Patents

Literature

53results about How to "Reduce dehydration energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane distillation dehydration method for polyatomic alcohol water solution produced from corn

InactiveCN101121639AReduce dehydration energy consumptionReduce lossesDistillationHydroxy compound separation/purificationDistillationLoss rate

The invention discloses a method for dehydrating polyol aqueous solution produced from corn, which belongs to the application technology of vacuum membrane distillation. The method adopts a membrane distillation device, first heats the polyol aqueous solution to a temperature of 61°C-65°C, and then uses a raw material pump to add the polyol aqueous solution into the hollow fiber membrane to form a vacuum environment of 0.085MPa-0.089MPa outside the membrane, thereby A vapor pressure difference is formed on both sides of the membrane. The water in the polyol aqueous solution inside the membrane enters the hollow fiber membrane through the membrane holes in the form of steam under the action of the vapor pressure difference, and then condenses into Water, collecting condensed water, so as to achieve dehydration and concentration of polyol aqueous solution produced from corn. The invention has the advantages of operating temperature below 65 DEG C, lower energy consumption compared with the existing common distillation method, high interception rate of polyalcohol by the membrane used, and low loss rate of polyalcohol.

Owner:TIANJIN UNIV

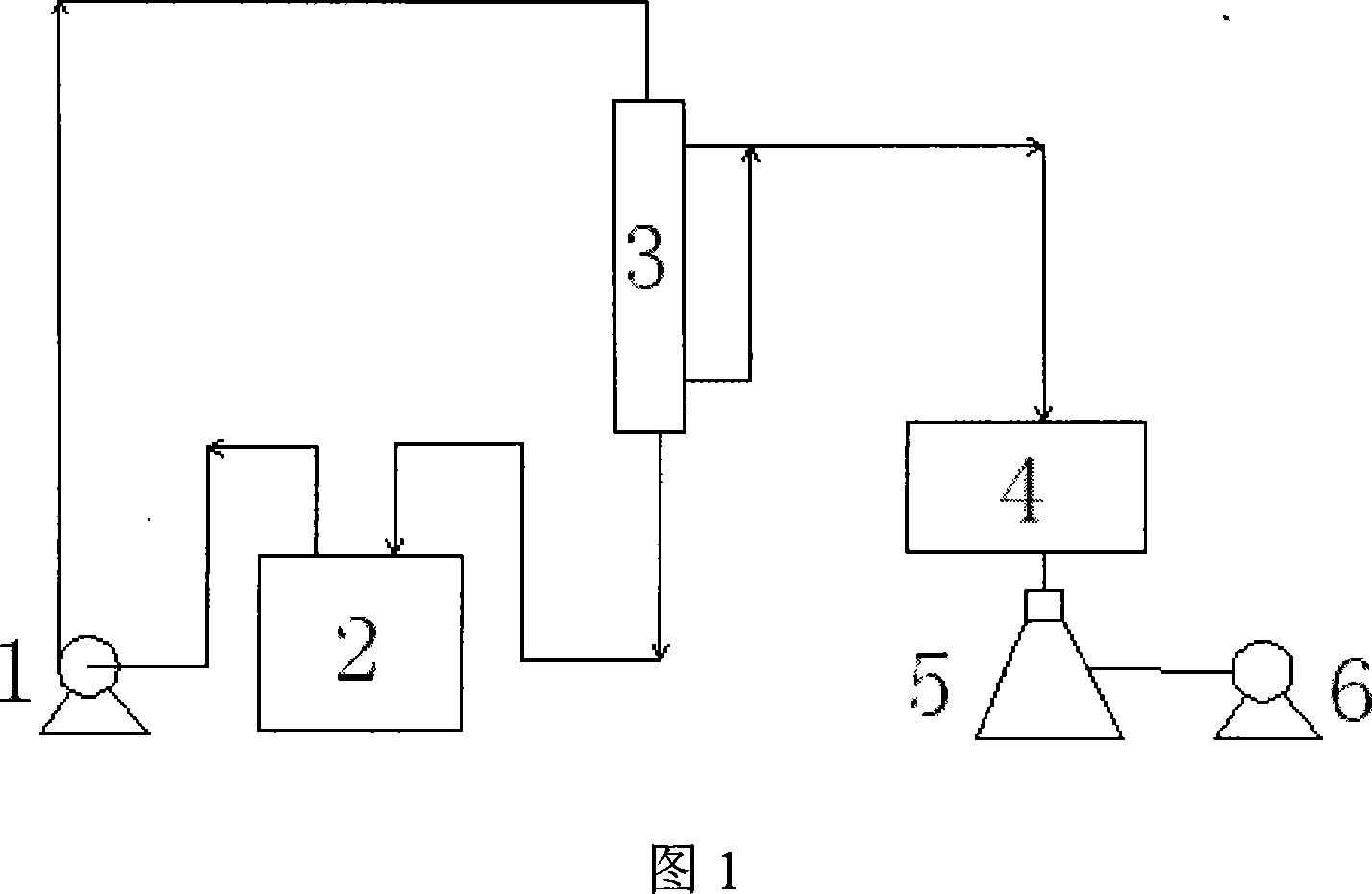

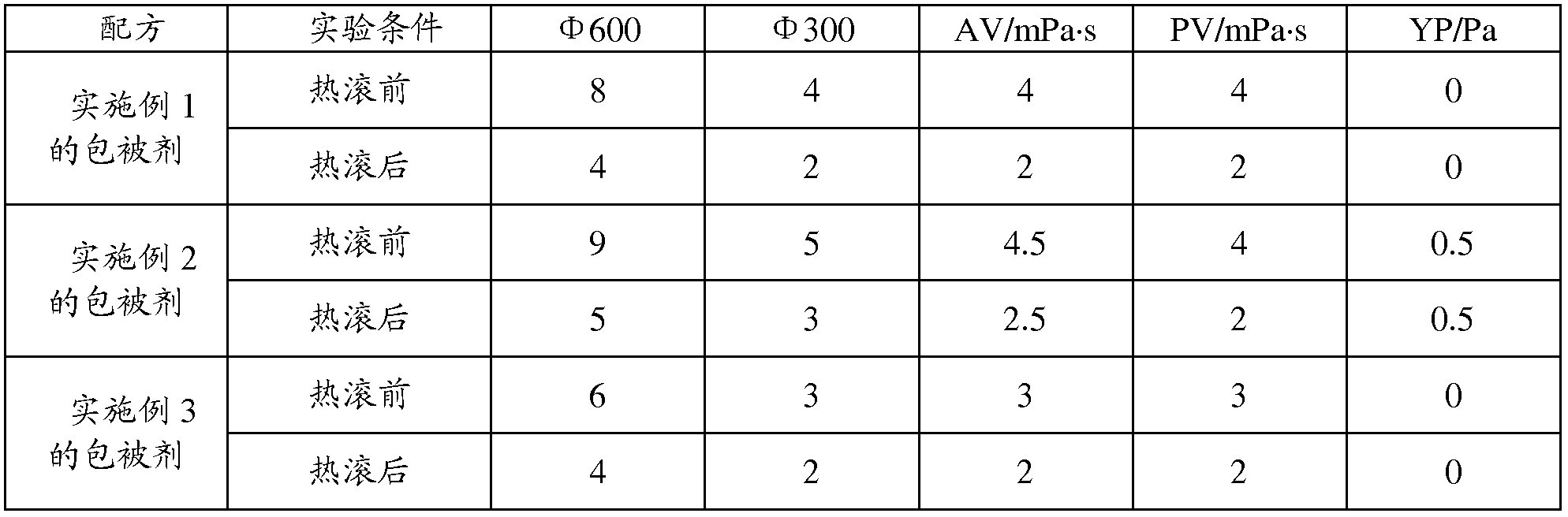

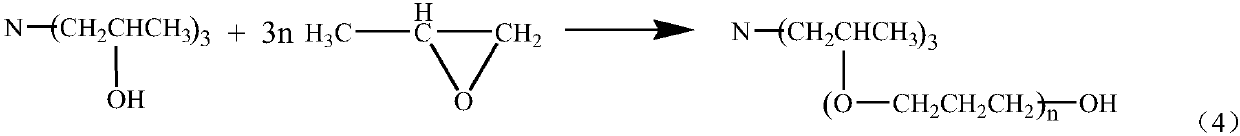

Cation coating agent for water-base drilling fluid and preparation method thereof

ActiveCN102796496ALess investmentReduce dehydration energy consumptionDrilling compositionWater basedCoating

The invention relates to a cation coating agent for water-base drilling fluid and a preparation method thereof, and an application of the cation coating agent in offshore deepwater water-base drilling fluid systems.

Owner:CHINA NAT OFFSHORE OIL CORP +1

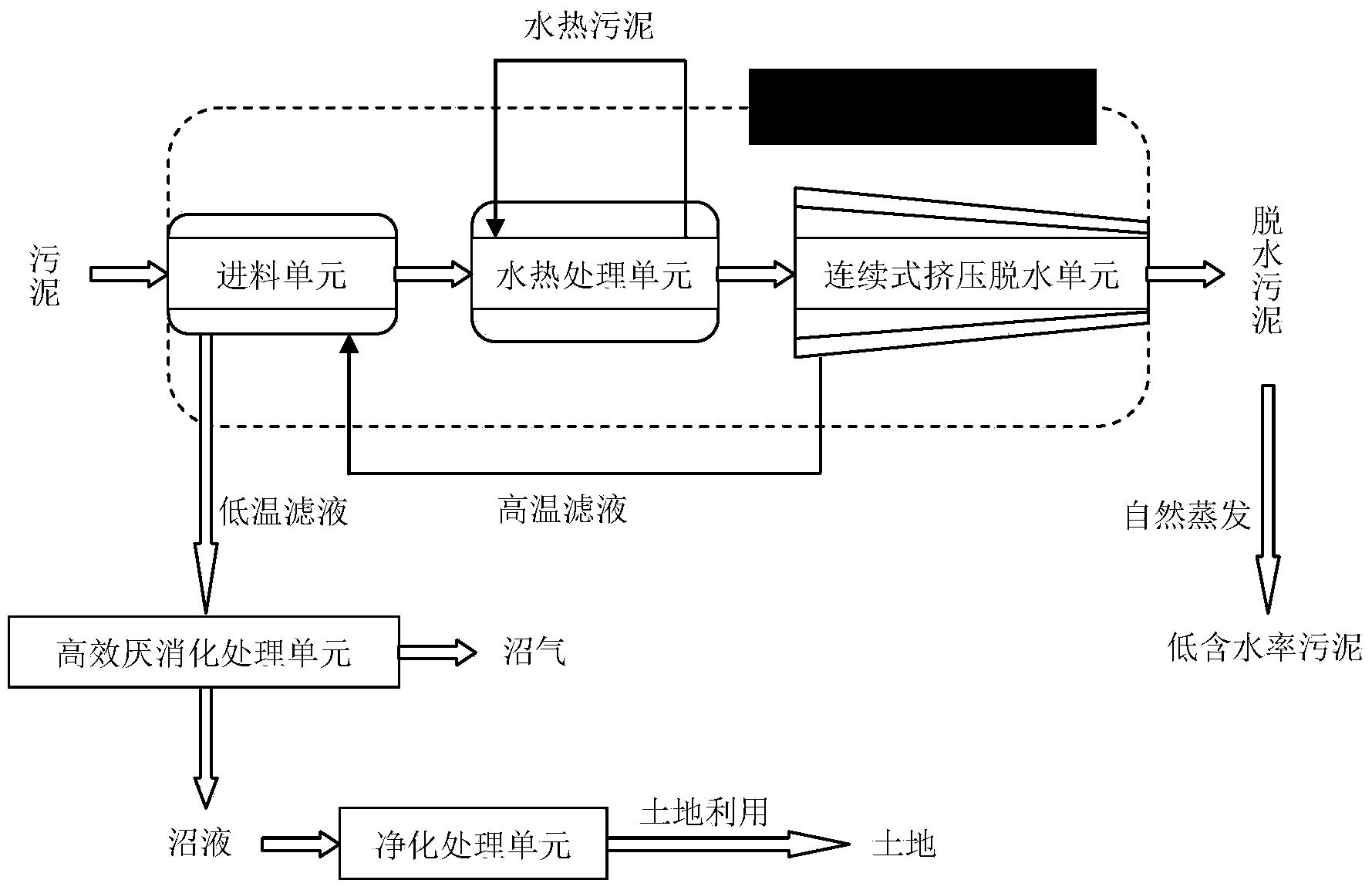

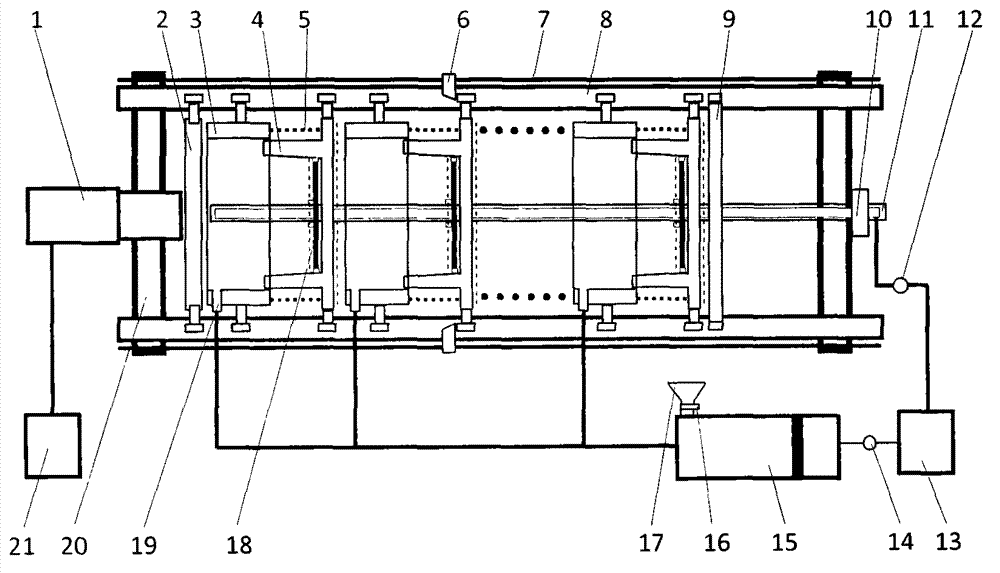

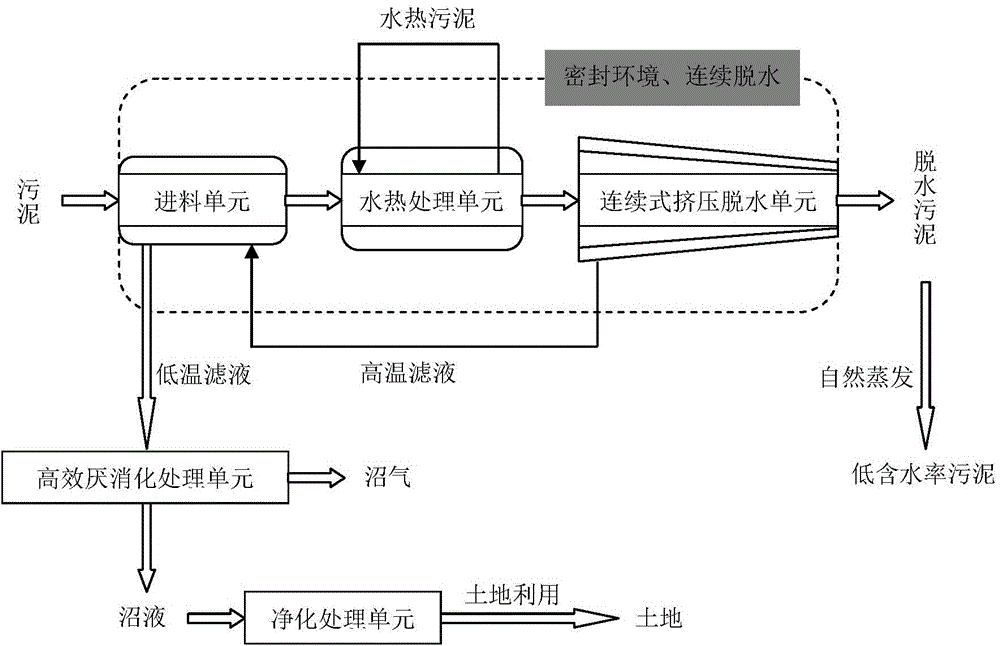

Continuous sludge dewatering method based on hydro-thermal treatment

ActiveCN103964662AAvoid heat consumptionHigh calorific valueSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal treatmentThermal reaction

The invention relates to a continuous sludge dewatering method based on hydro-thermal treatment, and belongs to the field of sludge treatment. An external heat exchanger of a feeding unit is filled with high temperature filtrate, sludge is continuously introduced in the feeding unit, and the high temperature filtrate is used for preheating the sludge; the sludge after preheating enters a hydro-thermal treatment unit under the pushing of the feeding unit, and is heated to above 150 DEG C for a hydro-thermal reaction through a heating device arranged on the outside of the hydro-thermal treatment unit; the standing time of the sludge inside the hydro-thermal treatment unit is controlled by an accelerator arranged at the interior of the hydro-thermal treatment unit; partial sludge after hydro-thermal treatment is flown back to the hydro-thermal treatment unit; the sludge passing through the hydro-thermal treatment unit is introduced in a continuous extrusion dewatering unit to realize continuous dewatering of the hydro-thermal sludge, and a cavity in the dewatering process is at a sealed state. According to the dewatering method, based on the hydro-thermal treatment for improving the sludge structure and physicochemical characteristics, the energy sources are fully utilized and recycled while the energy consumption input is saved, and the sludge dewatering in a liquid form is realized continuously.

