Straightening method for flat-bulb steel and straightening roll

A technology of flat bulb steel and straightening rolls, applied in the field of straightening of bulb flat steel, can solve the problems of backward production technology, high consumption of tooling, poor surface quality, etc., achieve high versatility, reduce labor intensity, and improve roll utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

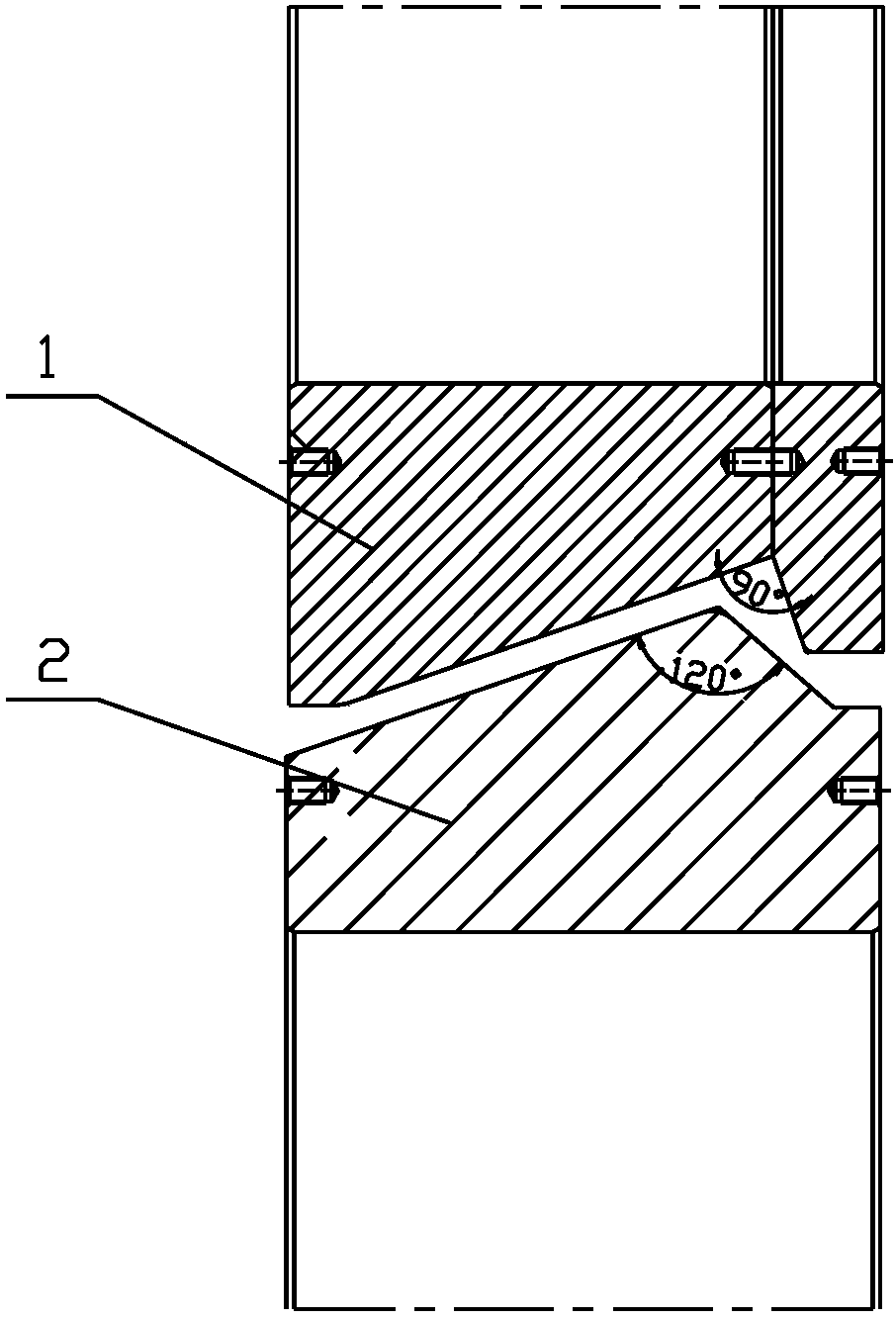

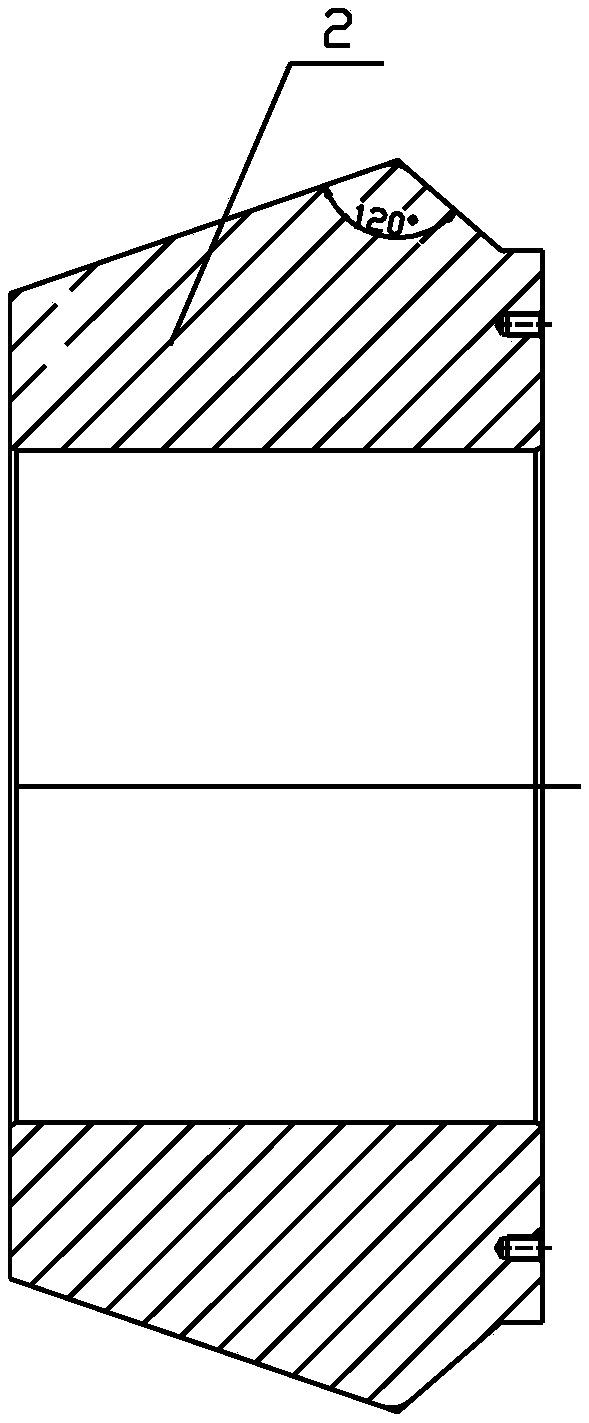

[0029] A kind of straightening method of bulb flat steel, concrete steps are as follows:

[0030] 1) The straightening method of marine bulb flat steel adopts the "oblique straightening method", that is, the bulb flat steel enters the 900 straightening machine at an angle of 18°; the pass position is adjusted at the center of the roller table;

