Roller cutting type flos carthami filament harvesting device

A cutting and drum technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of large vibration, missed mining, low efficiency, etc., to improve the success rate, continuous cutting and harvesting, and avoid missed mining. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

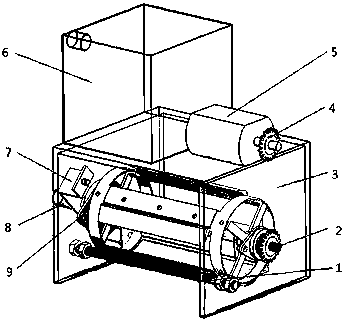

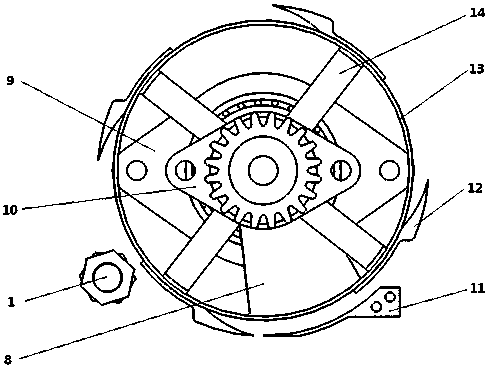

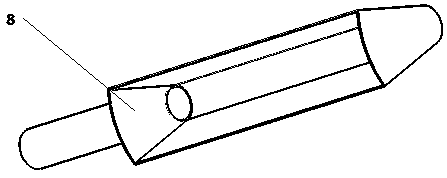

[0016] see figure 1 , figure 2 , a drum cutting type safflower filament harvesting device. During the forward movement of the whole machine, the bouquet touches the bar 1. If the height of the bouquet is lower than the bar 1, the bouquet enters the rear smoothly and hits the serrated fixed cutter 11. Under the effect of front movement, insert serrated fixed cutter 11. Now under the drive of motor 5, drive sprocket wheel 4, cylinder 13 and movable cutter 12 and do rotary motion, under the shearing action of movable cutter 12 and serrated fixed cutter 11, filigree is cut off. If the height of the flower ball is higher than the installation position of the stop bar 1, then as the frame 3 moves forward, the height of the flower ball will continue to decrease relative to the stop bar 1 until it can pass the stop bar 1 smoothly, then the flower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com