Preparation device and technology for producing high-quality liquid carbon dioxide

A technology for liquid carbon dioxide and preparation devices, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve problems such as affecting product quality, high operating costs, secondary air pollution, etc., and reduce equipment input costs and steam consumption. The effect of reducing, dehydration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

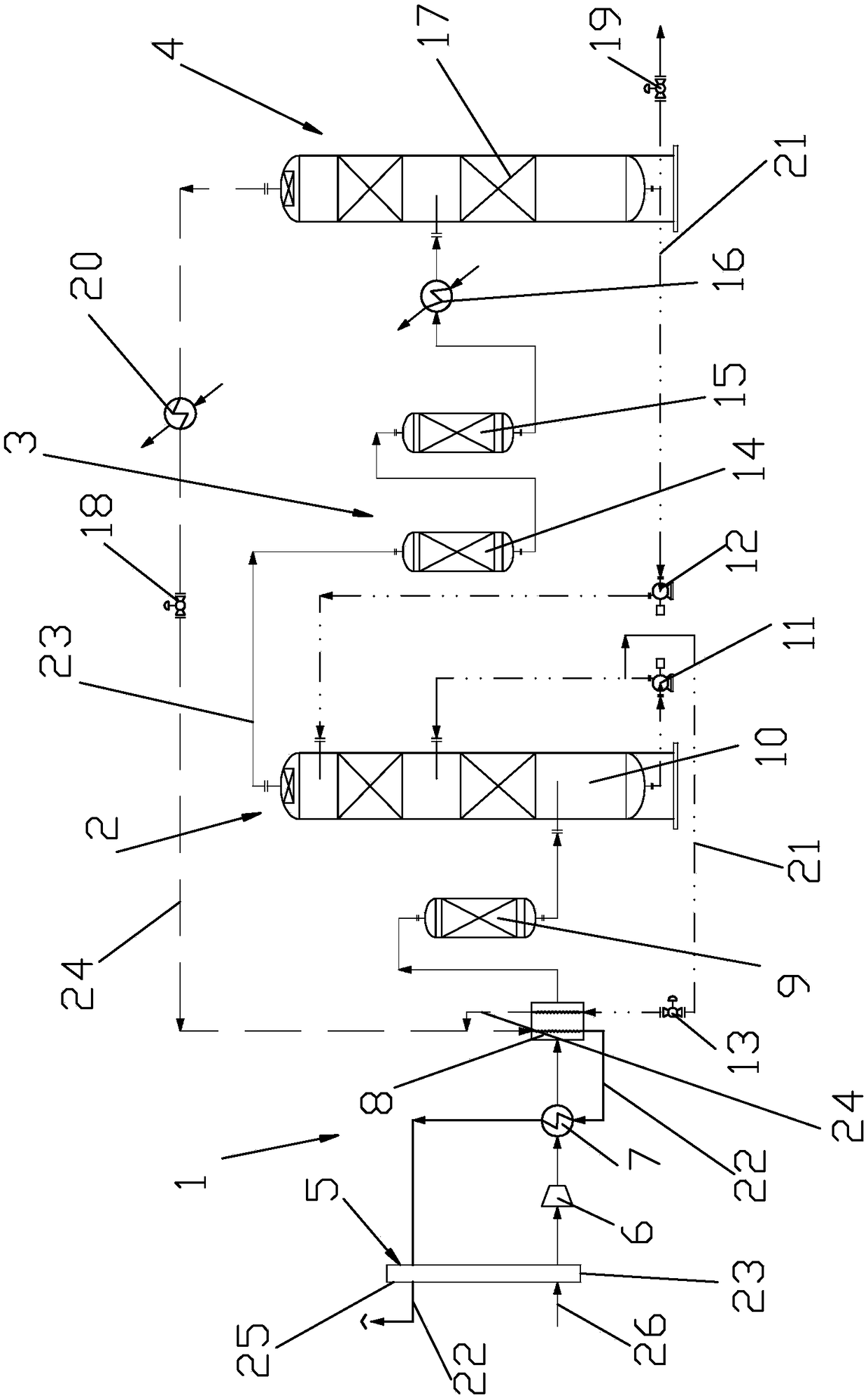

[0028] Such as figure 1 As shown, it is a preparation device for producing high-quality liquid carbon dioxide according to the present invention, including a drying system 1, a weight removal system 2, an impurity removal system 3 and a light removal system 4, and the drying system 1 includes a rotary dehumidifier 5 and a compressor 6 , heater 7, smoke cooler 8 and drier 9, rotary dehumidifier 5 includes dehumidification zone 25 and regeneration zone 26, smoke cooler 8, heater 7 and regeneration zone 26 are connected through regeneration gas pipeline 22, dehumidification zone 25 communicates with the compressor 6 through the raw gas pipeline 23, the compressor 6 communicates with the heater 7 through the raw gas pipeline 23, the heater 7 communicates with the smoke cooler 8 through the raw gas pipeline 23, and the smoke cooler 8 passes through the raw material The gas pipeline 23 is connected with the top of the drier 9. The weight removal system 2 includes a weight removal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com