Solvent-free epoxy resin as plugging material, and preparation method and application of the solvent-free epoxy resin

A technology of epoxy resin and plugging material, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low consolidation strength, insufficient work, etc., to reduce energy consumption, reduce toxicity, shorten reaction time and The effect of dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Synthesis of organosilicon-modified epoxy compounds

[0057] Add 255.0g of benzyl glycidyl ether into a closed reactor, blow nitrogen into it, heat to 85°C, add dropwise the mixed solution prepared by 44.4g of hydroxy silicone oil and 0.6g of catalyst benzyltriethylammonium chloride under stirring , after the dropwise addition, the temperature was raised to 130° C. to continue the reaction for 4 hours, and cooled to obtain 300.0 g of organosilicon-modified epoxy compounds;

[0058] (2) Synthesis of Pluronic polyol polyether modified epoxy resin

[0059] Add 224.4g of epoxy resin E-51 into a closed reactor, blow nitrogen into it, heat to 80°C, add dropwise 75.0g of Pluronic polyol polyether L under stirring 35 With the mixed solution of 0.6g catalyst benzyltriethylammonium chloride preparation, be warming up to 120 ℃ and continue to react for 3 hours after dropwise addition, cooling, obtain 300.0g Pluronic polyol polyether modified epoxy resin;

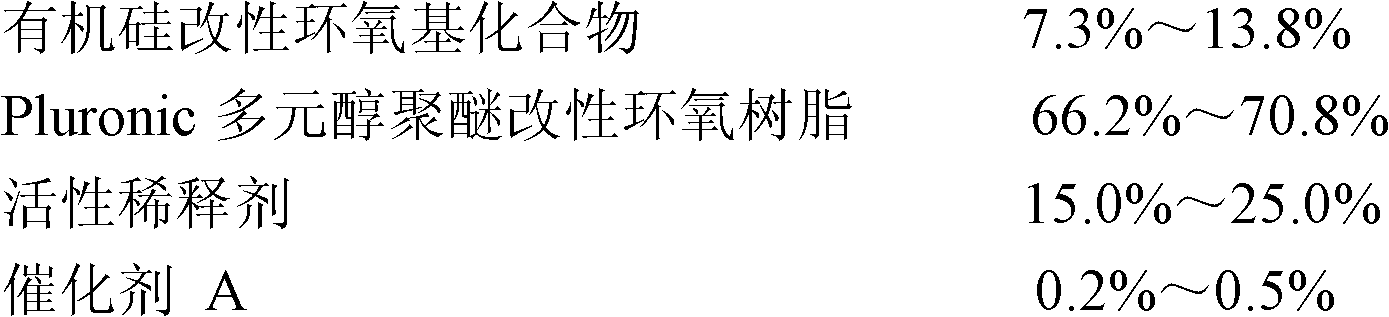

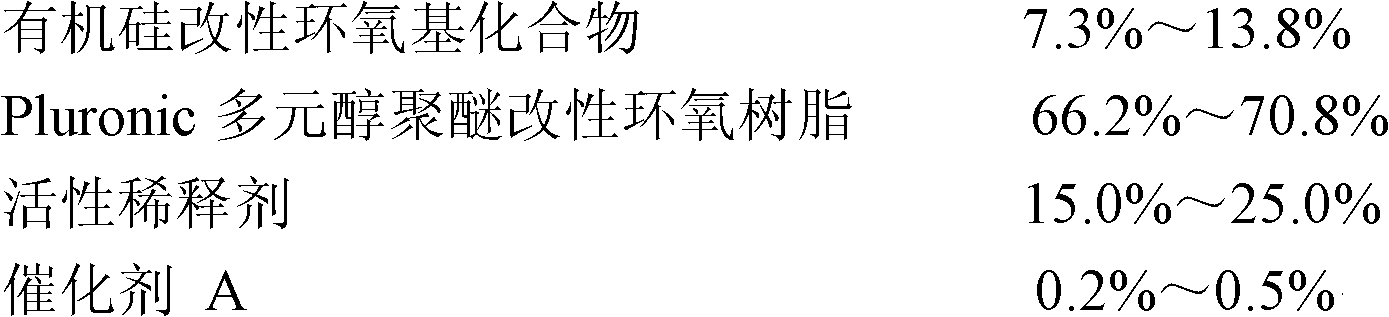

[0060] (3) Prepara...

Embodiment 2

[0067] (1) Synthesis of organosilicon-modified epoxy compounds

[0068] Add 264.0g of benzyl glycidyl ether into the closed reactor, blow in nitrogen gas, heat to 85°C, and add dropwise the mixed solution prepared by 35.4g of hydroxyl silicone oil and 0.6g of catalyst benzyltriethylammonium chloride under stirring , after the dropwise addition, the temperature was raised to 130° C. to continue the reaction for 4 hours, and cooled to obtain 300.0 g of organosilicon-modified epoxy compounds;

[0069] (2) Synthesis of Pluronic polyol polyether modified epoxy resin

[0070] Add 239.4g of epoxy resin E-51 into the closed reactor, blow in nitrogen, heat to 80°C, add dropwise 60.0g of Pluronic polyol polyether L under stirring 35 With the mixed solution of 0.6g catalyst benzyltriethylammonium chloride preparation, be warming up to 120 ℃ and continue to react for 3 hours after dropwise addition, cooling, obtain 300.0g Pluronic polyol polyether modified epoxy resin;

[0071] (3) Prep...

Embodiment 3

[0078] (1) Synthesis of organosilicon-modified epoxy compounds

[0079] Add 270.0g of benzyl glycidyl ether into a closed reactor, blow nitrogen into it, heat to 85°C, add dropwise the mixed solution prepared by 28.8g of hydroxyl silicone oil and 1.2g of catalyst benzyltriethylammonium chloride under stirring , after the dropwise addition, the temperature was raised to 130° C. to continue the reaction for 4 hours, and cooled to obtain 300.0 g of organosilicon-modified epoxy compounds;

[0080] (2) Synthesis of Pluronic polyol polyether modified epoxy resin

[0081] Add 254.1g of epoxy resin E-44 into the closed reactor, blow in nitrogen, heat to 80°C, add dropwise 45.0g of Pluronic polyol polyether L under stirring 44 With the mixed solution of 0.9g catalyst benzyltriethylammonium chloride preparation, be warming up to 120 ℃ and continue to react for 3 hours after dropwise addition, cooling, obtain 300.0g Pluronic polyol polyether modified epoxy resin;

[0082] (3) Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com