Owner:DALIAN UNIV OF TECH

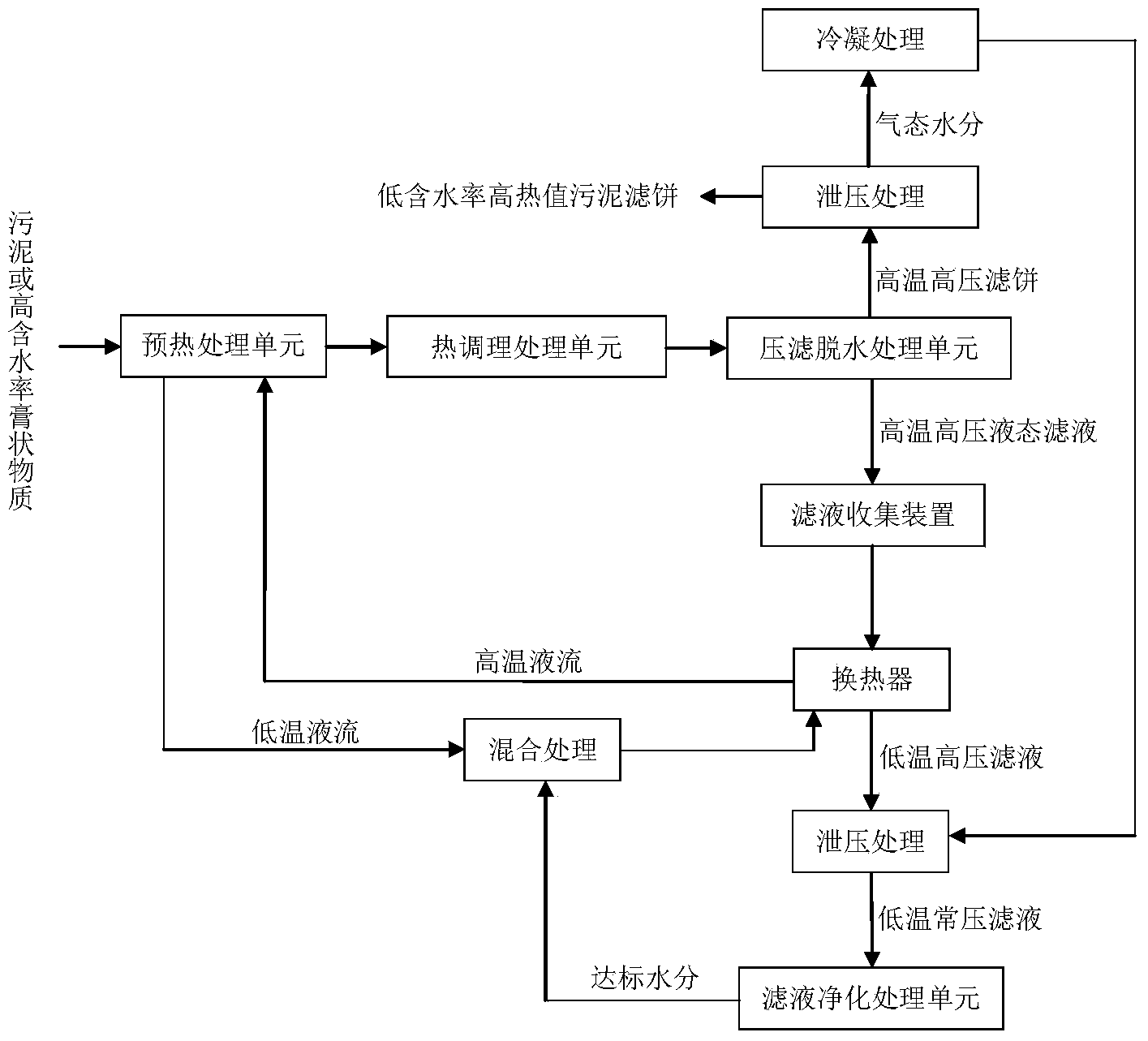

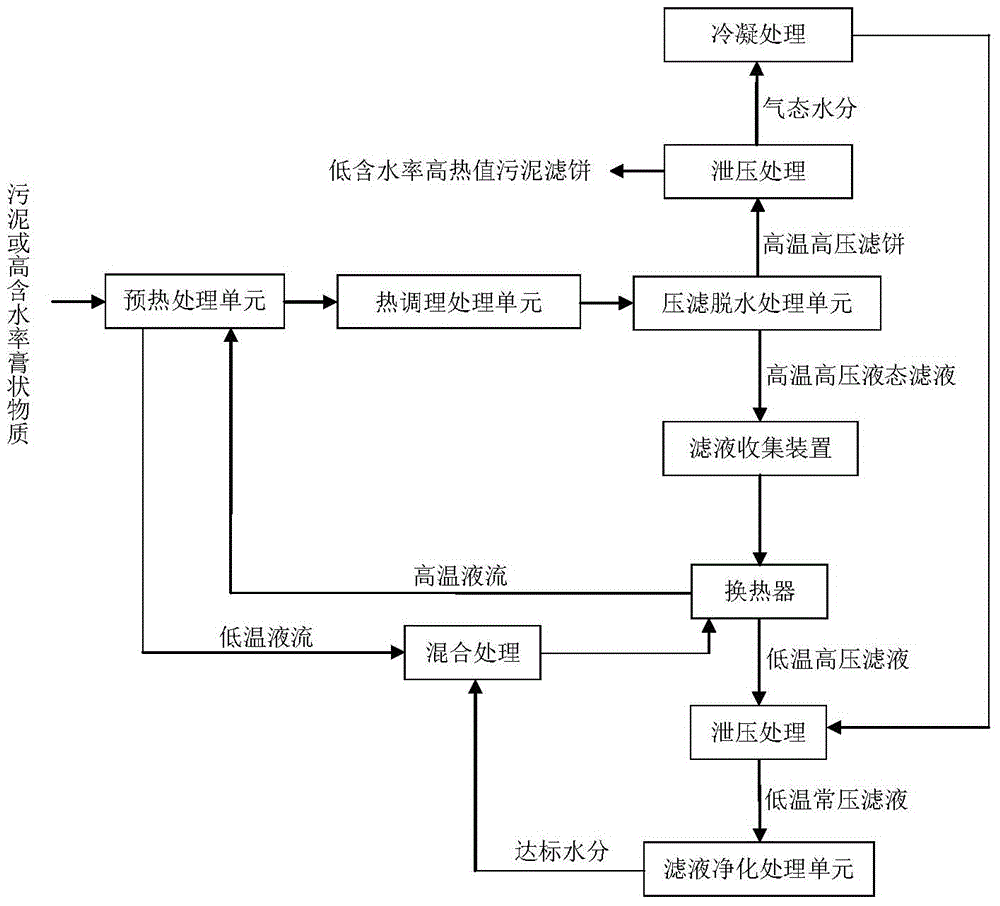

Sludge substance deep dehydrating method based on thermal conditioning coupling filter pressing

ActiveCN103508648ASimple structureImprove moisture distributionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisLiquid stateCoupling

The invention relates to a sludge substance deep dehydrating method based on thermal conditioning coupling filter pressing, belongs to the field of sludge treatment, is suitable for dehydration of various kinds of sludge, and particularly suitable for dehydration of surplus sludge. The method comprises the following steps: firstly carrying out heat exchange to a high temperature filtrate and the sludge, injecting the sludge with the raised temperature in a thermal conditioning processing unit, and performing a sufficient hydrothermal reaction at 120-250 DEG C; then immediately performing filter processing and dehydrating under the pressure to remove the moisture in a liquid state; at last, decompressing the high temperature sludge filter cake with pressure, further steaming and dehydrating with the sludge own high temperature and heat, so as to improve the dehydrating efficiency. The dehydrating method can improve sludge structure, physicochemical property and moisture distribution, save and fully utilize the heat, realize high-dryness and low-energy consumption dehydration of sludge, and improve the recycling value of the sludge.

Owner:DALIAN UNIV OF TECH

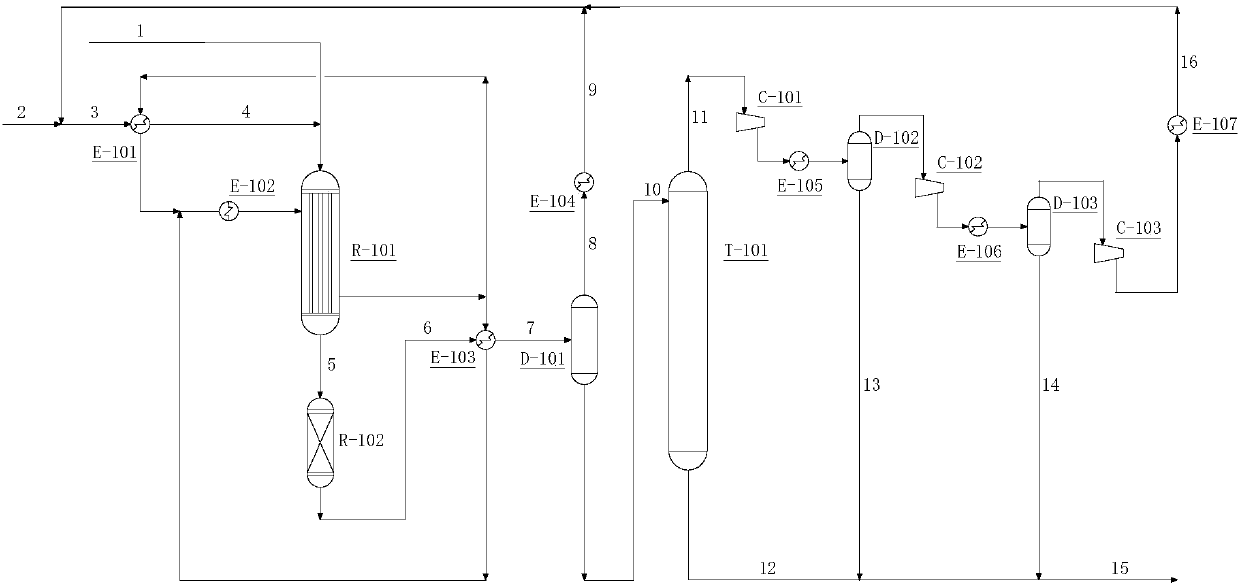

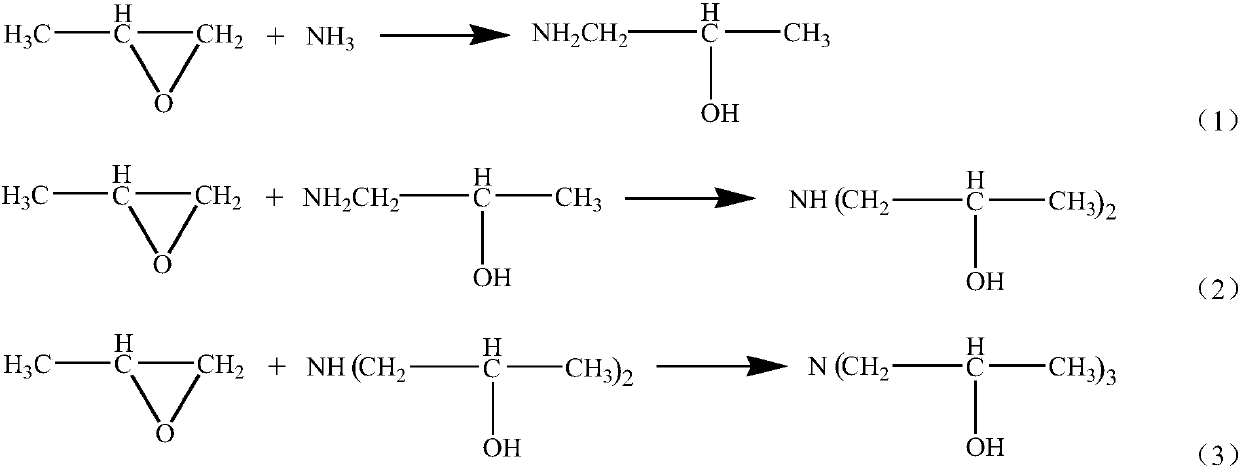

Method for producing isopropanolamine by liquid ammonia process

ActiveCN109748805AGuaranteed conversionReduce volumeOrganic compound preparationAmino-hyroxy compound preparationHigh energyTower

The invention relates to a method for producing isopropanolamine by a liquid ammonia process, mainly solving the problems such as high device investment, high energy consumption in dehydration and many by-products due to the fact that water is used as a catalyst in the prior art. The method has the advantages that anhydrous liquid ammonia and propylene oxide are used as raw materials for reaction,a tubular fixed bed reactor and an adiabatic fixed bed reactor are provided to ensure complete conversion of the propylene oxide, and the tubular fixed bed reactor removes heat of the hot water preheated reaction raw materials and reaction products under reduced pressure through heat removal of circulating hot water, so that most of reaction heat can be recycled; most of ammonia of the reaction products is recycled through a flash tank, and residual ammonia is recycled by an ammonia stripping tower with an compressor at the top; few by-products are generated, equipment investment and device energy consumption can be reduced, and the method can be applied to industrial production of the isopropanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

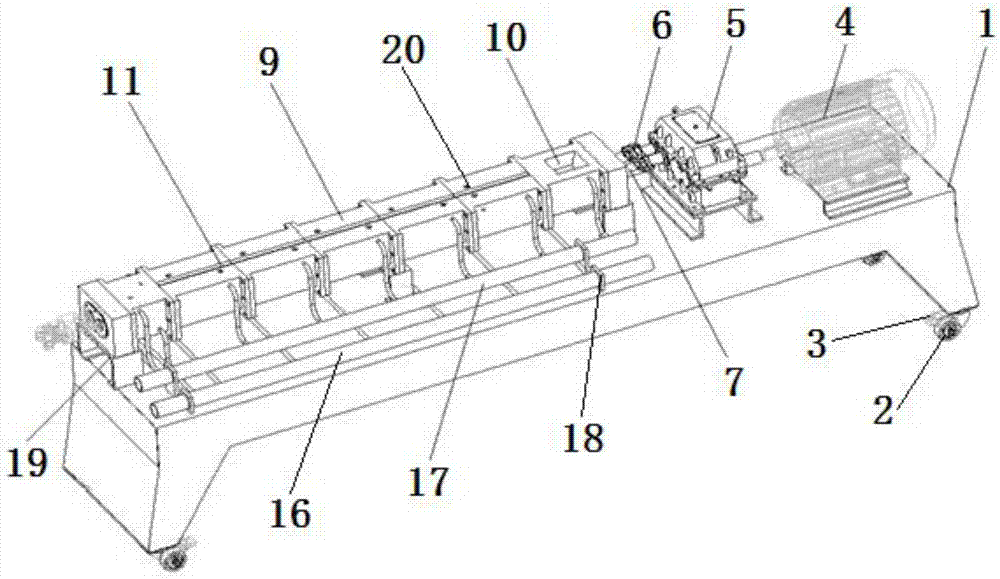

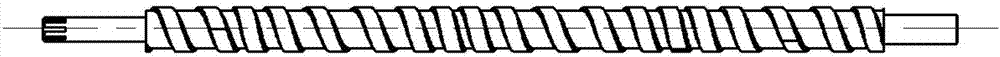

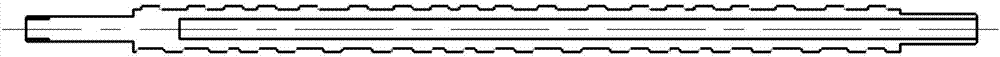

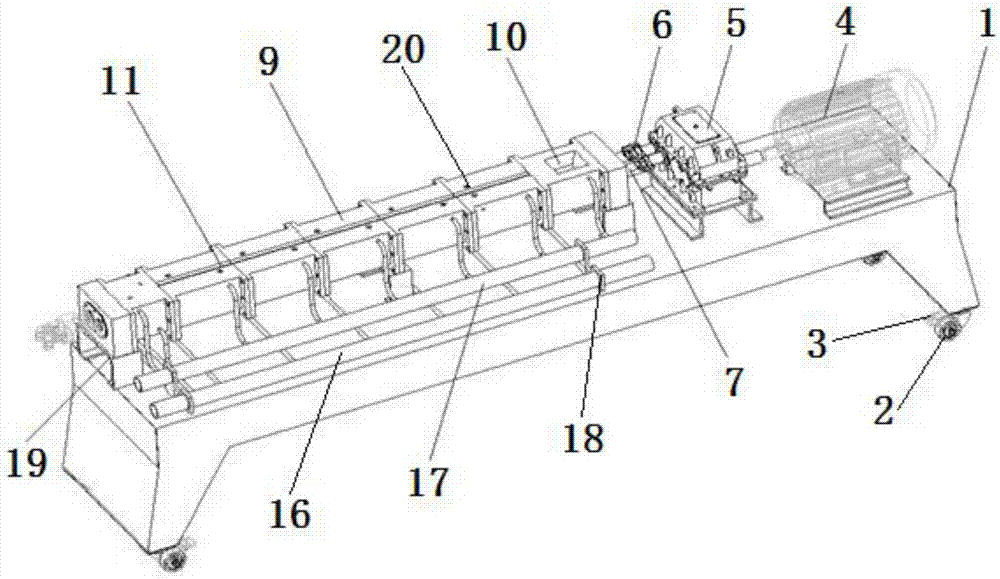

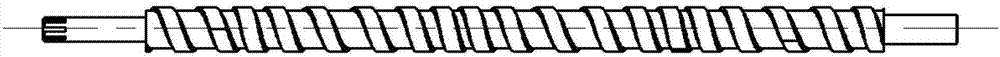

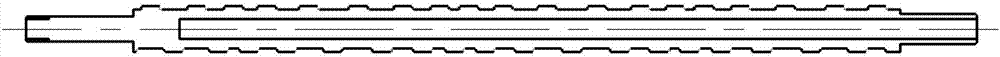

Emulsion mixture dual-screw water removal device

The invention belongs to the technical field of rubber after-processing auxiliary equipment, and particularly relates to an emulsion mixture dual-screw water removal device. A main structure comprises a base, universal wheels, a foot brake piece, a motor, a reducer casing, a coupler, a dual-screw assembly, a core shaft, a machine barrel, a feeding opening, a rotary air leakage roller, a scraping knife, a draining hole, a filter net, a steam hole, a first steam supply pipe, a second steam supply pipe, a support, a discharging hole and an exhaust hole; an emulsion mixture is subject to extrusion water removal to the maximum degree, water in the emulsion mixture is removed to the maximum degree, water can be effectively extruded, the losing of the emulsion mixture performance caused by continuous and excessive extrusion of the emulsion mixture can be avoided, different draw ratios are arranged according to the different water removal requirements, extrusion water removal of the emulsion mixture to the maximum degree can be achieved, the water removal rate of the emulsion mixture can be improved, the product yield is improved, and the device is simple in structure, energy-saving, environment-friendly, friendly in use environment and easy to use and popularize.

