Patents

Literature

112results about How to "Avoid stuck drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

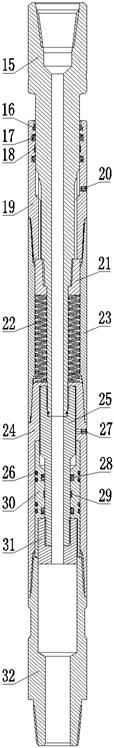

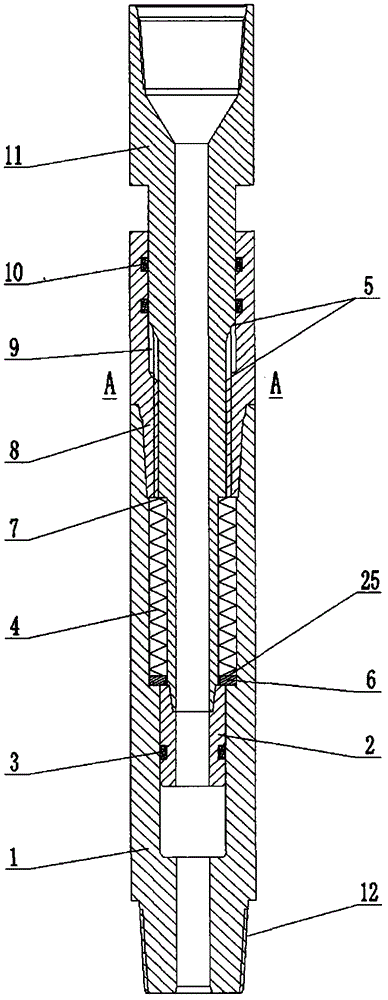

Pressure resistant tool for reducing frictional resistance of horizontal well section

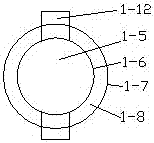

ActiveCN102587832AStrong axial vibration capabilityEffective destructionDirectional drillingBorehole drivesUpper jointDrive shaft

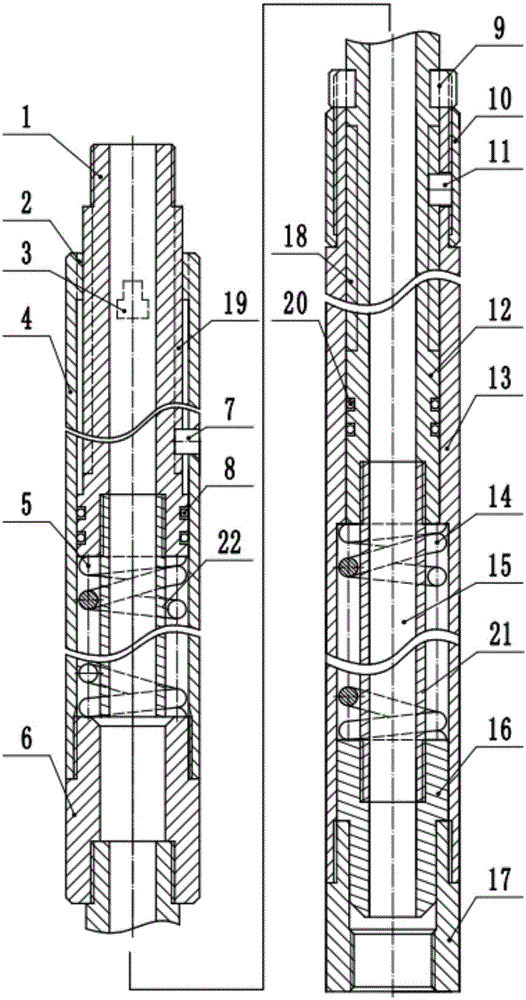

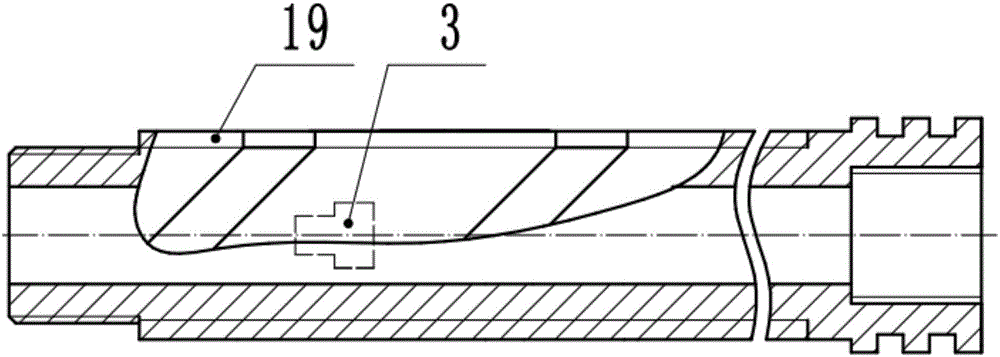

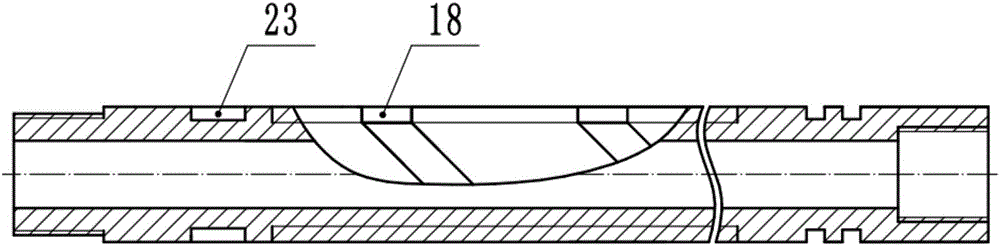

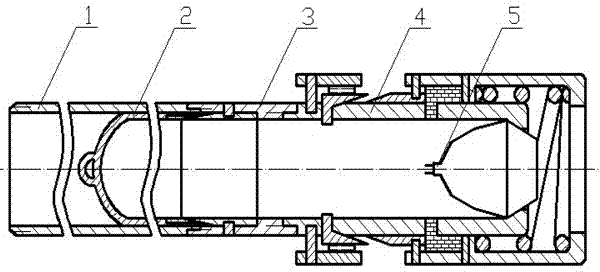

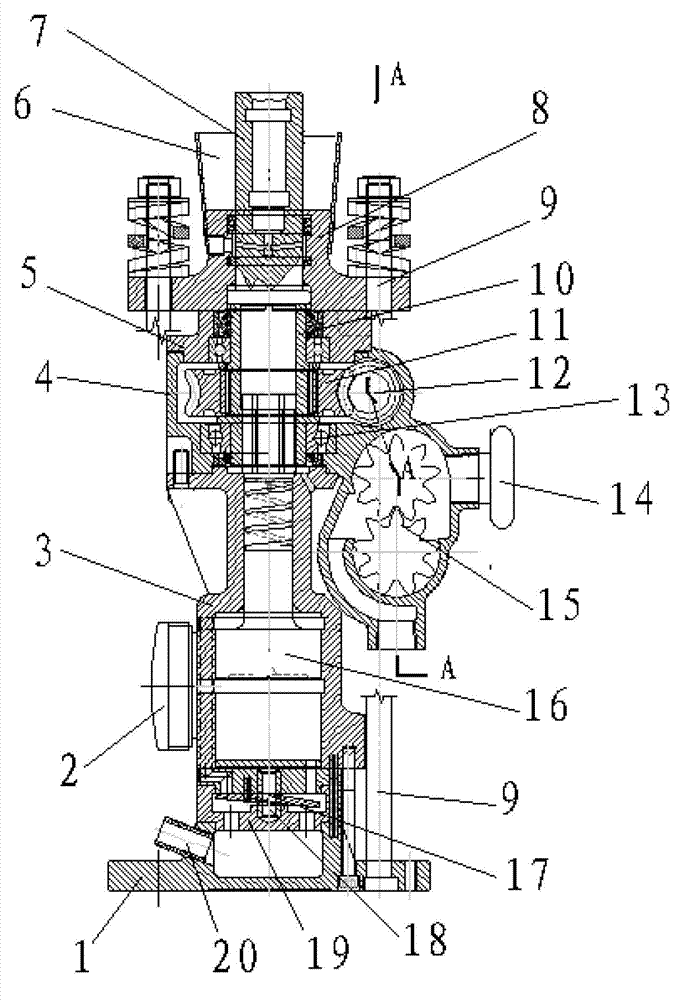

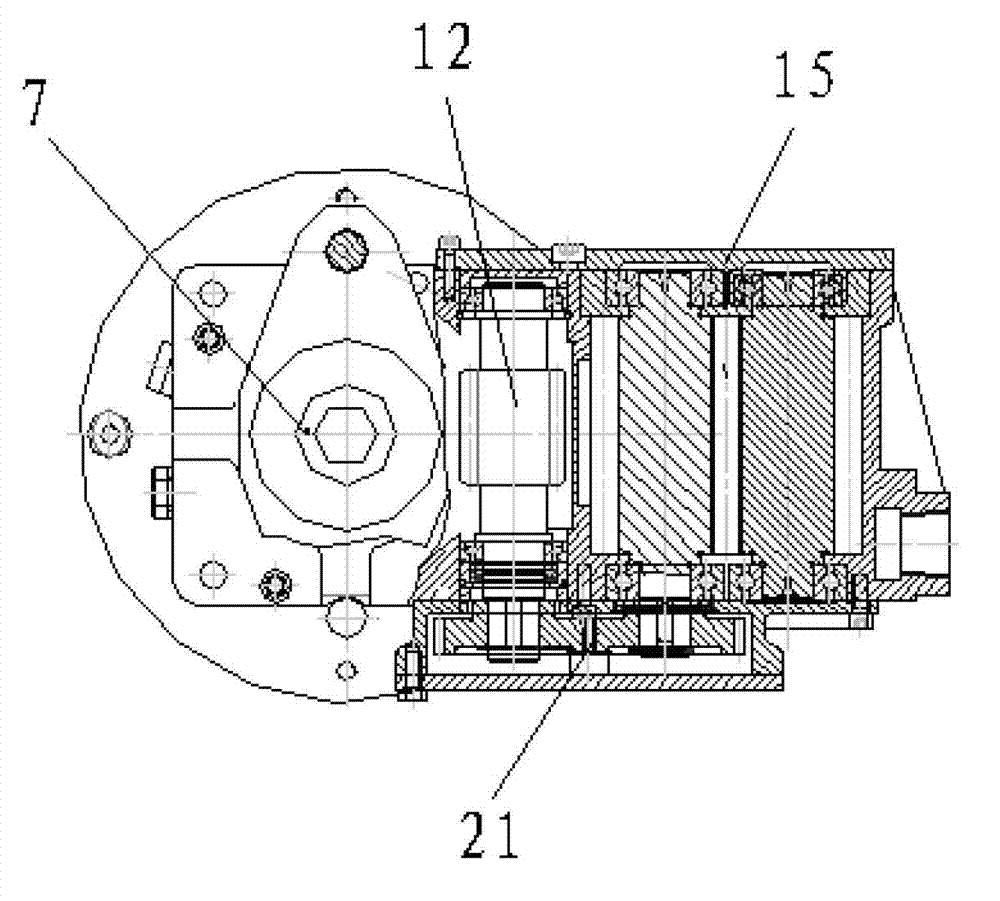

The invention relates to a pressure resistant tool for reducing frictional resistance of a horizontal well section, which is used for reducing the frictional resistance of the horizontal well section and improving horizontal section extending and drilling capacity. The technical scheme includes: the pressure resistant tool for reducing the frictional resistance of a whole well consists of a pulse part and a vibration part. The pulse part mainly comprises an upper joint, a power part, an upper abrasion-resistant block, an upper fixing sleeve, a lower abrasion-resistant block, a lower fixing sleeve, a lower valve and a lower joint. The vibration part mainly comprises a spline transmission shaft, a spline righting tube, a locking nut, a disk spring, a supporting shell, a piston rod, a piston bush, a piston nut and a pulse pup joint. The vibration part is in threaded connection with the upper end of the pulse part. The overall overflowing area of a valve part driven by a motor rotor is gradually reduced, and fluid energy is converted into a series of pulse pressure to be transmitted to the vibration part. The pressure resistant tool has the advantages of high axial vibration capacity and simple structure, the frictional resistance between a drill stem and the well wall can be reduced, and the horizontal well and large-displacement well horizontal section extending and drilling capacity is improved.

Owner:SOUTHWEST PETROLEUM UNIV

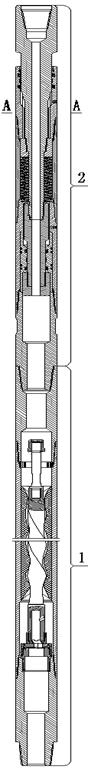

Well drilling vibrator of horizontal well

InactiveCN102747974AStrong axial vibration capabilitySimple structureVibration devicesVibration drillingPistonEngineering

The invention relates to a well drilling vibrator of a horizontal well. The well drilling vibrator comprises a shell, a piston head, a disc spring, an upper shoulder, a fixed sleeve, a sliding shaft, a valve shell, a spring, a central pipe, a sliding valve body, a nozzle, a water hole, a second flow passage, a valve plug, a first flow passage and a fixed valve seat, wherein the shell is in threaded connection with the fixed sleeve; the sliding shaft is arranged in a central hole formed by the shell and the fixed sleeve; the fixed sleeve is matched with the sliding shaft through a spline; the fixed valve seat is fixedly arranged in the valve shell through thread; the valve plug is matched with the fixed valve seat; when water pressure at the upper end of the valve plug reaches a limited value, the valve plug is separated from the fixed valve seat, the spring is compressed downwards by the central pipe, and drilling fluid flows by the first flow passage and then flows by the second flow passage; when pump capacity changes, the water pressure at the upper end of the valve plug also changes, the compression of the spring changes, the distance from the valve plug to the fixed valve seat changes, the flow area of the first flow passage also changes, and pulsating pressure is caused to change the compression amplitude of the disc spring by the upper shoulder of the sliding shaft, so that vibration is caused.

