Copying drum cutting type flos carthami harvesting device

A cutting and drum technology, applied in the field of profiling drum cutting type safflower harvesting device, can solve the problems of high labor intensity, bouquet shaking, difficulty in filament feeding, etc., and achieve the effect of solving serious shaking and improving picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

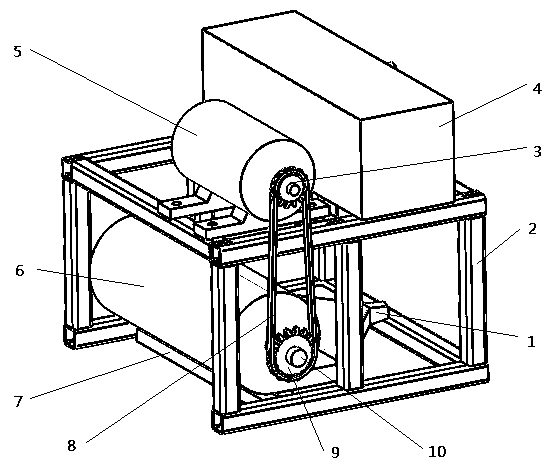

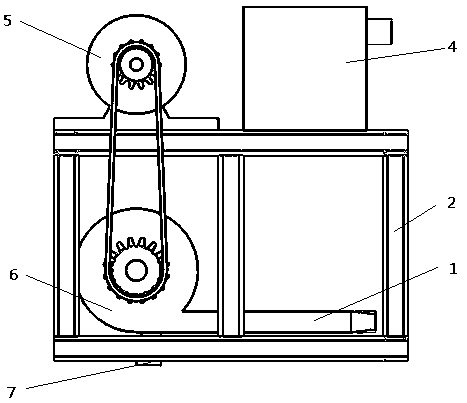

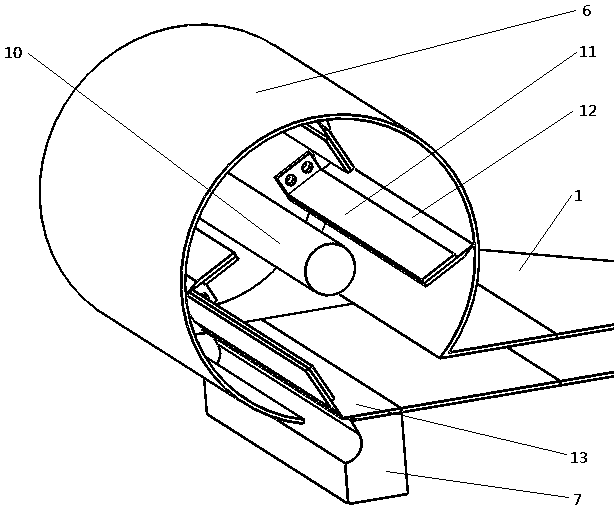

[0015] see figure 1 , a profiling drum cutting type safflower harvesting device. When the whole machine is moving forward, the flower ball first touches the air suction cover (6), under the action of negative pressure in the air suction cover (6), the filament enters the opening of the air suction cover (6), and the flower ball moves At the position of the profiling baffle (7), under the effect of negative pressure in the profiling baffle (7) and the air suction cover (6), the curd is temporarily fixed. The fixed knife (13) is installed on the top of the profiling baffle (7), and works together with the moving knife (12) installed on the main shaft (10) to complete the cutting process of the fixed curd filaments. Under the action of negative pressure in the air suction hood (6), the cut filaments pass through the air absorption collection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com