Drilling fluid for marine natural gas hydrate (NGH) reservoir

A drilling fluid and natural gas technology, applied in the field of drilling fluid, can solve the problems of fracture pressure reduction, temperature and pressure condition damage, well wall easy to collapse and fracturing, etc., to improve the inhibition effect of hydrate formation, reduce and prevent repeated crushing, Avoids the effect of severe pore size enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In Example 1, the content of each component in the drilling fluid is as follows: the mass ratio of sodium silicate is 2.8%, the mass ratio of sodium chloride is 14%, the mass ratio of ethylene glycol is 9%, and the mass ratio of potassium humate is 1.8%. The mass ratio of potassium polyacrylate is 1.8%, the mass ratio of xanthan gum is 0.4%, the mass ratio of polyvinylpyrrolidone K90 is 0.8%, the mass ratio of propylene glycol monomethyl ether is 0.8%, and the mass ratio of mono-n-butyl glycol ether is 0.8 %, the remaining component is prepared water.

Embodiment 2

[0035] In the second embodiment, the content of each component in the drilling fluid is: the mass ratio of sodium silicate is 3%, the mass ratio of sodium chloride is 15%, the mass ratio of ethylene glycol is 10%, the mass ratio of potassium humate is 2%, The mass ratio of potassium polyacrylate is 2%, the mass ratio of xanthan gum is 0.5%, the mass ratio of polyvinylpyrrolidone K90 is 1%, the mass ratio of propylene glycol monomethyl ether is 1%, and the mass ratio of mono-n-butyl glycol ether is 1 %, the remaining component is prepared water.

Embodiment 3

[0036] In the third embodiment, the content of each component in the drilling fluid is: the mass ratio of sodium silicate is 3.2%, the mass ratio of sodium chloride is 16%, the mass ratio of ethylene glycol is 11%, and the mass ratio of potassium humate is 2.2%. The mass ratio of potassium polyacrylate is 2.2%, the mass ratio of xanthan gum is 0.6%, the mass ratio of polyvinylpyrrolidone K90 is 1.2%, the mass ratio of propylene glycol monomethyl ether is 1.2%, and the mass ratio of mono-n-butyl glycol ether is 1.2 %, the remaining component is prepared water.

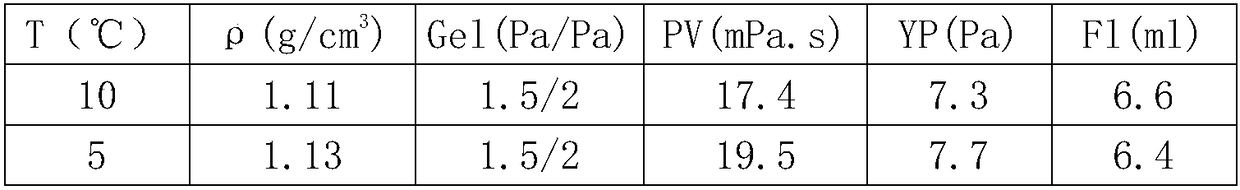

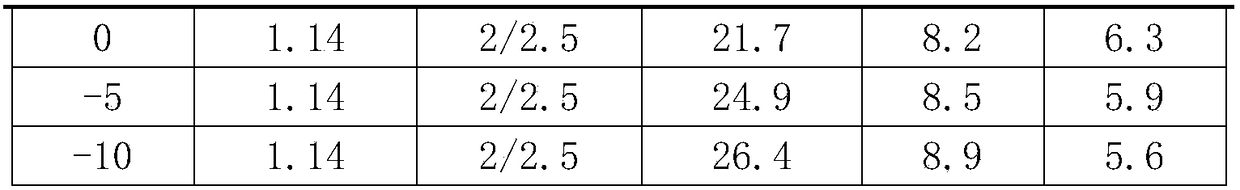

[0037] The drilling fluid configuration methods of the above Examples 1, 2, and 3 are conventional drilling fluid configuration methods, which are evaluated by the following experimental methods:

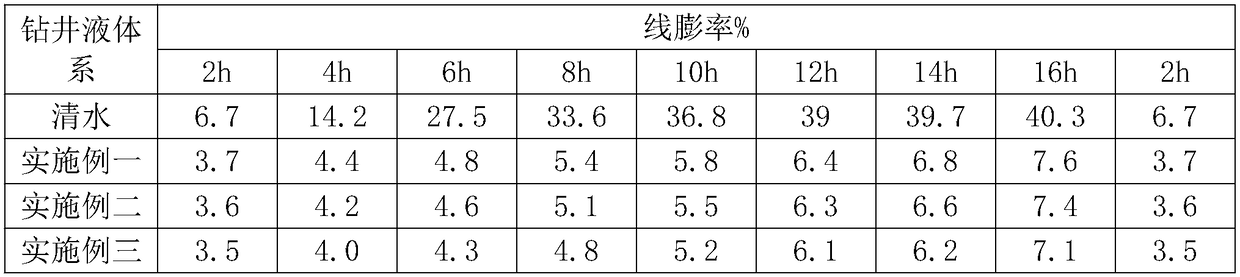

[0038] 1 Evaluation of drilling fluid shale hydration inhibition

[0039] In the indoor evaluation of the relevant performance of the drilling fluid, the inhibition evaluation experiment is an important part of it. The present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com