Strong pressure type sludge deep dehydration system

A deep dehydration and sludge technology, applied in dehydration/drying/concentrated sludge treatment, filtration separation, separation methods, etc., can solve the problems of increasing compressible stroke, low energy consumption of strong pressure mechanical dehydration, difficult feeding, etc., to achieve Easy to unload, save manpower and time, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

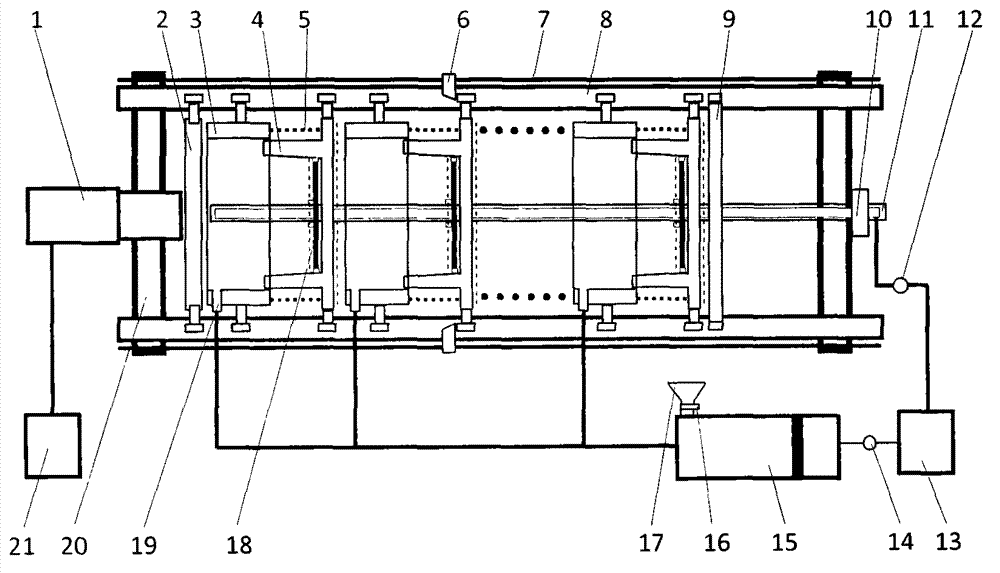

[0011] See the accompanying drawings, the sludge strong pressure deep dewatering system, the described sludge strong pressure deep dewatering system consists of a stroke bracket, a front top plate 2, a rear top plate 9, a shrinking steel rod 11, a piston grouting pump 15, a discharge plate 18 and two The dehydration unit arranged above is composed of the stroke bracket consisting of manipulator 6, guide rail 7, guide groove 8 and bracket 20. A pair of parallel guide grooves 8 are installed on the top surface of bracket 20. Guide rail 7 is arranged on the outside of guide groove 8. There is a manipulator 6, and the dehydration unit is composed of an outer ring body 3, an inner ring body 4, a limit chain 5 and a discharge plate 18. The inner ring body 4 and the outer ring body 3 are hollow, and one end of the inner ring body 4 is provided with a closed bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com