Clutch straight rod short-circuit grounding device

A grounding device, a straight-rod technology, applied in the direction of circuit, connection, conductive connection, etc., can solve the problems of inconvenient operation, poor safety, easy to fall off, etc., and achieve the effect of low production cost, easy operation and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

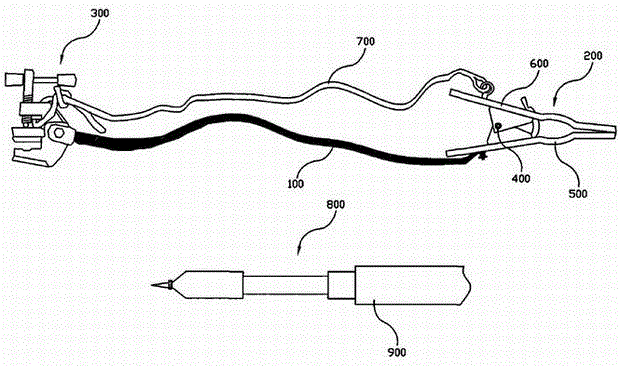

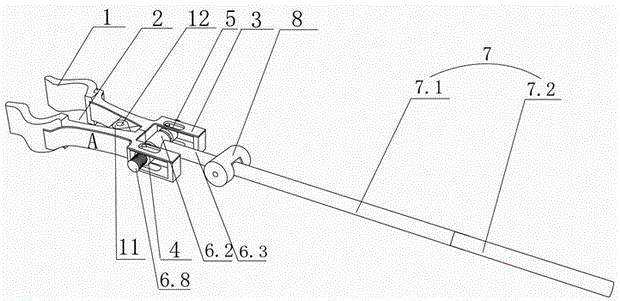

[0036] Such as Figure 2-5As shown, the clutch straight rod type short-circuit grounding device of the present invention includes a wire end clamp A and a handle 7. The wire end clamp A includes a pair of splints 1 connected to the steering shaft by means of a support piece 11 and an arc-shaped bite 2 is provided on the upper part. The tail A of the wire end clamp is provided with a pair module 3, and a movable nut 4 is arranged in the pair module 3, and the movable nut 4 is connected with the movable piece 5 arranged on the pair module 3 through a screw, and the movable nut 4 can rotate laterally along the screw rod , the movable piece 5 can slide on the pair of modules 3; the telescopic mechanism 6 includes a pair of telescopic rods 6.1, a cover cylinder 6.2, a guide cylinder 6.3, a rotating rod 6.4, and a side cylinder 6.5. The end of the guide cylinder 6.3 is connected with the cover cylinder 6.2, and the side The tube 6.5 is hollow, and it can be stretched in the cover tu...

Embodiment 2

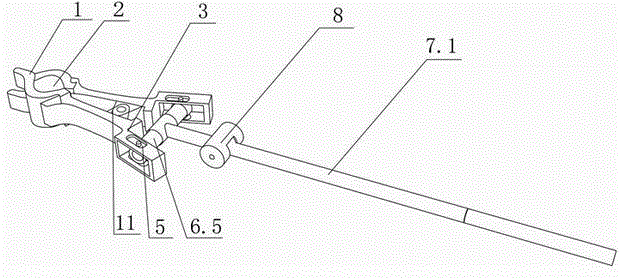

[0041] Such as Figure 6-7 As shown, the difference from Embodiment 1 is that the inner side wall of the one splint 1 is also provided with a depressing tongue 13, which is arranged between the rotating shaft 12 and the arc-shaped bite 2, and the other splint 1 is correspondingly A tongue depressing through hole is provided. The effect of this pressure 13 is, when wire end wire clamp A is in open state, depressing tongue 13 is used for propping up wire end wire clamp A, moves back and forth when avoiding expansion rod 6.1 to tighten up. When it is necessary to loosen the splint 1 for clamping, the pressing tongue 13 contacts the wire, and the wire terminal clamp A can be released. The remaining technical principles are the same as in Embodiment 1.

Embodiment 3

[0043] The difference from Embodiment 1 is that the telescopic rod 6.1, the rotating rod 6.4, and the gripping rod 7.3 are threaded as a whole, and the transmission mode is worm gear transmission, and the rest of the operation modes are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com