Patents

Literature

36results about How to "Prevent massive decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium carbonate soil amendment and industrial filler derived from carpet backing

InactiveUS20090300982A1Enhanced agricultural soil amendment benefitPrevent massive decompositionPigmenting treatmentCultivating equipmentsParticulatesDecomposition

The calcium carbonate component of waste carpet is concentrated by mechanical means and / or chemical means then subjected to a heat treatment at a temperature below the decomposition temperature of calcium carbonate to volatilize or modify organic compounds admixed with calcium carbonate so as to yield a free-flowing particulate filler composed of at least about 70% calcium carbonate.

Owner:CHEM PROD CORP

Ammonium glyphosate soluble granule auxiliary and preparation method thereof

ActiveCN103828799APrevent massive decompositionImprove physical stabilityBiocideAnimal repellantsGlyphosateMixed materials

The invention discloses an ammonium glyphosate soluble granule auxiliary, which consists of the following components in parts by weight: 700 to 800 parts of ammonium glyphosate, 50 to 100 parts of ammonium sulfate, 100 to 120 parts of auxiliaries and 6 to 15 parts of water. A preparation method comprises the following technical steps: (1) adding the ammonium glyphosate and the ammonium sulfate into a mixer for mixing in the ratio; (2) crushing the uniformly mixed materials by a crusher, slowly and uniformly adding the auxiliaries into the mixed materials, adding water, and kneading the mixture to form a humid material without obvious blocks; (3) transferring the kneaded material to a granulator for granulation; (4) drying obtained soluble granules at the temperature of not more than 50 DEG C for 2 hours, and sieving the soluble granules by a sieve to obtain glyphosate soluble granule finished products.

Owner:长兴德源环保助剂有限公司

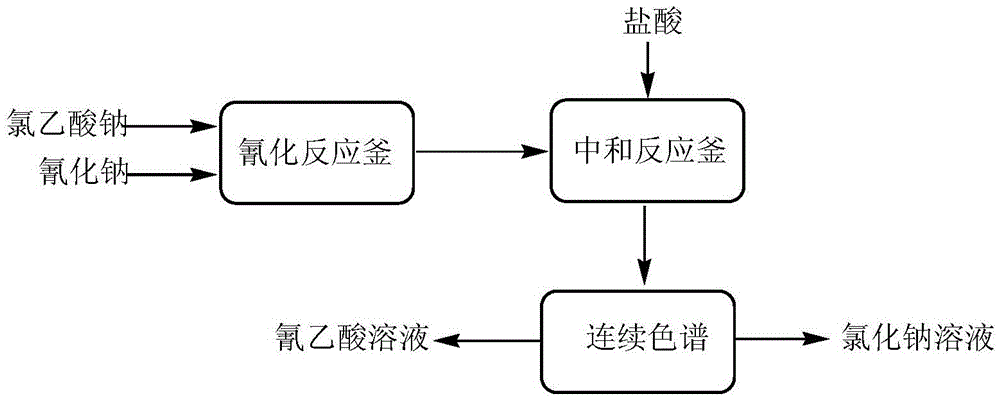

Preparation method for cyanoacetic acid and derivatives thereof

InactiveCN105481717APrevent massive decompositionEasy to operateOrganic compound preparationCarboxylic acid esters preparationDecompositionChromatographic separation

The invention discloses a preparation method for cyanoacetic acid and derivatives thereof. According to the invention, a mixed solution of cyanoacetic acid and sodium chloride is subjected to continuous chromatographic separation so as to obtain a cyanoacetic acid solution and sodium chloride; so the cyanoacetic acid solution with low chloride ion content or high-content solid cyanoacetic acid products and derivatives thereof are obtained, and the disadvantages of considerable decomposition and low yield of cyanoacetic acid in traditional distillation, concentration and separation are overcome. The preparation method is simple to operate, low in production cost, high in product yield and low in the amounts of waste gas, waste water and industrial residues, is an environment-friendly clean production method and can prepare the cyanoacetic acid solution with low chloride ion content or high-content solid cyanoacetic acid products and derivatives thereof.

Owner:CHONGQING UNISPLENDOUR CHEM

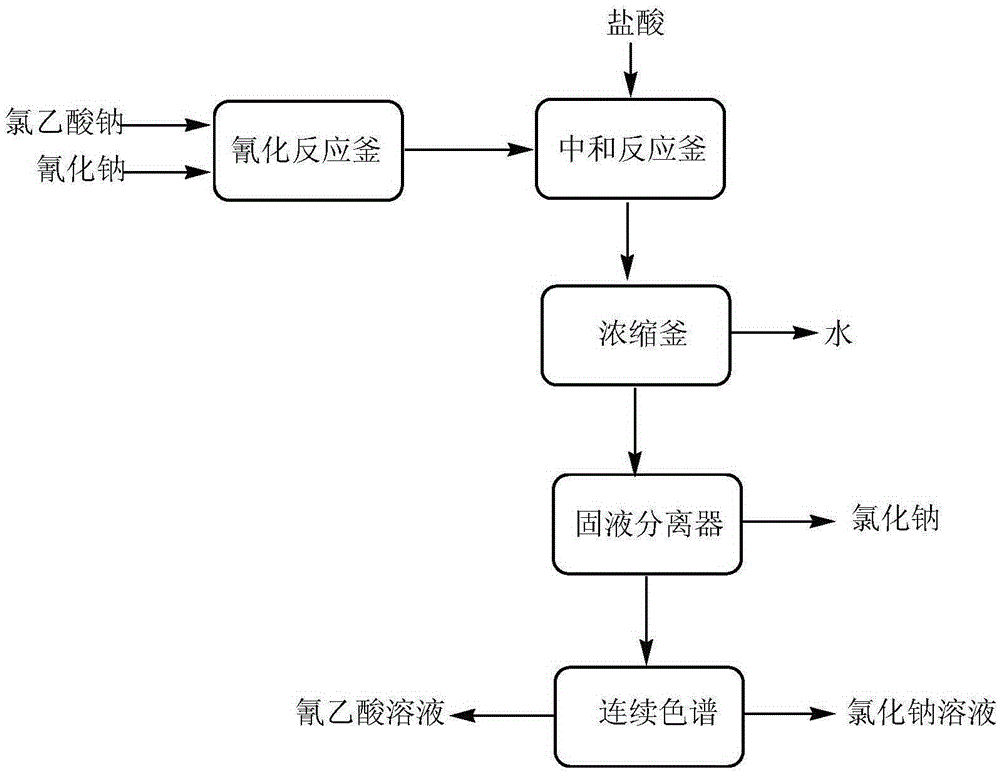

Preparation method of cyanoacetic acid and derivatives thereof

ActiveCN105294491APrevent massive decompositionAvoid Yield ProblemsOrganic compound preparationCarboxylic acid esters preparationDecompositionDesalination

The invention discloses a preparation method of cyanoacetic acid and derivatives thereof. Evaporation concentration of part of water in a mixture containing cyanoacetic acid and sodium chloride is carried out, and filtration is performed to remove the precipitated part of sodium chloride solids, thus avoiding the disadvantages of mass decomposition of cyanoacetic acid and low yield caused by the traditional distillation desalination, at the same time after desalination, the solution containing cyanoacetic acid and sodium chloride is separated into a cyanoacetic acid solution and a sodium chloride solution by continuous chromatography, thus avoiding decomposition in a cyanoacetic acid concentration process. The method provided by the invention has the advantages of simple operation, low production cost, high product yield and small amount of three wastes, and is a clean and environment-friendly production method, and can acquire a low chlorine ion content cyanoacetic acid solution or high content solid cyanoacetic acid product and derivatives thereof.