Owner:QINGDAO UNIV OF SCI & TECH

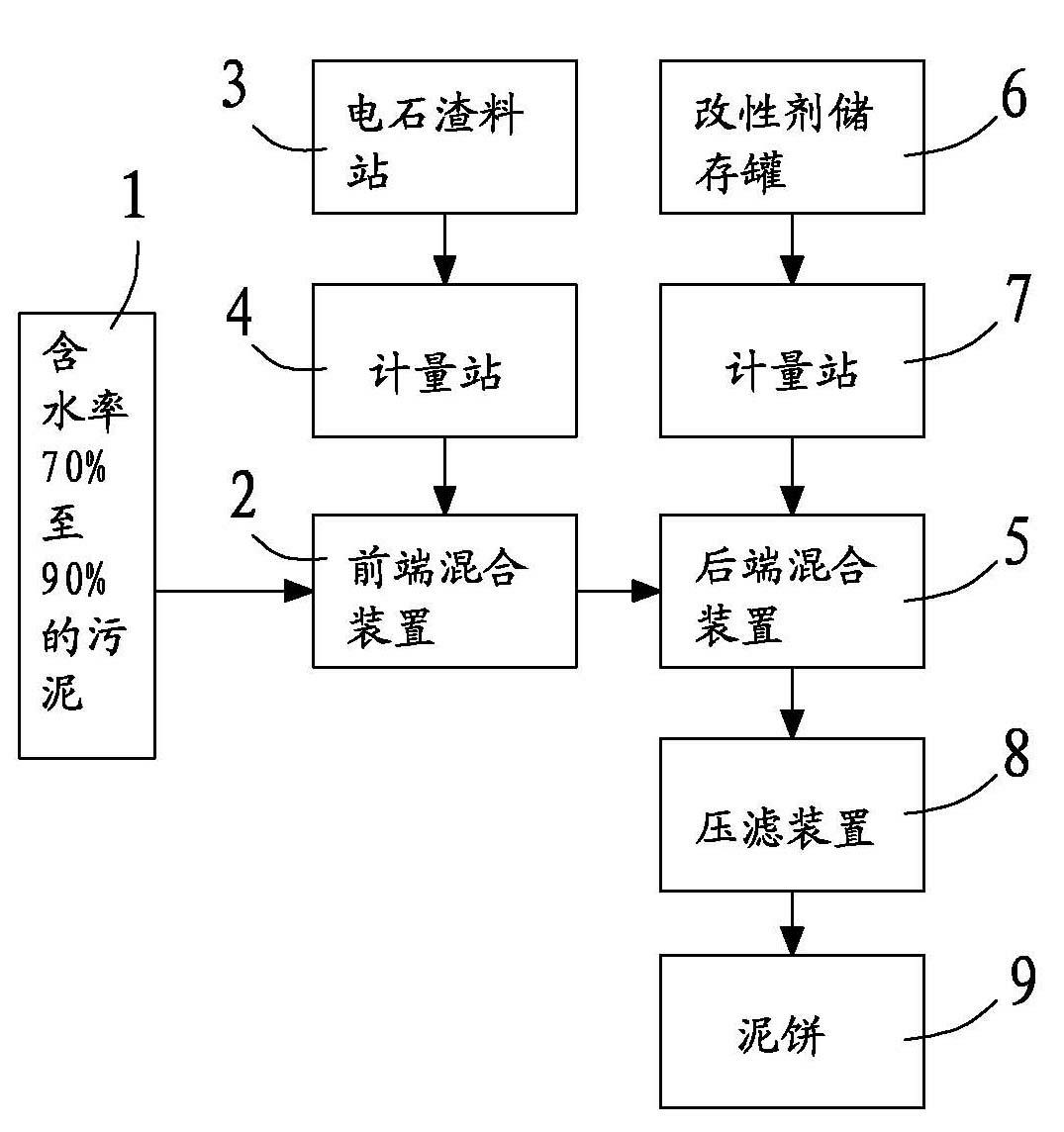

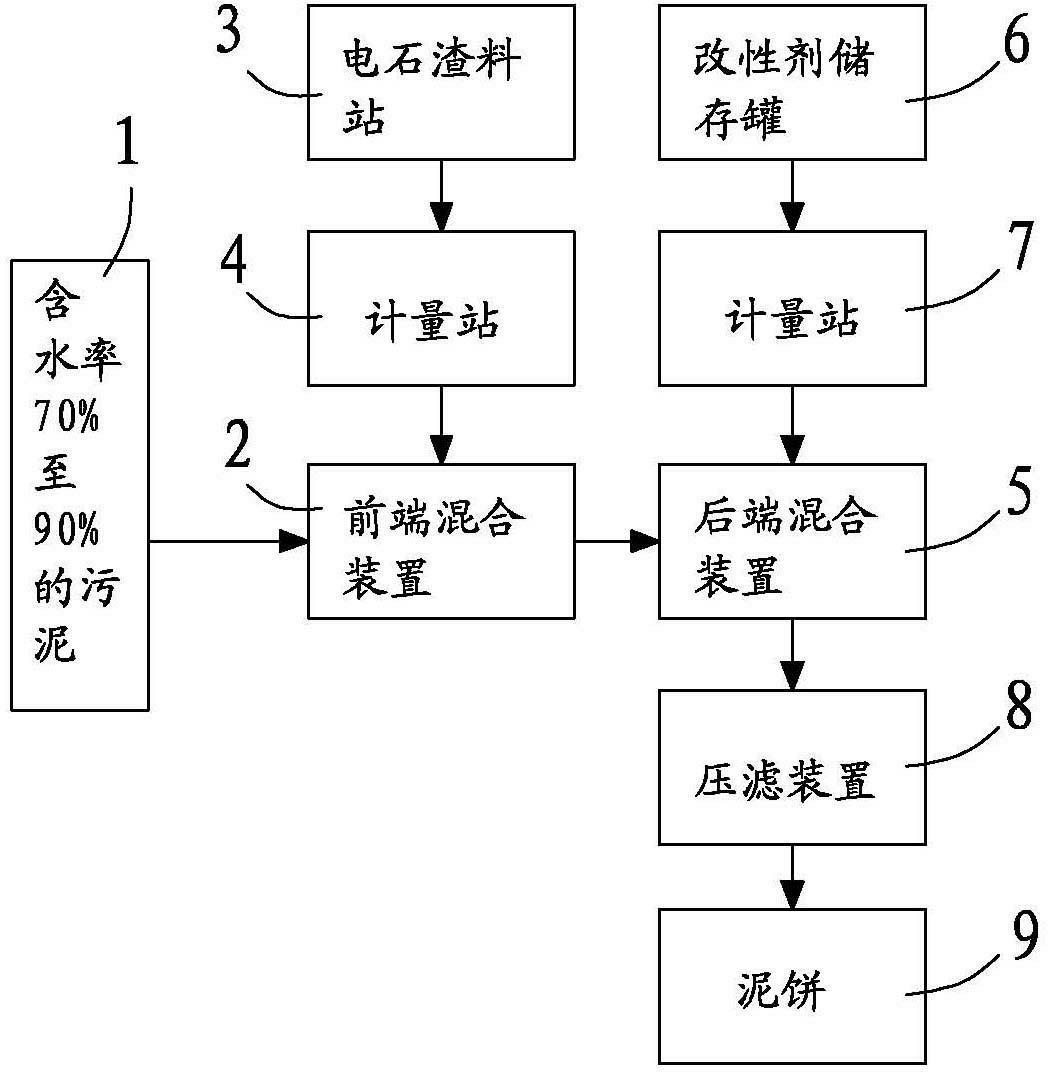

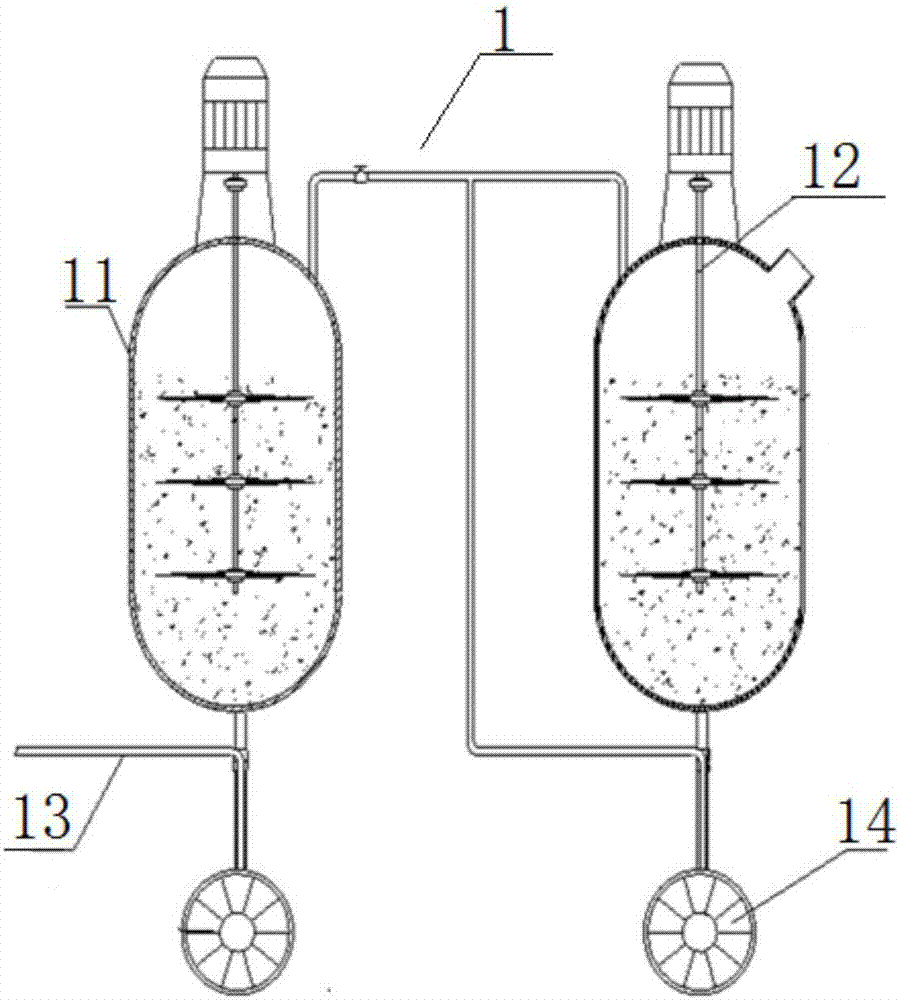

Method for pretreating and strengthening sludge dehydration by using acetylene sludge

ActiveCN102432152AFacilitate final disposalEfficient use ofSludge treatment by de-watering/drying/thickeningFilter pressPre treatment

The invention discloses a method for pretreating and strengthening sludge dehydration by using acetylene sludge. The method comprises adding a modifier and extruded sludge into sludge, wherein acetylene sludge is added before the modifier is added. The method comprises the following steps of: a, doping sludge of which the water content is higher than 70 percent into acetylene sludge, and stirringand mixing uniformly to obtain mixed sludge, wherein the doping amount of the acetylene sludge is 1-50 percent by volume based on the total amount of the sludge; b, continually adding a modifier in an amount which is 0.5-2 percent by volume based on the total amount of the sludge, and stirring to obtain sludge into which the modifier is added; and c, feeding the sludge into which the modifier is added into a plate-and-frame type filter press for extruding to obtain a dehydrated mud cake. In the method, the acetylene sludge is used together with a general modifier, so that the dehydration rateof mechanical filter pressing is increased, the amount and volume of sludge are reduced, and the dehydration energy consumption is lowered greatly simultaneously. In the method, useful components in acetylene sludge are fully utilized, the aims of changing waste into valuable and protecting the environment are fulfilled, and positive technical progress and remarkable economic effect are achieved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

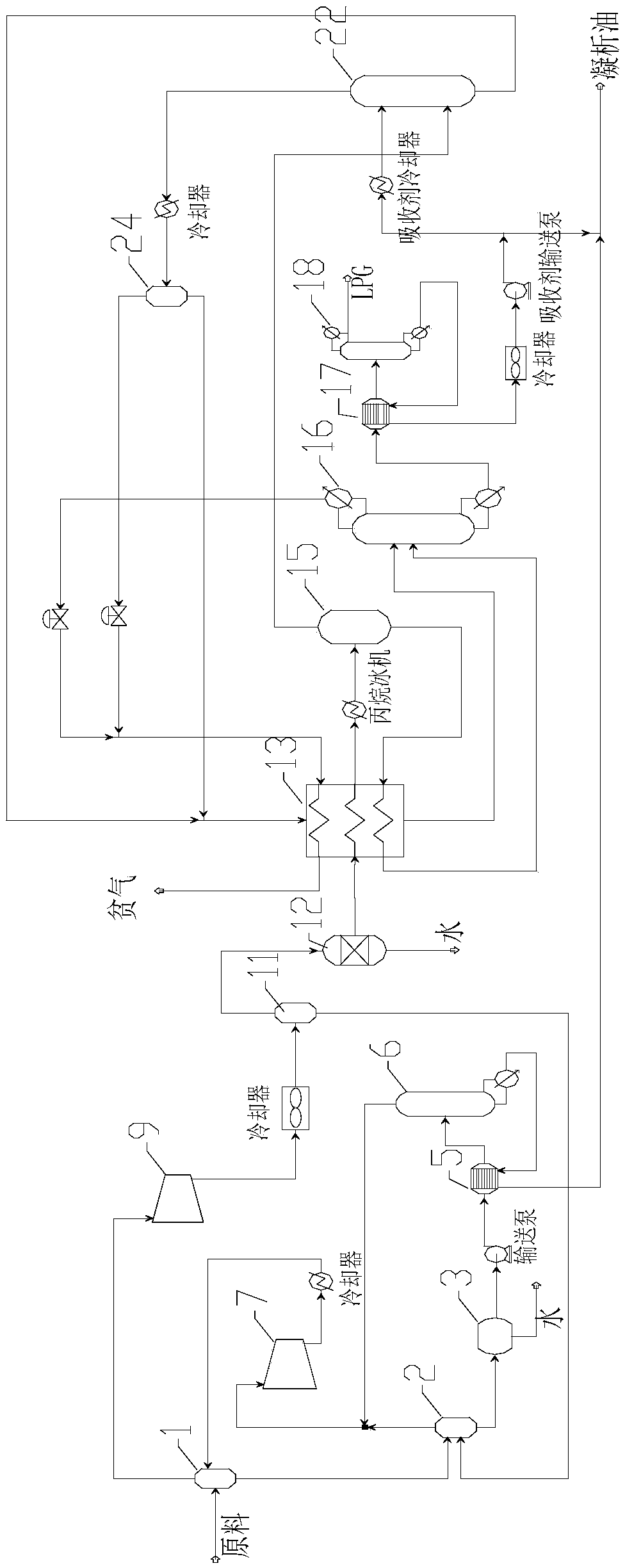

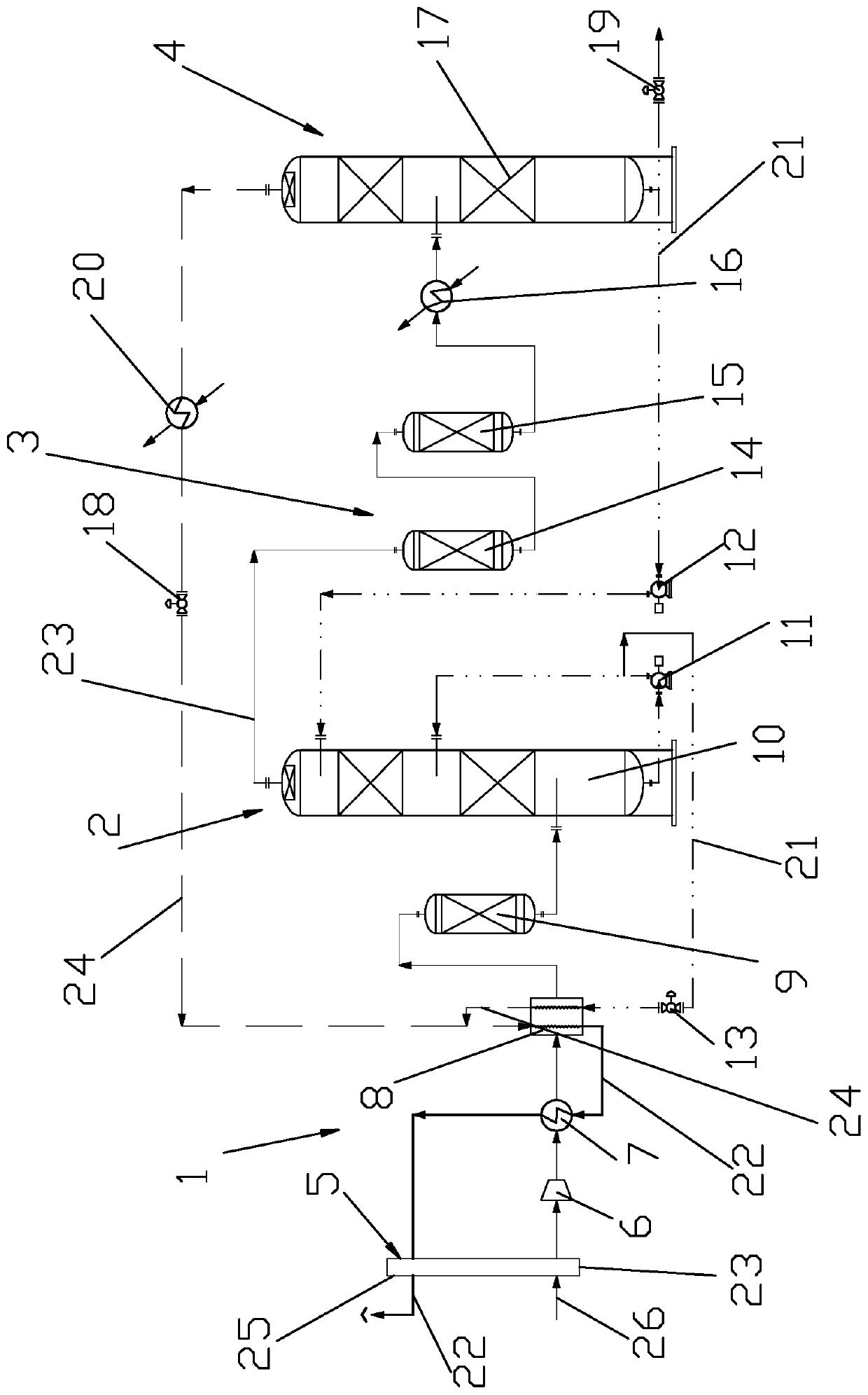

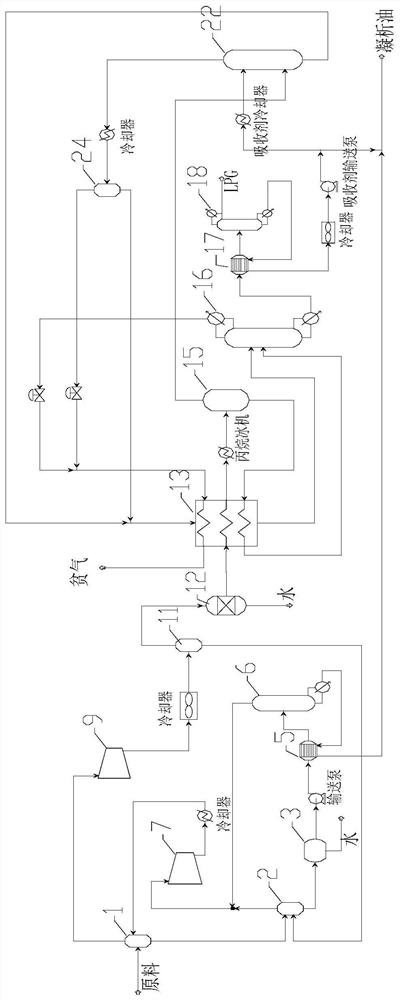

Recovery method of associated gas of oilfield

ActiveCN108641769AHigh yieldReduce dehydration energy consumptionSolidificationLiquefactionRecovery methodGas phase

The invention provides a recovery method of associated gas of an oilfield. A gas phase of a raw material subjected to primary gas-liquid separation is subjected to secondary gas-liquid separation anddewatering after being compressed and cooled, a liquid phase subjected to primary gas-liquid separation is subjected to flash evaporation, dewatering and steam stripping, and a gas phase obtained through steam stripping and a gas phase obtained after flash evaporation enter a dewatering link after two times of compression cooling; the gas phase subjected to dewatering drying is cooled and then subjected to low-temperature gas-liquid separation, a liquid phase subjected to low-temperature separation is heated and then subjected to ethane removal, the liquid phase with ethane removed is heated for butane removal, a liquid-phase LPG product is obtained, part of liquid-phase condensate oil with butane removed is cooled to serve as an absorbent and then subjected to multi-stage mass transfer and heat transfer with a gas phase subjected to low-temperature separation in the liquefaction step, the gas phase obtained after mass transfer and heat transfer serves as lean gas to be recovered afterbeing subjected to cooling, low-temperature separation, pressure reduction and cold recovery. High-value LPG products in the associated gas of the oilfield can be recovered, and the production cost is greatly reduced with an efficient and economical technique.