Owner:CHINA PETROLEUM & CHEM CORP +1

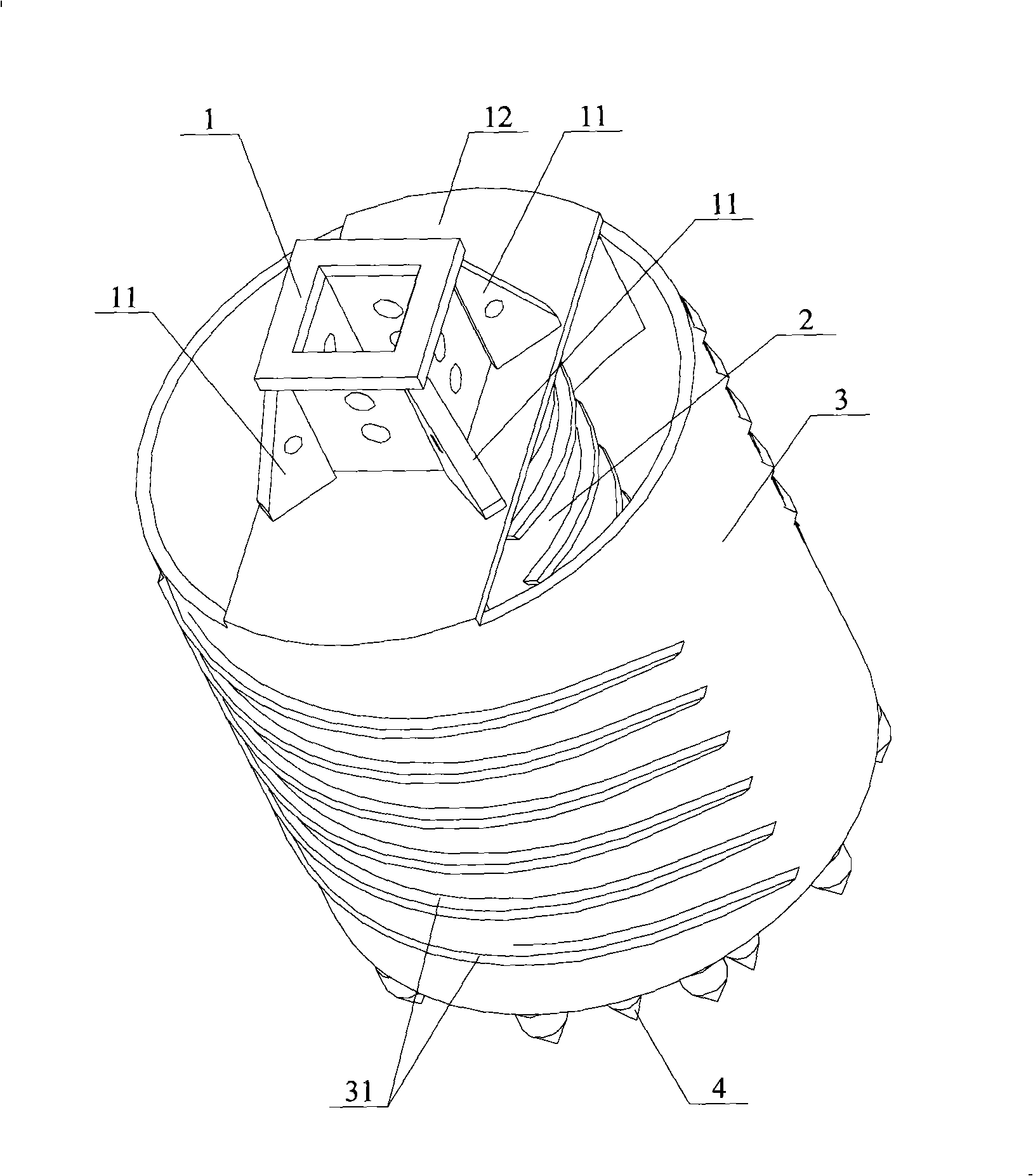

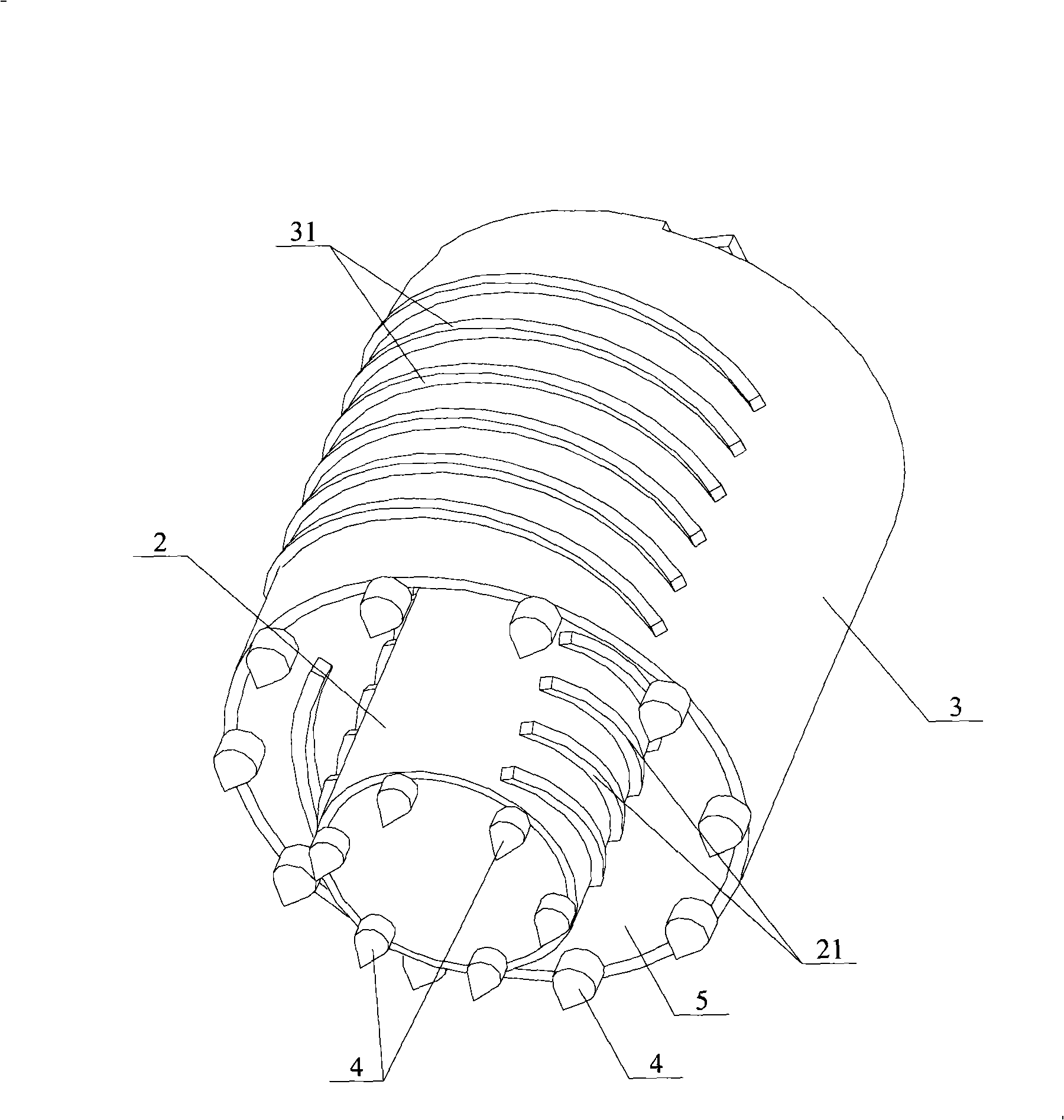

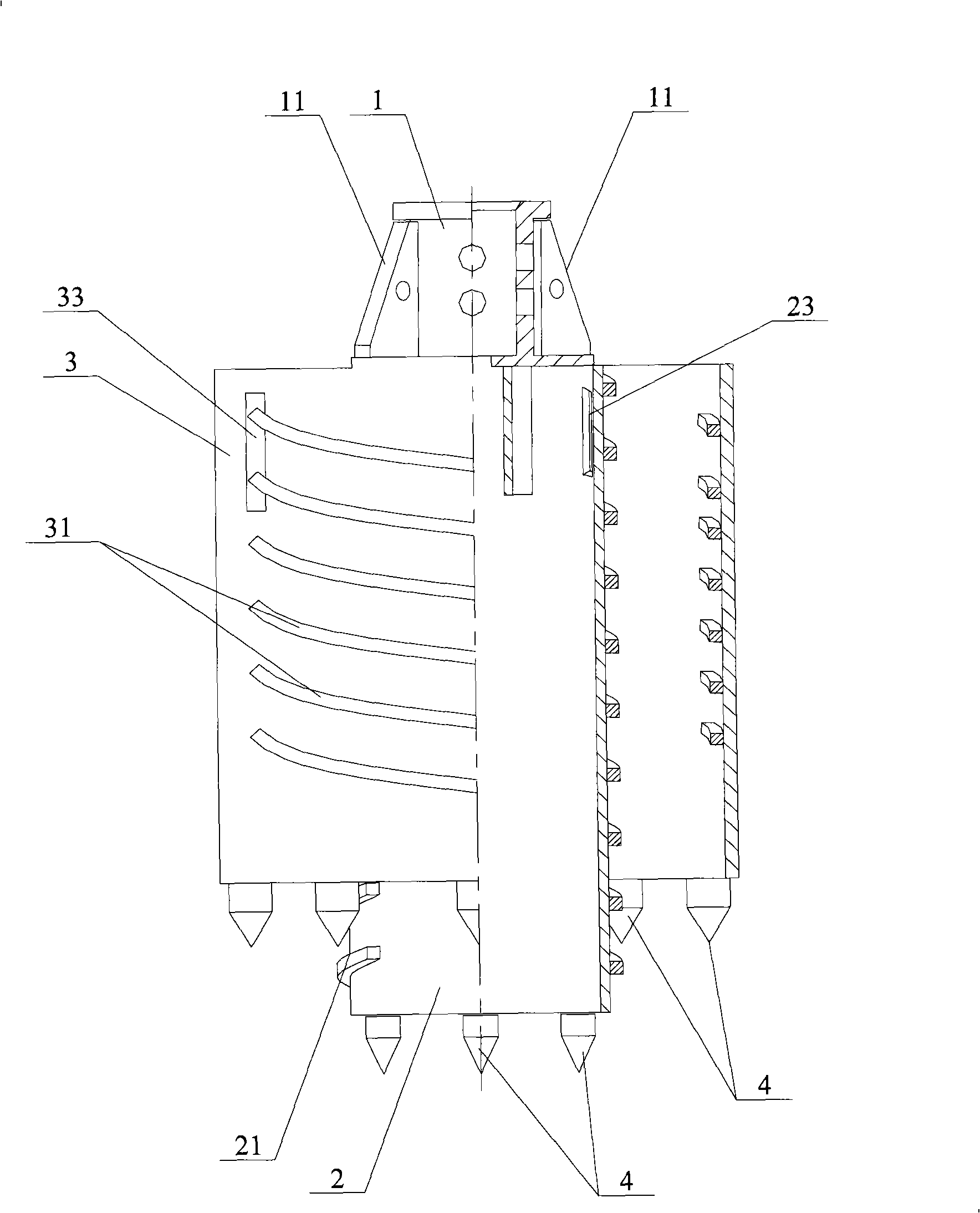

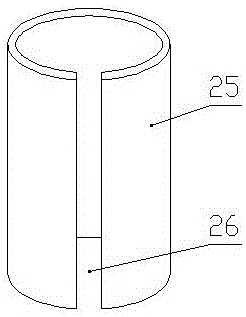

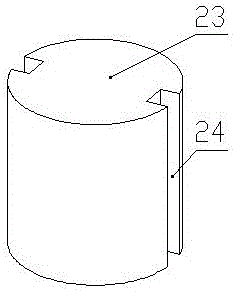

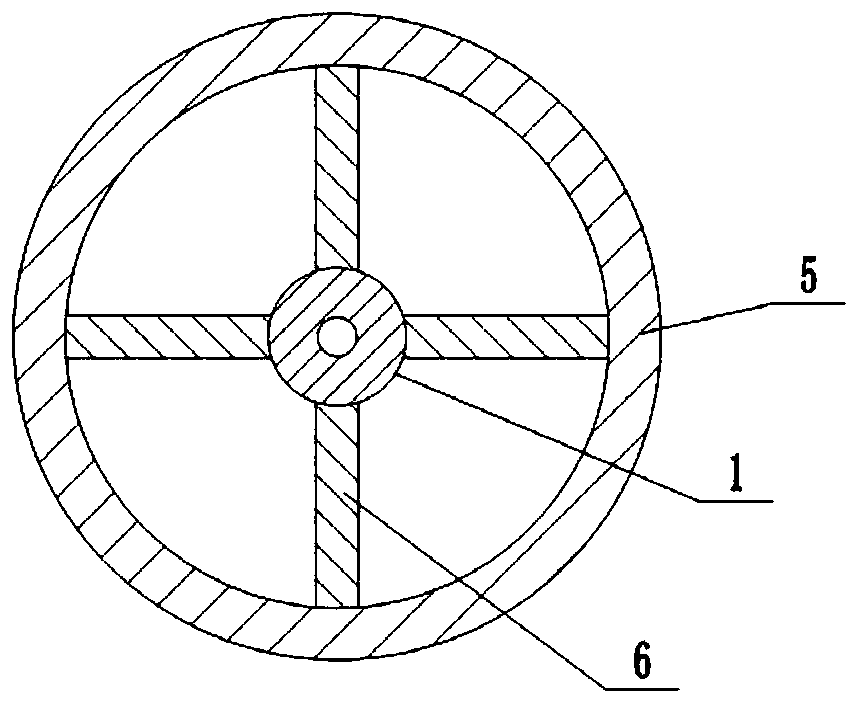

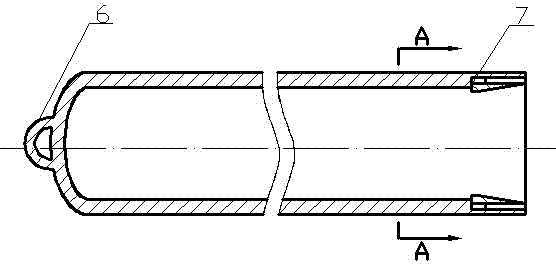

Double-layer barrel type drilling tool

InactiveCN101343982AImprove drilling efficiencyImprove slag carrying capacityDrill bitsEngineeringDrill pipe

The invention discloses a double-layer cylindrical drilling tool, which comprises a connecting part, an inner cylinder body, an outer cylinder body and a plurality of cutting tools. The upper end part of the inner cylinder body is fixedly connected with the connecting part; the outer cylinder body is nested at the outer side of the inner cylinder body, and an annular cavity is formed between the inner cylindrical surface of the outer cylinder body and the outer cylindrical surface of the inner cylinder body; the upper end part of the outer cylinder body is fixedly connected with the connecting part; the plurality of cutting tools are respectively fixedly arranged on the lower edges of the inner cylinder body and the outer cylinder body; and a plurality of guiding strips which present spiral elevating status along the cylindrical surface of the cylinder body are respectively arranged on the inner cylinder body and the outer cylinder body. The space used for carrying boring mud in the double-layer cylindrical drilling tool is divided into two parts, namely the inner cavity of the inner cylinder body and an annular space formed between the inner cylinder body and the outer cylinder body, thereby being favorable for carrying hard boring mud particles, greatly enhancing the mud carrying capability of the drilling tool, further effectively avoiding the accidents of drill pipe sticking and the like and enhancing the drilling efficiency and the hole forming speed.

Owner:BEIJING SANY HEAVY MASCH CO LTD

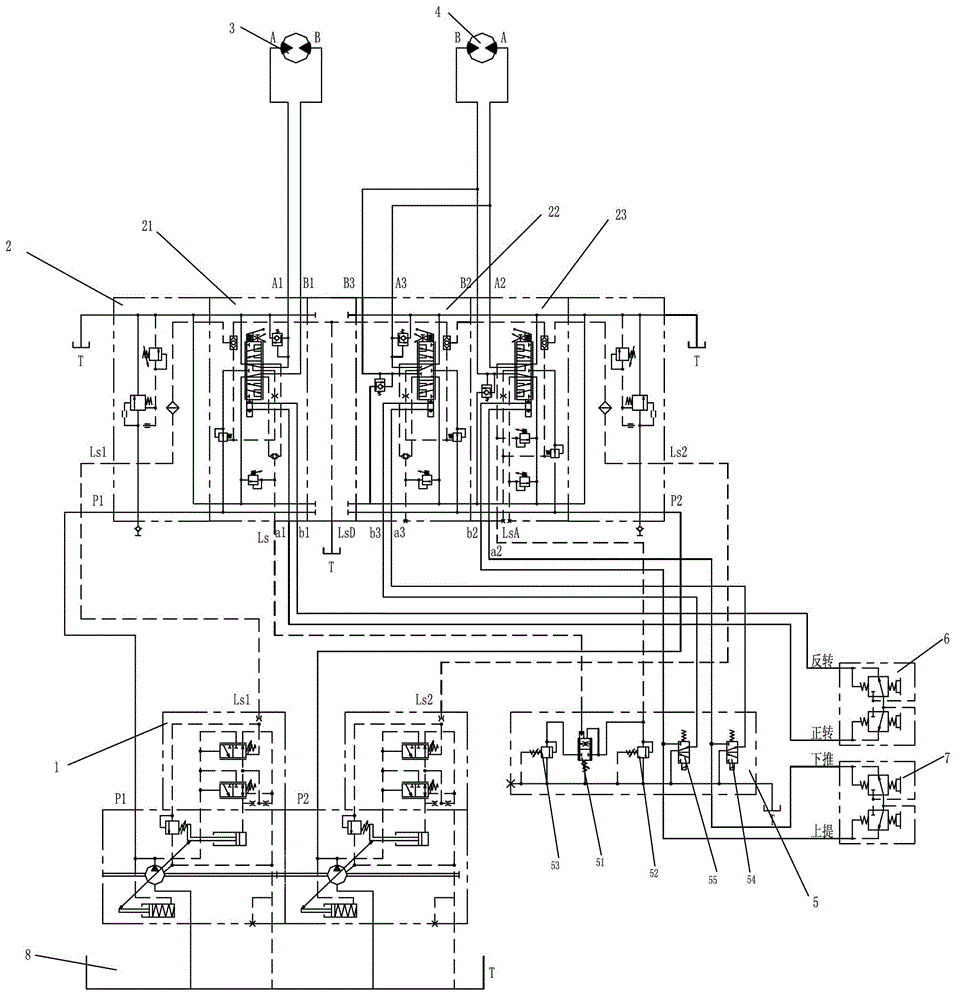

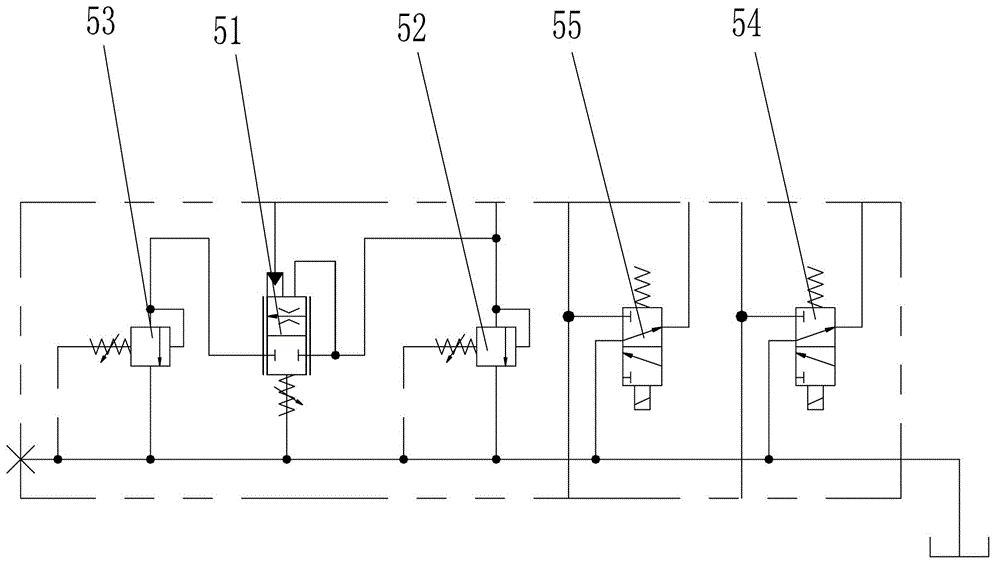

Double-pump hydraulic control loop of key drilling action of cutting drill rig

ActiveCN102747948AAvoid stuck drillPrevent slippingServomotor componentsServomotorsFuel tankEngineering

