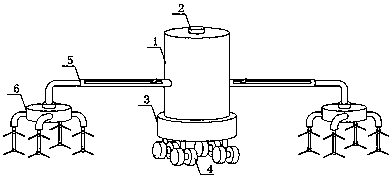

Irrigating device after corn planting

InactiveCN107912282AWater evenlyHigh degree of automationWatering devicesCultivating equipmentsEngineeringWater holding

The invention discloses an irrigating device after corn planting, which comprises a water tank, a water holding cover, a power distribution box, an electric roll wheel, a water delivering disk, watering frames, a mounting ring, a chute, a water connecting pipe, a slide buckle pillar, a screwing bolt, a water cabin, a water receiving opening, a sealing plate, a connecting block, a water connectinghole, a water dividing disk, a motor, a rotary pouring disk, a sheathing disk, a watering rod, a driving gear, a sleeve block and a water outlet. The irrigating device has the beneficial effect that the device is high in automatic degree in use, free from labor operation, and saves time and force and guarantees the using convenience. People can change the extending length of the water connecting pipe by gliding the slide buckling pillar forwards and backwards on the chute of the mounting ring upon the watering demand of corn planting lands with different widths, thus the working positions of two watering frames can be changed, the watering position and the overall width of the whole device are changed; the device has more accurate soil watering position, the adaption universality is guaranteed; the device is convenient to operate, and every member is flexible in connection.

Owner:防城港市绿华源农林科技有限公司

Thermal imaging image attenuation device, control module and thermal imaging equipment

Owner:HANGZHOU HIKMICRO SENSING TECH CO LTD

Bending processing device for deep processing of boron-magnesium alloy

ActiveCN108637057BConvenient bending workImprove efficiencyShaping toolsShaping safety devicesMagnesium alloyElectric heating

The invention discloses a bending processing device and method for boron-magnesium alloy deep processing. The bending processing device comprises a device body and supporting legs; a boron-magnesium alloy is arranged on the inner side of the device body; protective baffles are installed on the outer side of the boron-magnesium alloy; electric heating ovens are arranged on the upper side and the lower side of the boron-magnesium alloy; the outer sides of the electric heating ovens are connected with the device body through first sliding rods; first limiting sleeves are arranged inside the device body, and the inner sides of the first limiting sleeves are connected with the first sliding rods; and second limiting sleeves are fixed inside the device body, the inner sides of the second limiting sleeves are connected with second sliding rods, and movable bases are fixed to the lower ends of the second sliding rods. According to the bending processing device and method for boron-magnesium alloy deep processing, through the arrangement of the electric heating ovens and electric telescopic rods, high efficiency of the boron-magnesium alloy in the deformation process can be ensured, the boron-magnesium alloy is also prevented from being damaged in the deformation process, and the using value of the whole bending processing device is improved.

Owner:EASTERN LIAONING UNIV

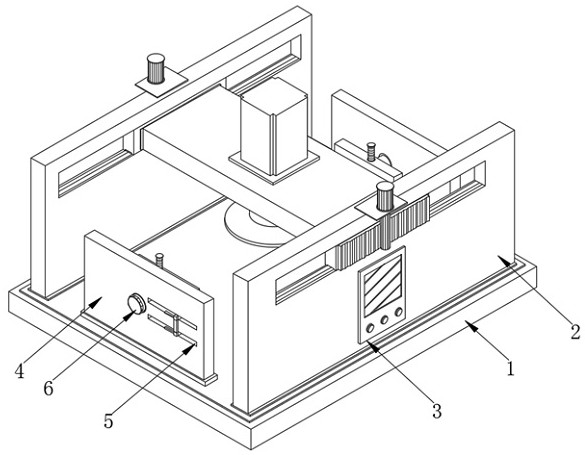

Welding fixing device

InactiveCN106624560AGuaranteed stabilityEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesFixed positionFixed frame

The invention discloses a welding fixing device comprising a left positioning unit, a right positioning unit, a control unit and a fixed frame. A toothed belt is arranged on the fixed frame. The left positioning unit and the right positioning unit are installed on the fixed frame in a guide rail and toothed belt engaged manner. The left positioning unit and the right positioning unit are electrically connected with the control unit. The left positioning unit and the right positioning unit are each used in cooperation with multiple positioning rods for fixing welding parts. According to the welding fixing device, different fixing positions can be arranged according to the welding parts of different shapes, and the stability during welding is ensured; the working position of welding can be changed, and workers can conveniently conduct welding; and rubber is used as contact objects of a pressing mechanism and the welding parts, it is ensured that the welding parts cannot be damaged by the pressing mechanism, and it is ensured that the welding parts cannot deform due to fixation.