Owner:CHONGQING UNISPLENDOUR CHEM

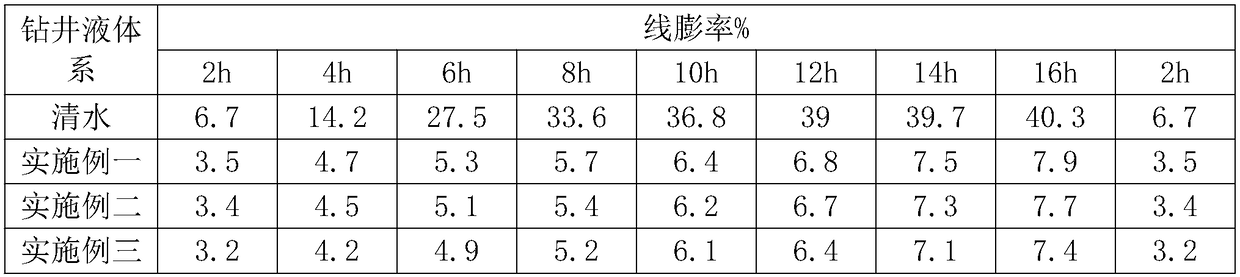

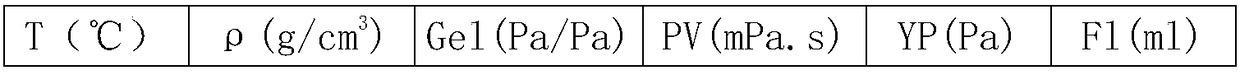

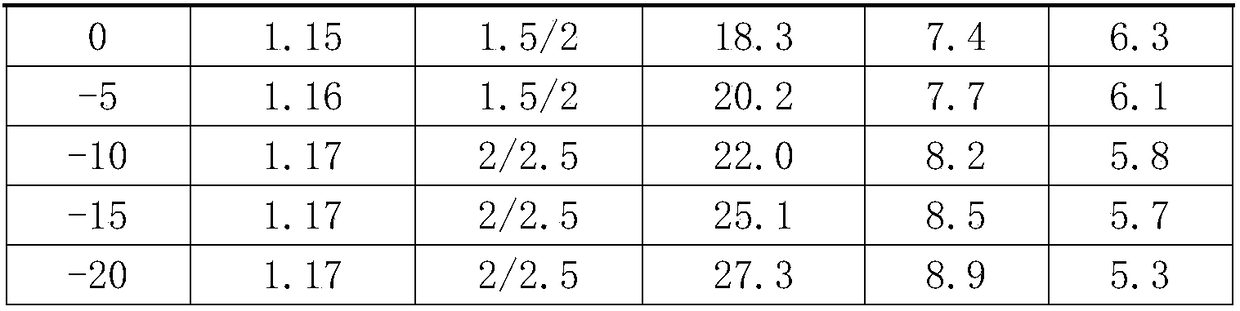

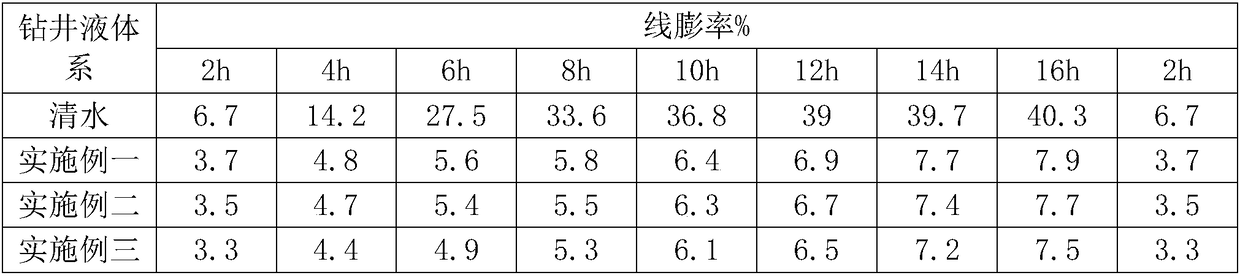

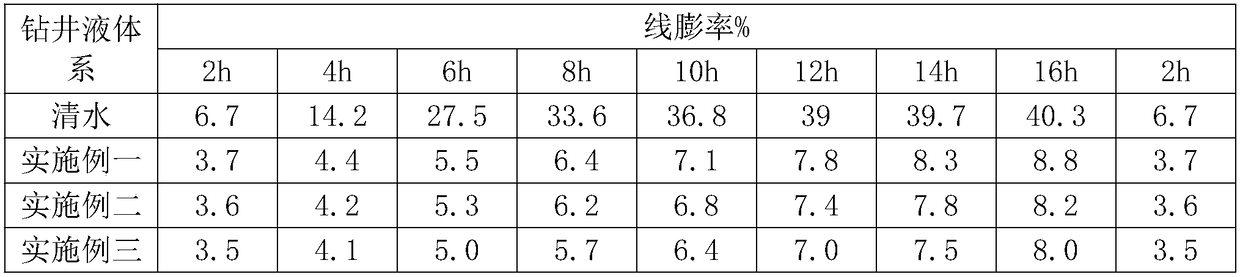

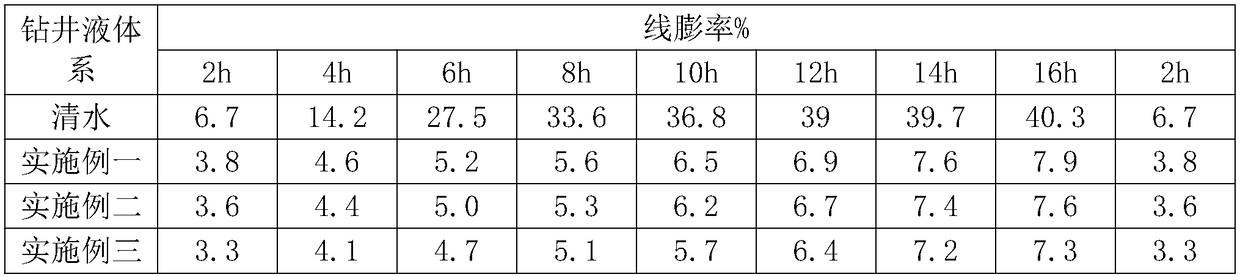

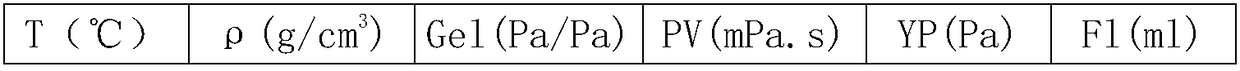

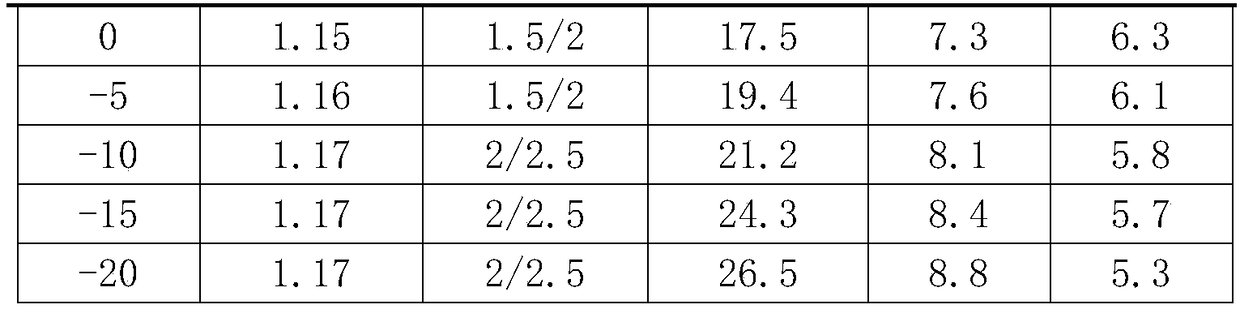

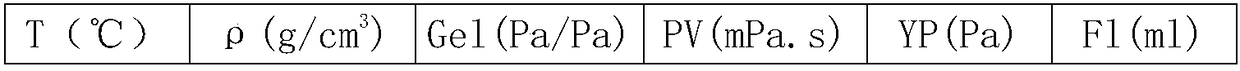

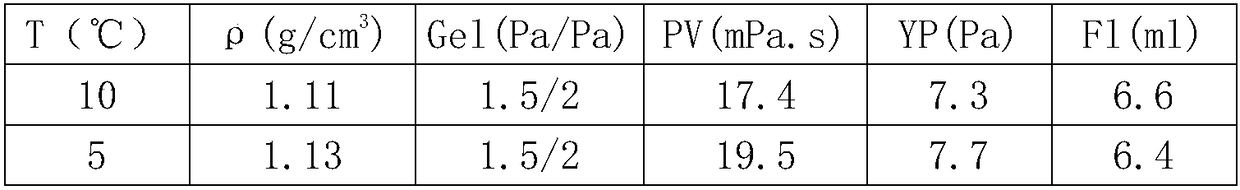

Frozen-soil hydrate deposit polyvinyl alcohol type drilling fluid

The invention discloses frozen-soil hydrate deposit polyvinyl alcohol type drilling fluid, and relates to the field of natural gas hydrate exploitation. The drilling fluid is prepared from the following components: polyvinyl alcohol, sodium chloride, methyl alcohol, ethylene glycol, sulfonated phenolic resin SMP-2, potassium humate, xanthan gum, polyvinylpyrrolidone K30, polyoxyethylene and prepared water. The frozen-soil hydrate storage polyvinyl alcohol type drilling fluid can be used for frozen-soil-layer natural gas hydrate deposit drilling, and has the effects of no solid phase and low temperature resistance; a kinetic inhibitor and a synergist are added into the drilling fluid for compounding, so that relatively strong hydrate generation inhibition effect is achieved; and moreover, the drilling fluid is small in environmental harm by components, and has the advantages of being efficient, environmentally friendly, adopting cheap and easily available raw materials, and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Natural gas hydrate storage compound drilling fluid for frozen earth region

The invention discloses a natural gas hydrate storage compound drilling fluid for a frozen earth region and relates to the field of exploration of natural gas hydrate. The drilling fluid comprises thefollowing components: polyethylene glycol, sodium chloride, ethylene glycol, low viscosity carboxymethylcellulose LV-CMC, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, butyl cellosolve,tetracaproyl trimethyl ammonium bromide and prepared water. The