A double-pump hydraulic control loop of a key drilling action of a cutting drill rig comprises a double linkage load-sensitive variable pump set, a double oil intake linkage load-sensitive multi-way valve, a rotary motor, a propulsion motor, a drilling logic control block, a rotation guide handle, a propulsion guide handle, and a hydraulic oil tank. An oil inlet of the double linkage load-sensitive variable pump set is connected with the hydraulic oil tank. An oil outlet and a load-sensitive opening are connected with an oil inlet and a load-sensitive opening of the double oil intake linkage load-sensitive multi-way valve respectively. Each valve pressure difference compensator of the load-sensitive multi-way valve is provided with an external control opening. The external control openings are connected with the drilling logic control block. The rotation guide handle and the propulsion guide handle are connected with the drilling logic control block or a guide control opening of the load-sensitive multi-way valve. The double-pump hydraulic control loop has the advantages that power head rotation-proportion-controlled propulsion is achieved, independent load-sensitive control of rotation and propulsion is achieved, propulsion speed is increased, and the like.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

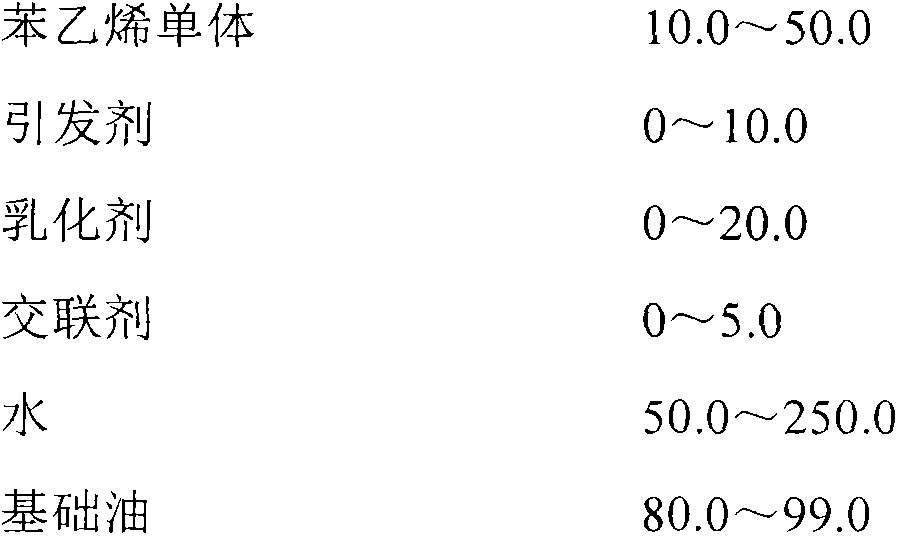

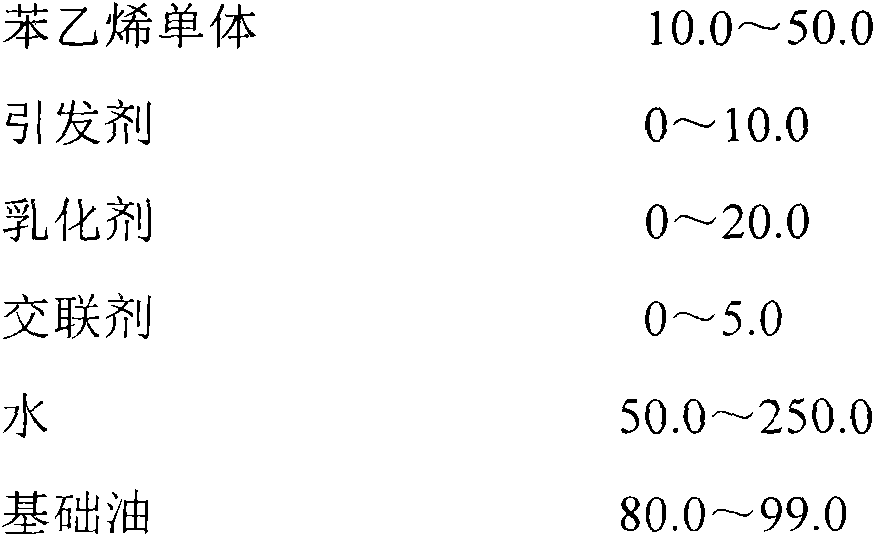

Water-based drilling fluid lubricant composition and preparation method thereof

The invention discloses a water-based drilling fluid lubricant composition and a preparation method thereof. The lubricant composition is composed of the following components in parts by weight: 10.0 to 50.0 parts of styrene monomer, 0 to 10.0 parts of initiator, 0 to 20.0 parts of emulsifier, 0 to 5.0 parts of crosslinking agent, 50.0 to 250.0 parts of water, and 80.0 to 99.0 parts of base oil. The preparation method comprises the following steps: sequentially mixing styrene monomers, an initiator, an emulsifier, a crosslinking agent, and water according to the formula mentioned above so as to form a reaction solution, placing the reaction solution in a chamber with a proper temperature for a proper period of time to carry out emulsion polymerization so as to obtain a milk-white emulsion composition, and adding the composition into industrial base oil so as to obtain the lubricant composition; wherein the average particle size of the emulsion composition is 10 to 70 nm. The lubricant composition has the characteristics of small particle size, easiness in dispersing in drilling fluid, good compatibility, low water loss rate, and good lubricating effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

3D printing plasma intelligent Mohole drilling and completion method

The invention discloses a 3D plasma intelligent Mohole drilling and completion method. The method comprises the following steps that a drilling platform is built, drilling equipment is mounted, and drilling is started. The drilling equipment comprises a 3D printer system assembly, a pumping system for muddy water, rock debris and the like as well as mixtures thereof, an intelligent well casing lifting and fixing system, a well casing printed by a 3D printer, a manifold system assembly, a downhole hole-drilling, hole-broadening and well-cementing intelligent executor (drilling robot), a drilling platform, an intelligent control treatment center and the like. The well casing is printed by the 3D printer, the pumping system discharges mud, the rock debris and the like, the plasma drilling executor implements drilling, and underground equipment is provided with thermal insulation and cooling protection. According to the 3D plasma intelligent Mohole drilling and completion method, a first 3D printing spray-head, a second 3D printing spray-head, a blockage system spray-head, plasma liquation well cementation, spray gun well cementation, a hole broadening spray-head, a hole-drilling spray-head and a high-pressure gas spray-head work cooperatively; the intelligent well casing lifting and fixing system fixes and lifts the well casing printed by the 3D printer intelligently; and drilling can be constructed in the land and at a deep sea.

Owner:张发旺 +1

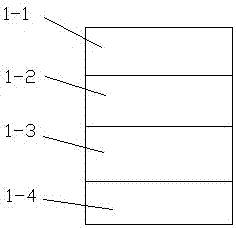

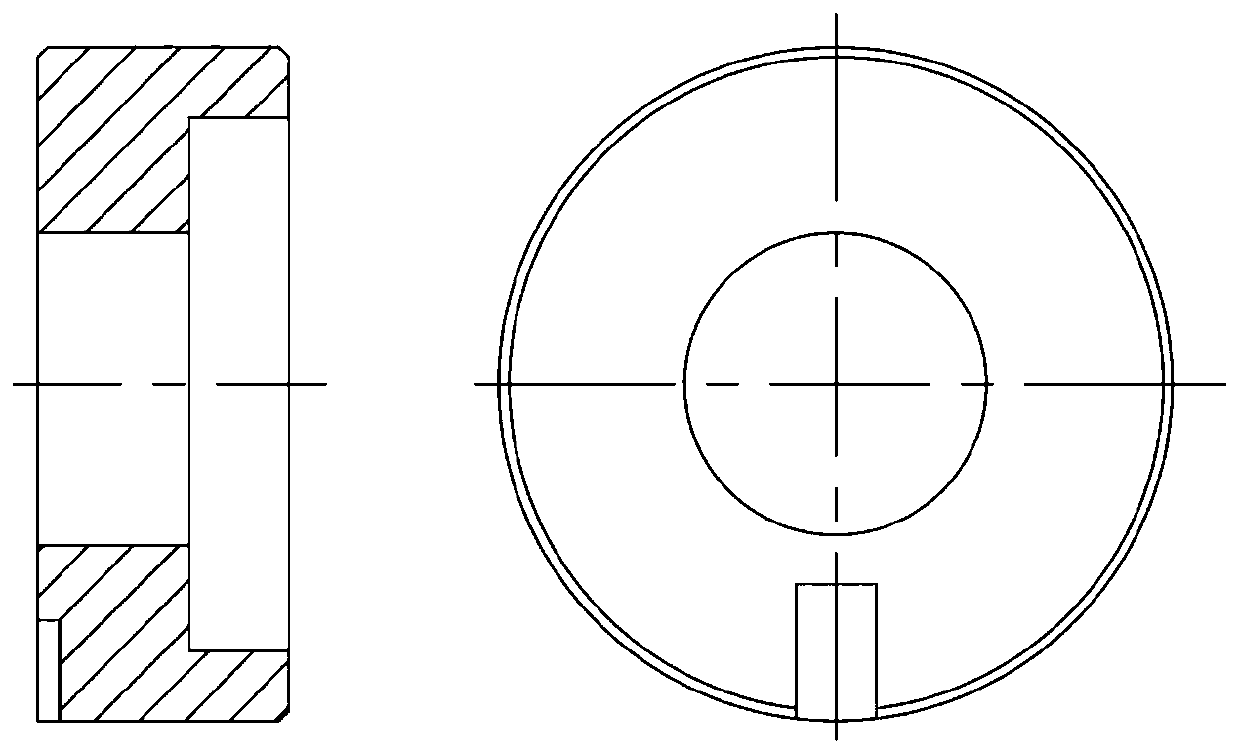

Weakly-consolidated rock test piece machining technology

ActiveCN106338422AProtect your healthAvoid stuck drillPreparing sample for investigationRock coreTest sample

Provided is a weakly-consolidated rock test piece machining technology. The technology comprises the following steps that 1, drilling is conducted on the field to take a cylindrical rock core; 2, one or two chip grooves are formed in the circumferential surface of the rock core in the generatrix direction; 3, the rock core is placed in a fixture, and it is guaranteed that the center line of the rock core coincides with the center line of a drilling tube; 4, a radial drill and an air blower are started, and the rock core is machined to be a long-column-type test sample of which the outer diameter is 51 mm; 5, a PVC pipe and the long-column-type test sample are placed on a cutting machine to be cut; 6, the circumferential surface of the test sample which is 100 mm long and / or the circumferential surface of the test sample which is 50 mm long are ground. According to the weakly-consolidated rock test piece machining technology, drilling machining is conducted on the field drilling rock core test sample through a drilling system, one or two chip grooves are formed in the circumferential surface of the rock core in the generatrix direction in advance, drilling jamming caused by chip agglomeration in the weakly-consolidated rock standard test sample machining process is effectively avoided, the unsmooth drilling phenomenon is avoided, and the completeness of the test piece can be guaranteed by adopting an air cooling mode.

Owner:HENAN POLYTECHNIC UNIV

Composite oriented drilling equipment for coal mine underground complex stratum and application thereof

PendingCN108590529AStable trackingEasy to cleanSurveyConstructionsUltimate tensile strengthData transmission

The invention provides composite oriented drilling equipment for a coal mine underground complex stratum and application thereof. The composite oriented drilling equipment comprises a drilling tool, an oriented screw motor, a wireless electromagnetic wave while-drilling measuring system and a drill bit. The drill bit, the oriented screw motor, the wireless electromagnetic wave while-drilling measuring system, a normal drill stem and a water braid are connected in sequence in a screw-threading mode. Electromagnetic waves are used as a transmission medium, the depth of remote sensing is large, the transmission speed is high, the data transmission is reliable and effective, and adaptation to the underground drilling condition is high; the detected data in holes can be effectively transmittedby the normal drill stems and the stratum; compared with wired while-drilling measuring, the intensity of the drill stems is high, shearing strength and fatigue strength are better, manpower, materials and financial resources are saved; and the composite oriented drilling equipment for the coal mine underground complex stratum and the application thereof are a preferred mode and equipment for coalmine underground oriented drilling.