[0031] 2) The passes of the upper and lower straightening rollers are straightened and bent up and down, and the side walls of the pass are adjusted horizontally.

[0032] 3) The straightening pressure decreases sequentially from the entrance direction, the pressure of 1 roll is 15mm, and the pressure of each roll is reduced by 1-3mm, the up and down bending is adjusted according to the pressure, and the horizontal bending is adjusted according to the axial force;

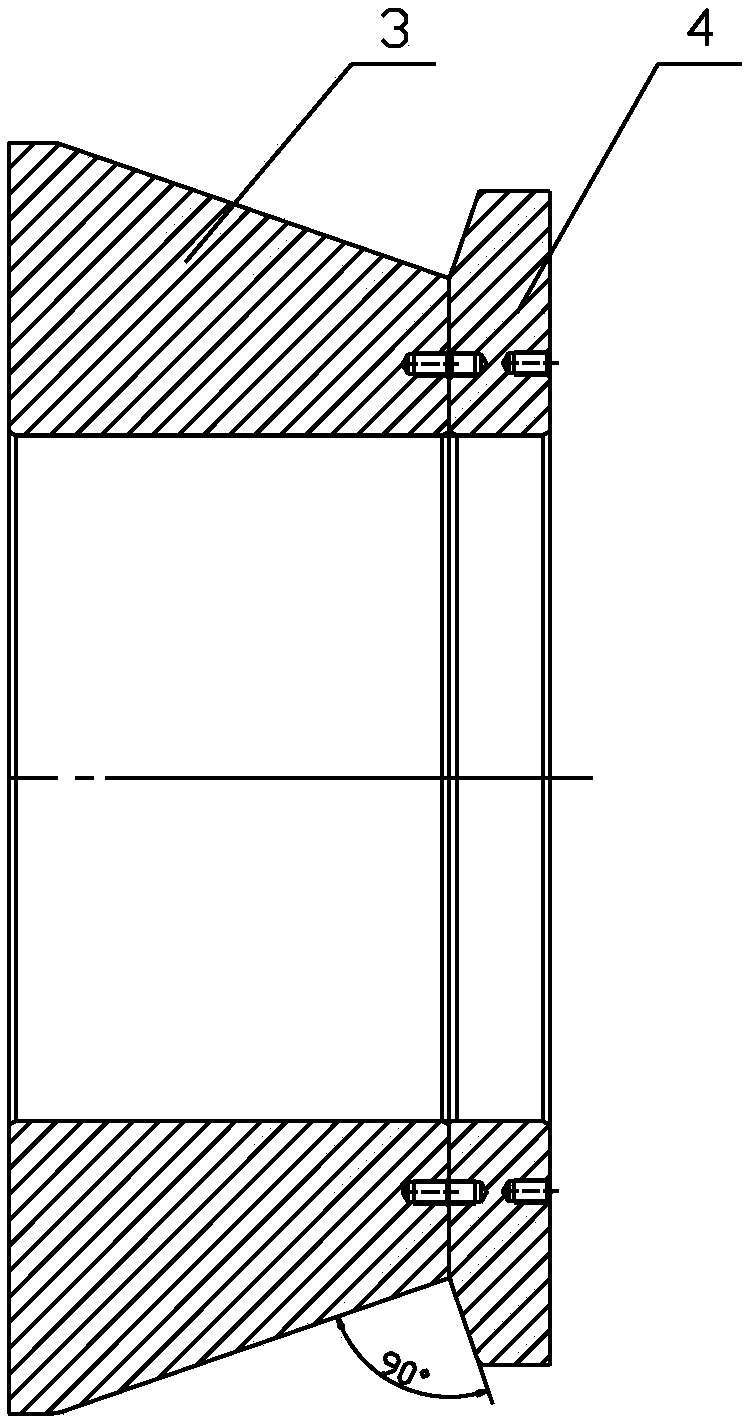

[0033] 4) When the main roller and the upper roller are directly assembled, the model 180 rail head is produced. When producing larger-sized spherical flat steel, a gasket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com