drilling fluid can be used for drilling the natural gas hydrate storage drilling of a frozen layer, and plays roles of being free of solid phases and low-temperature resistant. By adding a dynamic inhibitor into the drilling fluid to be compounded with a synergist, the drilling fluid has a relatively high hydrate generation inhibiting effect, and the components of the drilling fluid are small in environmental damage, so that the drilling fluid has the advantages of high efficiency, environmental protection, low cost of raw materials, easily available materials and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Energy-saving and emission-reducing sulfanilamide synthesis method and sulfanilamide

InactiveCN108395390AImprove conversion rateReduce dosageSulfonic acid amide preparationSulfonic acid preparationChlorosulfuric acidSynthesis methods

The invention relates to an energy-saving and emission-reducing sulfanilamide synthesis method and sulfanilamide, and belongs to the field of sulfanilamide synthesis. The synthesis method comprises the steps of with existence of phosphorus pentoxide, carrying out sulfonation reaction on a mixture of chlorosulfonic acid and carbon tetrachloride and acetanilide for multiple times, and degassing after sulfonation reaction every time; sequentially carrying out chlorination reaction, ammonization reaction and hydrolysis reaction. The molar ratio of chlorosulfonic acid to acetanilide is (2.75 to 3.25):1, and the volume ratio of chlorosulfonic acid to carbon tetrachloride is 1:(1.0 to 1.2). Each degassing operation is characterized by filling an inert gas into a reaction liquid at the speed of 0.3 to 0.5L / min per litter of solution, and extracting the air at the speed of 0.6 to 1.0L / min per litter of solution. The raw materials are thoroughly reacted, the dosage of the chlorosulfonic acid isless, the product yield is high, hydrogen chloride is fully recovered, and the discharge amount is reduced. The sulfanilamide prepared through the synthesis method is environmental-friendly in process, high in purity and low in cost.

