Eccentric workpiece turn-over vehicle

A technology for flipping cars and workpieces, which is applied in metal processing, manufacturing tools, metal processing equipment, etc. It can solve the problems of affecting the quality of assembled products, the service life of flipping cars, the failure to fully consider the change of force, and the inability to realize flipping, etc., to achieve protection Safety, space-saving, and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

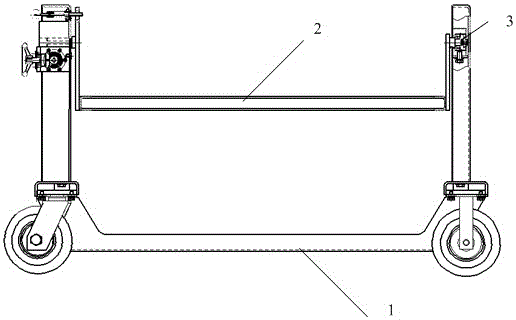

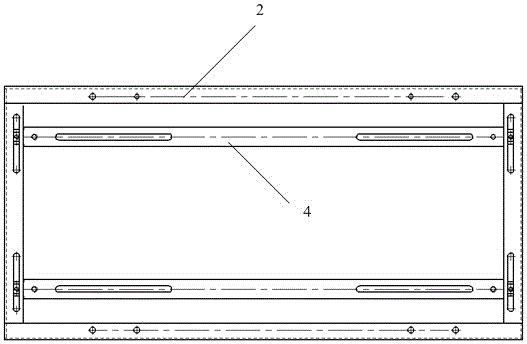

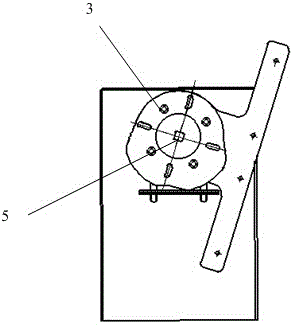

[0020] like Figure 1 to Figure 4 As shown, the present invention provides an eccentric workpiece overturning vehicle for loading L-shaped locomotive circuit breakers, comprising a base frame 1, brackets respectively arranged at two symmetrical ends of the base frame 1, and also including two brackets passing through a rotating shaft 5. A revolving frame 2 that is rotatably connected and located between the two brackets, and the revolving frame 2 is an adjustable bracket, wherein at least one end of the rotating shaft 5 is provided with a shock absorbing cam 3; an elastic device on the bracket and used to provide rotational resistance to the shock absorbing cam 3;

[0021] It also includes: a turbine gearbox rotatably connected to the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com