Owner:SHAANXI TAIHE TECH CO LTD

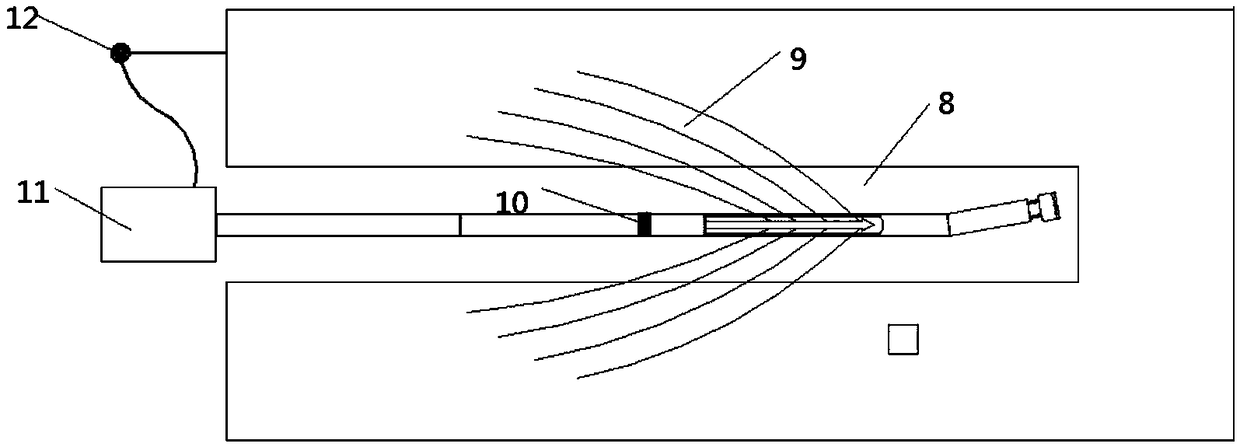

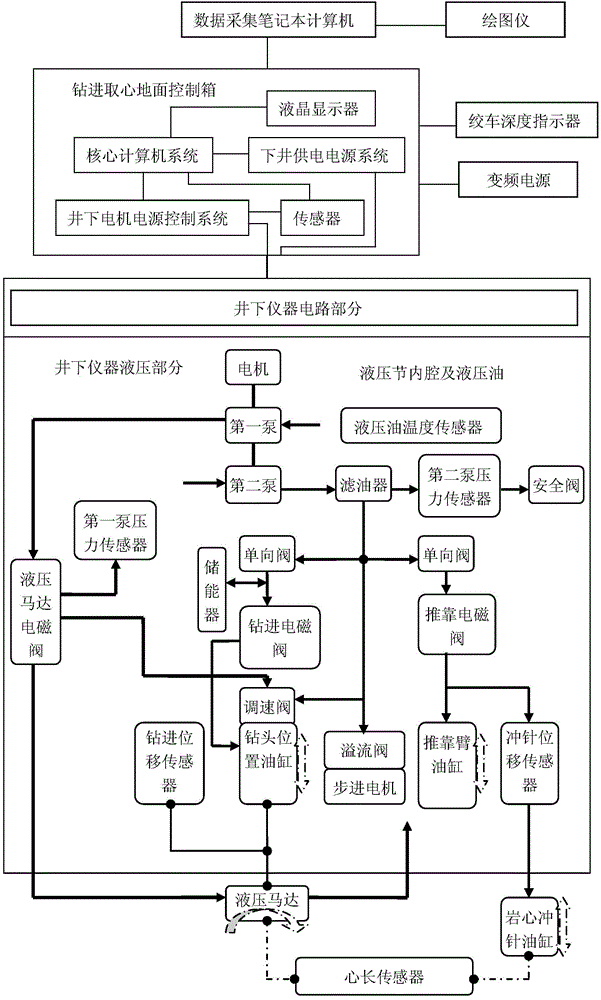

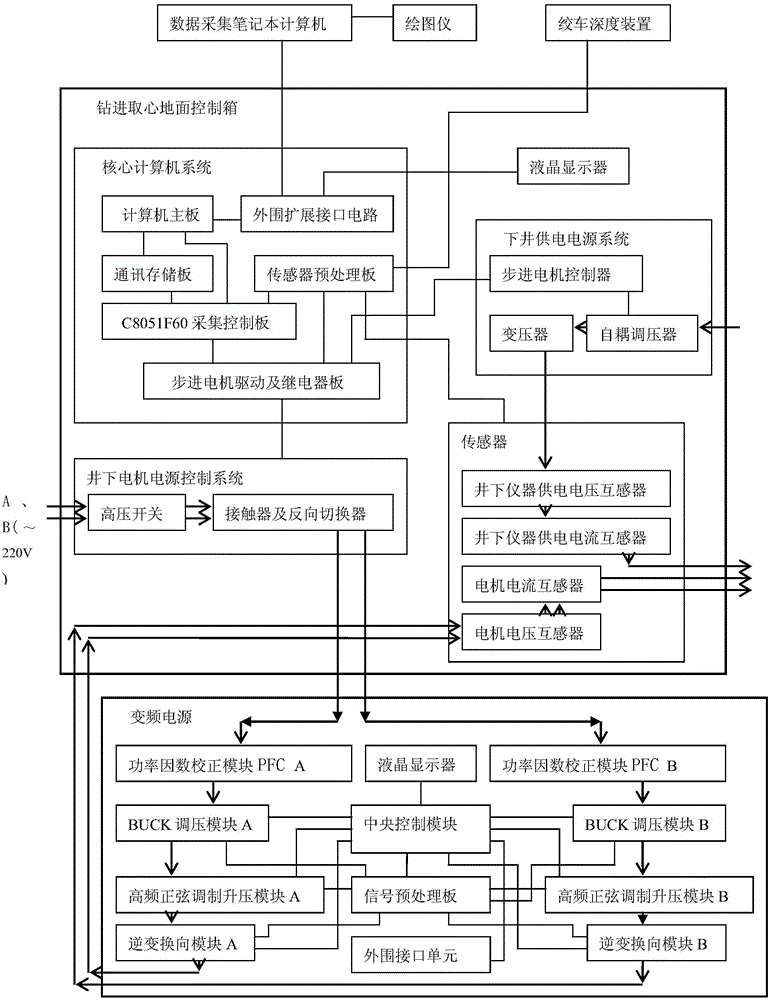

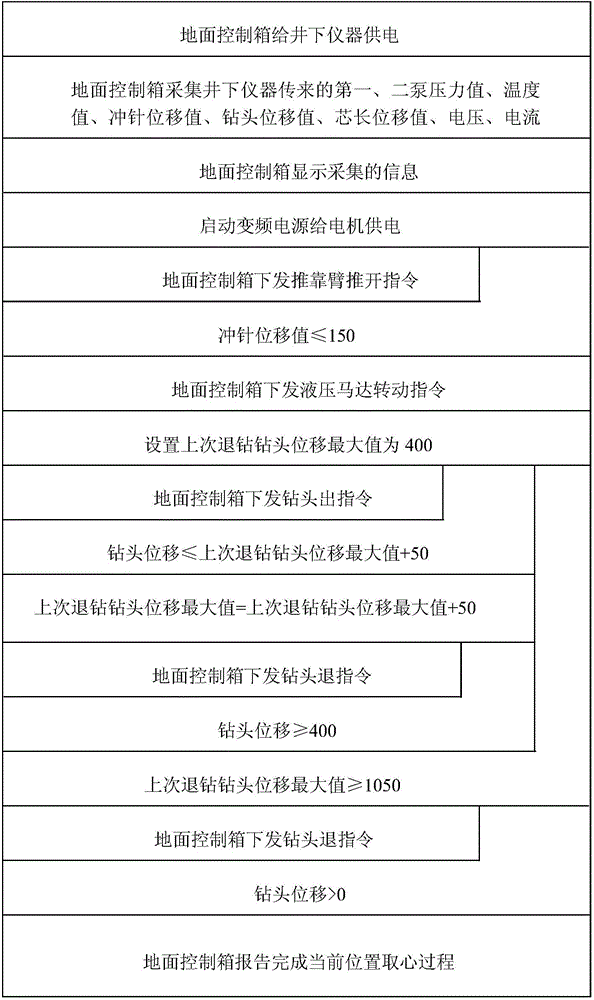

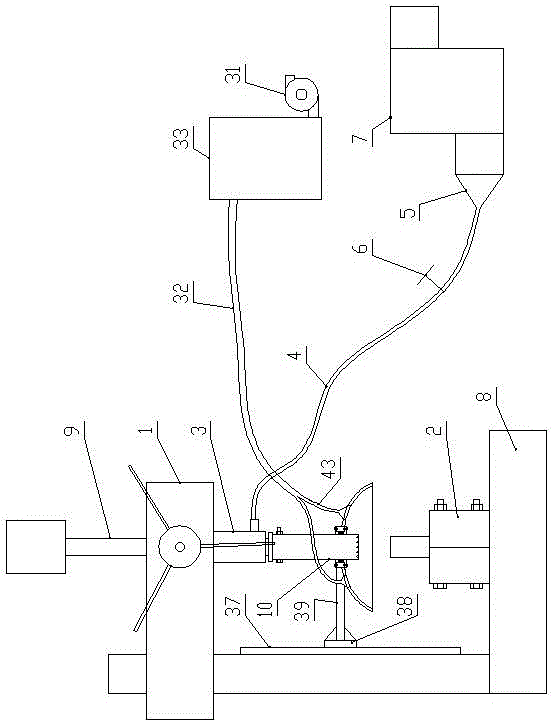

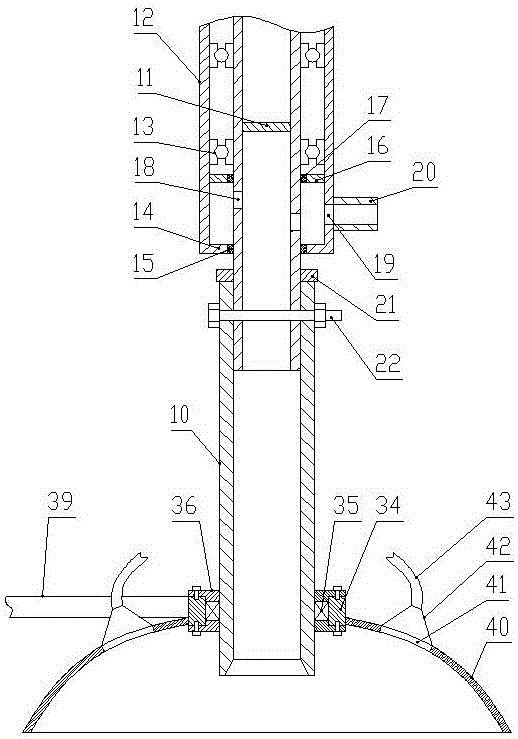

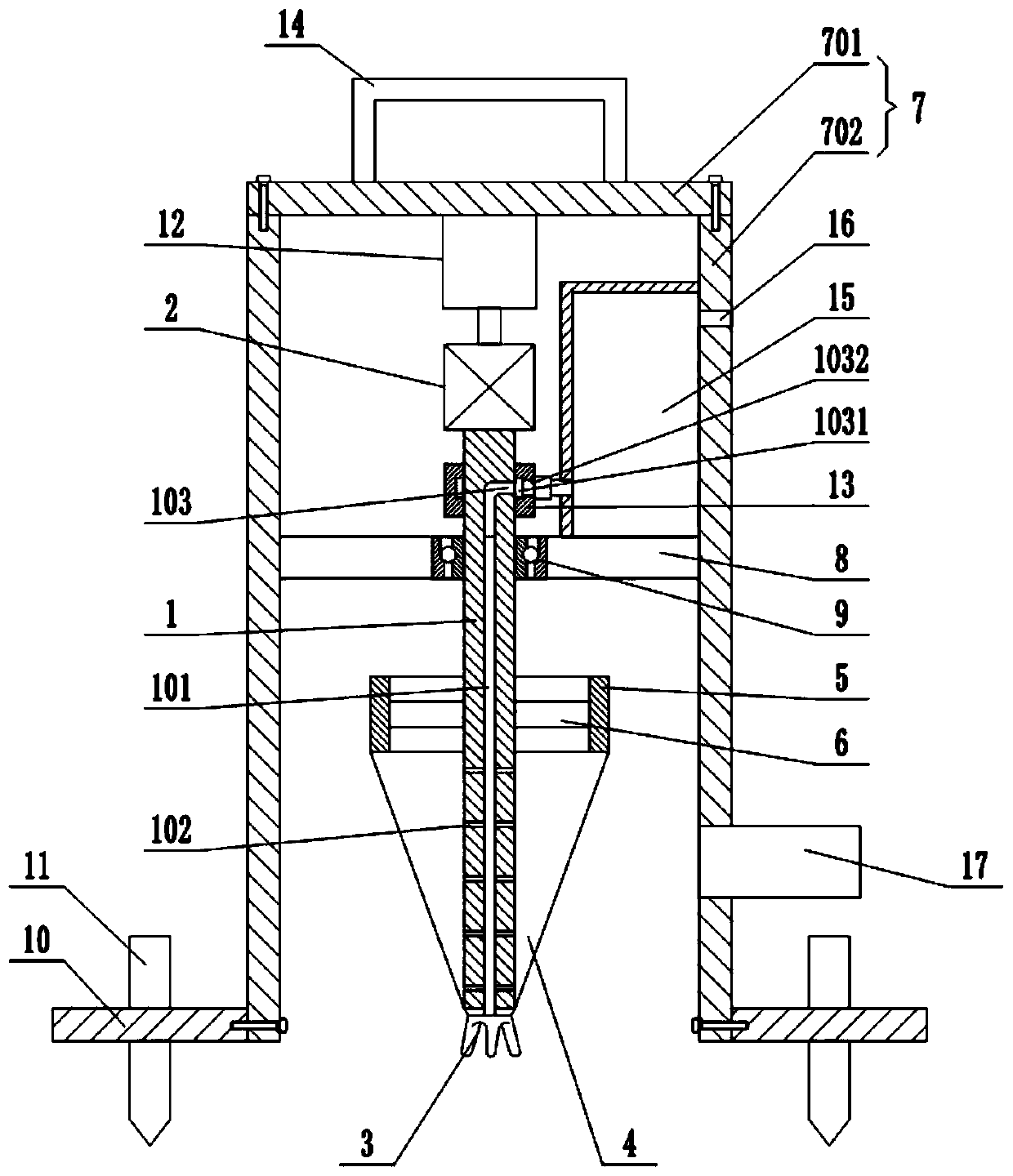

Control system and control method of logging drilling sidewall coring tool

ActiveCN104373120AWill not affect working statusFulfill control requirementsBorehole/well accessoriesHydraulic motorAutomatic control

The invention discloses a control system of a logging drilling sidewall coring tool. The control system comprises a drilling coring ground control box, a winch depth device, a variable frequency power source, a downhole instrument circuit part and a downhole instrument hydraulic part, wherein data acquisition and feedback control are performed on the coring tool through the drilling coring ground control box, various states of a downhole instrument can be detected in time through the downhole instrument circuit part, the power supply state of a downhole motor and the power supply state of the downhole instrument are monitored through a sensor, and the downhole motor can be adjusted and controlled by processing acquired data and controlling the variable frequency power source. According to a control method, automatic control over coring of the coring tool is achieved through the ground control box, an execution motor can be continuously started, a backup arm expands, the stretching displacement of a punch pin is minimal, the pressure of a second pump is maximal, a hydraulic motor rotates, a drill bit stretches out, the hydraulic motor stops rotating when the drilling displacement reaches the core breaking position, and a series of continuous actions that the core breaking drill bit retreats and is taken back is completed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

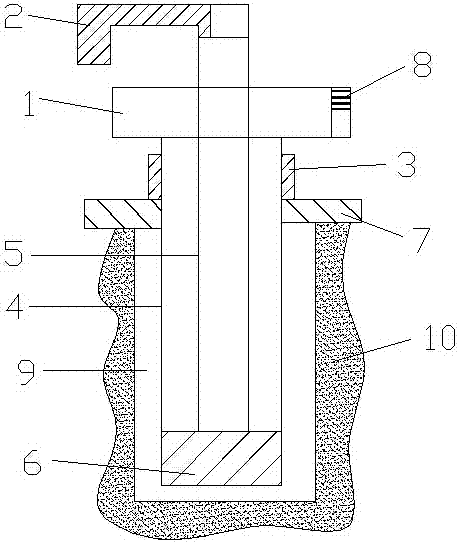

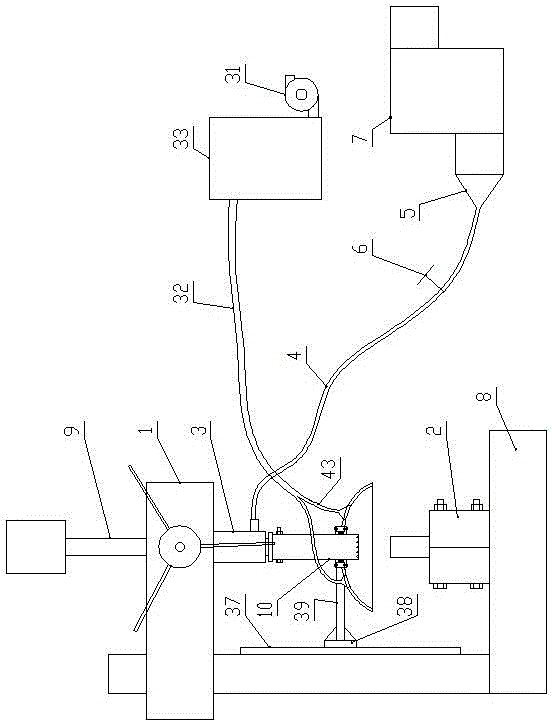

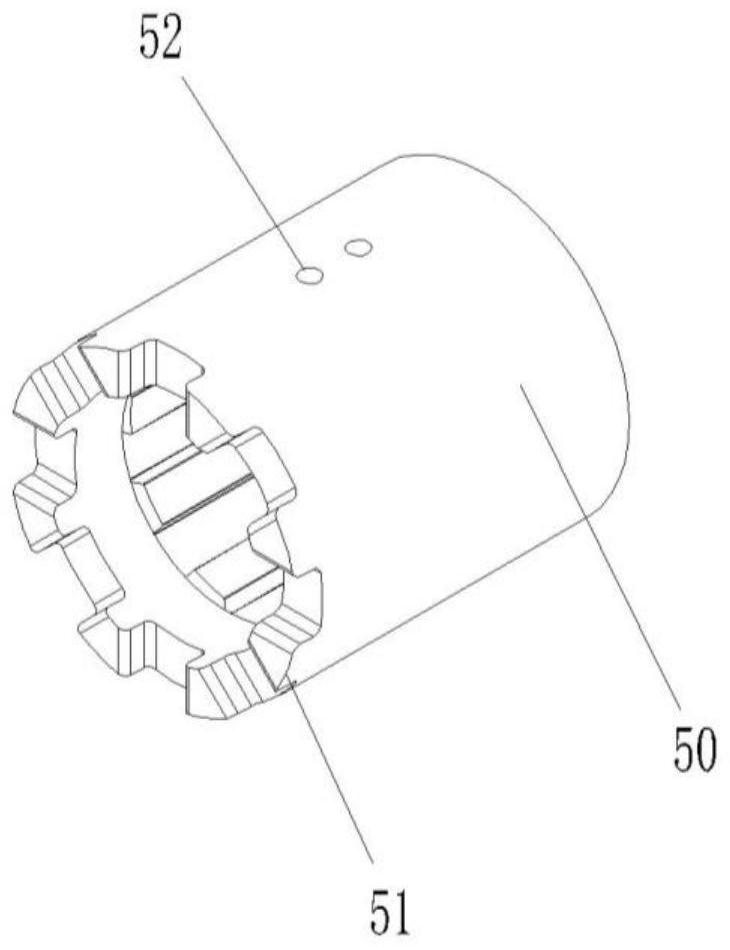

Drilling system for weak cemented rock test piece

ActiveCN106441989AAvoid damagePrevent high pressure wind from overflowingWithdrawing sample devicesAir volumeWorking environment