Owner:新乡市锦源化工有限公司

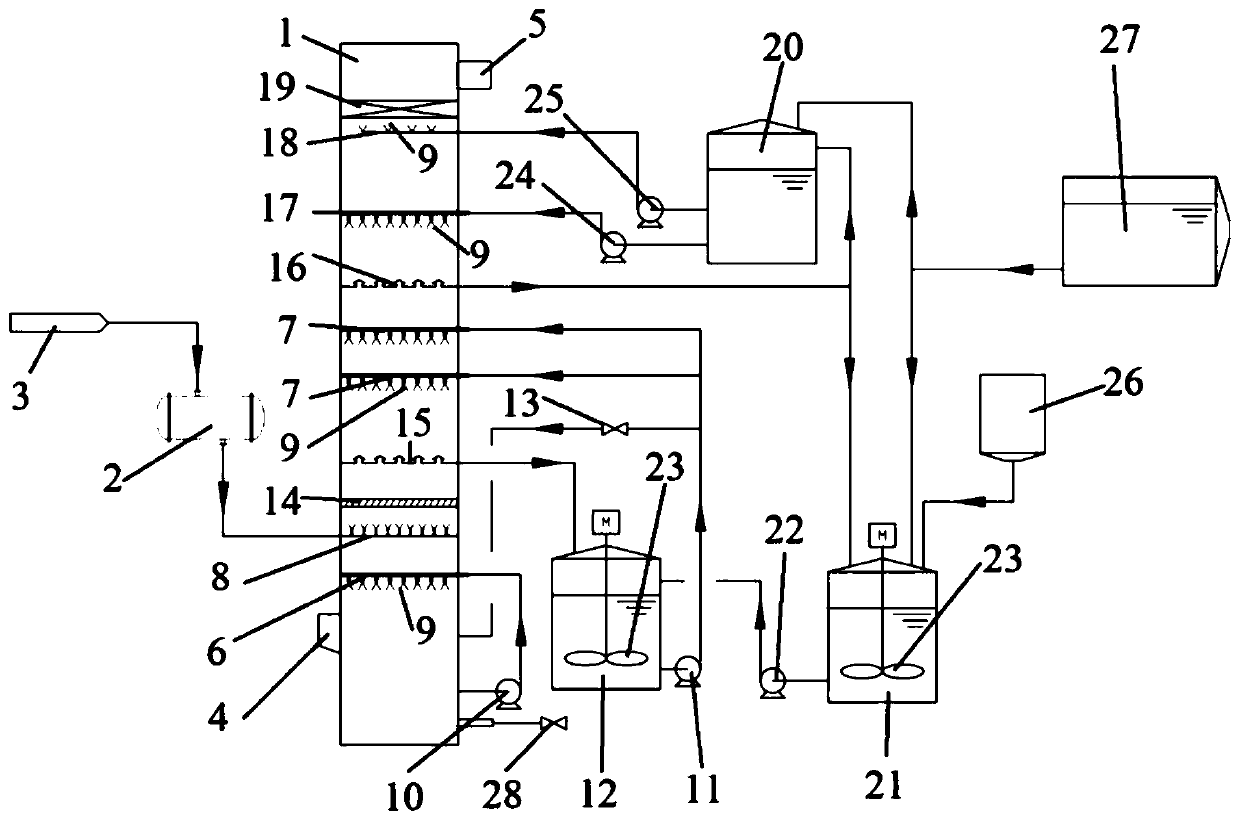

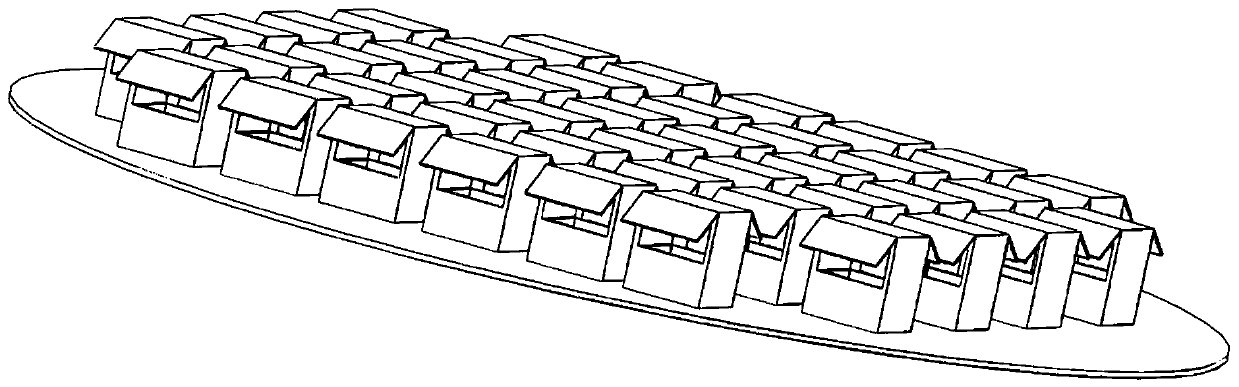

Cotreatment device for ship tail gas pollutants

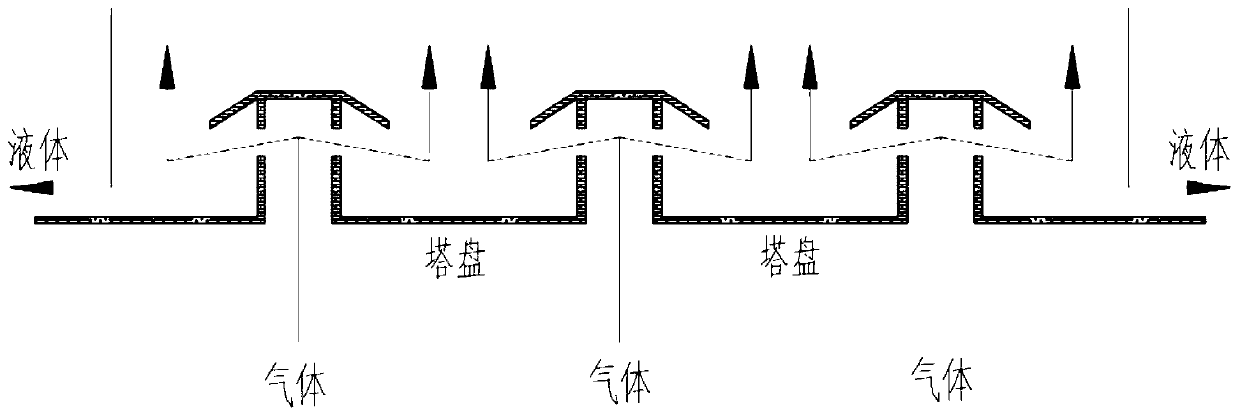

PendingCN110385027APrevent massive decompositionWill not occupyGas treatmentDispersed particle separationDecompositionSpiral flow