Owner:CHINA TIANCHEN ENG

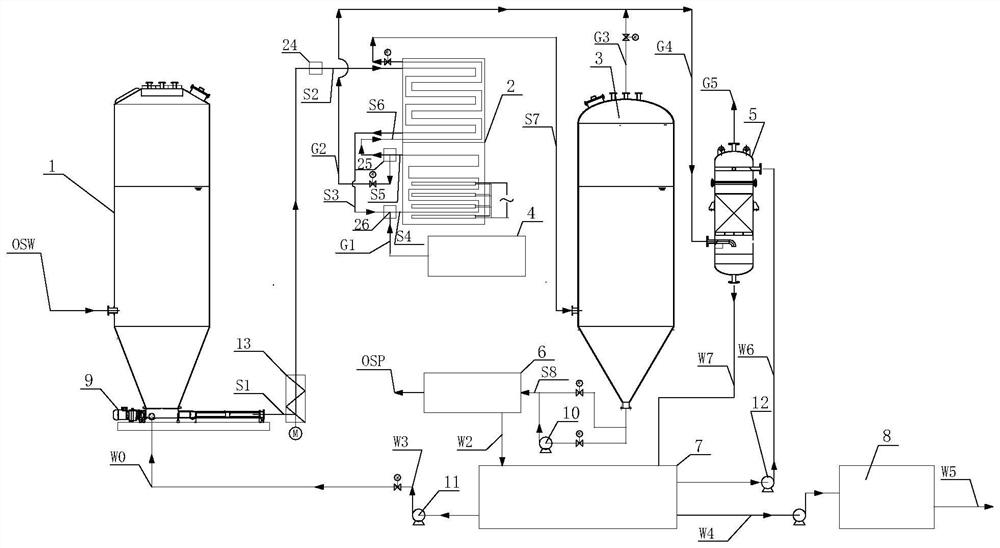

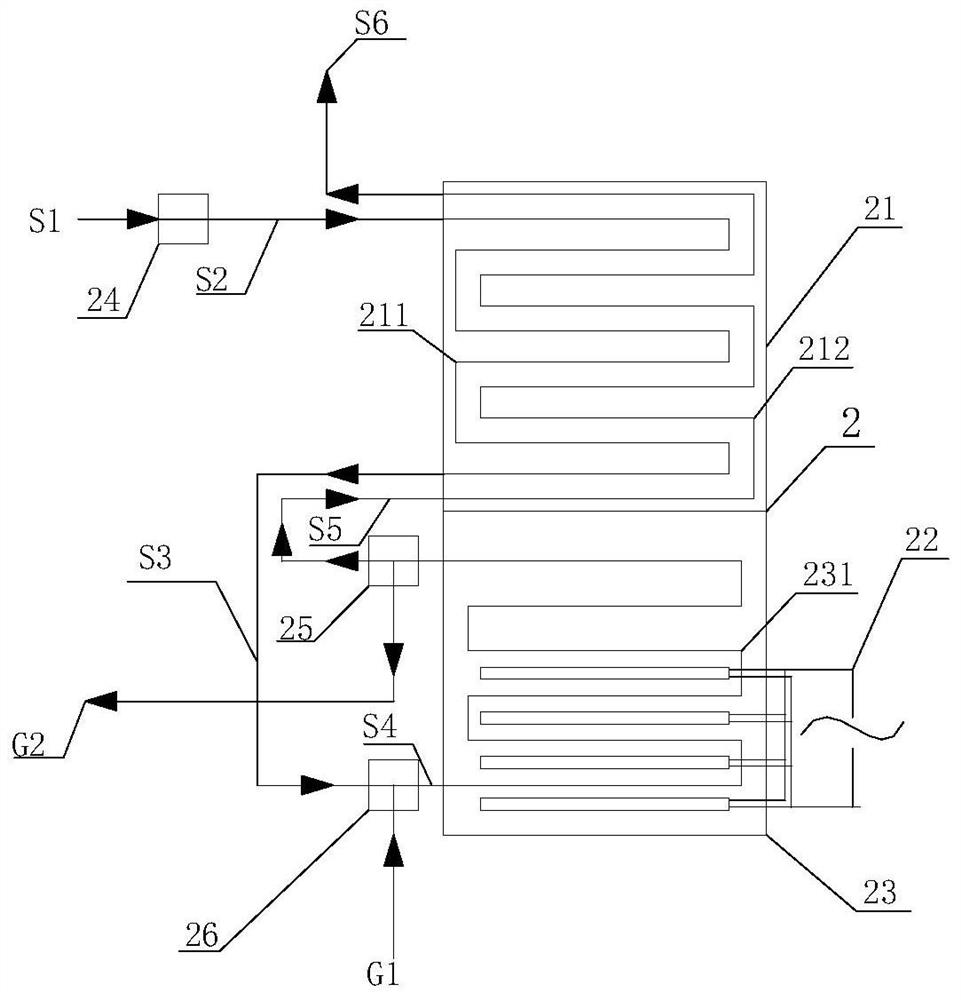

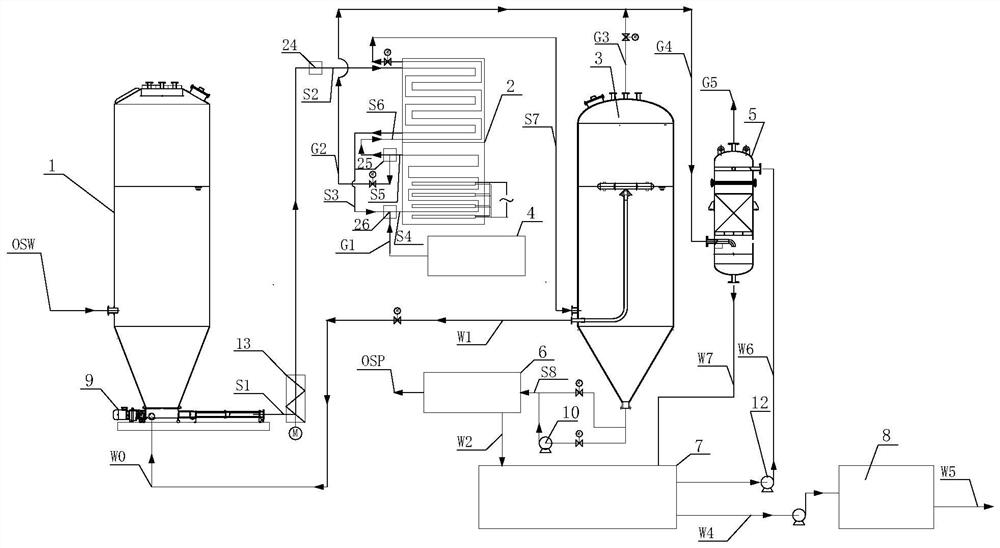

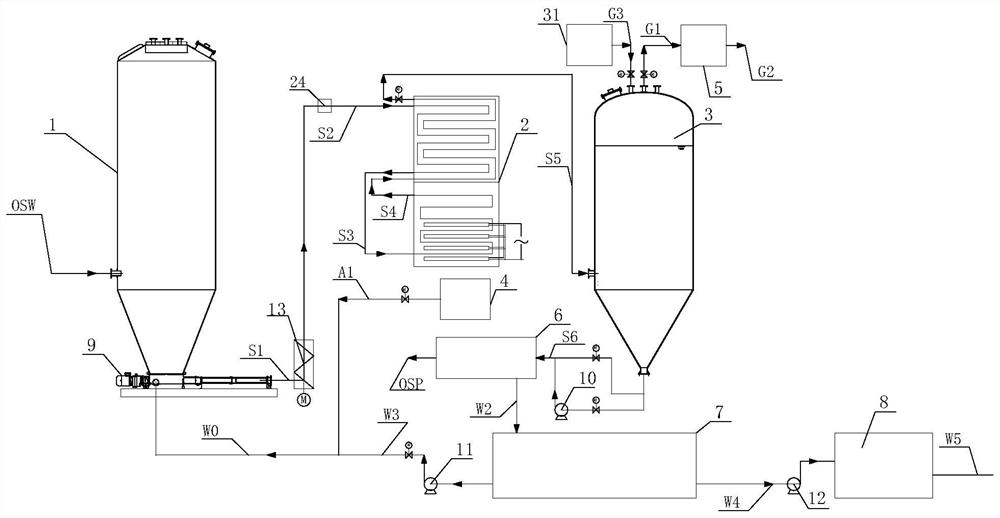

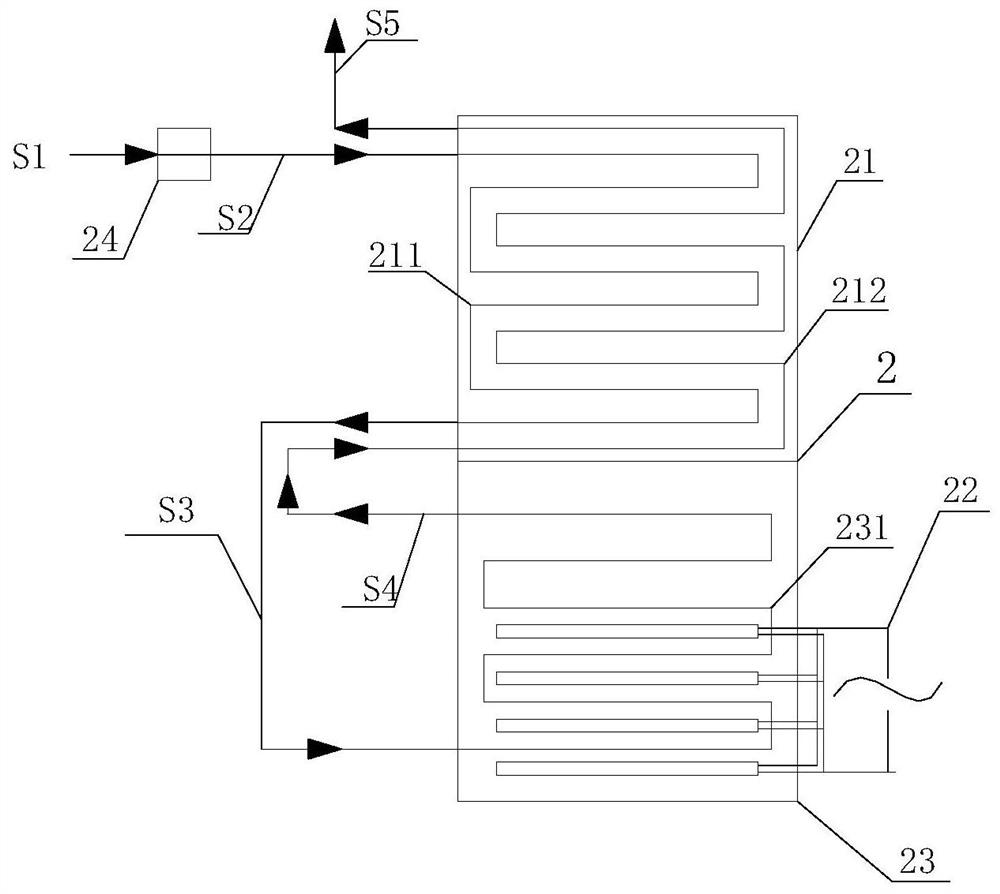

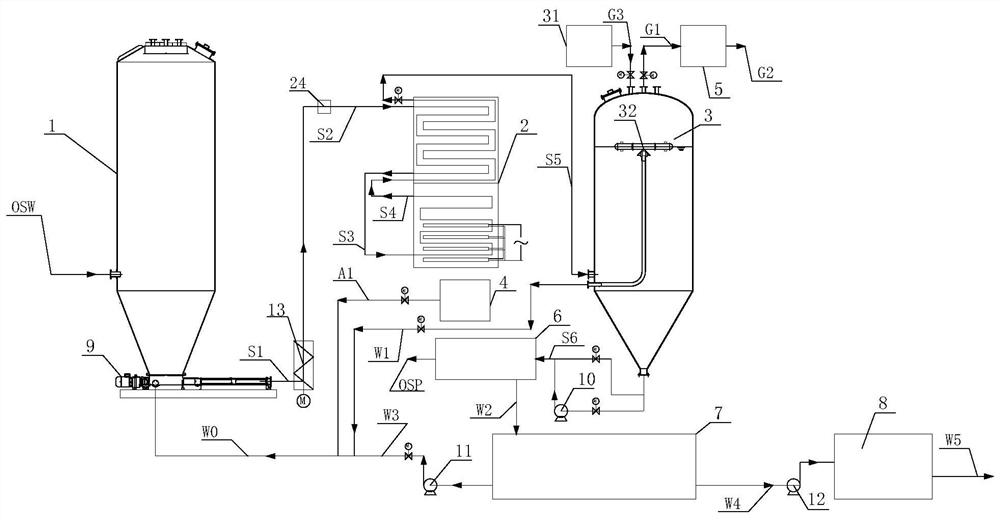

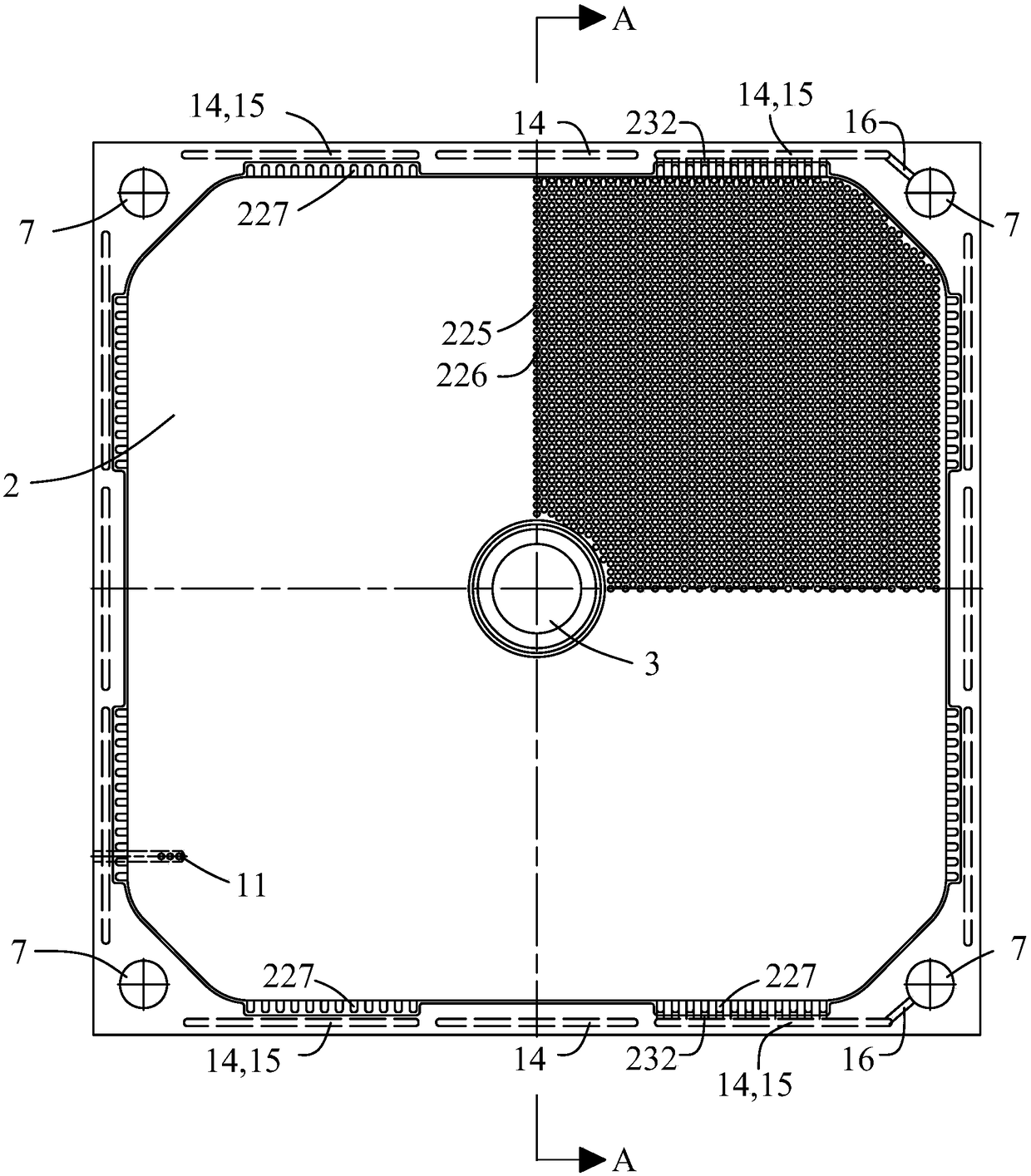

Organic solid waste wet oxidation treatment system and treatment process thereof

ActiveCN113511788ASave conditioning energyWell mixedSludge treatment by oxidationSludge processingSludgeProcess engineering

The invention discloses an organic solid waste wet oxidation treatment system and a treatment process thereof. The organic solid waste wet oxidation treatment system comprises a sludge storage tank, a pipeline type self-heat-exchange and reaction integrated assembly, a reaction sludge pressure storage tank, a mechanical dehydration unit, a sewage tank, a sludge pump and a water injection pump; sludge and process injected water can be mixed through the sludge pump, so that a conditioning tank for conditioning in a traditional process is omitted; the pressure drop can be regulated and controlled through mud-mud heat exchange and wet oxidation reaction of the pipeline type self-heat-exchange and reaction assembly and by controlling the proportion of reaction gas reserved in the pipeline type self-heat-exchange and reaction assembly; by adopting the reaction mud pressure storage tank to store pressure energy of a part of reaction mud and primarily settle the reaction mud, the adjusting range of the adjusting valve can be reduced, the service life of the valve is prolonged, and the pressure energy can be used for dehydrating the reaction mud and reinjecting and tempering supernate, so that most of heat in the technological process is fully recycled, and the technological energy consumption is greatly reduced; and the product can be recycled, and remarkable environmental protection and economic benefits are obtained.