A drilling system for a weak cemented rock test piece comprises a radial drill, a clamp, a sealed connection device, a dust suction device, an air guide pipe, an air gathering cover, a volume adjusting valve and an air blower, wherein the clamp is arranged on a platform of the radial drill, the air blower is arranged on one side of the radial drill, a drill rod of the radial drill adopts a hollow structure, the lower end of the drill rod is coaxially connected with a drill barrel, the sealed connection device located above the drill barrel is arranged outside the drill rod, a baffle located above the drill barrel is arranged in the drill rod, an air outlet of the air blower is connected with one end of the air guide pipe through the air gathering cover, the other end of the air guide pipe is connected with the sealed connection device, and an air outlet of the sealed connection device communicates with the inner wall of the drill rod; the volume adjusting valve is arranged on the air guide pipe. Drill blocking caused by accumulation of chippings in the weak cemented rock standard sample machining process is effectively avoided, the unfavorable phenomenon of drilling is avoided, the intactness of the test piece can be ensured in an air cooling mode, dust suction in the field is performed, and dust pollution to the working environment is avoided.

Owner:HENAN POLYTECHNIC UNIV

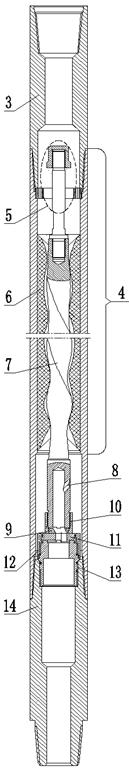

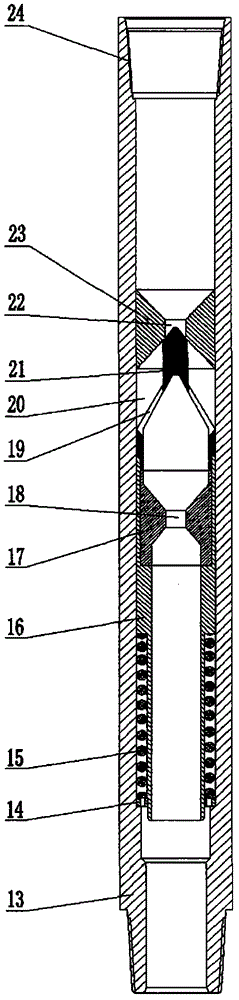

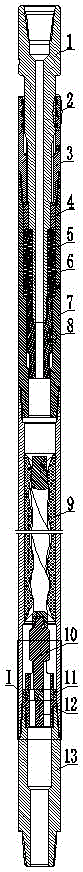

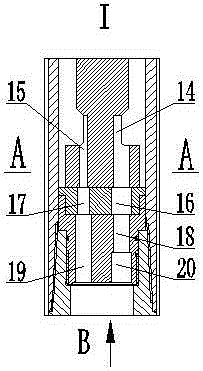

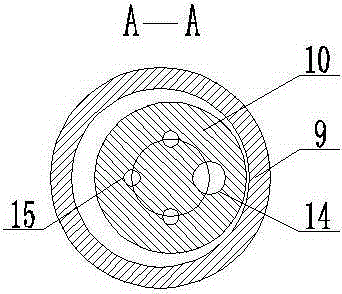

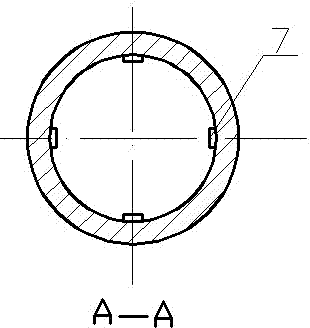

Water hammer pulse vibration pressurizing tool for long-horizontal-section horizontal well

InactiveCN105221073AStrong axial vibration capabilityIncreased axial compressionVibration drillingWear resistantAxial pressure

The invention relates to a water hammer pulse vibration pressurizing tool used for increasing axial pressure in a long-horizontal-section horizontal well. The technical scheme includes that the water hammer pulse vibration pressurizing tool mainly comprises a transmission shaft, a transmission shaft shell, a pressurizing assembly shell, a pressurizing assembly, a piston sleeve, a power assembly, a dynamic valve part, a wear-resistant valve, a static valve part and a lower joint, the transmission shaft shell, the pressurizing assembly shell, the power assembly and the lower joint are sequentially in threaded connection from top to bottom, the transmission shaft is matched with an inner hole of the transmission shaft shell, the upper end of the transmission shaft is connected with the piston sleeve through a thread, the pressurizing assembly is mounted between an isolating sleeve and the piston sleeve, the dynamic valve part is connected with the lower end of the power assembly through a thread, the static valve part is mounted in an inner hole in the upper end of the lower joint, and the wear-resistant valve is mounted in an inner hole in the upper end of the static valve part. The water hammer pulse vibration pressurizing tool has the advantages of good axial pressurizing effect, high vibration ability and simple structure, and extending and drilling ability of the long-horizontal-section horizontal well can be improved.

Owner:SOUTHWEST PETROLEUM UNIV

Environmental-friendly lubricating agent for drilling fluid, and preparation method of environmental-friendly lubricating agent

InactiveCN108276973ALittle environmental pollutionReduce pollutionDrilling compositionPhenolFatty alcohol

The invention discloses an environment-friendly lubricating agent for a drilling fluid and a preparation method of the environment-friendly lubricating agent. The environment-friendly lubricating agent for the drilling fluid has the advantages of environment friendliness, low manufacturing cost, and capability of reducing friction forces between a drill tool and a well wall mud cake as well as between clay particles and reducing resistance. The environment-friendly lubricating agent for the drilling fluid is prepared from the following components in percentage by mass: 30 percent to 42 percentof oleic acid, 44 percent to 60 percent of long-chain fatty alcohol, 5 percent to 15 percent of organic silicone oil, 1 percent to 3 percent of polyoxyethylene octyl phenol ether, 0.1 percent of sulfuric acid, and 0.1 percent of sodium hydroxide. The preparation method comprises the steps of uniformly mixing the oleic acid and the long-chain fatty alcohol, heating, adding the sulfuric acid, stirring, adding the sodium hydroxide for stirring, adding the organic silicone oil for stirring, and adding the polyoxyethylene octyl phenol ether for uniformly mixing. The environment-friendly lubricating agent for the drilling fluid has the advantages of environment friendliness, less pollution, capability of reducing resistance, and benefit to improving the drilling speed and preventing jamming ofa drilling tool.

Owner:四川泓华油气田工程科技有限公司

Low-permeability plugging agent

The invention discloses a low-permeability plugging agent which is composed of the following components in percentage by mass: 60-70% of organic material, 15-25% of high-temperature-resistant fiber and 10-15% of surfactant. The low-permeability plugging agent does not have the polymer component, is still available under high-temperature conditions, and does not influence the rheological properties of the drilling fluid in a conventional environment under high-density conditions. By reasonably optimizing the particle size distribution, the low-permeability plugging agent can effectively plug various pore throats and cracks and enhance the stratum loading capacity.

Owner:ASTAR PETROTECH

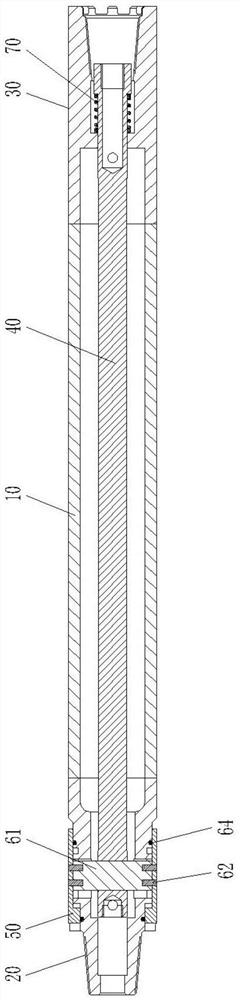

Novel broadeningequipment

InactiveCN110067514AAvoid offsetGuaranteed concentricityDrill bitsDrilling machines and methodsDrive motorDrill bit

The invention belongs to the technical field of geological prospecting equipment, and particularly discloses novel broadening equipment, including a drill rod and a drive motor used for driving the drill rod to rotate, one end of the drill rod, not connected with the drive motor, is provided in sequence with a guide drill bit, a broadening drill bit and supporting rings, the guide drill bit is arranged on the end portion of the drill rod, the supporting rings are coaxial with the drill rod, and a plurality of the supporting rods are installed between the internal wall of the supporting rings and the external wall of the drill rod. Broadening direction of the broadening drill bit is dragged and guided by the guide drill bit to keep concentric degree of the broadening direction and boreholedirection; the guide drill bit can break obstacles in front to avoid sticking of s drill due to collapse of holes in the process of broadening; the external wall of the guide drill ring makes contactwith the internal wall of boreholes, and when the drill rod rotates, the supporting rings matches the supporting rods to support the drill rod and avoid deviation of the drill rod, so that the concentricity of the boreholes after the broadening and boreholes of hole broadening gun is guaranteed, and the efficiency of the broadening is improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

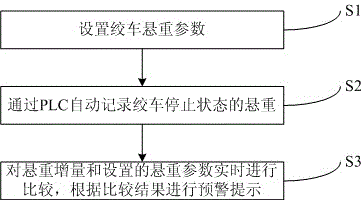

Method and system for preventing jamming of drilling tool

The invention discloses a method for preventing jamming of a drilling tool. The method for preventing jamming of the drilling tool is characterized by comprising the steps of S1, arranging winch hanging load parameters; S2, automatically recording a winch hanging load in a stopping state through a PLC; S3, conducting real-time comparison on a hanging load increment and the set hanging load parameters, and conducting an early warning prompt according to the comparison result. The method for preventing jamming of the drilling tool can effectively prevent jamming of the drilling tool in the well drilling process, avoid damage of a device, and save jam release cost and expedite the well drilling speed.

Owner:SICHUAN HONGHUA ELECTRIC

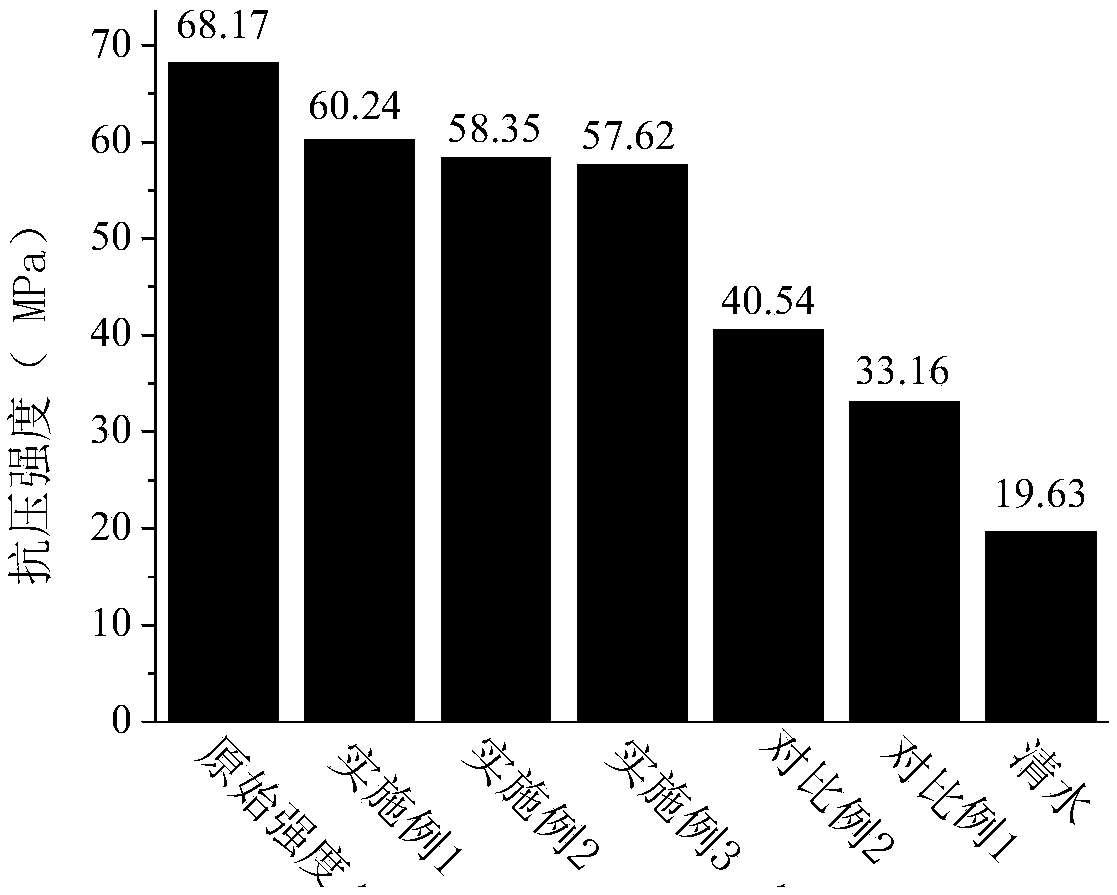

Water-based drilling fluid for stabilizing shale gas stratum borehole wall and application thereof