The invention provides a cotreatment device for ship tail gas pollutants. The cotreatment device comprises an absorption tower and an ozone generator connected with the absorption tower, wherein an air source is connected with and arranged on the ozone generator; one end of the absorption tower is connected with a tail gas inlet; the other end of the absorption tower is connected with a tail gas outlet; a cooling layer and an absorption layer are arranged in the absorption tower along the moving direction of tail gas; and an ozone ejector is arranged between the cooling layer and the absorption layer. According to the invention, the ozone ejector is located in the absorption tower and between the cooling layer and a spiral-flow plate; ship tail gas with a high temperature enters the tail gas inlet located in the bottom of the absorption tower, and contacts with cooling water sprayed from the cooling layer, so decomposition of a large amount of ozone is avoided; the ship tail gas then passes through the absorption layer along the flowing direction of the tail gas, and nitrogen oxides and sulfur dioxide in the tail gas are absorbed by magnesium hydroxide; the ship tail gas passes through a second column tray to contact with seawater sprayed from a water washing layer, and the nitrogen oxides and sulfur dioxide are further washed and absorbed; and water mist is intercepted by a demister, so treated ship tail gas is finally discharged from the tail gas outlet located at the top of the absorption tower.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Compound drilling fluid for natural gas hydrate (NGH) reservoir in siltstone

InactiveCN108611073AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPotassiumCaprolactam

The invention discloses a compound drilling fluid for natural gas hydrate (NGH) reservoir in siltstone, and relates to the field of NGH exploitation. The drilling fluid comprises following components:sodium formate, sodium chloride, glycol, potassium chloride, potassium humate, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, ethylene glycol butyl ether, tetra-n-butyl ammonium phosphate, and make-up water. The drilling fluid is suitable for NGH drill wells in siltstone reservoir, is resistant to low temperature, and can inhibit and reduce the solid phase. The drilling fluid is compounded with a kinetic inhibitor and a synergist to inhibit the generation of hydrates. Moreover, the components of the drilling fluid are basically harmless to the environment, and the drilling fluidhas the advantages that the efficiency is high, the environment is protected, and the raw materials are cheap and easily available.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

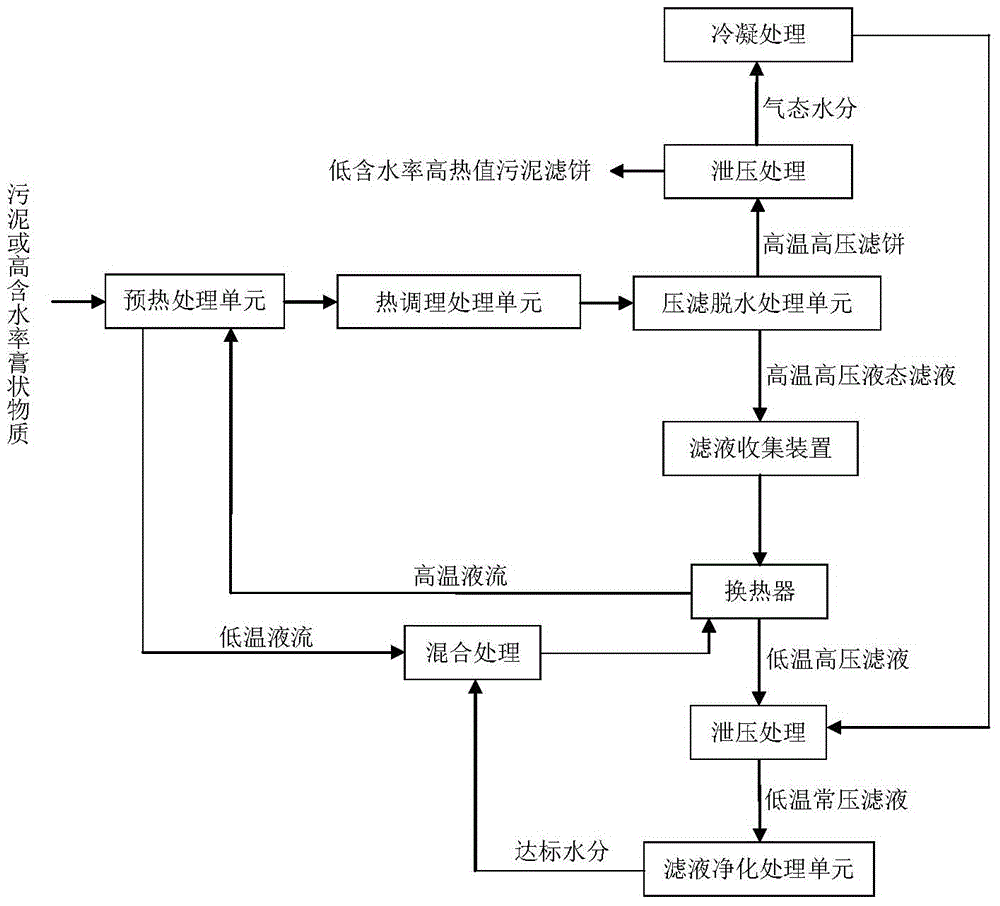

A deep dehydration method for sludge-like substances based on thermal conditioning coupled with filter press

ActiveCN103508648BPrevent massive decompositionInhibition of caramelization reactionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisHydrothermal reactionRaised temperature

The invention relates to a sludge substance deep dehydrating method based on thermal conditioning coupling filter pressing, belongs to the field of sludge treatment, is suitable for dehydration of various kinds of sludge, and particularly suitable for dehydration of surplus sludge. The method comprises the following steps: firstly carrying out heat exchange to a high temperature filtrate and the sludge, injecting the sludge with the raised temperature in a thermal conditioning processing unit, and performing a sufficient hydrothermal reaction at 120-250 DEG C; then immediately performing filter processing and dehydrating under the pressure to remove the moisture in a liquid state; at last, decompressing the high temperature sludge filter cake with pressure, further steaming and dehydrating with the sludge own high temperature and heat, so as to improve the dehydrating efficiency. The dehydrating method can improve sludge structure, physicochemical property and moisture distribution, save and fully utilize the heat, realize high-dryness and low-energy consumption dehydration of sludge, and improve the recycling value of the sludge.

Owner:DALIAN UNIV OF TECH

A kind of glyphosate ammonium salt soluble granule and preparation method thereof

ActiveCN103828799BPrevent massive decompositionImprove physical stabilityBiocideAnimal repellantsGlyphosateMixed materials

The invention discloses an ammonium glyphosate soluble granule auxiliary, which consists of the following components in parts by weight: 700 to 800 parts of ammonium glyphosate, 50 to 100 parts of ammonium sulfate, 100 to 120 parts of auxiliaries and 6 to 15 parts of water. A preparation method comprises the following technical steps: (1) adding the ammonium glyphosate and the ammonium sulfate into a mixer for mixing in the ratio; (2) crushing the uniformly mixed materials by a crusher, slowly and uniformly adding the auxiliaries into the mixed materials, adding water, and kneading the mixture to form a humid material without obvious blocks; (3) transferring the kneaded material to a granulator for granulation; (4) drying obtained soluble granules at the temperature of not more than 50 DEG C for 2 hours, and sieving the soluble granules by a sieve to obtain glyphosate soluble granule finished products.