Owner:清元协同环境(苏州)有限公司

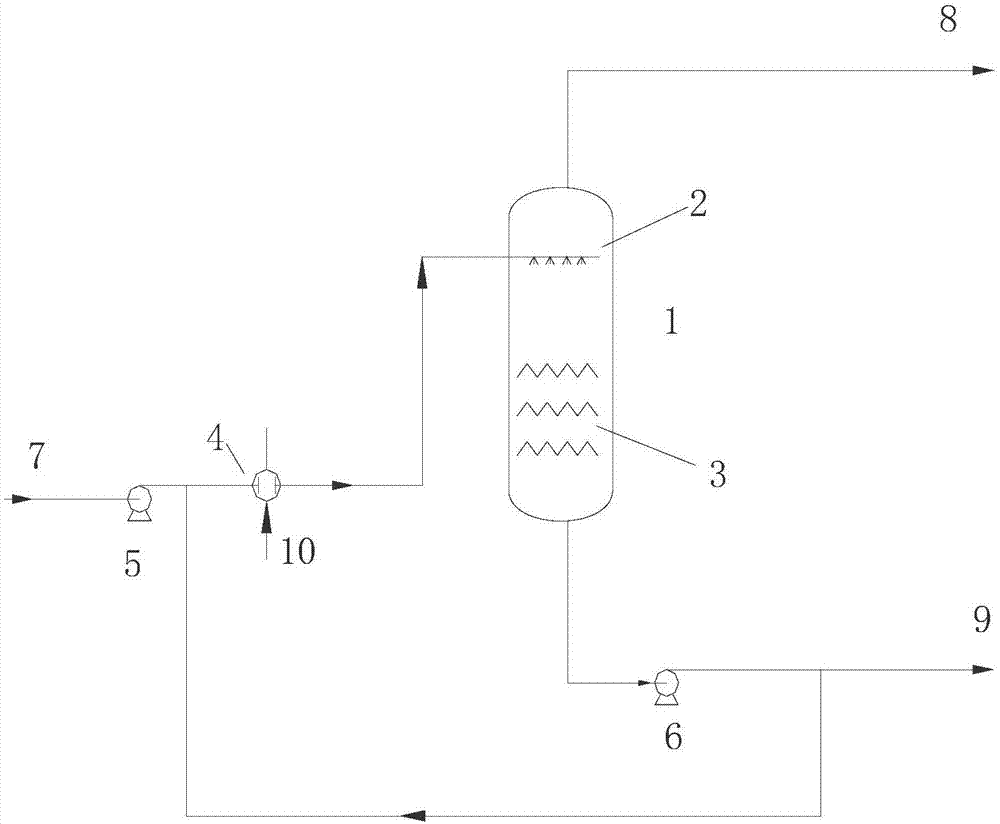

Energy-saving sump oil dehydration device and treatment method thereof

ActiveCN107880930AAchieve deep dehydrationLess waterTreatment with plural serial refining stagesEvaporationOil water

The invention provides an energy-saving sump oil dehydration device and a treatment method thereof. The energy-saving sump oil dehydration device comprises a sump oil dehydration tower, a sump oil atomizer, a Venturi rod layer, a circulating heater, a pump for sump oil to be dehydrated and a circulating sump oil pump. A circulating heating and atomizing technologies are used; low-temperature afterheat of an oil refining device is fully utilized; heated sump oil is atomized into fine fogdrop, so that the oil-water boundary tension is reduced; the oil-water evaporation area is increased; the deep dehydration of the sump oil is realized. The energy-saving sump oil dehydration device has the advantages that the flow process is simple; the operation is simple and convenient; the energy consumption is low; the dehydration effect is good; the applicability is wide. The energy-saving sump oil dehydration device can be used for light sump oil dehydration, can also be used for heavy sump oil dehydration and is particularly applicable to deep dehydration of seriously emulsified sump oil; the water content in the sump oil can be lowered to 2 percent or less; the requirement of sump oil refining on the water content is met.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD +1

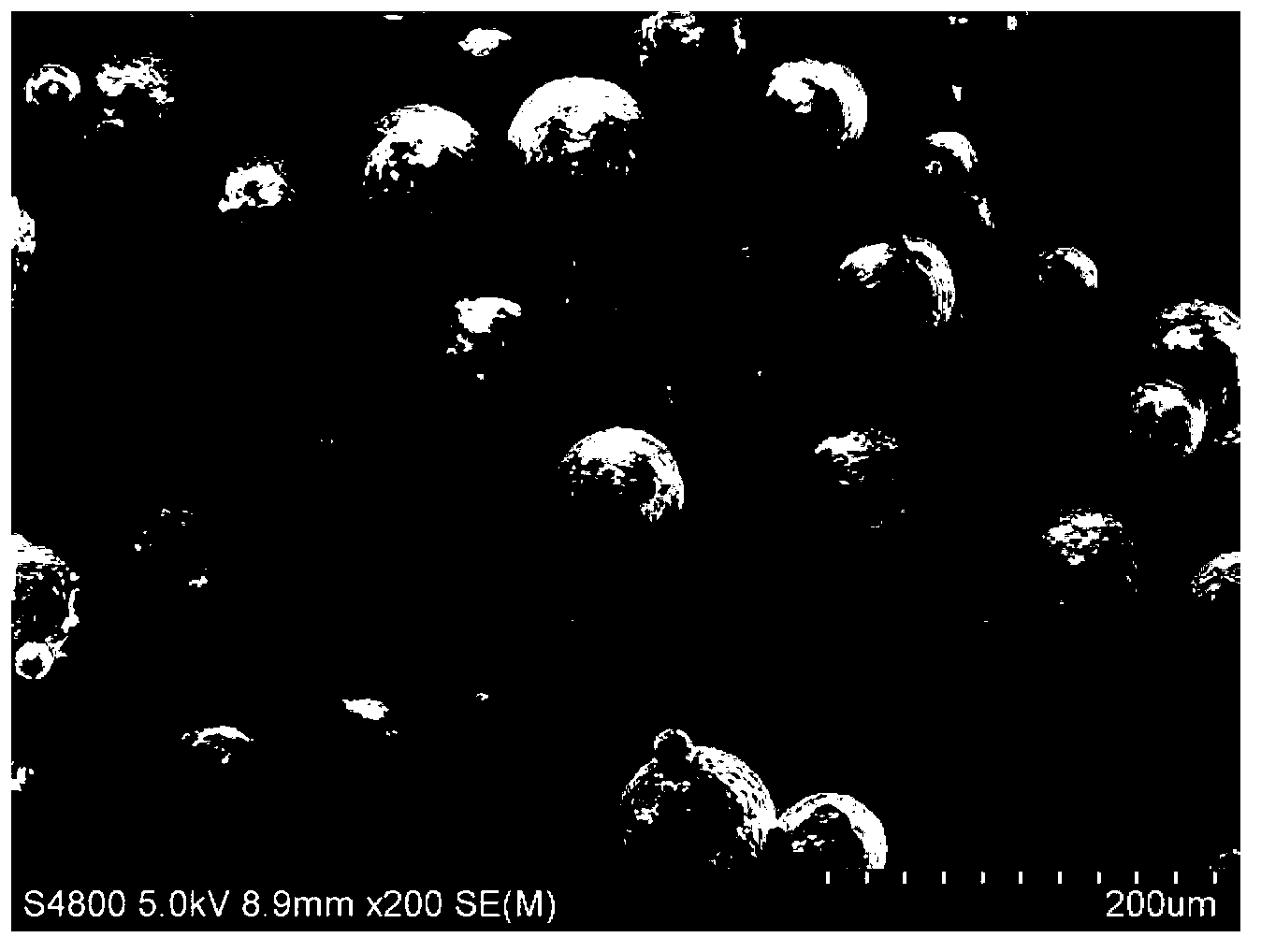

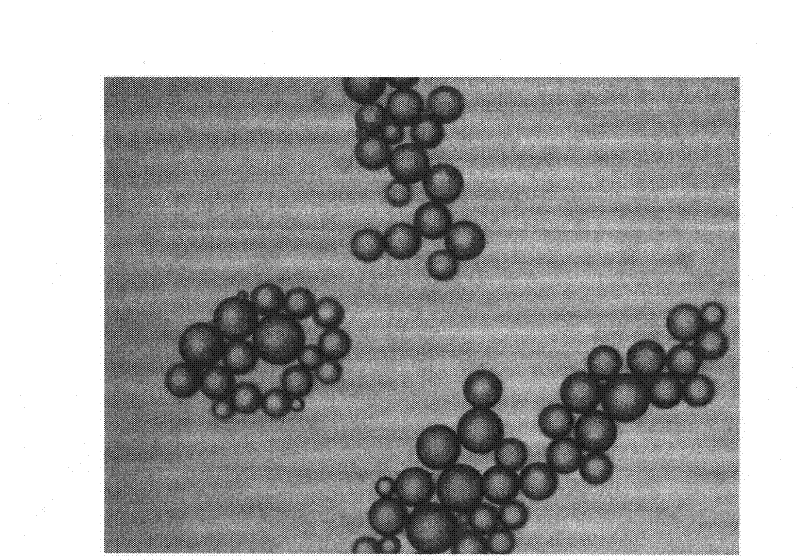

Method for preparing anionic polyacrylamide microspheres

The invention discloses a method for preparing anionic polyacrylamide microspheres. A reversed phase suspension polymerization method is adopted and comprises the following main steps of: a) dissolving a dispersing agent in a disperse phase; b) adding aqueous alkali into monomer solution of acrylamide to obtain neutral monomer solution; c) heating the monomer solution to the temperature of between 45 and 60DEG C in the nitrogen atmosphere, adding an initiator, and performing reaction at the temperature of between 60 and 65DEG C; and d) performing azeotropic water removal at the temperature of between 50 and 65DEG C in the vacuum degree of 0.01-0.05MPa to obtain the target product, wherein the weight part ratio of the disperse phase to the dispersing agent to the monomer solution to the initiator is (70-95):(0.4-2):(5-30):(0.0001-0.001). The product is white or transparent solid microspheres, and has high content of active ingredient and more stable properties and is more convenient to store for a long time and transport in a long distance and more easily quantitatively prepared into the required solution on spot compared with emulsion and solution products.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

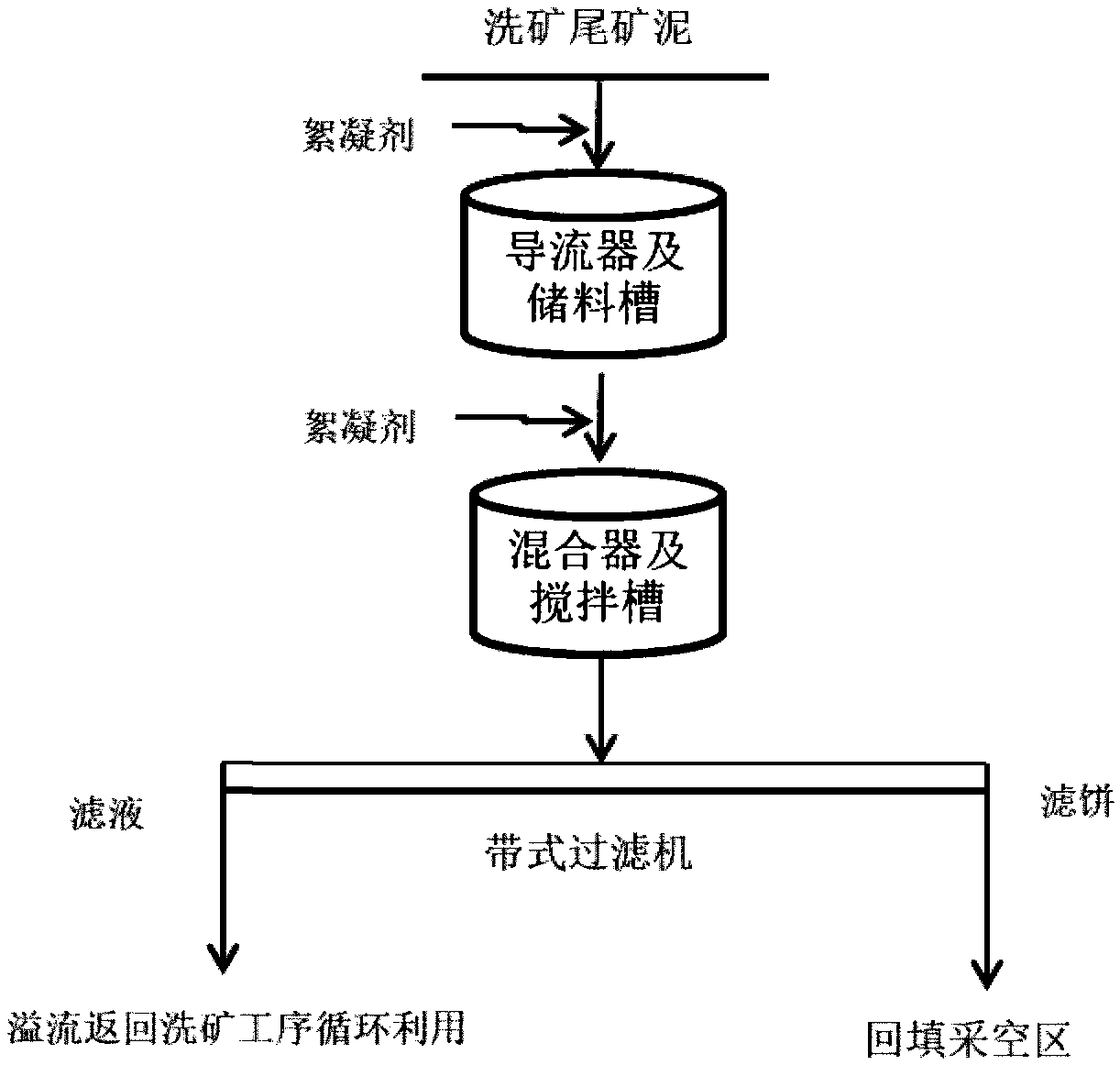

Method for dewatering washing tailing slime of bauxite ore

InactiveCN109107753AObvious safety and environmental protection effectsReduce dehydration energy consumptionWet separationEngineeringEnergy consumption

The invention relates to a method for dewatering washing tailing slime of bauxite ore. The method includes the steps that firstly, tailing slime of the bauxite ore is fed into a storage tank through afluid director, flocculant is added, preliminary flocculation is carried out, and slurry is obtained; and then the slurry is fed into a pipe mixer, modified flocculant is added, further flocculationis carried out, thorough stirring is carried out, three-stage dewatering is carried out by adopting a belted filter, and a filter cake and filtrate with the moisture content not higher than 35wt% areobtained. According to the method for dewatering the washing tailing slime of the bauxite ore, the modified flocculant is utilized ingeniously, thus compact fine tailing slime particles are convertedinto loose flocculation, and filtration and dewatering of the tailing slime are facilitated; the moisture content of the generated filter cake is no more than 35wt%, the filter cake has no fluidity, and can be used for backfilling goaf, tailing wet storage of the tailing slime is changed into dry disposal, safety and the environmental protection effect are obvious, energy consumption of filtrationand dewatering is low, and water resources are saved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

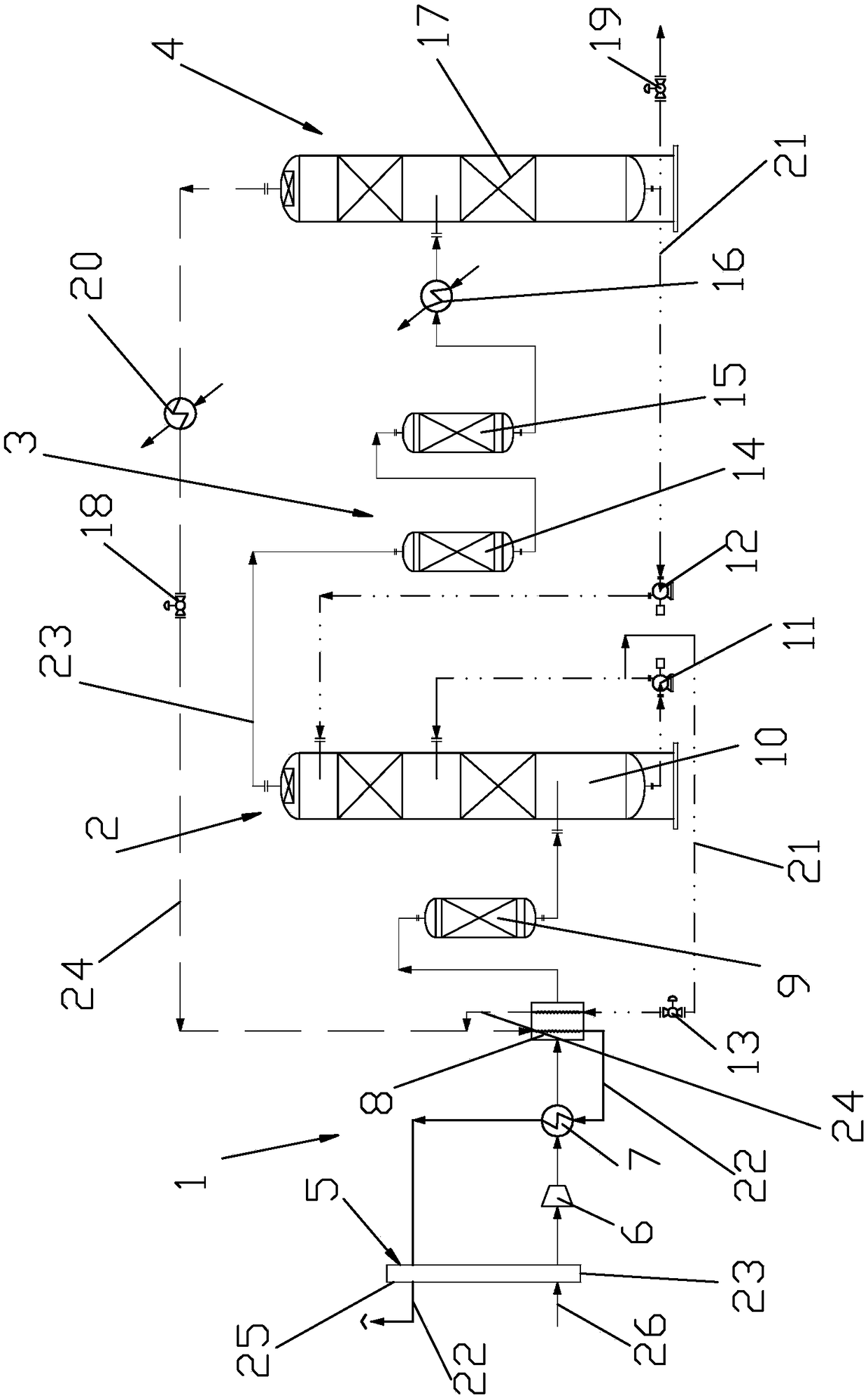

Preparation device and technology for producing high-quality liquid carbon dioxide

ActiveCN108821288AReduce dehydration energy consumptionReduce the temperatureCarbon compoundsProcess equipmentProcess engineering

The invention discloses a preparation device for producing high-quality liquid carbon dioxide. The preparation device comprises a drying system, a heavy component removing system, an impurity removingsystem and a light component removing system; a rotating wheel dehumidifying machine comprises a dehumidifying region and a regeneration region; a smoke cooler, a heater and the regeneration region are communicated through a regenerated gas pipeline; the dehumidifying region is communicated with a compressor through a raw gas pipeline; the compressor is communicated with the heater through the raw gas pipeline; the heavy component removing system comprises a heavy component removing tower, a heavy component removing circulating pump and a CO2 washing pump; a preparation technology comprises the following steps: (1) drying and dehydrating; (2) washing and removing a heavy component; (3) carrying out low-temperature deep impurity removal; (4) carrying out liquefaction and rectification. Thepreparation device and the preparation technology, disclosed by the invention, have the advantages of simple technology, low operation energy consumption and convenience for operation; under the condition that a few of sets of equipment need to be increased based on previous process equipment, and the liquid carbon dioxide with the content more than 99.995 percent can be stably produced; the generation of solid wastes is reduced and the investment cost is reduced.

Owner:杭州快凯高效节能新技术有限公司

Wet oxidation treatment system and process for organic solid waste

InactiveCN112679064ASave conditioning energyWell mixedSludge treatment by oxidationSludge processingSludgeProcess engineering

The invention discloses a wet oxidation treatment system and process for organic solid waste. The wet oxidation treatment system comprises a sludge storage tank, a pipeline type self-heat-exchange and reaction integrated assembly, a reaction sludge pressure storage tank, a mechanical dehydration unit, a sewage tank, a sludge pump and a water injection pump. According to the invention, sludge and process injected water can be mixed through the sludge pump, so hardening and tempering of a hardening and tempering tank in a traditional process are omitted; a pressure drop can be regulated and controlled through sludge-sludge heat exchange and a wet oxidation reaction of the pipeline type self-heat-exchange and reaction integrated assembly and by controlling the proportion of reaction gas reserved in the pipeline type self-heat-exchange and reaction integrated assembly; and the reaction mud pressure storage tank is used for storing a part of pressure energy of reaction mud and primarily settling the reaction mud, so the adjusting range of an adjusting valve can be reduced, the service life of the valve can be prolonged, the pressure energy can be used for dehydration of the reaction mud and reinjection tempering of supernatant, and thus, most of heat in a technological process is fully recycled, technological energy consumption is greatly reduced, a product can be recycled, and remarkable environmental protection and economic benefits are obtained.