Owner:重庆王滔机械制造有限公司

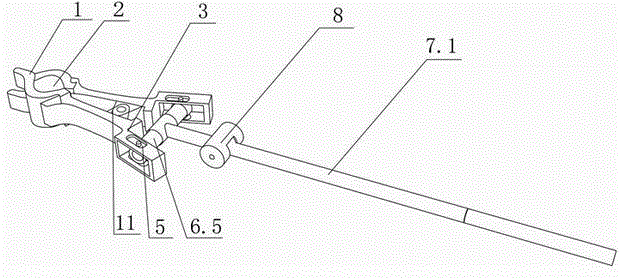

Clutch rotating short-circuit grounding device

ActiveCN102969585APrevent returnThere will be no automatic fall-offLine/current collector detailsElectric connection structural associationsComputer moduleEngineering

The invention discloses a clutch rotating short-circuit grounding device. The clutch rotating short-circuit grounding device comprises a wire-end cable clamp (A) and a holding rod (7), wherein the wire-end cable clamp (A) comprises a pair of clamping boards (1) which are in rotary connection with each other through a rotating shaft, and the upper part of each clamping board (1) is provided with an arc-shaped occlusion opening (2). The clutch rotating short-circuit grounding device is characterized in that the tail end of the wire-end cable clamp (A) is provided with a pair of modules (3) which are internally provided with movable nuts (4); each movable nut (4) is movably connected with the corresponding module (3) and can transversely rotate and slide in the corresponding module (3); a telescoping mechanism (6) is firmly connected to the movable nuts (4) and is connected to the holding rod (7); and the holding rod (7) is provided with an operating mechanism controlling the expansion of the telescoping mechanism (6). The clutch rotating short-circuit grounding device has the advantages of being high in safety performance, and capable of avoiding the automatic falling of the wire-end cable clamp as the wire-end cable clamp is manually controlled to clamp or release a wire.

Owner:STATE GRID CORP OF CHINA +2

Electric appliance element processing operation table

The invention discloses an electric appliance element processing operation table. The electric appliance element processing operation table comprises a carrying table and a sliding seat, the overlooking section of the sliding seat is of an inverted-U-shaped structure, sliding grooves are formed in the inner surface walls of the horizontal ends of the two sides of the sliding seat, and the inner surface walls of the sliding grooves are in rolling connection with the carrying table through balance rollers; clamping pipes are welded to the upper surface of the carrying table at equal intervals; an operation groove is formed in the surface of each operation rod, a filter screen is fixed to the lower surfaces of the horizontal ends of the two sides of the sliding seat through bolts, and limiting frames are welded to one sides of the horizontal ends of the two sides of the sliding seat. According to the electric appliance element processing operation table, a working platform adopts the carrying table with a telescopic rolling structure so that the carrying table can be driven by a servo motor to move back and forth on the inner surface wall of the sliding seat, thereby the specific working position of the carrying table is changed, the specific operating positions of the four operating rods are adjusted, and the comprehensive processing of a to-be-processed element can be achieved.