Owner:长兴德源环保助剂有限公司

Drilling fluid suitable for natural gas hydrate (NGH) reservoir in frozen soil area

InactiveCN108611076AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPotassiumPolyvinylpyrrolidone

The invention discloses a drilling fluid suitable for natural gas hydrate (NGH) reservoir in a frozen soil area, and relates to the field of NGH exploitation. The drilling fluid comprises following components: sodium formate, sodium chloride, methanol, glycol, low viscosity carboxymethyl cellulose (LV-CMC), potassium humate, xanthan gum, polyvinylpyrrolidone K30, polyvinyl methyl ether, and make-up water. The drilling fluid is suitable for drill wells in NGH reservoir in a frozen soil layer, does not contain any solid phase, and is resistant to low temperature. The drilling fluid is compoundedwith a kinetic inhibitor and a synergist to inhibit the generation of hydrates. Moreover, the components of the drilling fluid are basically harmless to the environment, and the drilling fluid has the advantages that the efficiency is high, the environment is protected, and the raw materials are cheap and easily available.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Production process of ultra-clean high-purity hydrogen peroxide

ActiveCN113636526AHigh purityQuality improvementPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhysical chemistryElectronic industry

The invention discloses a production process of ultra-clean high-purity hydrogen peroxide, and relates to the technical field of chemical engineering, and the production process comprises the following steps: (1) oxidizing industrial hydrogen peroxide to obtain oxidized hydrogen peroxide, wherein the oxidizing sequentially comprising discharge of inert gas and oxidation of an oxidizing agent; (2) filtering the obtained oxidized hydrogen peroxide by using exchange resin to obtain resin filtered hydrogen peroxide; and (3) carrying out micro-filtration treatment on the resin filtered hydrogen peroxide by adopting a filter membrane, wherein filtrate obtained by filtration is high-purity hydrogen peroxide. The industrial hydrogen peroxide is treated by the process disclosed by the invention, the purity of the industrial hydrogen peroxide can be greatly improved, so that the industrial hydrogen peroxide can be better applied to a cleaning agent, a corrosive agent and a photoresist remover of a semiconductor crystal wafer, preparation of a high-grade insulating layer in the electronic industry and removal of inorganic impurities in an electroplating solution, the effect is remarkable, and the product quality is improved.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Drilling fluid suitable for marine natural gas hydrate reservoir

InactiveCN108359422AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPotassiumPolyvinylpyrrolidone

The invention discloses drilling fluid suitable for a marine natural gas hydrate reservoir, and relates to the field of mining of natural gas hydrate. The drilling fluid is prepared from the followingcomponents: sodium formate, sodium chloride, methanol, ethylene glycol, potassium chloride, low-viscosity carboxymethyl cellulose LV-CMC, potassium humate, xanthan gum, polyvinylpyrrolidone K30, polyvinyl methyl ether and prepared water. The drilling fluid disclosed by the invention can be used for drilling the marine natural gas hydrate reservoir and has solid-free and low temperature-resistantfunctions, the drilling fluid has a stronger hydrate generation inhibiting effect through adding a kinetic inhibitor and a synergist for compounding, components of the drilling fluid have small harm to environment, and the drilling fluid has the advantages that the efficiency is high, environmental protection is realized, raw materials are low in cost and easy to obtain, and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

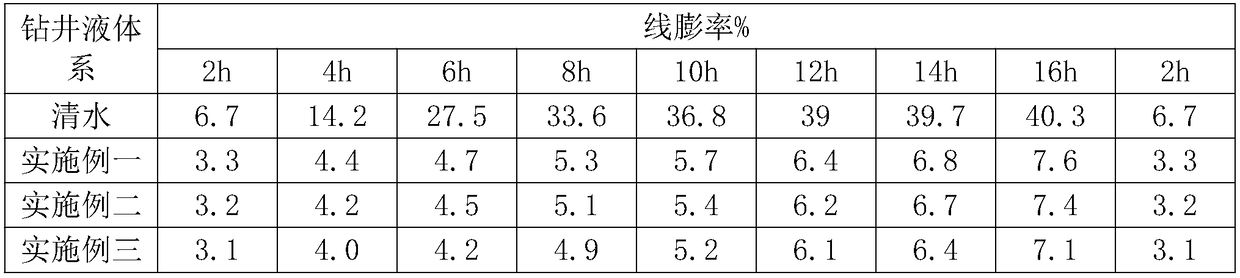

Method and device for removing light components in trioxymethylene

ActiveCN102633770BReduce partial pressureEfficient removalOrganic chemistryFractional distillationPolyoxymethylenePhysical chemistry

The invention discloses a method and a device for removing light components in trioxymethylene, which belong to the technical field of purification of trioxymethylene. The method includes the following steps of firstly, feeding extracted trioxymethylene, benzene and small amount of mixture of water and organic matter into a light component removing tower to remove light components, returning to extraction process after gas on the top of the light component removing tower is condensed and cooled; and secondly; feeding trioxymethylene at the bottom of the light component removing tower and small amount of mixture of water, methyl alcohol, formaldehyde, formic acid and the like to be stripped in a stripper. By adding the stripper, temperature at the bottom of the light component removing tower and backflow ratio can be reduced by the additional stripping process, energy consumption is reduced greatly, trioxymethylene can be prevented from being decomposed greatly, and purity of trioxymethylene can be improved effectively.

Owner:XINGTAI RISUN COAL CHEM IND

Method for preparing slow release-type tebuthiuron granular herbicide

InactiveCN106376559APrevent massive decompositionReduce pollutionBiocideAnimal repellantsAdhesiveDistillation

The invention belongs to the field of pesticide, and especially relates to a method for preparing a slow release-type tebuthiuron granular herbicide. The method comprises the following steps: dissolving tebuthiuron in a lower boiling organic solvent; taking expanded vermiculite and zeolite, crushing the materials to mixed carrier powder with 20-325 mesh; adding the mixed carrier powder in a tebuthiuron solution to obtain tebuthiuron-carrier powder mixed liquor; adding the tebuthiuron-carrier powder mixed liquor in an adhesive, continuously stirring the materials for 0.1-0.6 h until the materials are uniformly mixed; performing underpressure distillation on the tebuthiuron-carrier powder mixed liquor after being uniformly mixed with the adhesive, granulating the obtained solid to obtain the tebuthiuron-carrier powder particles; and performing reduced pressure distillation to recover the organic solvent to obtain the slow release-type tebuthiuron granular herbicide. The method has the following advantages that 1) the chemical and physical stability is good, massive decomposition of an original drug can be avoided; 2) security is good, pollution on environment is little, processing, storage and transport are convenient; and 3) tebuthiuron can be continuously and uniformly released to perform continuous weeds removing effect.