Owner:TSINGHUA UNIV

Rapid sewage sludge drying process based on microwave-polar medium material

ActiveCN108503003AAccelerate the rate of flocculation and sedimentationImprove purification effectSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSludge cakeSlurry

The invention discloses a rapid sewage sludge drying process based on a microwave-polar medium material. According to the method, mixed slurry prepared from a mixed solvent and the polar medium material are added to sludge-containing sewage in a flocculation stirring tank in the process of sludge flocculation and sedimentation, wherein the mixed solvent is prepared from organic polymer flocculantPAM (polyacrylamide) and inorganic polymer coagulant PAC (polyaluminium chloride), so that activated carbon powder and the manganese dioxide polar medium material are fully and uniformly mixed with sludge in the process of sludge flocculation and finally uniformly distributed in the precipitated aqueous sludge, and then the precipitated flocculated water-containing sludge uniformly mixed with thepolar medium material is filtered by a belt filter press, and sludge cakes are formed and transported into microwave drying equipment by a conveyor belt for rapid drying. Utilization efficiency of microwave energy is increased by adding the medium material to the sludge, the heating rate is increased, the purpose of rapidly drying the sludge is achieved, emission of pollutants in the sewage is reduced, sludge dehydration energy consumption is reduced by 40%-50%, and dehydration efficiency is increased by 50% or higher.

Owner:广州微碳科技有限公司

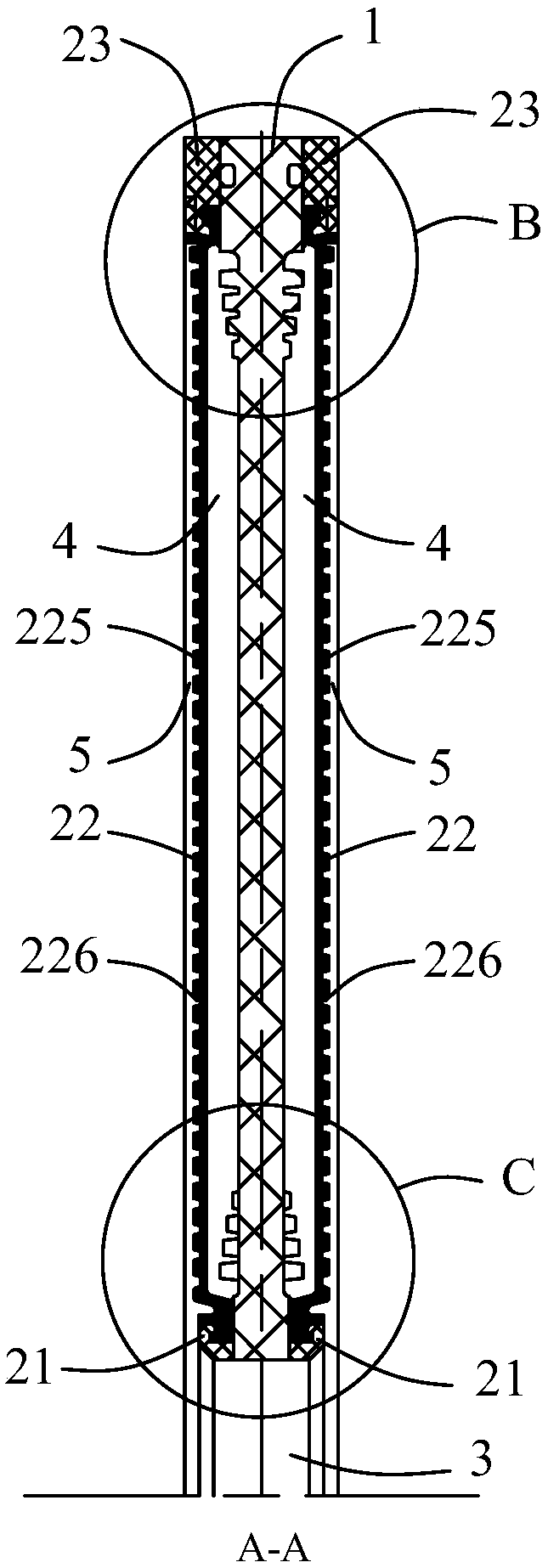

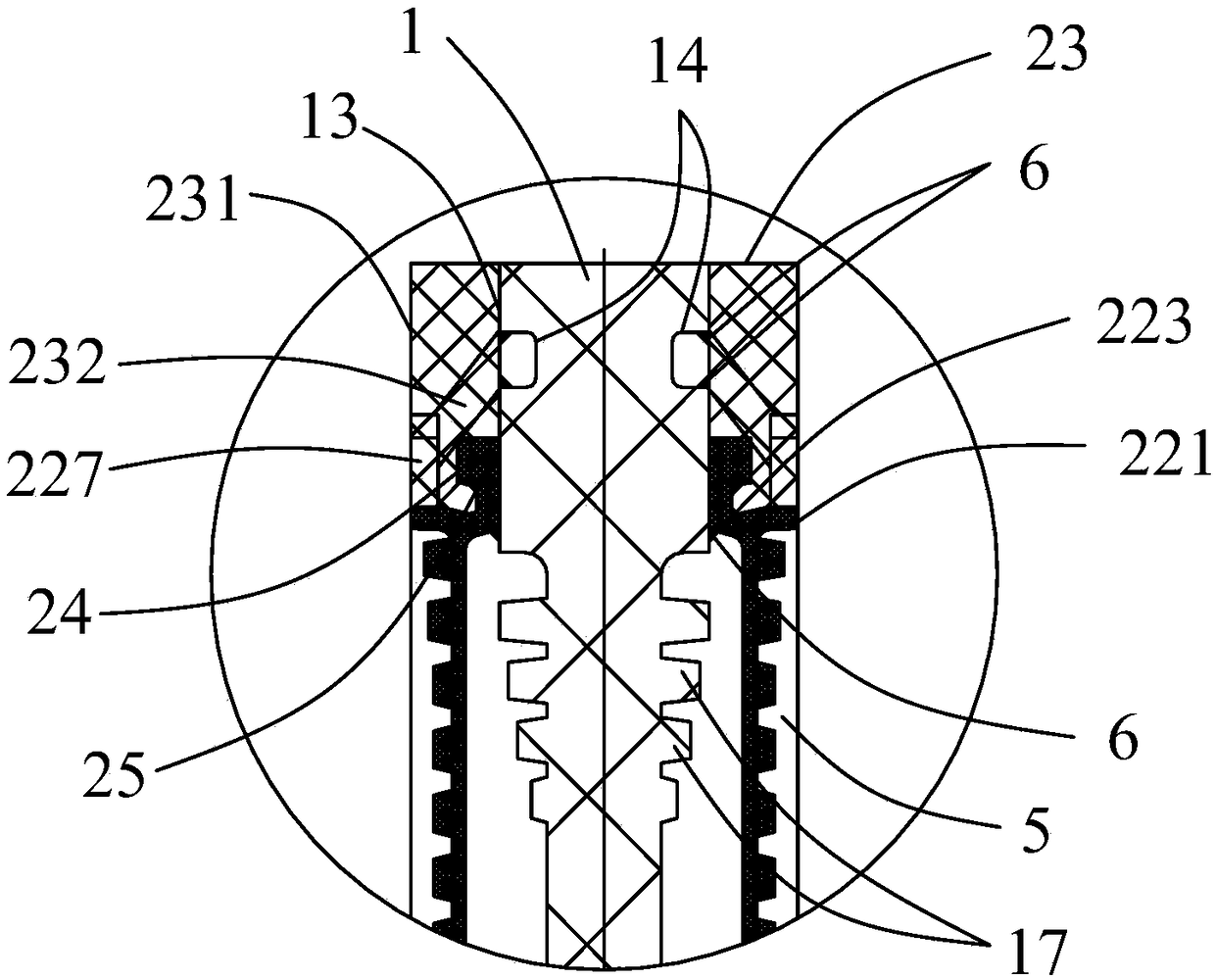

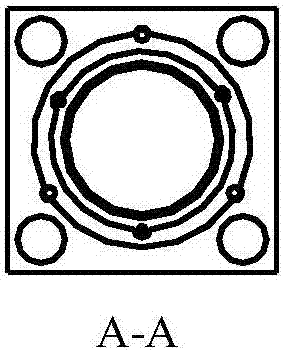

High-elastic diaphragm filter plate and preparation method thereof

PendingCN109126231AStrong resistance to compression deformationImprove deformation abilityFiltration separationEngineeringDiaphragm seal

The invention provides a high-elastic diaphragm filter plate and a preparation method thereof. The diaphragm filter plate comprises a core plate, a diaphragm, a feed hole, a sealed squeezing medium cavity, and a squeezing medium hole formed in the core plate and communicated with the squeezing medium cavity. The diaphragm comprises a hard ring made of hard plastic, a diaphragm main part made of high elastic materials, and a diaphragm frame part made of hard plastic. The squeezing medium cavity is located between the diaphragm main part and the core plate, the outer surface, in the backward direction of the core plate, of the diaphragm frame part is a diaphragm sealing surface, and a filter chamber is formed in the side of the outer surface of the diaphragm main part. The compressive deformation resistance of the hard plastic is high and thus can ensure the sealing performance of the sealing surface of the diaphragm, and the service life of a diaphragm filter plate is greatly prolonged;while the high elastic material has strong deformation ability, the diaphragm main part thus has a larger pressing stroke, the high squeezing rate of the diaphragm filter plate is thus ensured, a filter cake with low water content can be obtained, and ultimately energy consumption for dewatering is greatly reduced.

Owner:ZHEJIANG FUJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD

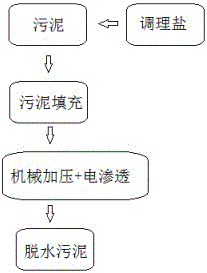

Method for electric dehydration of sludge strengthened by conditioning salt

ActiveCN106830592AReduce energy consumptionReduce dehydration energy consumptionSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentElectricityElectroosmosis technique

The invention discloses a method for electric dehydration of sludge strengthened by a conditioning salt. A proper conditioning salt is added into the sludge to be dewatered, then the combination of mechanical pressing and a conventional electroosmosis technique is adopted for the dehydration, a scientific method of the mechanical pressing combined with salt conditioning effectively reduces the energy consumption of electroosmosis dehydration of the sludge, the time for electroosmosis dehydration is further shortened, and the effect of the electroosmosis dehydration is enhanced. In the condition of the combined electric dehydration, the required time for the water content in the sludge is reduced to 60% is 25-35 min, and the energy consumption of dehydration is 0.033-0.065 kWh / kg sludge.

Owner:SUN YAT SEN UNIV

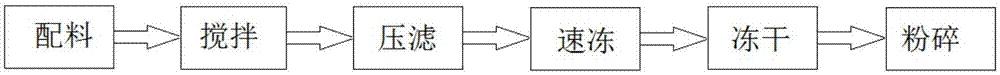

Ca-Zn composite stabilizer production system and production technology thereof

InactiveCN107383899AThe solution is not easy to crushSolve the technical problem of excessive crushing finenessCoatingsHeat resistanceFreeze-drying

The invention discloses a calcium-zinc composite stabilizer production system and a production process thereof, belonging to the technical field of heat stabilizer production. The calcium-zinc composite stabilizer production system of the present invention comprises a stirring device, a drying device and a pulverizing device which are sequentially arranged and connected according to the technological process; wherein: the stirring device includes a reaction kettle, a stirring rod, a discharge pipe and a water pump, and the The stirring rod is directly inserted into the middle and lower part of the reactor, the discharge pipe communicates with the bottom of the reactor, and the water pump communicates with the upper part of the reactor through a water pipe; the drying device is a vacuum freeze-drying device. Compared with the stabilizers of the prior art, the calcium-zinc composite stabilizer prepared by the production process of the present invention adopts three groups of components in a ratio of 1:1 for the first time, and achieves cold resistance, heat resistance and smoothness when applied to high-grade plastics. , toughness, wear resistance and other unexpected technical effects, and the service life has been proved by destructive tests, at least increasing the original service life by more than 20%.

Owner:马鞍山市宝博科技有限公司

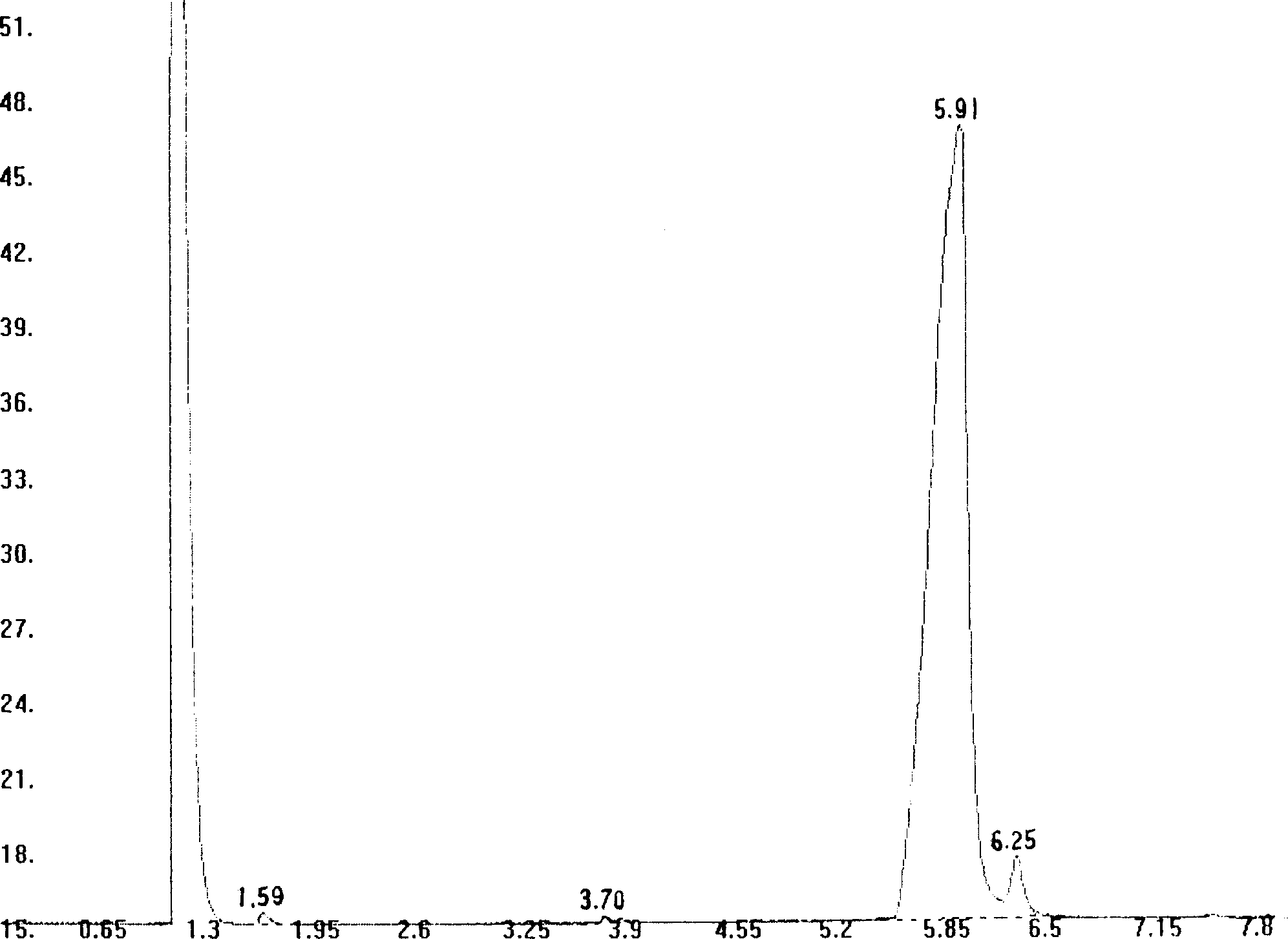

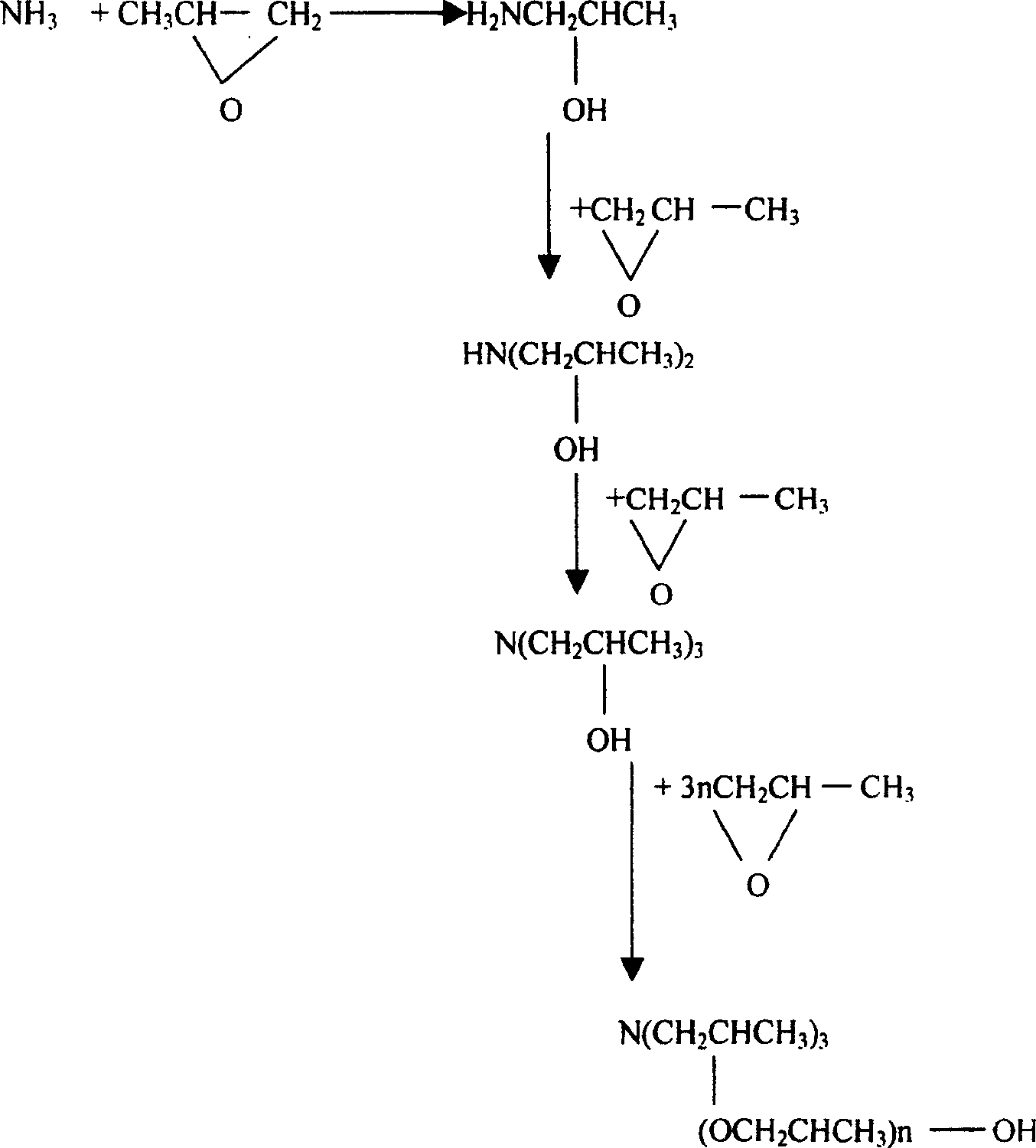

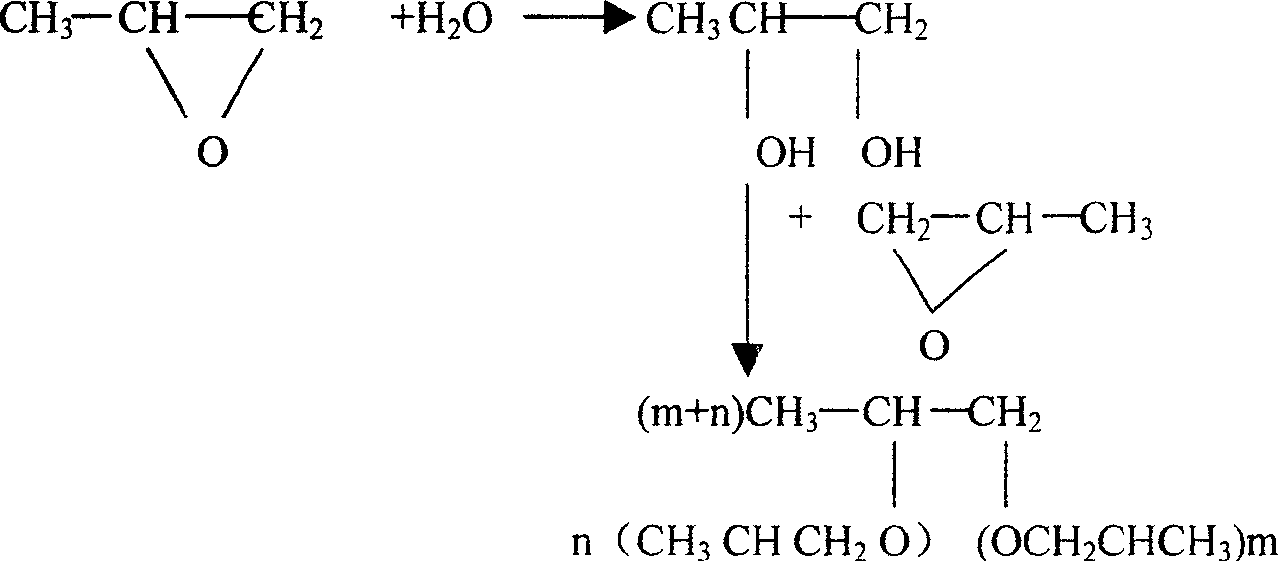

Process for synthesis of triisopropanolamine

ActiveCN1308287CIncrease moisture contentHigh purityOrganic compound preparationAmino-hyroxy compound preparationReaction temperatureMonoisopropanolamine

The invention provides a process for synthesis of triisopropanolamine by using liquid ammonia and trimethylene oxide as raw material, water as catalyst, stock preparing by the mol ratio of liquid ammonia : trimethylene oxide = 1 : 3.00 - 3.05, charging deionized water in one time, charging liquid ammonia and trimethylene oxide in two times, fully stirring, sustaining the pressure <0.5 MPa, sustaining reaction temperature between 20-75 deg. C for 1.0-3.0 hours, decompressing for dehydration till the water content is less than 5%.