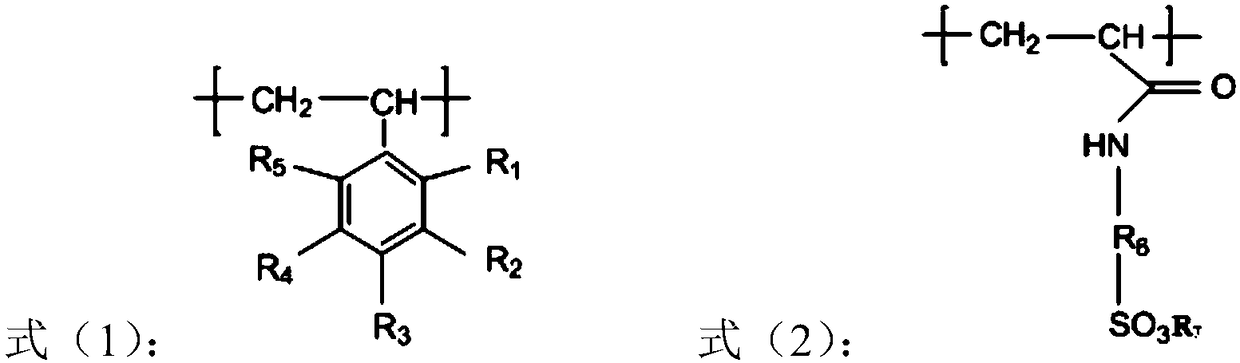

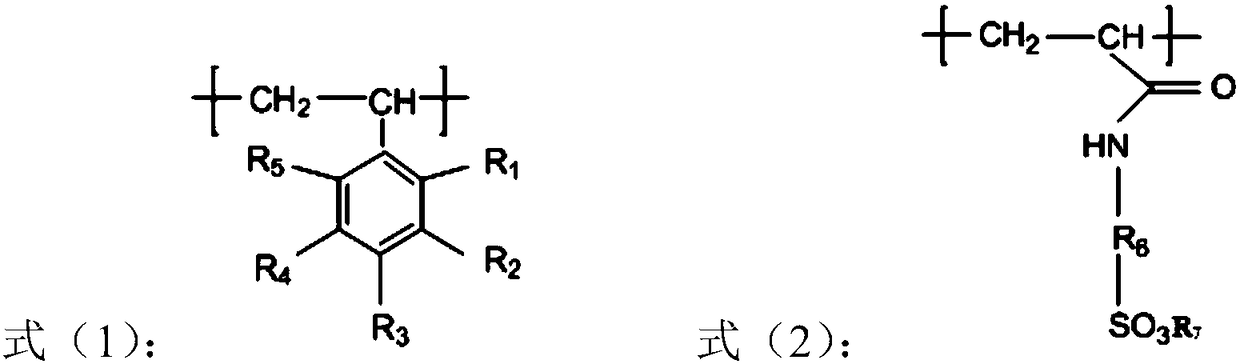

InactiveCN108531147AInhibition of hydrationReduced compressive strengthFlushingDrilling compositionCelluloseWater based

Relating to the technical field of shale gas drilling, the invention discloses a water-based drilling fluid for stabilizing a shale gas stratum borehole wall and application thereof. The water-based drilling fluid comprises a nanofilm structure plugging agent, a waterproofing agent, a surface hydration inhibitor, polymeric alcohol, bentonite, polyanionic cellulose, a sulfonated lignite resin and water, wherein the waterproofing agent is N-perfluoroalkyl sulfonyl propyl triethoxysilane, and the nanofilm structure plugging agent includes a montmorillonite sheet, a structural unit shown as formula (1) and a structural unit shown as formula (2). The water-based drilling fluid provided by the invention shows good performance of inhibition, rheology and retarding of the shale compressive strength reduction when applied to stabilization of the shale gas stratum borehole wall.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-density water-based drilling fluid and preparation method thereof

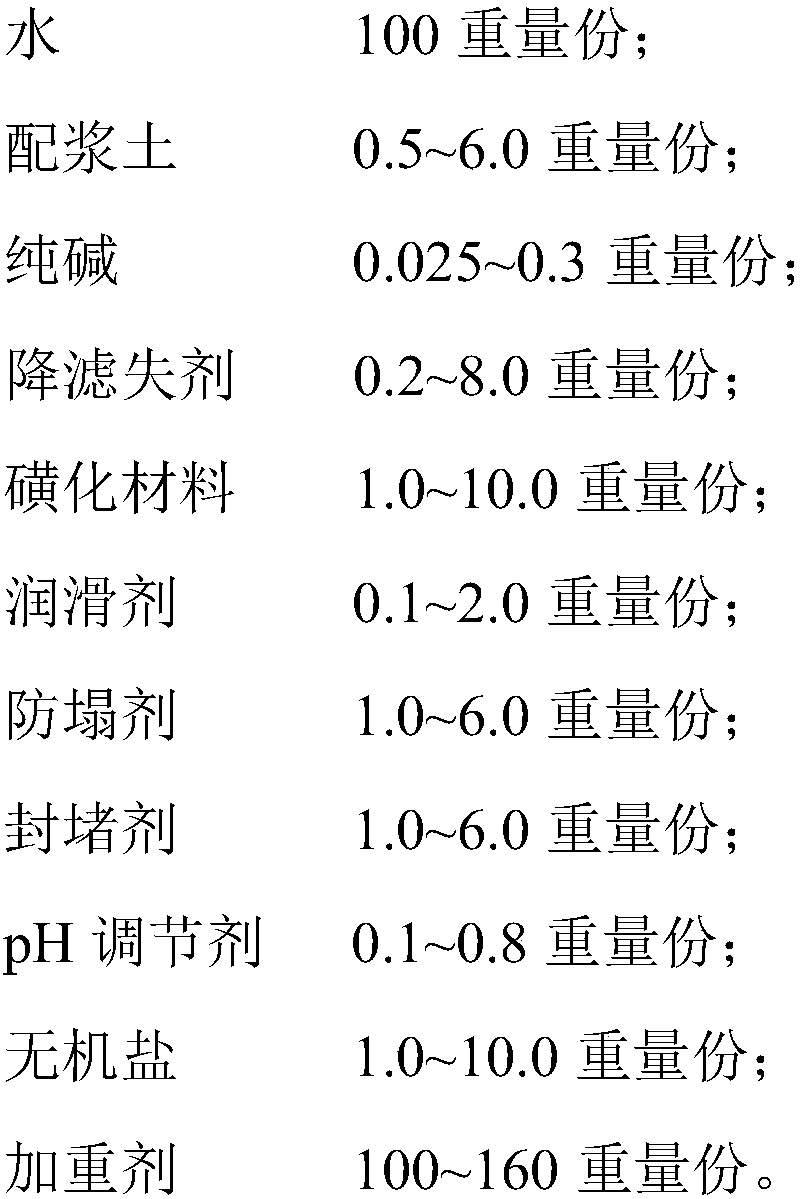

InactiveCN109868122AMeet the requirements of safe drillingGood settlement stabilityDrilling compositionWater basedInorganic salts

The invention relates to the technical field of drilling fluids, and provides a high-density water-based drilling fluid system for safely drilling through a diabase formation. The drilling fluid comprises the following components, in parts by weight: 100 parts by weight of water, 0.5-6.0 parts by weight of slurry mixing soil, 0.025-0.3 part by weight of sodium carbonate, 0.2-8.0 parts by weight ofa fluid loss reducing agent, 1.0-10.0 parts by weight of a sulfonated material, 0.1-2.0 parts by weight of a lubricant, 1.0-6.0 parts by weight of an anti-collapse agent, 1.0-6.0 parts by weight of ablocking agent, 0.1-0.8 part by weight of a pH adjusting agent, 1.0-10.0 parts by weight of an inorganic salt and 100-160 parts by weight of a weighting agent. The high-density drilling fluid systemprovided by the invention can not only ensure that the diabase formation is safely drilled, but also can carry diabase fallen blocks caused by release of ground stress in the initial stage of drillingthrough the diabase formation out of the ground in time, effectively avoid an occurrence of complex situations such as stuck drilling, and improve drilling efficiency on the basis of ensuring safe drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reciprocating rotating bidirectional replacement device

ActiveCN106703728AAvoid getting stuckAvoid deformation and fractureDirectional drillingBorehole/well accessoriesWindow openingMechanical engineering

The invention relates to the technical field of a radial horizontal rotating drilling work, and particularly relates to a reciprocating rotating bidirectional replacement device. The upper end of a motor joint of the device is connected with an underground power motor, a limiting locking block is welded and fixed to the outer wall of a motor joint, and a spiral guide groove I is arranged on the outer wall of the motor joint; the outside of the motor joint is sleeved with an outer cylinder I and sealed through a sealing ring I; multiple limiting locking grooves are evenly distributed on the circumference on the inner wall of the upper end of the outer cylinder I, the limiting locking blocks and the limiting locking grooves are matched to each other and can move downwards and unlock along the limiting locking groove. A soft drilling pipe can pass through a sleeve window opening position in radial horizontal rotary drilling work and spirally move and pass when taking out from a stratum, thereby avoiding blockage of the soft drilling pipe in the stratum, preventing the soft drilling pipe from deformation rupture, drill bit dropping, and jamming by excessive upwards lifting force, effectively prevent underground complex condition in the radial horizontal rotary drilling work, reduce the working risk and working cost, and improve the working efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

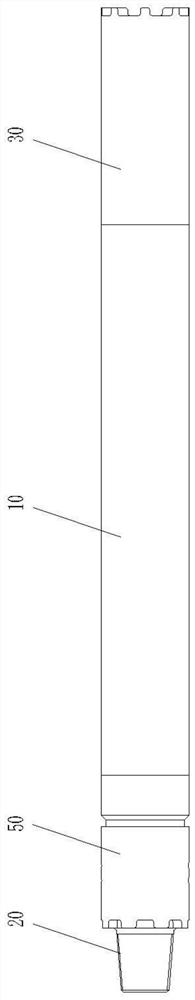

High-temperature and high-pressure resistant quick drillable composite material bridge plug with combined sealing structure

The invention relates to a high-temperature and high-pressure resistant quick drillable composite material bridge plug with a combined sealing structure. The bridge plug comprises a mandrel, and an upper push ring, an upper block, an upper block guide cone, a combined sealing structure, a lower block guide cone, a lower block and a lower limiting body coating the mandrel in sequence, wherein the lower limiting body is fixedly connected with the mandrel; and the upper push ring, the upper block, the upper block guide cone, the combined sealing structure, the lower block guide cone, the lower block and the lower limiting body are all prepared by high-temperature resistant composite materials. The bridge plug has the following beneficial effects: the composite material parts of the bridge plug are all prepared by the high-temperature composite materials, so that the mechanical performance is not obviously reduced at high temperature, and the reliability of the bridge plug is guaranteed. The unique material design enables easy drilling and milling; and the milled chips are smaller, and are easier to be circulated and returned out to prevent drilling blockage. In addition, as the composite materials are low in density and light in mass, the bridge plug is specifically suitable for such operations as separate layer fracturing and plugging of inclined wells and horizontal wells, and overcomes such defects as easy blockage and difficult drilling and milling in metal bridge plugs.

Owner:北京玻钢院复合材料有限公司

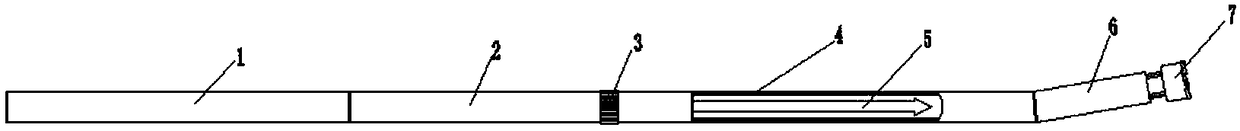

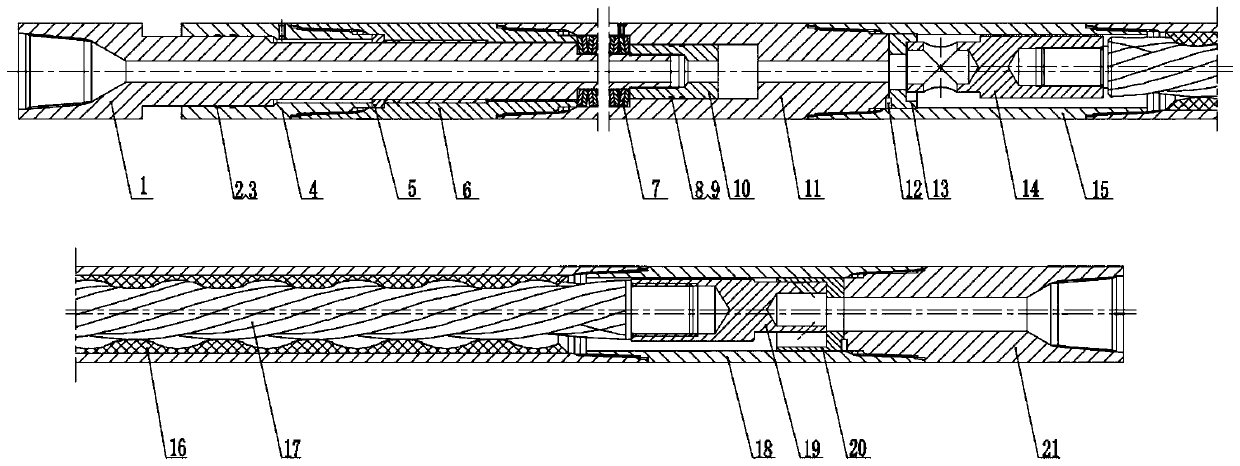

Method and drilling tool for directional-blasting well drilling

InactiveCN103527080AHinder progressAccelerate solidificationDirectional drillingWell drillingHigh energy

The invention relates to a method and drilling tool for directional-blasting well drilling in petroleum and natural gas well drilling. The method comprises the steps that rocks are melted and divided in an extruding mode through high-energy jet flows generated through explosion of perforating bullets, a large-aperture jet hole similar to a hole after explosive blasting is formed, perforating bullets can explode one by one at intervals in proper positions in the jet hole through a mechanism, and therefore the purpose of circulative directional blasting well drilling is achieved. The drilling tool mainly comprises a bullet bin, perforating bullets and a gun head. The bullet bin is a hollow steel pipe with one side sealed, a hanging ring is arranged at the sealed position of the bullet bin, and four bullet bin wedge slide keys are arranged at the position, not sealed, of the bullet bin. When the bullet bin is fully filled, the bullet bin wedge slide keys stretch out to prevent the perforating bullets from falling down, and when the bullet bin reaches the connector, the bullet bin wedge slide keys retreat in a sliding mode, and the perforating bullets can fall down to the automatic bullet sending position of the gun head. According to the method and drilling tool, cost is saved, the well drilling speed is improved, the accident rate of well drilling can be reduced, and operation is simple and convenient.