Owner:YANCHENG SOUTH CHEM

Polyvinyl alcohol compound drilling fluid for natural gas hydrate (NGH) reservoir in frozen soil area

InactiveCN108611078AStable in natureImprove rheologyDrilling compositionPolyvinyl alcoholPhenyl Ethers

The invention discloses a polyvinyl alcohol compound drilling fluid for natural gas hydrate (NGH) reservoir in a frozen soil area, and relates to the field of NGH exploitation. The drilling fluid comprises following components: polyvinyl alcohol, sodium chloride, methanol, glycol, sulfonated phenolic resin (SMP-2), potassium humate, xanthan gum, polyvinylpyrrolidone K-90, propylene glycol phenyl ether, polyvinyl methyl ether, and make-up water. The drilling fluid is suitable for NGH drill wells in a frozen soil layer, does not contain any solid phase, and is resistant to low temperature. The drilling fluid is compounded with a kinetic inhibitor and a synergist to inhibit the generation of hydrates. Moreover, the components of the drilling fluid are basically harmless to the environment, and the drilling fluid has the advantages that the efficiency is high, the environment is protected, and the raw materials are cheap and easily available.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Compound polyvinyl alcohol drilling fluid applied to storage of hydrates in frozen soil layers

The invention provides compound polyvinyl alcohol drilling fluid applied to storage of hydrates in frozen soil layers and relates to the field of exploitation of natural gas hydrates. The drilling fluid comprises the following components: polyvinyl alcohol, sodium chloride, ethylene glycol, sulfonated phenolic resin SMP-2, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, ethylene glycoldiethyl ether, tetrahexamethyltrimethyl ammonium bromide and prepared water. The drilling fluid is capable of being applied to drilling with storage of the natural gas hydrates in the frozen soil layers, is free of solid phase and has resistance to low temperature; a kinetic inhibitor is added into the drilling fluid and is compounded with a synergist; the drilling fluid has an excellent effect of inhibiting generation of hydrates; meanwhile, the components of the drilling fluid are low in harm to the environment; and the drilling fluid has the advantages of high efficiency, environment friendliness and cheap and easily available raw materials.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Marine hydrate storage polyvinyl alcohol type drilling fluid

InactiveCN108441189AStable in natureGood rheologyDrilling compositionSolid phasesEnvironmental chemistry

The invention discloses marine hydrate storage polyvinyl alcohol type drilling fluid and relates to the field of natural gas hydrate production. The drilling fluid is prepared from the following components including polyvinyl alcohol, sodium chloride, methanol, potassium chloride, ethylene glycol, sulfonated phenolic resin SMP-2, potassium humate, xanthan gum, polyvinylpyrrolidone K30, polyvinyl methyl ether and prepared water. The drilling fluid can be used for marine natural gas hydrate storage drilling, has the effects of no solid phase and low temperature resistance, has stronger hydrate generation inhibition effect by adding a kinetic inhibitor for compounding with a synergist and has the advantages of high efficiency, environmental protection, cheapness and availability in raw materials and the like as the components of the drilling fluid are small in environmental harm.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Complex frozen soil hydrate storage polyvinyl alcohol drilling fluid

InactiveCN108441192AStable in natureImprove rheologyDrilling compositionPolyethylene oxidePhenyl Ethers

The invention discloses complex frozen soil hydrate storage polyvinyl alcohol drilling fluid, and relates to the field of natural gas hydrate exploitation. The drilling fluid is prepared from the following components: polyvinyl alcohol, sodium chloride, ethylene glycol, sulfonated phenolic resin SMP-2, potassium polyacrylate, xanthan gum, polyvinylpyrrolidone K90, polyethylene oxide, propylene glycol phenyl ether and prepared water. The drilling fluid can be used for frozen soil layer natural gas hydrate storage drilling, and has the effects of no solid phase and low-temperature resistance. The drilling fluid has higher hydrate generation and inhibition effects by compounding an added kinetic inhibitor with a synergist; in addition, the components of the drilling fluid have little hazard to the environment and have the advantages of high efficiency, environment friendliness, low-priced and easily-obtained raw materials and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Silty mudstone natural gas hydrate storage compound type drilling fluid

InactiveCN108359420AReduce and prevent repeated breakageImprove rheologyDrilling compositionPotassiumPolyethylene glycol

The invention discloses silty mudstone natural gas hydrate storage compound type drilling fluid, and relates to the field of natural gas hydrate exploitation. The drilling fluid is prepared from the following components: polyethylene glycol, sodium chloride, ethylene glycol, potassium chloride, potassium humate, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, polyvinyl methyl ether, tetrahexyltrimethyl ammonium bromide and prepared water. The silty mudstone natural gas hydrate storage compound type drilling fluid can be used for silty mudstone natural gas hydrate storing and drilling, has the effects of resisting a low temperature, inhibiting and reducing the solid phase; a kinetic inhibitor and a synergist are added into the drilling fluid for compounding, so that relatively strong hydrate generation inhibition effect is achieved; and moreover, the drilling fluid is small in environmental harm by components, and has the advantages of being efficient, environmentally friendly, adopting cheap and easily available raw materials, and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Marine facies natural gas hydrate storage compound drilling fluid

InactiveCN108251081AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPhenyl EthersPotassium

The invention discloses marine facies natural gas hydrate storage compound drilling fluid and relates to the field of exploitation of natural gas hydrate. The drilling fluid is prepared from the following components: sodium formate, sodium chloride, methyl alcohol, ethylene glycol, potassium chloride, low viscosity carboxymethyl cellulose (LV-CMC), potassium humate, xanthan gum, polyvinyl caprolactam, propylene glycol phenyl ether, tetrahexamethyltrimethylammonium bromide and prepared water; the drilling fluid can be used for marine facies natural gas hydrate storage drilling and has the effects of no solid phase and low temperature resistance. By adding a kinetic inhibitor and a synergist for compounding, the drilling fluid has a stronger hydrate formation inhibition effect; in addition,the drilling fluid components have little damage to the environment; the drilling fluid has the advantages of high efficiency, environment friendliness, low-priced and easily-obtained raw materials and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Compound drilling fluid for natural gas hydrate (NGH) reservoir in silt mudstone

The invention relates to a compound drilling fluid for natural gas hydrate (NGH) reservoir in silt mudstone, and relates to the field of NGH exploitation. The drilling fluid comprises following components: polyethylene glycol, sodium chloride, glycol, potassium chloride, low viscosity carboxymethyl cellulose (LV-CMC), potassium polyacrylate, xanthan gum, polyvinylpyrrolidone K90, polyvinyl methylether, and make-up water. The drilling fluid is suitable for NGH drill wells in silt mudstone reservoir, is resistant to low temperature, and can inhibit and reduce the solid phase. The drilling fluidis compounded with a kinetic inhibitor and a synergist to inhibit the generation of hydrates. Moreover, the components of the drilling fluid are basically harmless to the environment, and the drilling fluid has the advantages that the efficiency is high, the environment is protected, and the raw materials are cheap and easily available.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Preparation method of slow-release imazapyr particles

InactiveCN106359389AGood chemical and physical stabilityPrevent massive decompositionBiocideAnimal repellantsDrugPhysical stability

The invention belongs to the field of pesticide, and in particular relates to a preparation method of slow-release imazapyr. The preparation method comprises the following steps: dissolving the imazapyr in the low boiling organic solvent; taking the expanded vermiculite and the zeolite, grinding into 20 to 325 meshes of mixed carrier powder; adding the mixed carrier powder into the imazapyr solution to obtain the mixture solution of the imazapyr and carrier powder; adding binder into the mixture solution of the imazapyr and carrier powder and stirring for 0.1 to 6 hours until the mixing is uniform; and then distilling the mixture solution of the imazapyr and carrier powder under the reduced pressure after being mixed with binder uniformly to obtain solid particles and imazapyr-carrier powder particles; distilling under the reduced pressure to recover organic solvent and obtain the slow-release imazapyr particles. The preparation method has the following advantages: 1, chemical and physical stability is good to avoid a lot of decomposition of the original drug; safety is good, the environmental pollution is easy to process, store and transport; 3, continuous release of imazapyr plays a sustained weed control effect.