Owner:东安万鸿电子有限公司

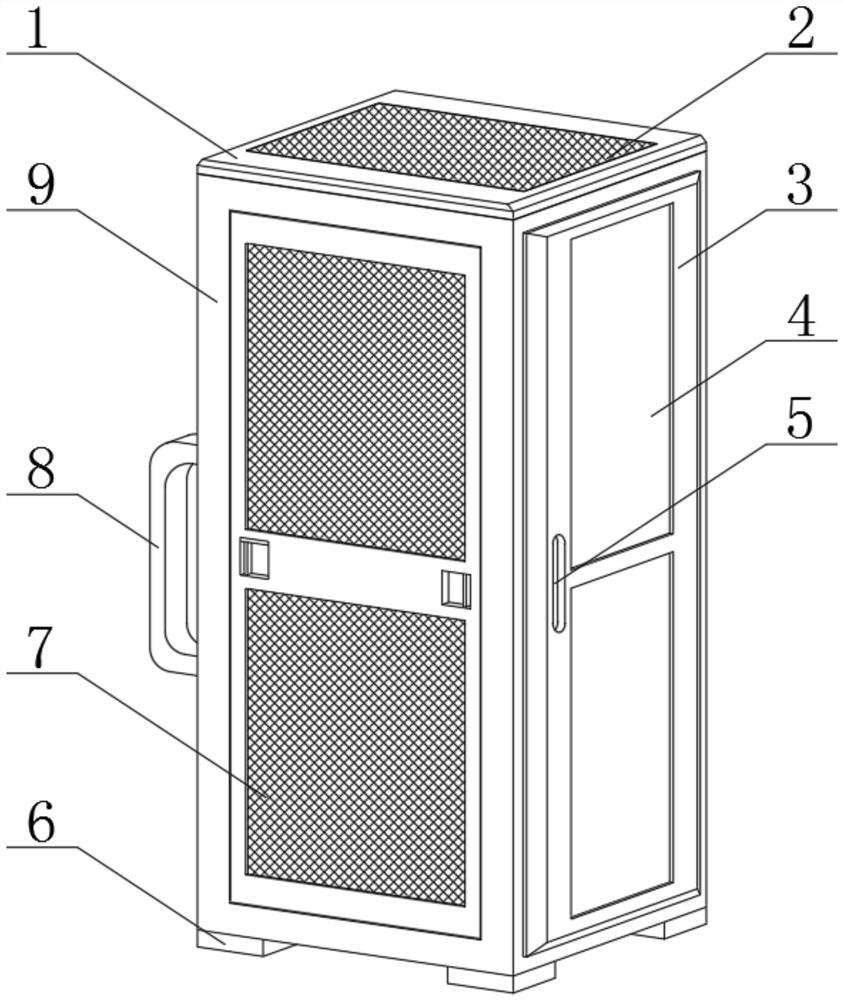

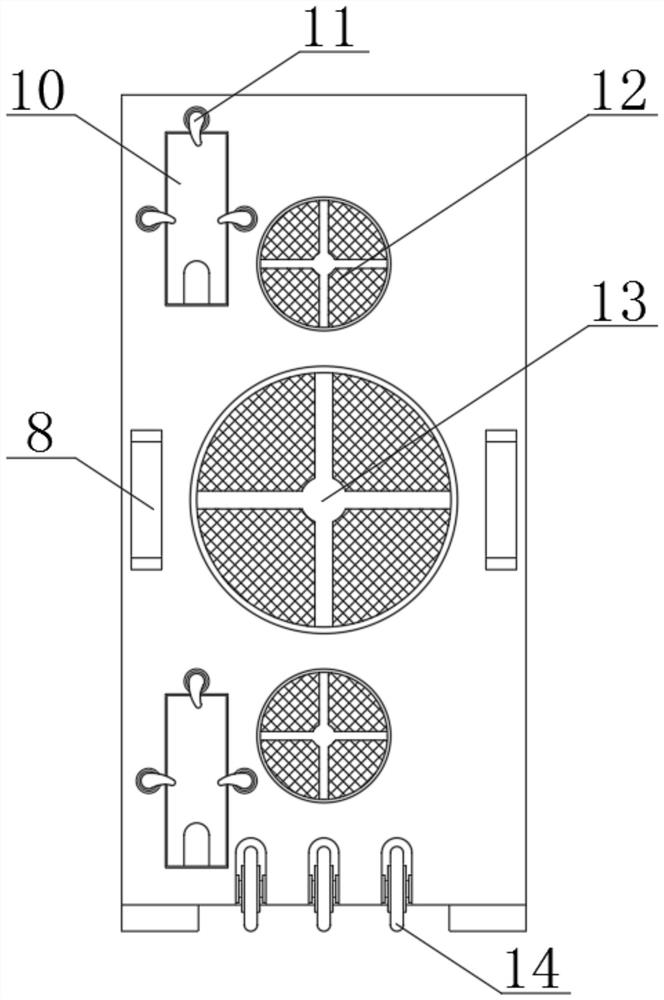

Network cabinet with high heat dissipation

InactiveCN112449551AImprove job stabilityExtended service lifeServersCasings/cabinets/drawers detailsThermodynamicsWorking environment

The invention discloses a high-heat-dissipation network cabinet, and the cabinet comprises a top plate and a top dustproof net; the top dustproof net is arranged in the middle of the top of the top plate, and a novel side heat dissipation plate, an auxiliary heat dissipation device and a main heat dissipation device are additionally arranged on the basis of existing equipment. When the cabinet isin operation, a user can install a plurality of heat dissipation fans on the side face heat dissipation plate for heat dissipation work according to work requirements, meanwhile, in the work process of the heat dissipation device, the main heat dissipation device and the auxiliary heat dissipation device on the back face of the work box can effectively assist the heat dissipation device in heat dissipation work, and the work heat dissipation performance of the heat dissipation device is effectively improved; the working environment of the internal network equipment is optimized, the novel pushhandle and the moving wheels are additionally arranged on the basis of existing equipment, the convenience of the device is improved, and a user can effectively and conveniently change the working position of the device according to working requirements.

Owner:合肥昌嵩精密制造有限公司

Bridge engineering safety construction platform

InactiveCN113638313ASuitable working positionChange the protruding angleBridge structural detailsBridge engineeringArchitectural engineering

The invention belongs to the technical field of bridge engineering, and particularly relates to a bridge engineering safety construction platform which comprises a moving mechanism, a hoisting mechanism, standing mechanisms and an adjusting mechanism capable of changing the distance between the standing mechanisms, the hoisting mechanism is mounted on the upper portion of the moving mechanism, and the standing mechanisms are mounted at one end of the hoisting mechanism. The construction platform further comprises an adjusting mechanism capable of changing the distance between the standing mechanisms. The adjusting mechanism comprises a second motor, a telescopic hydraulic rod, a threaded lead screw, a positioning block and a movable threaded block. According to the bridge engineering safety construction platform, through the arrangement of the adjusting hydraulic rods and the bearing sliding plates, the upper part can be driven to be close to the two sides of a bridge, and the hoisting mechanism can reach a proper working position; by means of the arrangement of the lifting hydraulic rod, the extending angle of the lifting arm can be changed, and then the standing mechanism can be conveyed to a proper working position by the steel wire lifting rope.

Owner:徐州崇威桥梁工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com