Owner:HONGBAOLI GRP CO LTD

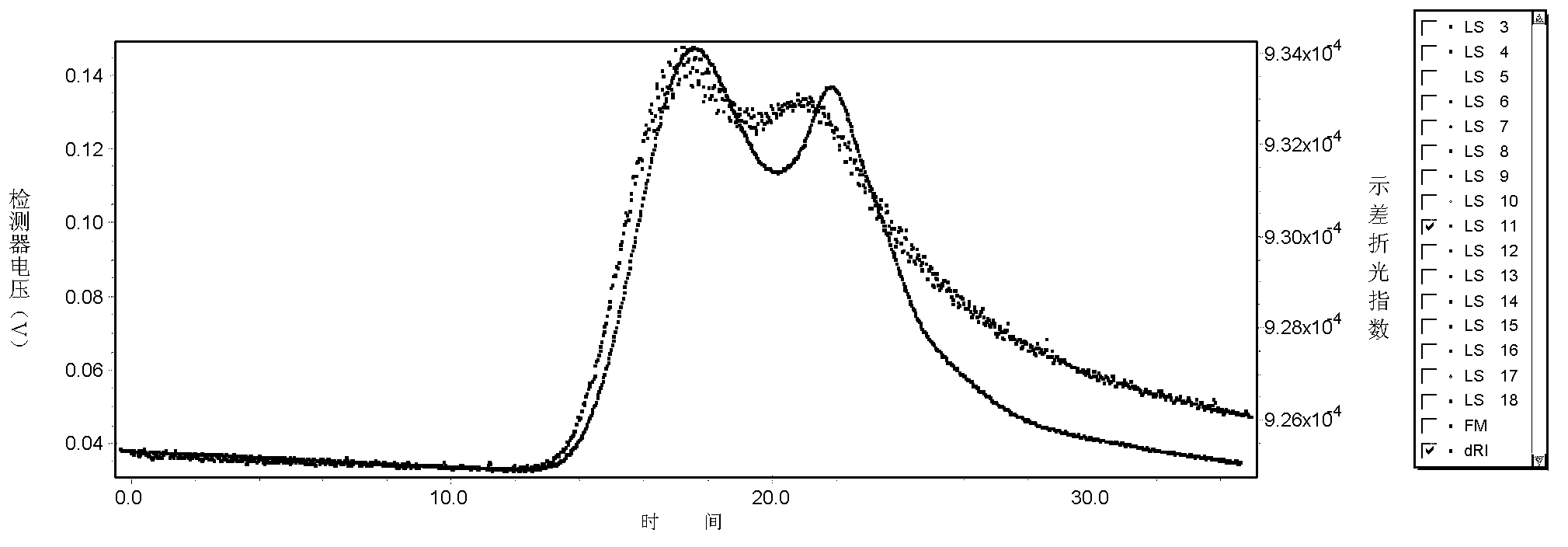

Preparation method of dry powder type paper retention and filter aid

InactiveCN101555670AHigh strengthChemically stablePaper/cardboardRetention agents additionFiberNitrogen

The invention relates to a synthetic method of a paper retention and filter aid. The method adopts the scheme that the nonionic monomer, the cationic monomer and the deionized water are mixed according to the proportion (300-500:35-75:320-510) of weight ratio after nitrogen charging and oxygen removal at the temperature of 10-30 DEG C and under the stirring condition; and a water-soluble initiator with weight ratio of 0.12-0.83 is added with water for dissolution and then is added in the mixed liquor; and the polyreaction is carried out for 3-8 hours at the temperature of 0-90 DEG C. The invention is the copolymer of the acrylamide and the cationic monomer, the copolymer and the particles in the pulp are flocculated after electrical neutralization or bridging to be retained on the filter cloth, and the invention can improve the retention rate of the fiber fines and the filler particles on the net, promote the dehydration of the paper and reduce the loss volume of the fiber in the white water; and the invention not only can improve the surface properties of the paper, but also can enhance the tensile property of the paper.

Owner:东营市诺尔化工有限责任公司

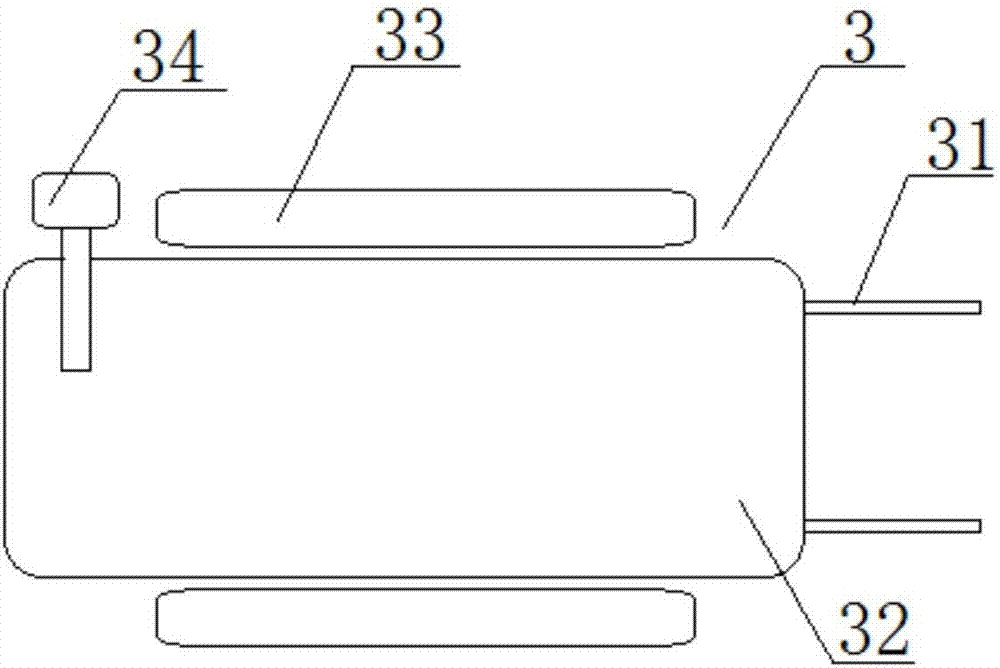

Dual-screw non-closed water removal device used for gunpowder continuous processing

PendingCN107289736AGuaranteed performanceEnsure safetyDrying solid materials without heatHeating arrangementGunpowderElectric machinery

The invention belongs to the technical field of gunpowder processing auxiliary equipment, and relates to a dual-screw non-closed water removal device used for gunpowder continuous processing. A main structure comprises a base, universal wheels, a foot brake piece, a motor, a reducer casing, a coupler, a dual-screw assembly, a core shaft, a machine barrel, a gunpowder inlet, a rotary air leakage roller, a scraping knife, a draining hole, a filter net, a hot water hole, a first hot water supply pipe, a second hot water supply pipe, a gunpowder outlet and an exhaust hole; water-containing gunpowder is subject to extrusion water removal to the maximum degree, water in the water-containing gunpowder is removed to the maximum degree, water can be effectively extruded, the damage or the dangerous condition of the gunpowder performance caused by continuous and excessive extrusion of the water-containing gunpowder can be avoided, the dual-screw assembly can be arranged to have different draw ratios according to the different water removal requirements, extrusion water removal of the water-containing gunpowder to the maximum degree can be achieved, the water removal rate of the water-containing gunpowder can be improved, the structure is simple, and the device is energy-saving, environment-friendly, friendly in use environment and easy to use and popularize.