Owner:YANCHENG SOUTH CHEM

Compound drilling fluid applied to storage of natural gas hydrates in frozen soil areas

InactiveCN108359425AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPolyethylene oxidePotassium

The invention provides compound drilling fluid applied to storage of natural gas hydrates in frozen soil areas and relates to the field of exploitation of natural gas hydrates. The drilling fluid comprises the following components: sodium formate, sodium chloride, ethylene glycol, low-viscosity carboxymethyl cellulose LV-CMC, potassium polyacrylate, xanthan gum, polyvinylpyrrolidone K90, polyethylene oxide, polyvinyl methyl ether and prepared water. The drilling fluid is capable of being applied to drilling with storage of the natural gas hydrates in frozen soil layers, is free of solid phaseand has resistance to low temperature; a kinetic inhibitor is added into the drilling fluid and is compounded with a synergist; the drilling fluid has an excellent effect of inhibiting generation of hydrates; meanwhile, the components of the drilling fluid are low in harm to the environment; and the drilling fluid has the advantages of high efficiency, environment friendliness and cheap and easilyavailable raw materials.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Drilling fluid for marine natural gas hydrate (NGH) reservoir

The invention discloses a drilling fluid for marine natural gas hydrate (NGH) reservoir, and relates to the field of NGH exploitation. The drilling fluid comprises following components: sodium silicate, sodium chloride, glycol, potassium humate, potassium polyacrylate, xanthan gum, polyvinylpyrrolidone K90, propylene glycol monomethyl ether, mono-n-butyl glycol ether, and make-up water. The drilling fluid is suitable for NGH drill wells in the sea, does not contain any solid phase, and is resistant to low temperature. The drilling fluid is compounded with a kinetic inhibitor and a synergist toinhibit the generation of hydrates. Moreover, the components of the drilling fluid are basically harmless to the environment, and the drilling fluid has the advantages that the efficiency is high, the environment is protected, and the raw materials are cheap and easily available.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Compound type frozen soil natural gas hydrate reservoir drilling fluid

The invention provides compound type frozen soil natural gas hydrate reservoir drilling fluid and relates to the field of exploitation of natural gas hydrate. The drilling fluid is prepared from the following components: sodium silicate, sodium chloride, ethylene glycol, potassium humate, potassium polyacrylate, xanthan gum, polyvinylpyrrolidone K90, ethylene glycol ethyl ether, mono-n-butyl ethylene glycol ether and preparation water; the drilling fluid can be used for drilling the frozen soil layer natural gas hydrate reservoir and has solid-phase-free and low-temperature-resisting effects;a kinetic inhibitor and a synergist are added into the drilling fluid and are compounded so that the drilling fluid has a relatively strong hydrate generation inhibition effect; the components of thedrilling fluid have small dangers to environment and the drilling fluid has the advantages of high efficiency, environment protection, low-price and easy-to-obtain raw materials and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Natural gas hydrate storage compound drilling fluid for frozen earth region

InactiveCN108728060AEnhanced inhibitory effectReduce the degree of leakageDrilling compositionPotassiumCaprolactam

The invention discloses a natural gas hydrate storage compound drilling fluid for a frozen earth region, relating to the field of exploration of natural gas hydrate. The drilling fluid comprises the following components: sodium formate, sodium chloride, ethylene glycol, potassium humate, potassium polyacrylate, xanthan gum, polyvinyl caprolactam, ethylene glycol diethyl ether, tetracaproyl trimethyl ammonium bromide and prepared water. The drilling fluid can be used for drilling the natural gas hydrate storage drilling of a frozen layer, and plays roles of being free of solid phases and low-temperature resistant. By adding a dynamic inhibitor into the drilling fluid to be compounded with a synergist, the drilling fluid has a relatively high hydrate generation inhibiting effect, and the components of the drilling fluid are small in environmental damage, so that the drilling fluid has the advantages of high efficiency, environmental protection, low cost of raw materials, easily availableraw materials and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Compound polyvinyl alcohol drilling fluid for marine hydrate reservoirs

The invention discloses compound polyvinyl alcohol drilling fluid for marine hydrate reservoirs, and relates to the field of natural gas hydrate mining. The drilling fluid is prepared from the following components: polyvinyl alcohol, sodium chloride, methyl alcohol, ethylene glycol, sulfonated phenolic resin SMP-2, potassium humate, xanthan gum, polyvinyl caprolactam, polyvinyl methyl ether, tetra-n-hexyltrimethyl ammonium bromide and prepared water, can be applied to drilling of submarine natural gas hydrate reservoirs, and has the characteristics of freeness from solid phase and low temperature resistance; a kinetic inhibitor and a synergist are added into the drilling fluid for compounding, so that the drilling fluid has a better hydrate generation inhibition effect; moreover, the drilling fluid components have little harm to the environment, so that the drilling fluid has the advantages of high efficiency, environmental friendliness, cheap and readily-available raw materials and the like.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Compound drilling fluid applied to deposit of natural gas hydrates in seafloor

InactiveCN108359430AReduce and prevent repeated breakageImprove rheologyDrilling compositionOcean bottomPhenyl Ethers

The invention provides compound drilling fluid applied to deposit of natural gas hydrates in the seafloor and relates to the field of exploitation of natural gas hydrates. The drilling fluid comprisesthe following components: polyethylene glycol, sodium chloride, methyl alcohol, ethylene glycol, potassium humate, xanthate gum, polyvinylpyrrolidone K90, propylene glycol phenyl ether, polyvinyl methyl ether and prepared water. The drilling fluid is capable of being applied to drilling with deposit of the natural gas hydrates in the seafloor, is free of solid phase and has resistance to low temperature; a kinetic inhibitor is added into the drilling fluid and is compounded with a synergist; the drilling fluid has an excellent effect of inhibiting generation of hydrates; meanwhile, the components of the drilling fluid are low in harm to the environment; and the drilling fluid has the advantages of high efficiency, environment friendliness and cheap and easily available raw materials.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com