Transfer-electron type electroosmosis-advanced oxidation sludge dewatering system and dewatering method thereof

A technology of sludge dewatering and advanced oxidation, which is applied in the fields of oxidation treatment of sludge, electrochemical sludge treatment, chemical instruments and methods, etc., to achieve the effect of improving dehydration effect, increasing dehydration rate, and slowing down the degree of corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

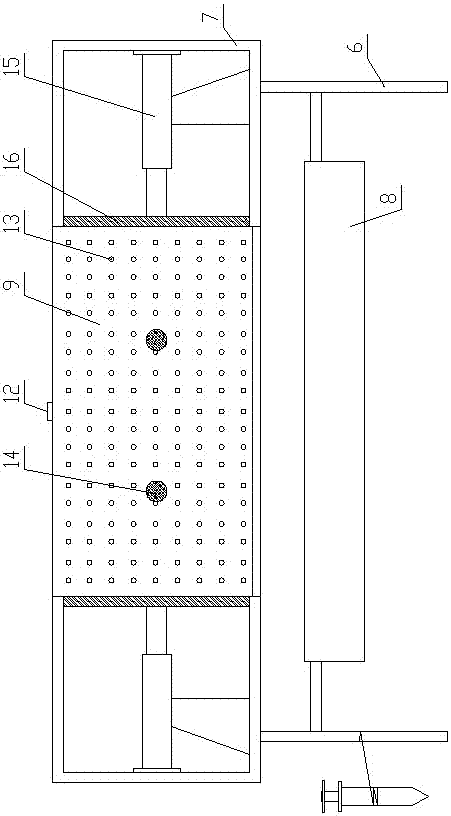

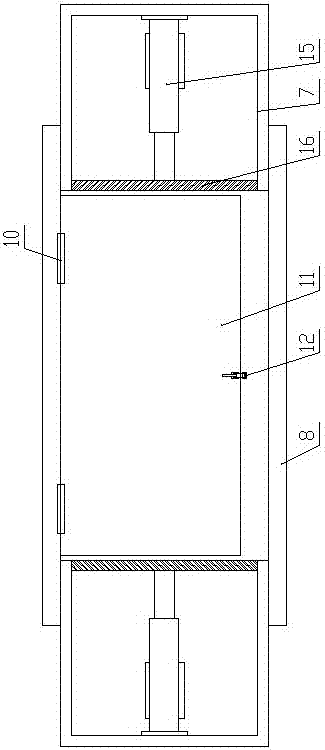

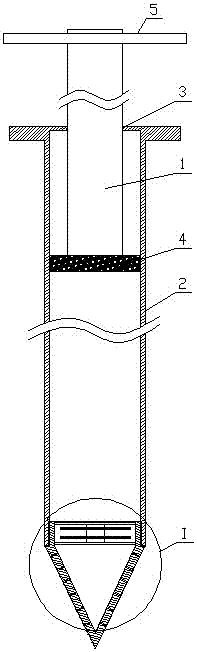

[0038] Such as Figure 1-5 As shown, the conversion electrode type electroosmotic advanced oxidation sludge dewatering system of the present invention includes a power supply, a positive and negative pole converter and a chassis 6 (the power supply and the positive and negative pole converters are existing conventional technologies, not shown in the figure), and the bottom An installation frame 7 is arranged above the frame 6, and an electroosmotic liquid collection bin 8 located below the installation frame 7 is installed on the bottom frame 6. An electroosmosis reactor 9 having a rectangular parallelepiped shape is installed on the installation frame 7. The line is connected with a dosing injection device 24, and the length direction of the electroosmosis reactor 9 is the left and right horizontal direction, and the width and length of the electroosmosis liquid collection chamber 8 are greater than the width and length of the electroosmosis reactor 9, and the electroosmosis r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com