Owner:QINGDAO UNIV OF SCI & TECH

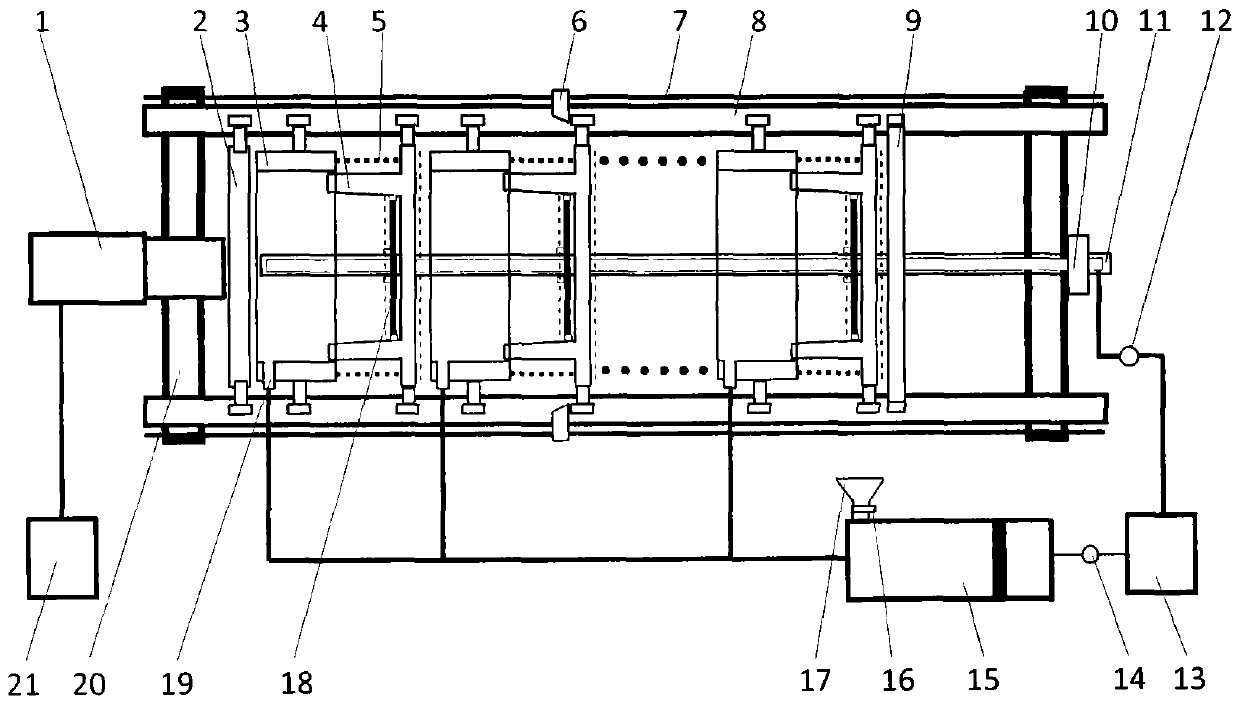

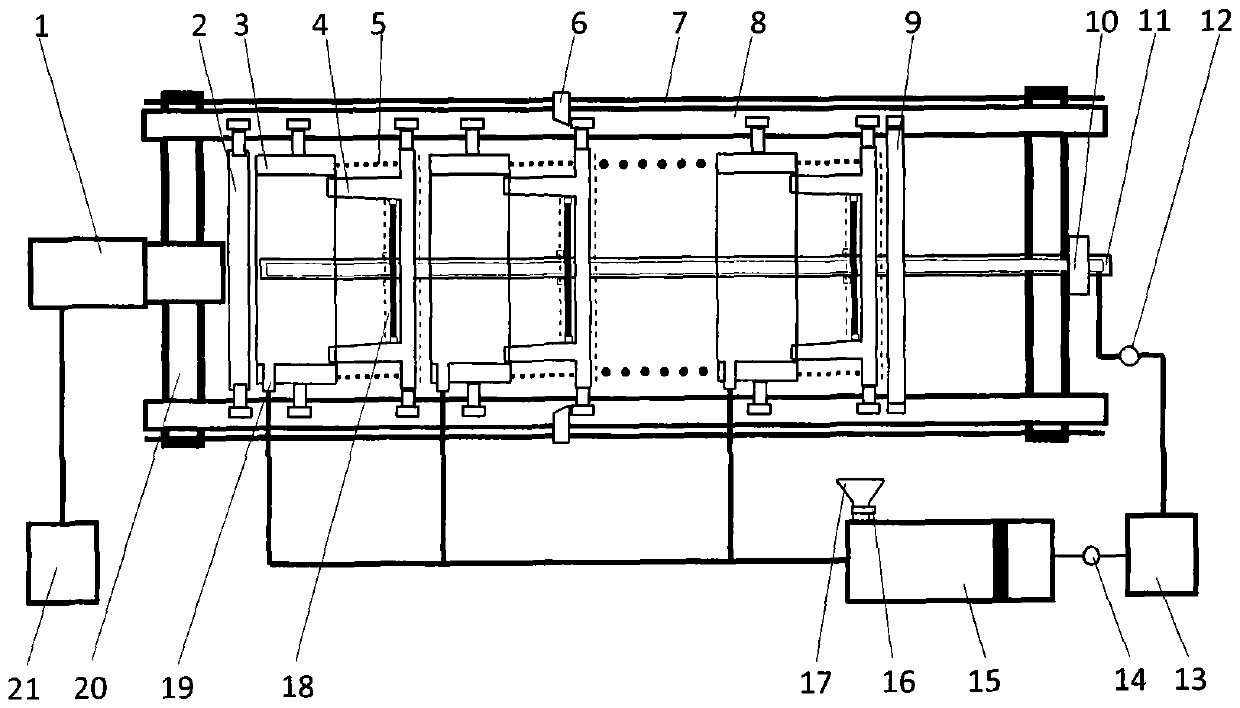

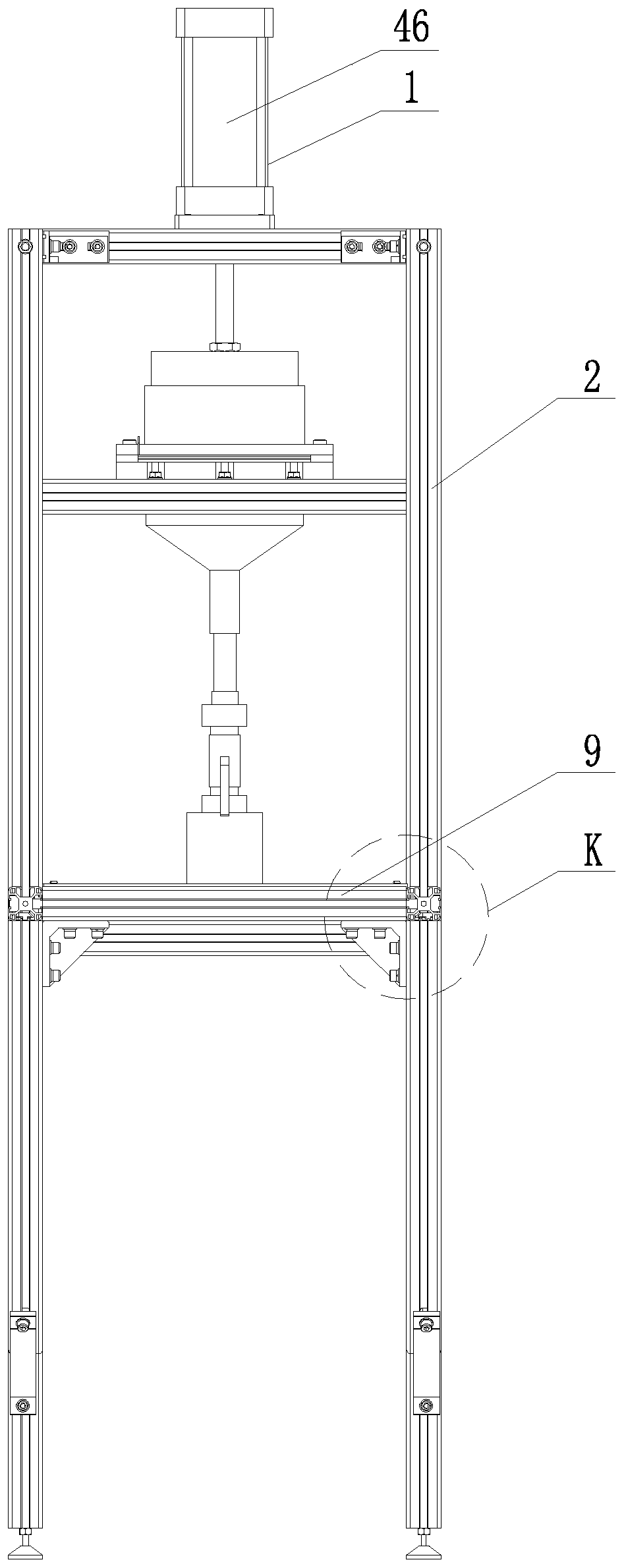

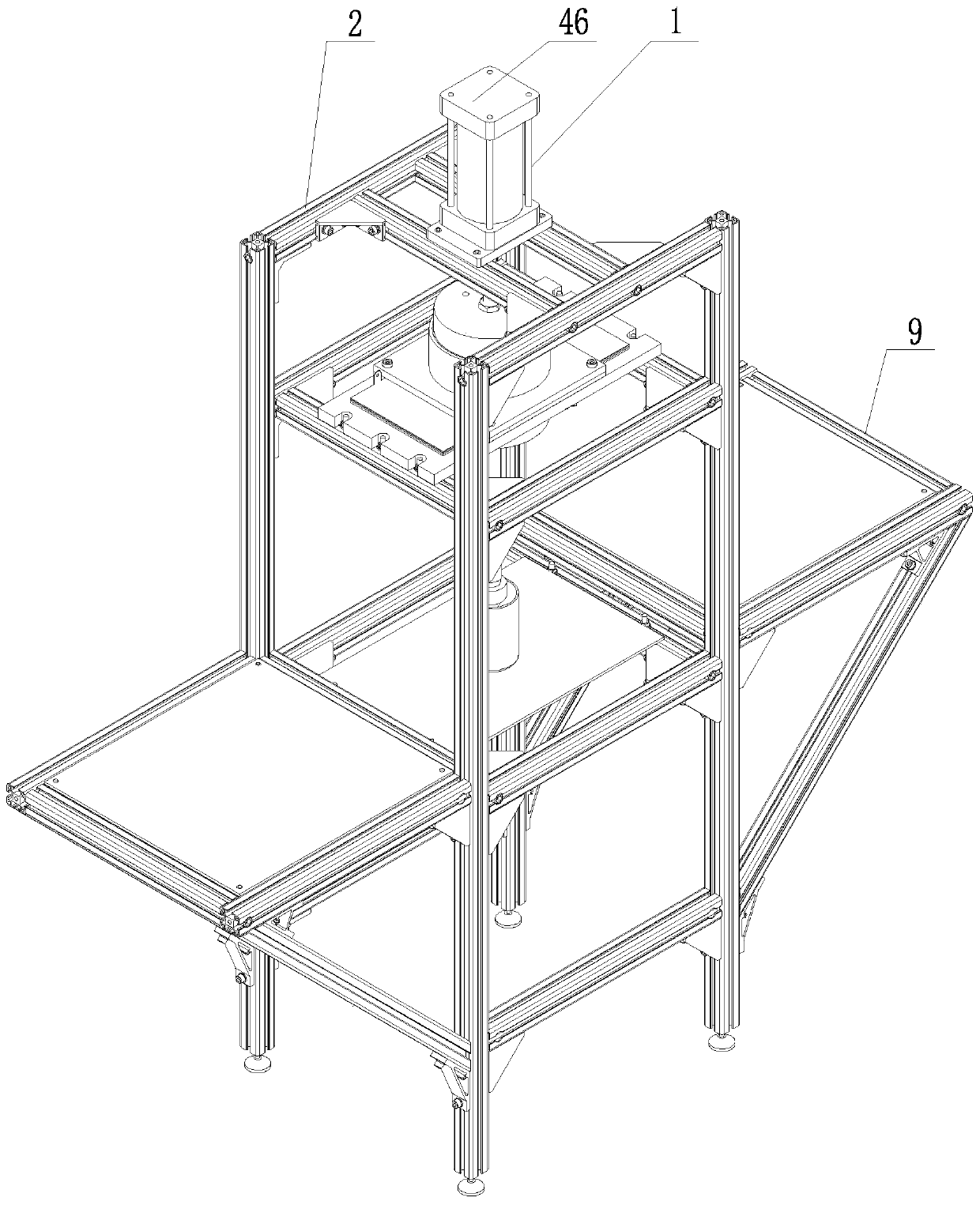

Strong pressure type sludge deep dehydration system

ActiveCN104492134AExpand follow-up treatment channelsWith contraction functionSludge treatment by de-watering/drying/thickeningFiltration separationGeotechnicsSludge

The invention relates to a strong pressure type sludge deep dehydration system, belonging to the technical field of environmental geotechnics. The strong pressure type sludge deep dehydration system is composed of a stroke support, a front top plate, a rear top plate, a shrinking steel rod, a piston grouting pump, a discharging plate and more than two arranged dehydrating units; According to the strong pressure type sludge deep dehydration system, the piston grouting pump is adopted to grout under strong pressure, so that a problem that sludge with low moisture content is difficultly fed is solved; the dehydrating units have shrinking functions and can realize sludge deep dehydration under strong pushing action of a hydraulic oil cylinder; the discharging plate can be used for discharging the dehydrated sludge automatically under the cooperative action of the shrinking steel rod and a mechanical arm; the whole system can realize continuous and automatic operation, and the time and labor costs are saved; and the strong pressure type mechanical dehydration mode is adopted, the energy consumption is low, the effect is good, the dehydration treatment cost is reduced and the follow-up sludge disposal way is expanded.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

A continuous sludge dewatering method based on hydrothermal treatment

ActiveCN103964662BHigh calorific valueReduce H contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal treatmentHot Temperature

The invention relates to a continuous sludge dewatering method based on hydro-thermal treatment, and belongs to the field of sludge treatment. An external heat exchanger of a feeding unit is filled with high temperature filtrate, sludge is continuously introduced in the feeding unit, and the high temperature filtrate is used for preheating the sludge; the sludge after preheating enters a hydro-thermal treatment unit under the pushing of the feeding unit, and is heated to above 150 DEG C for a hydro-thermal reaction through a heating device arranged on the outside of the hydro-thermal treatment unit; the standing time of the sludge inside the hydro-thermal treatment unit is controlled by an accelerator arranged at the interior of the hydro-thermal treatment unit; partial sludge after hydro-thermal treatment is flown back to the hydro-thermal treatment unit; the sludge passing through the hydro-thermal treatment unit is introduced in a continuous extrusion dewatering unit to realize continuous dewatering of the hydro-thermal sludge, and a cavity in the dewatering process is at a sealed state. According to the dewatering method, based on the hydro-thermal treatment for improving the sludge structure and physicochemical characteristics, the energy sources are fully utilized and recycled while the energy consumption input is saved, and the sludge dewatering in a liquid form is realized continuously.

Owner:DALIAN UNIV OF TECH

A preparation device for producing high-quality liquid carbon dioxide and its preparation process

ActiveCN108821288BReduce dehydration energy consumptionReduce the temperatureCarbon compoundsProcess equipmentProcess engineering

The invention discloses a preparation device for producing high-quality liquid carbon dioxide. The preparation device comprises a drying system, a heavy component removing system, an impurity removingsystem and a light component removing system; a rotating wheel dehumidifying machine comprises a dehumidifying region and a regeneration region; a smoke cooler, a heater and the regeneration region are communicated through a regenerated gas pipeline; the dehumidifying region is communicated with a compressor through a raw gas pipeline; the compressor is communicated with the heater through the raw gas pipeline; the heavy component removing system comprises a heavy component removing tower, a heavy component removing circulating pump and a CO2 washing pump; a preparation technology comprises the following steps: (1) drying and dehydrating; (2) washing and removing a heavy component; (3) carrying out low-temperature deep impurity removal; (4) carrying out liquefaction and rectification. Thepreparation device and the preparation technology, disclosed by the invention, have the advantages of simple technology, low operation energy consumption and convenience for operation; under the condition that a few of sets of equipment need to be increased based on previous process equipment, and the liquid carbon dioxide with the content more than 99.995 percent can be stably produced; the generation of solid wastes is reduced and the investment cost is reduced.

Owner:杭州快凯高效节能新技术有限公司

Sludge strong pressure deep dewatering system

ActiveCN104492134BExpand follow-up treatment channelsWith contraction functionSludge treatmentFiltration separationGeotechnicsSludge

The invention relates to a strong pressure type sludge deep dehydration system, belonging to the technical field of environmental geotechnics. The strong pressure type sludge deep dehydration system is composed of a stroke support, a front top plate, a rear top plate, a shrinking steel rod, a piston grouting pump, a discharging plate and more than two arranged dehydrating units; According to the strong pressure type sludge deep dehydration system, the piston grouting pump is adopted to grout under strong pressure, so that a problem that sludge with low moisture content is difficultly fed is solved; the dehydrating units have shrinking functions and can realize sludge deep dehydration under strong pushing action of a hydraulic oil cylinder; the discharging plate can be used for discharging the dehydrated sludge automatically under the cooperative action of the shrinking steel rod and a mechanical arm; the whole system can realize continuous and automatic operation, and the time and labor costs are saved; and the strong pressure type mechanical dehydration mode is adopted, the energy consumption is low, the effect is good, the dehydration treatment cost is reduced and the follow-up sludge disposal way is expanded.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

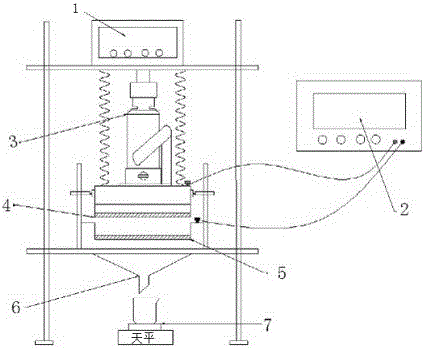

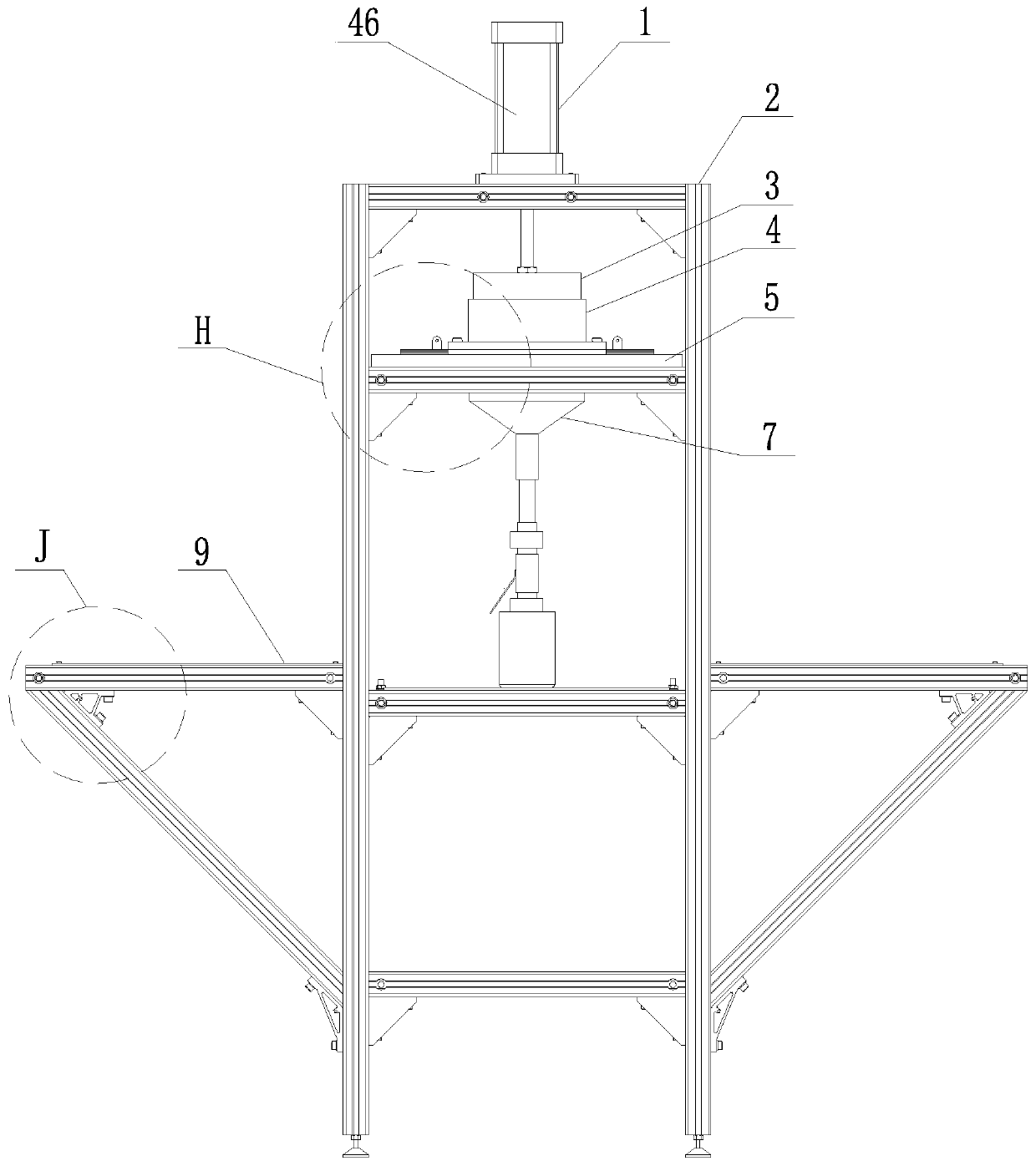

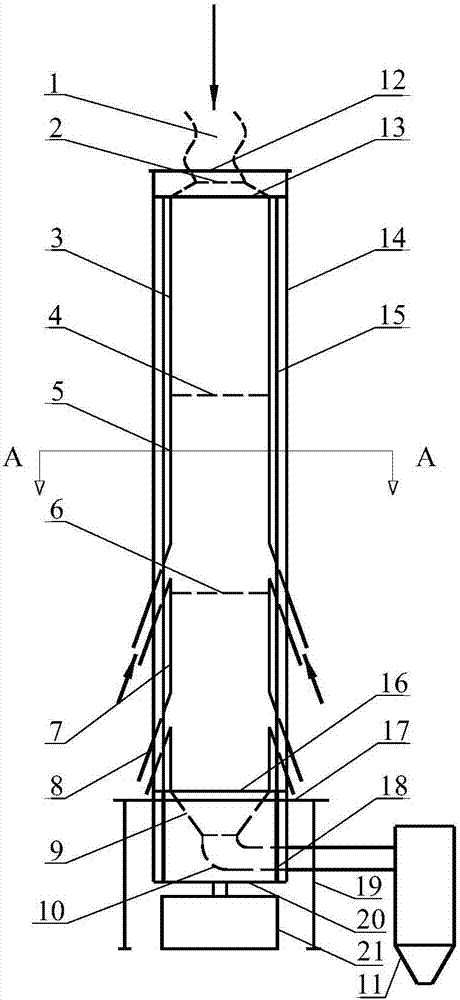

Oily sludge reduction comprehensive experiment device

PendingCN111574004AConvenient frequency settingUniform sonicationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesThermodynamicsSludge

The invention discloses an oily sludge reduction comprehensive experiment device and belongs to the technical field of oily sludge treatment and aims to solve the problems of inconvenient pressure adjustment, single electroosmosis electric field arrangement mode, inconvenience in setting ultrasonic composite action frequency, uneven sound wave, action and failure to quantitatively investigate adsorption-assisted dehydration in the prior art. An air cylinder of a pneumatic device is fixed at the top of a bracket; a piston rod of the air cylinder of the pneumatic device is vertically arranged downwards and connected with the top of a piston cylinder outer cover of an integrated piston; a cathode dehydration material layer is arranged at the lower end of the integrated piston and fixedly connected with the bracket; the lower end of the cathode dehydration material layer is connected with the upper end of a water collection and vacuum suction filtration device in a sealed mode; and experiment platforms are fixed to the left side and the right side of the bracket respectively. In a whole experiment process, different electric fields, pressures, ultrasonic waves and vacuum suction filtration modes are adopted to perform comprehensive dehydration on oily sludge, so that optimal process conditions are further explored, energy consumption is reduced, and a dehydration effect and efficiency are improved.

Owner:哈工大机电工程(嘉善)研究院

Dehydration method of huge-body high-water-content and low-permeability waste residue

InactiveCN108915060AReduce energy consumptionReduce dehydration energy consumptionFatty/oily/floating substances removal devicesSewerage structuresPlastic wasteHigh water content

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

A deep dehydration method for sludge-like substances based on thermal conditioning coupled with filter press

ActiveCN103508648BPrevent massive decompositionInhibition of caramelization reactionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisHydrothermal reactionRaised temperature

The invention relates to a sludge substance deep dehydrating method based on thermal conditioning coupling filter pressing, belongs to the field of sludge treatment, is suitable for dehydration of various kinds of sludge, and particularly suitable for dehydration of surplus sludge. The method comprises the following steps: firstly carrying out heat exchange to a high temperature filtrate and the sludge, injecting the sludge with the raised temperature in a thermal conditioning processing unit, and performing a sufficient hydrothermal reaction at 120-250 DEG C; then immediately performing filter processing and dehydrating under the pressure to remove the moisture in a liquid state; at last, decompressing the high temperature sludge filter cake with pressure, further steaming and dehydrating with the sludge own high temperature and heat, so as to improve the dehydrating efficiency. The dehydrating method can improve sludge structure, physicochemical property and moisture distribution, save and fully utilize the heat, realize high-dryness and low-energy consumption dehydration of sludge, and improve the recycling value of the sludge.

Owner:DALIAN UNIV OF TECH

An experimental system and method for vibrating classification, drying and quality improvement of low-rank coal

ActiveCN104941905BSolve the problem of uneven dryingGuaranteed heat and mass transfer effectSievingScreeningEngineeringCoal

An experimental system and method for vibration grading, drying and quality improving of low-rank coal belong to drying and quality improving systems and methods of the low-rank coal. The system is formed by a vibration grading barrel, a grading barrel support, a multi-screening-face mechanism, a grading barrel exciter, a hot smoke input pipeline at the upper portion of a barrel body, a discharging port in the lower portion of the barrel body and a hot smoke replenishing pipeline outside the barrel body, wherein the multi-screening-face mechanism is arranged inside the barrel body. Raw low-rank coal is added into vibration grading drying barrels from the upper portion, pre-grading is carried out by the grading drying barrels under the effect of the exciter, the calibers of screening faces are reduced from top to bottom, the pre-graded low-rank coal forms material layers on the screening faces with different calibers, high temperature hot smoke enters the drying barrels from the upper portion of the barrel body and is in contact with particles of the largest fraction, a coal sample in a vibrating screen is dried, and a screening barrel continuously vibrates to keep the materials loose. The temperature is reduced after the hot smoke passes through the screening face, the hot smoke enters the lower layer of the screening barrel to dry the particles of the next fraction and so on. Finally, the particles of the smallest fraction are discharged into a tail gas separating device along with cooled smoke tail gas.

Owner:CHINA UNIV OF MINING & TECH

A method for recovering oilfield associated gas

ActiveCN108641769BHigh yieldReduce dehydration energy consumptionSolidificationLiquefactionFluid phaseOil field

The invention provides a recovery method of associated gas of an oilfield. A gas phase of a raw material subjected to primary gas-liquid separation is subjected to secondary gas-liquid separation anddewatering after being compressed and cooled, a liquid phase subjected to primary gas-liquid separation is subjected to flash evaporation, dewatering and steam stripping, and a gas phase obtained through steam stripping and a gas phase obtained after flash evaporation enter a dewatering link after two times of compression cooling; the gas phase subjected to dewatering drying is cooled and then subjected to low-temperature gas-liquid separation, a liquid phase subjected to low-temperature separation is heated and then subjected to ethane removal, the liquid phase with ethane removed is heated for butane removal, a liquid-phase LPG product is obtained, part of liquid-phase condensate oil with butane removed is cooled to serve as an absorbent and then subjected to multi-stage mass transfer and heat transfer with a gas phase subjected to low-temperature separation in the liquefaction step, the gas phase obtained after mass transfer and heat transfer serves as lean gas to be recovered afterbeing subjected to cooling, low-temperature separation, pressure reduction and cold recovery. High-value LPG products in the associated gas of the oilfield can be recovered, and the production cost is greatly reduced with an efficient and economical technique.

Owner:CHINA TIANCHEN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com