Multi-layer roll press belt sludge dewatering machine

A deep dehydration and sludge technology, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve secondary pollution management and operation technology, large amount of chemical method, high energy consumption and operating cost, etc. problems, to achieve the effect of shortening the sludge dewatering time, avoiding sludge splashing and improving dewatering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

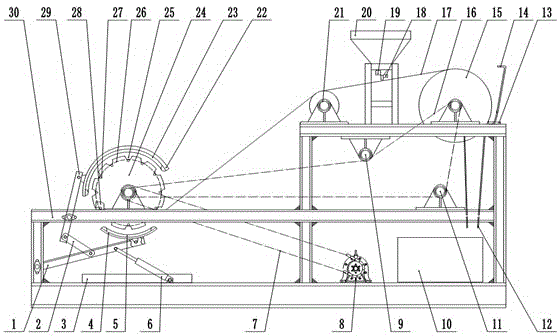

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] See the accompanying drawings, the multi-layer roll filter belt type sludge deep dewatering machine, the sludge deep dewatering machine is composed of the lower pressure tile rocker 1, the connecting rod 2, the filtrate collection tank 3, the lower pressure tile 4, the lower pressure tile Sealing strip 5, hydraulic cylinder 6, drive chain 7, gear motor 8, first redirection sprocket 9, mud cake collection tank 10, second redirection sprocket 11, discharge hopper 12, mud cake scraper 13, discharge Baffle plate 14, cleaning drum 15, transmission chain 16, filter belt 17, discharge control valve 18, vibrator 19, feed hopper 20, diverting roller 21, upper pressure tile 22, upper pressure tile sealing strip 23, It consists of a pressure-bearing drying drum 24, an axial groove 25, a radial groove 26, a limit contact 27, an angle limiter 28, an upper pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com