Owner:SOUTHWEST PETROLEUM UNIV

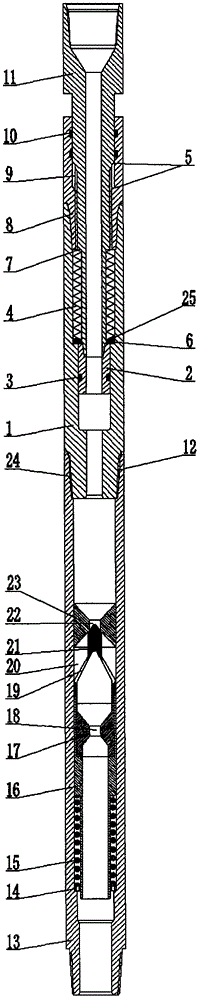

Device for reducing friction between drilling tool and well wall and method thereof

ActiveCN110748297AStrong axial vibration capabilityReduce frictional resistanceDrilling rodsVibration drillingWell drillingStructural engineering

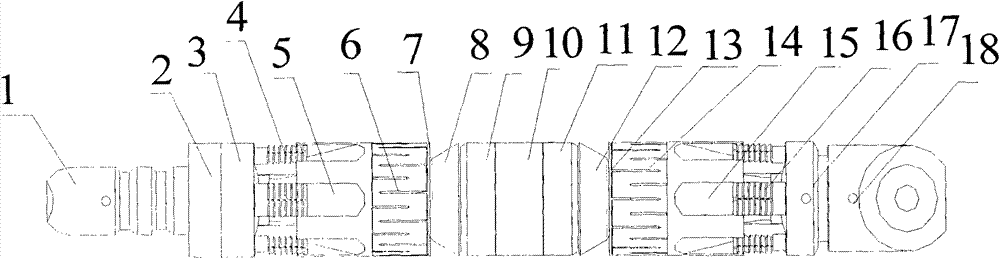

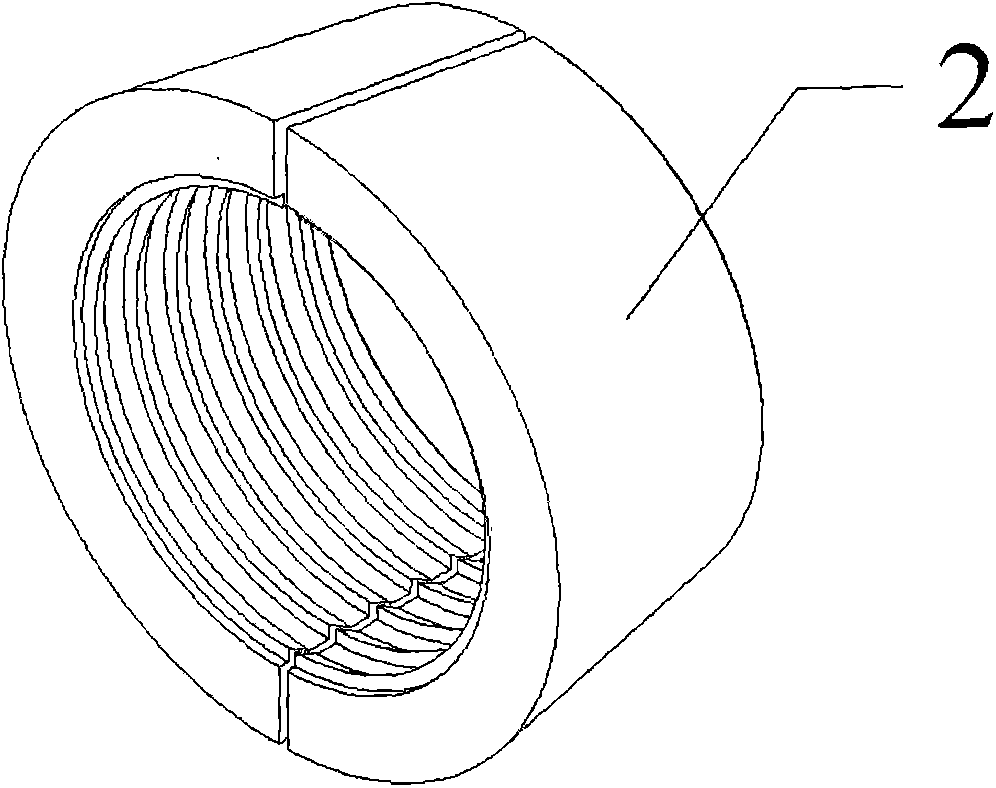

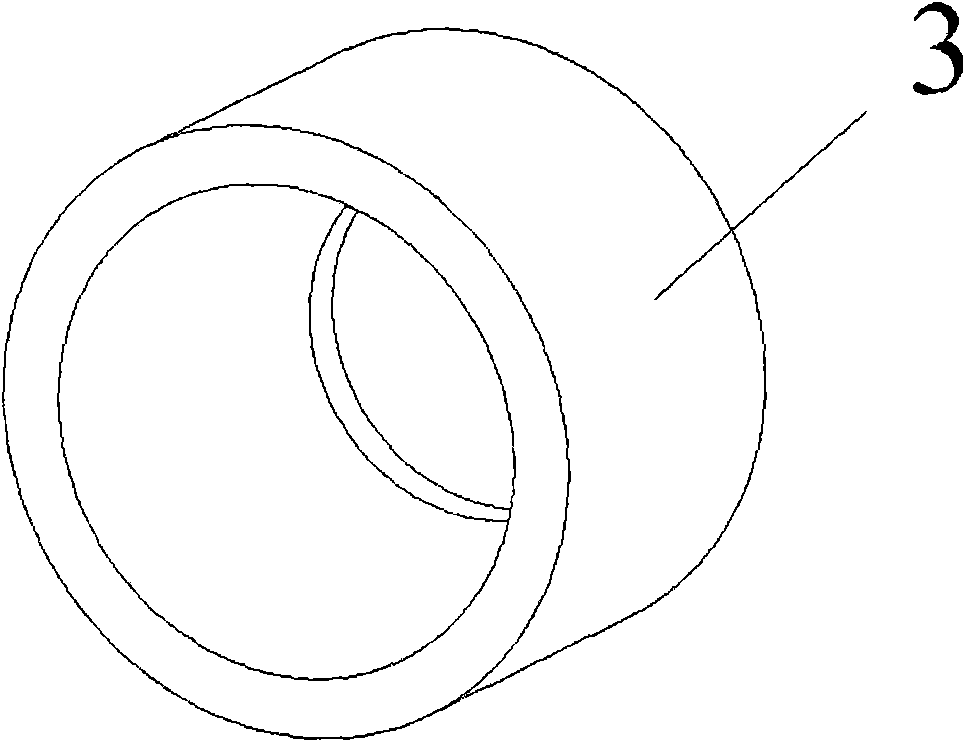

The invention relates to a tool for reducing friction between a drilling tool and a well wall, improving well drilling efficiency and shortening a well drilling cycle and a method thereof. According to the technical scheme, the tool for reducing the friction between the drilling tool and the well wall mainly comprises a sliding rod, a sealing ring, a check ring, a first upper shell, a limiting semi-circular ring, a second upper shell, a disc spring, a sealing ring, a check ring, a piston, a third upper shell, a common flat key, an upper fixed valve, an upper moving valve, a fourth upper shell,a stator, a rotor, a lower shell, a lower moving valve, a lower fixed valve and a lower interface, wherein the first upper shell, the second upper shell, the third upper shell, the fourth upper shell, the stator, the lower shell and the lower interface are in threaded connection in sequence, under the driving of the rotor, an inclined hole runner of the lower moving valve is periodically opened and closed, the energy of fluid is converted into a series of pulse pressures, and static friction between the drilling tool and the well wall is broken, so that the purpose of reducing the friction and improving the drilling capacity of a horizontal section is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

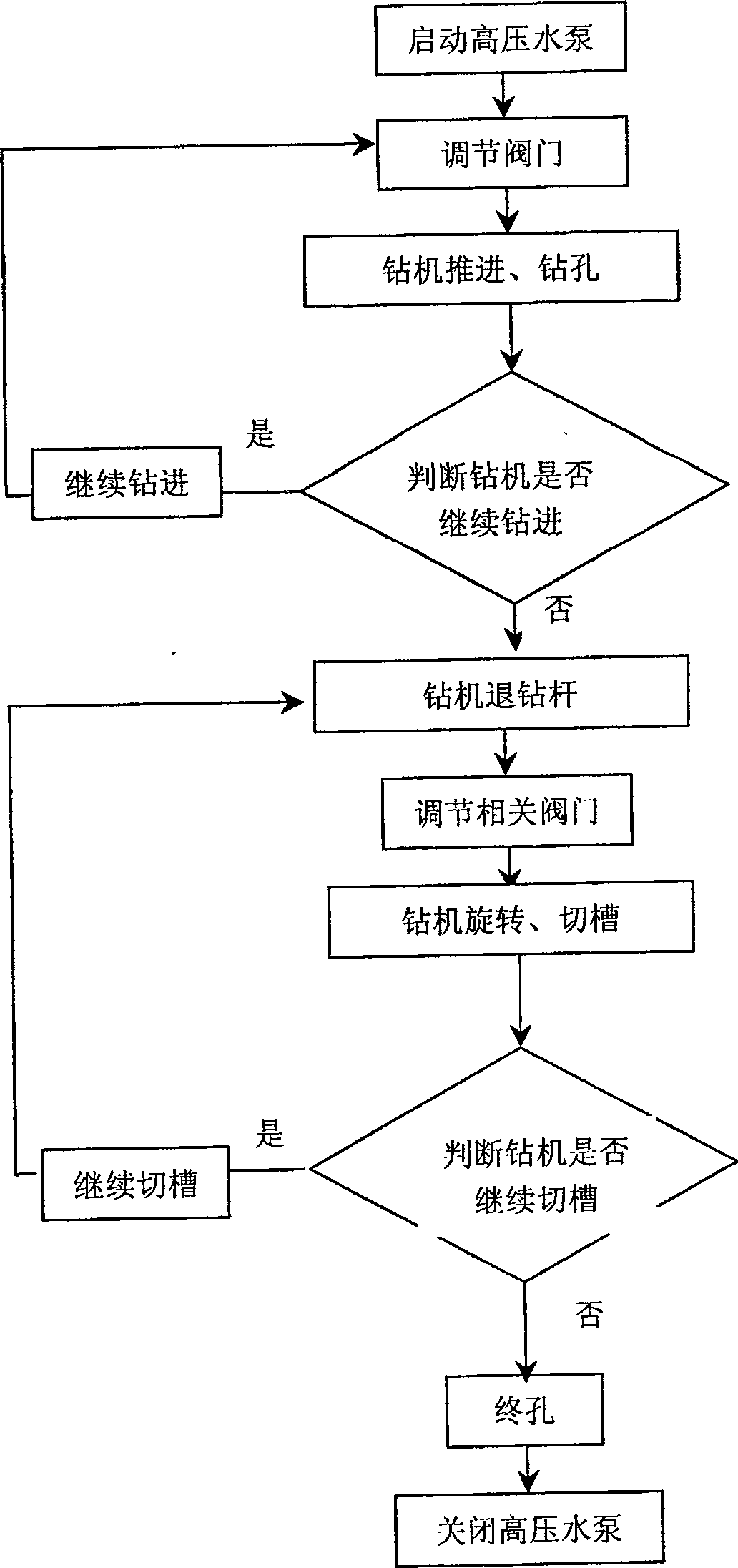

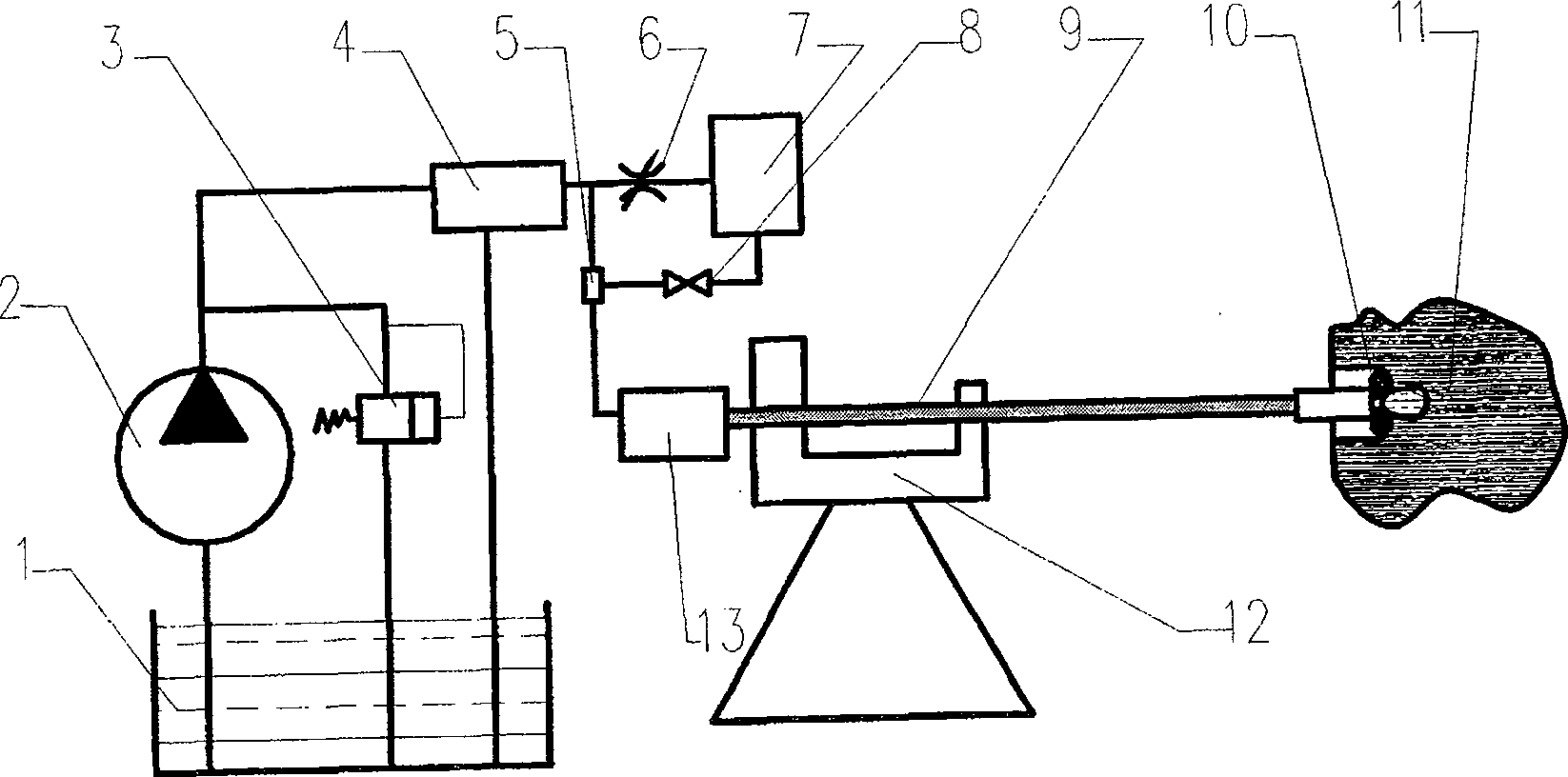

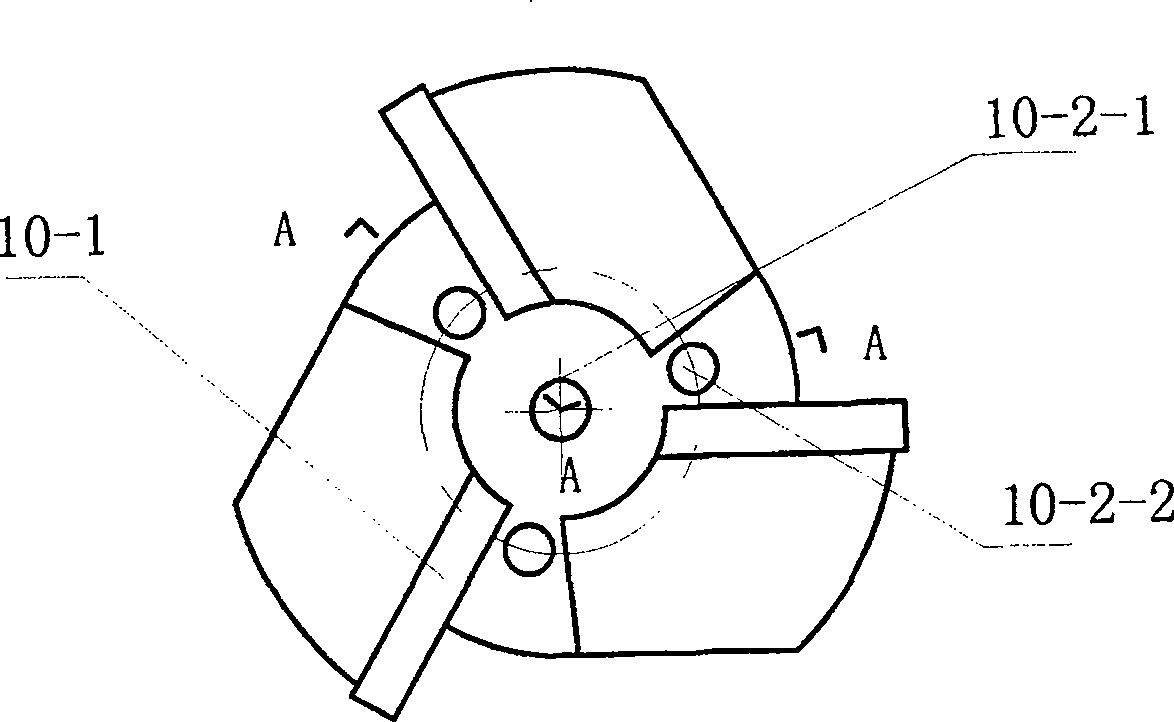

Coal bed gas drainage method and device

The present invention relates to a gas pumping and exchanging method and devices in a coal mine and coal seam, and belongs to the coal mine security field; the present invention aims to prolong the service life of the drill and improve the drilling depth and the drilling speed, and to enhance the safety during pumping gas and to improve the validation of the coal seam. The present invention is characterized in that the method is performed by following steps: starting a high-voltage water pump, adjusting a valve, drill pushing, hole drilling, adjusting the valve drill rotating, grooving, and shutting down the high-voltage water pump. The devices involved in the method mainly comprises the high-voltage water pump, a mixing chamber, abrasive cans, a high-voltage sealed rotator, a drill, drill pipes and a multifunctional drill; the method uses the multiphase oscillation jet to cut off and break the coal seam and also to drill holes and cut grooves; the power effect leads to the evolution of the coal seam fractured field, thereby improving the validation of the coal seam. And the cinder produced is wee and can flow away with water, thereby avoiding the drill holding and the hole bursting; the method can be used to pump and exchange gas in different quality coal mines and to improve the pumping and exchanging capability of the gas.

