A load and conveying device for pap printing

A conveying device and paper technology, applied in the directions of transportation and packaging, object supply, pile separation, etc., can solve the problems of difficulty in feeding materials, inability to adjust the fixed height of the structure, etc., to speed up printing efficiency, facilitate transportation, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

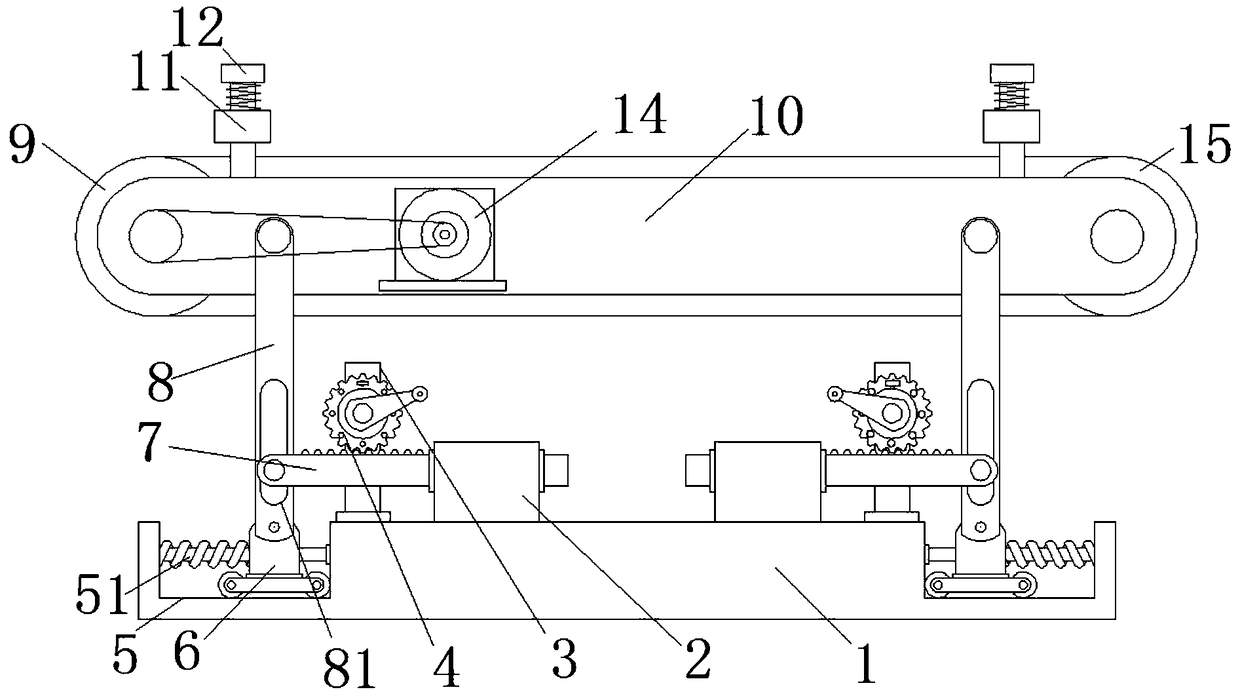

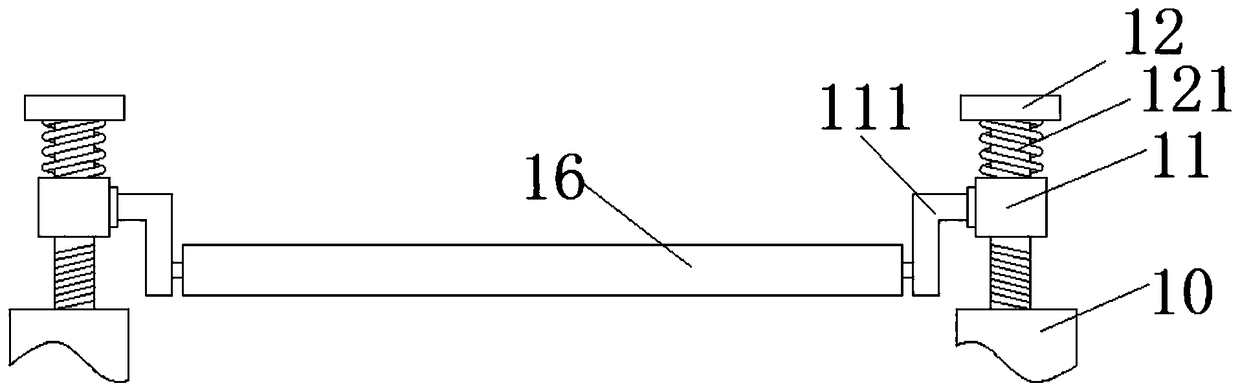

[0019] see Figure 1-2 , this embodiment provides a paper printing boosting conveying device, including a base 1, the top of the base 1 is fixedly connected with a mounting base 2 and a supporting base 3, the supporting base 3 is connected with a gear 4 through a rotating shaft, and the inner wall of the mounting base 2 slides A sliding rod 7 is connected, the top of the sliding rod 7 meshes with the gear 4 through the gear teeth, grooves 5 are opened on both sides of the base 1, the inner wall of the groove 5 is fixedly connected with a limit light rod 51, and a slider is slidably sleeved on the limit light rod 51 6. A movable rod 8 is hinged on the top of the slider 6, and a chute 81 is provided on the movable rod 8. The end of the slider 7 away from the mounting seat 2 is movably connected to the inner wall of the chute 81 through a rotating shaft, and the top of the movable rod 8 is connected to a Mounting frame 10, driven conveyor roller 15 and driving conveyor roller 9 a...

Embodiment 2

[0022] see Figure 1-2 , a further improvement has been made on the basis of Embodiment 1: the gear 4 is plugged on the support base 3 through a pin and a socket, so that after the height of the mounting frame 10 is adjusted, the mounting frame 10 can be made to The position is fixed to prevent shaking. The outer side of the slider 6 is connected to the inner wall of the groove 5 with a second spring arranged on the outer side of the limit light rod 51. Through the setting of the second spring, it is more convenient to return the slider 6 to its original position. easy.

[0023] In the embodiment of the present invention, the bottom of the slider 6 is rollingly connected with the groove 5 through rollers, which can make the slider 6 slide better in the groove 5 and reduce friction. Tight roller 16 is when paper is pressed, avoids that pinch roller 16 is too hard and easily damages paper, and better protects paper, and the gear 4 is fixedly equipped with a hand lever, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com