Intelligent food detection and extraction workbench

A food detection and workbench technology, applied in the direction of testing food, material inspection products, preparation of samples for testing, etc., can solve problems such as unfavorable sample preservation, adverse effects on samples, affecting testing results, etc., to avoid ultrasonic blank areas, difficult Ultrasonic blank area, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

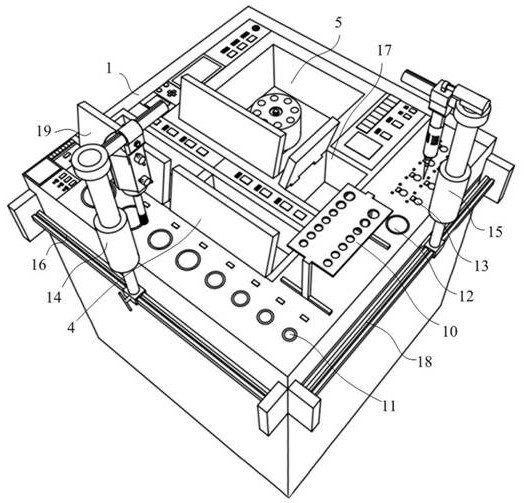

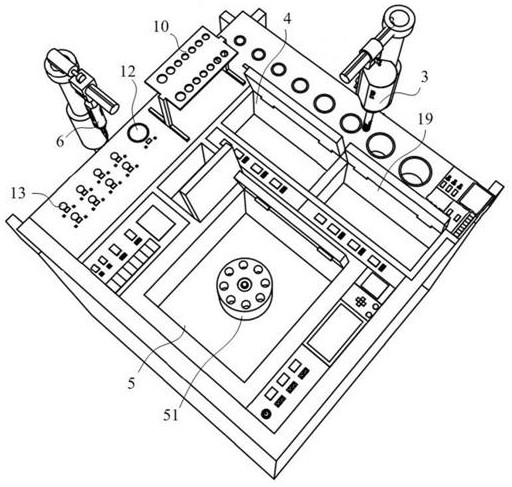

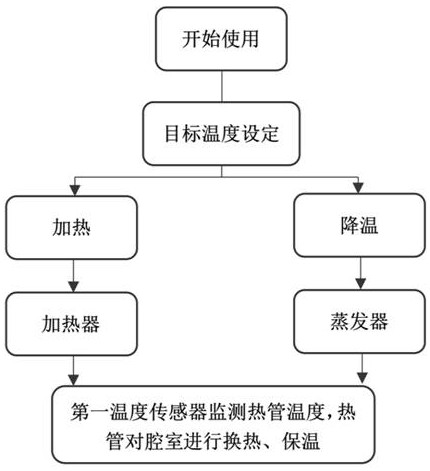

[0037] Such as figure 1 and figure 2 As shown, the present embodiment provides an embodiment of an intelligent food detection and extraction workbench 1, including a workbench 1 and a heat preservation mechanism, and the workbench 1 is provided with a homogenizer 3, an ultrasonic instrument 4, a centrifugal machine 5 and pipette 6, and is provided with a centrifuge tube accommodating cavity 11, a raw liquid tube accommodating cavity 12 and a liquid pipetting tube accommodating cavity 13, and the centrifuge tube accommodating cavity 11 is arranged to be more than two, and the The homogenizer 3 is arranged above the centrifuge tube accommodating cavity 11, and the workbench 1 is provided with a first lifting arm 14 for driving the homogenizer 3 to lift. The slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com