Oily sludge reduction comprehensive experiment device

An experimental device and sludge reduction technology, applied in sludge treatment, electrochemical sludge treatment, water/sludge/sewage treatment, etc., can solve the inconvenient setting of ultrasonic composite action frequency, the inability to quantitatively investigate adsorption-assisted dewatering, The problem of single electroosmosis electric field setting can achieve the effect of improving dehydration efficiency, improving dehydration effect and efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 3

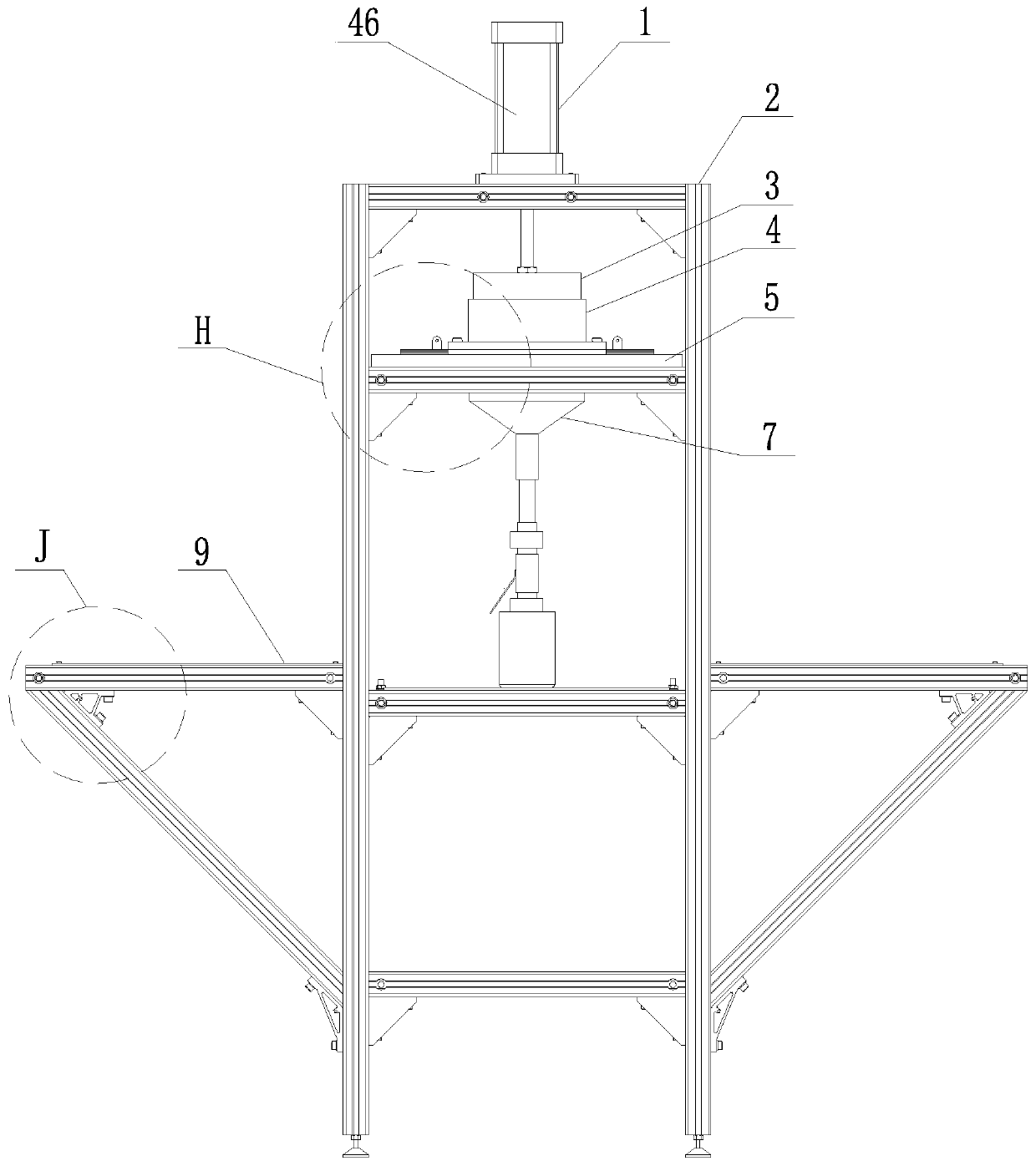

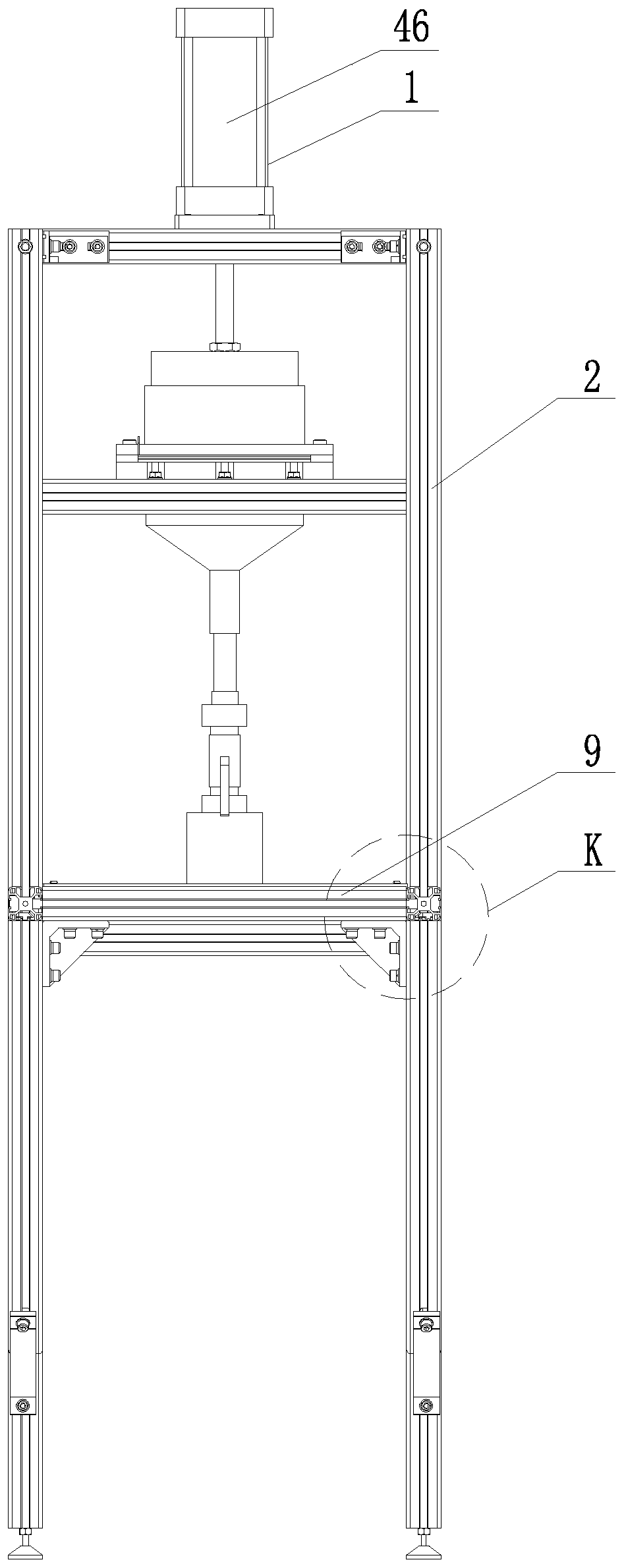

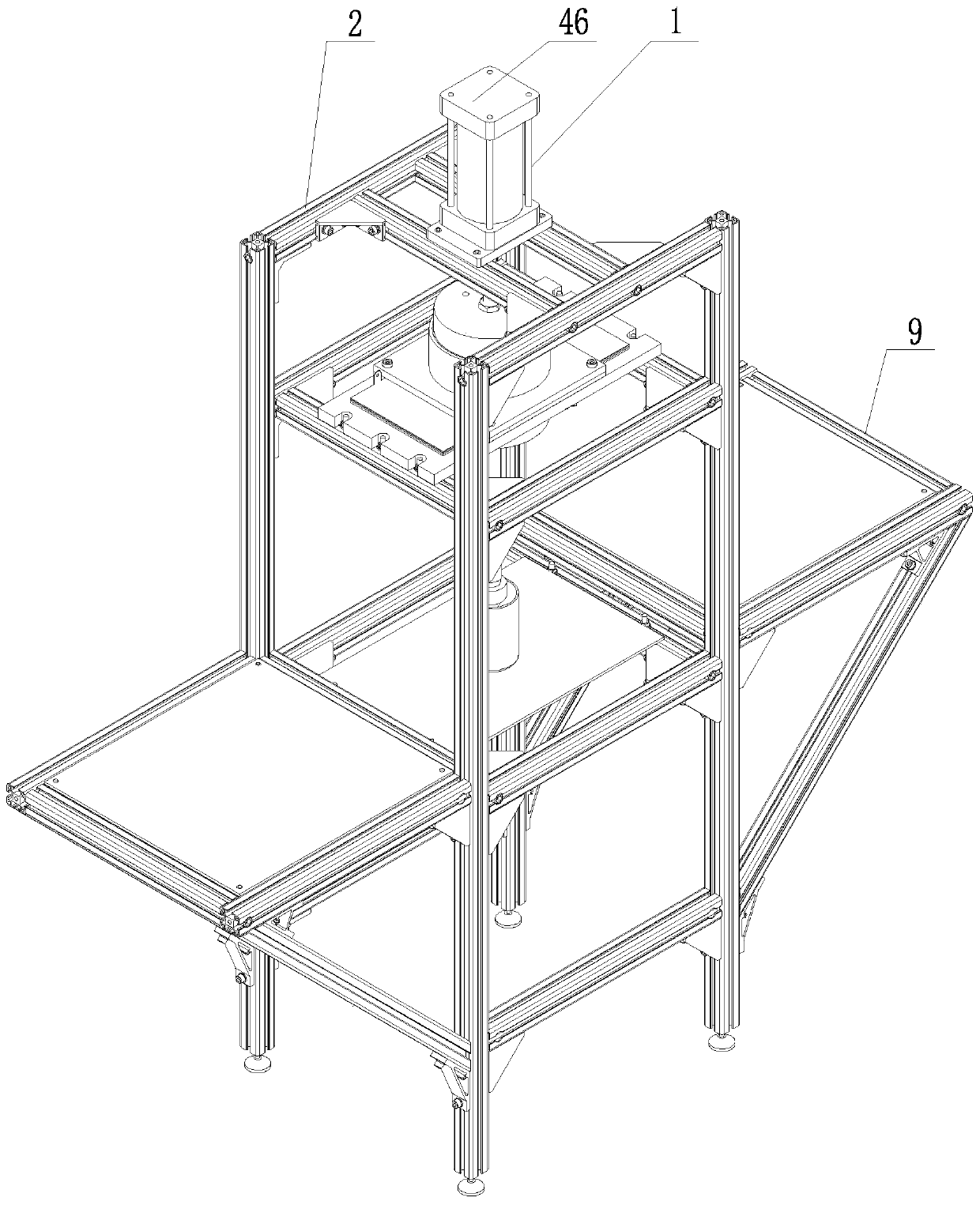

[0033] Specific implementation mode three: as figure 1 , Figure 5 , Image 6 , Figure 12 , Figure 13 , Figure 15 As shown, the comprehensive experimental device for oily sludge reduction described in Embodiment 1, the integrated piston 3 includes a joint nut 32, a piston cylinder cover 33, an insulating washer 35, an anode joint 36, a vibrator mounting plate 38, Anode plate 39, dehydration insulating sleeve 40, dehydration steel drum 41 and 2-4 ultrasonic vibrators 34;

[0034] The dehydration steel drum 41 is a cavity structure with upper and lower ends open. The dehydration insulating sleeve 40 is arranged in the dehydration steel drum 41 and bonded to the inner wall of the dehydration steel drum 41. The piston rod of the cylinder 46 is connected to the piston cylinder outer cover through the joint nut 32. The top of 33 is fastened and connected (the piston rod of cylinder 46 is provided with external thread, and the top of piston cylinder housing 33 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com