Owner:CHONGQING UNIV

Low-density water-based drilling fluid and preparation method thereof

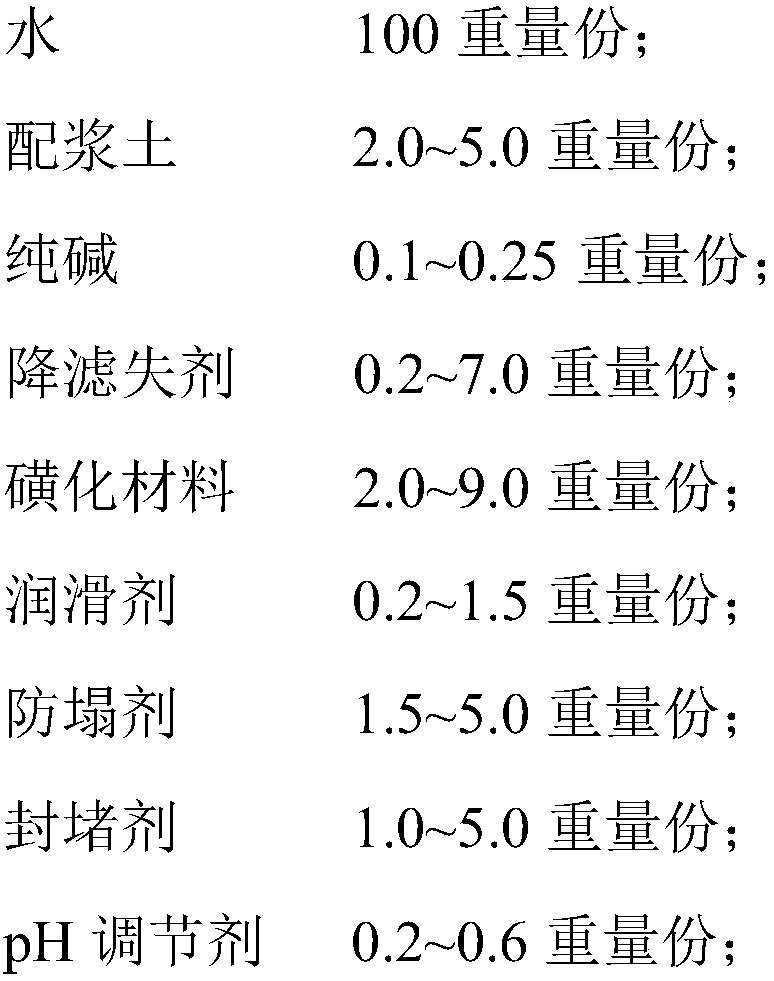

InactiveCN109868123AMeet the requirements of safe drillingGood settlement stabilityDrilling compositionWater basedInorganic salts

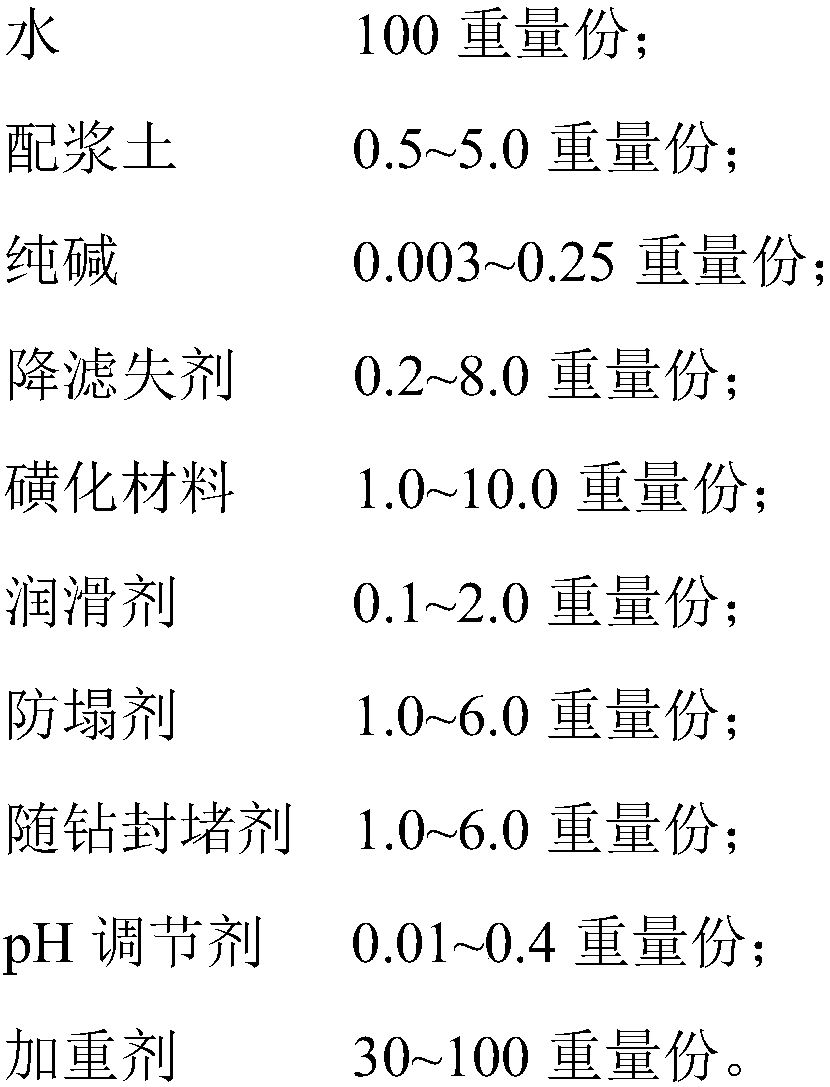

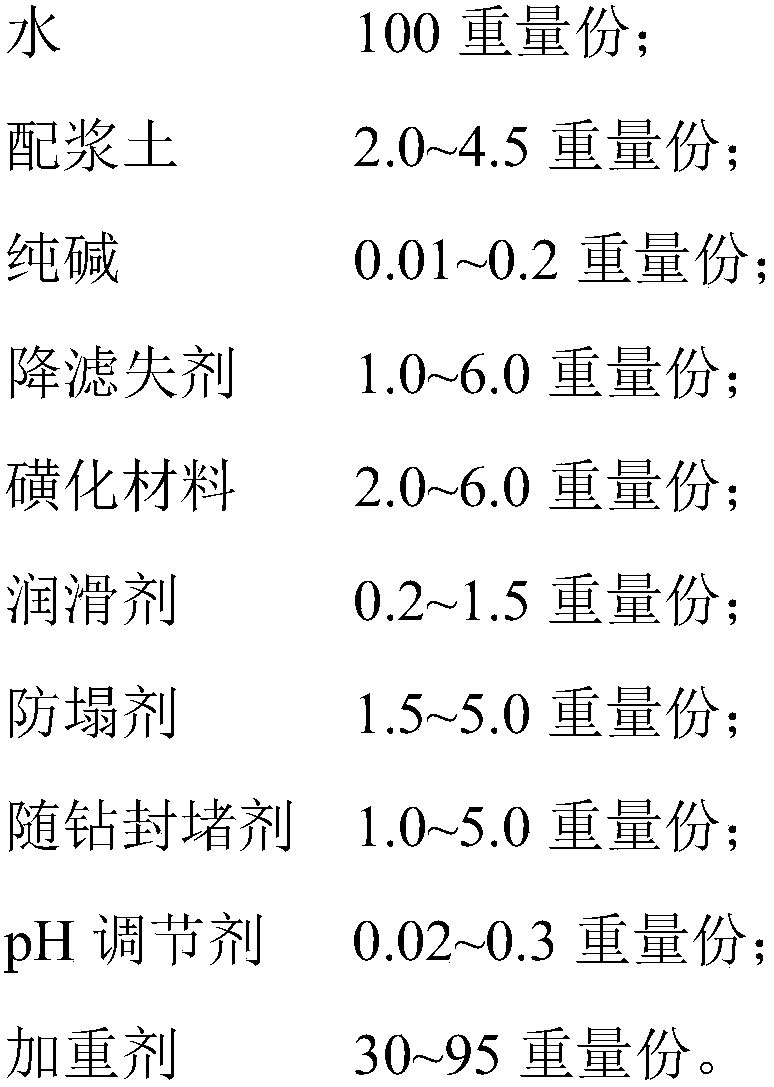

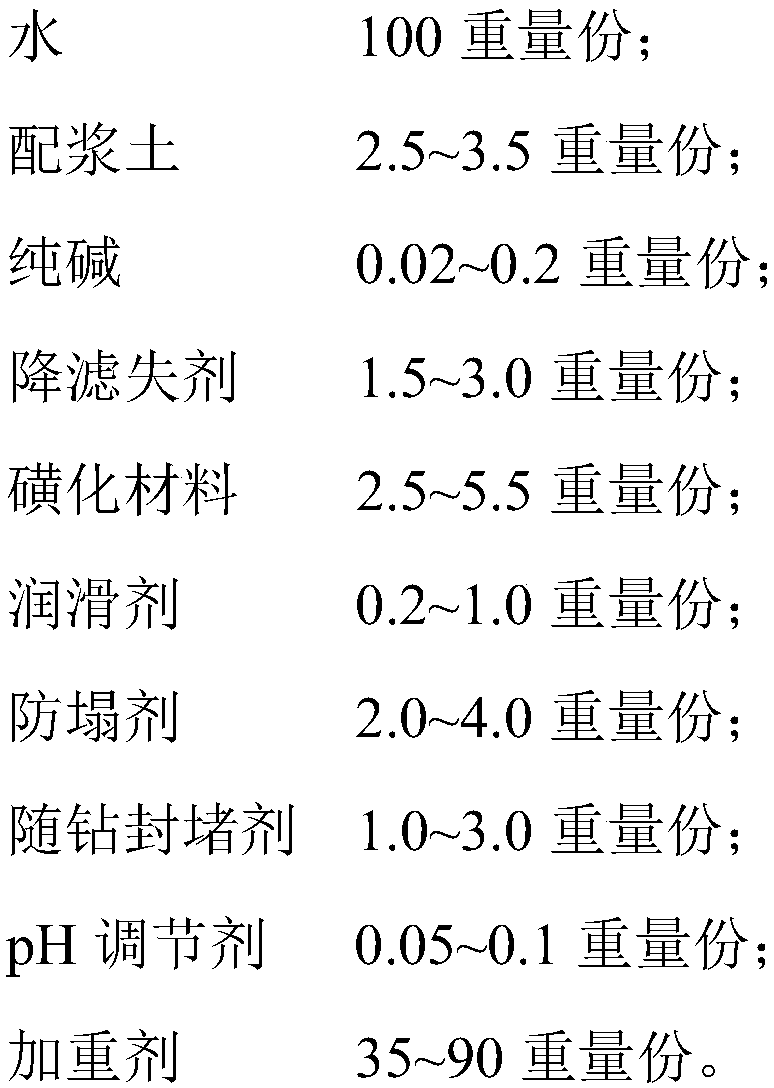

The invention provides a low-density water-based drilling fluid system for safely drilling through a long open-hole diabase formation. The drilling fluid system comprises the following components, inparts by weight: 100 parts by weight of water, 0.5-5.0 parts by weight of slurry mixing soil, 0.003-0.25 part by weight of sodium carbonate, 0.2-8.0 parts by weight of a fluid loss agent, 1.0-10.0 parts by weight of a sulfonated material, 0.1-2.0 parts by weight of a lubricant, 1.0-6.0 parts by weight of an anti-collapse agent, 1.0-6.0 parts by weight of a plugging agent while drilling, 0.01-0.4 part by weight of a pH adjusting agent and 40-80 parts by weight of a weighting agent; and the drilling fluid system further comprises 0.1-10.0 parts by weight of an inorganic salt. The drilling fluidprovided by the invention has good rheological performance and rock-carrying capacity; the drilling fluid can not only safely drill through the diabase formation, but also can meet the purpose that fallen diabase returns to the ground in time, effectively avoid stuck drilling, ensure safe drilling and shorten a well construction period through improvement of plugging while drilling and collapse resistance of the system.

Owner:CHINA PETROLEUM & CHEM CORP +1

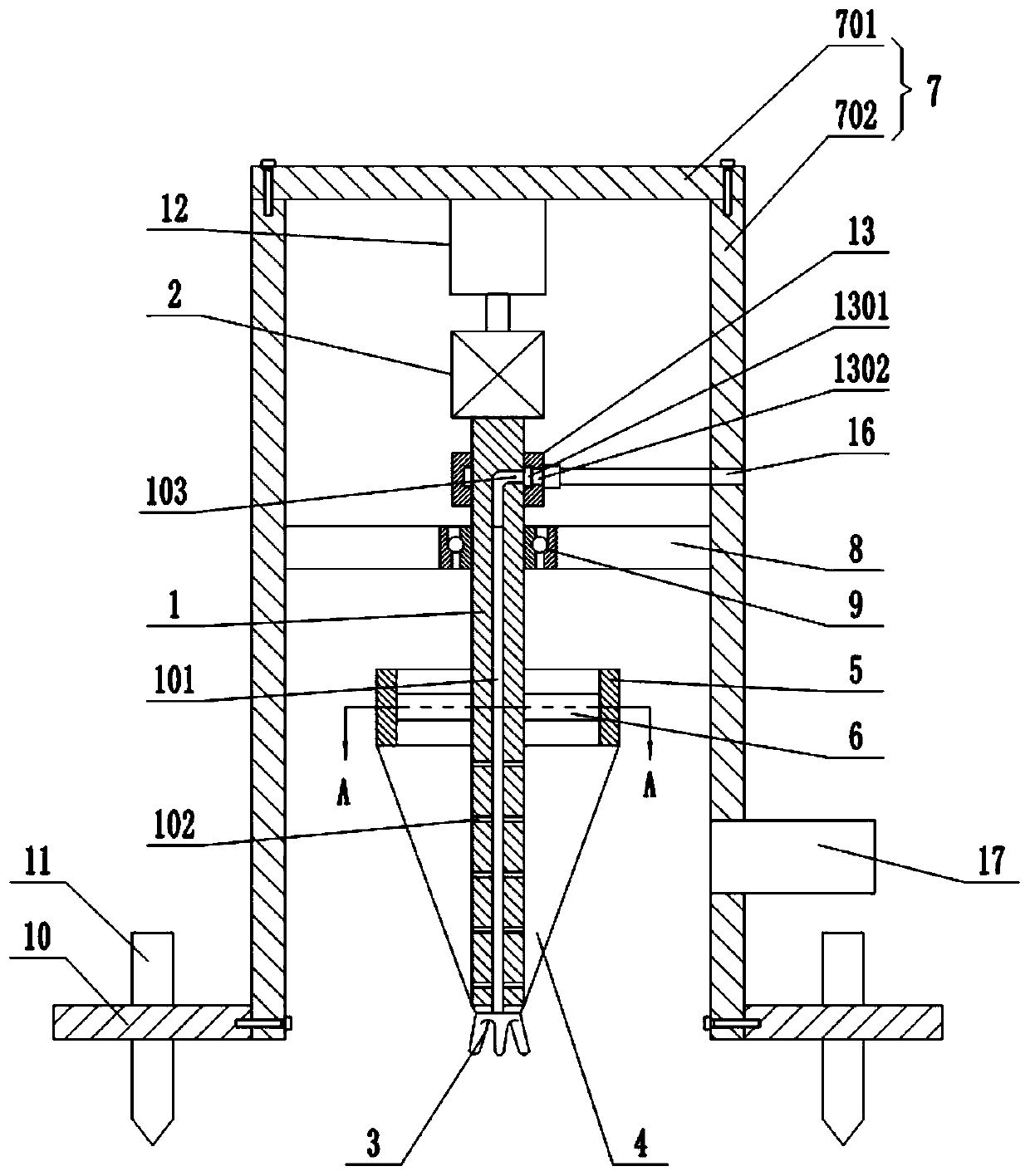

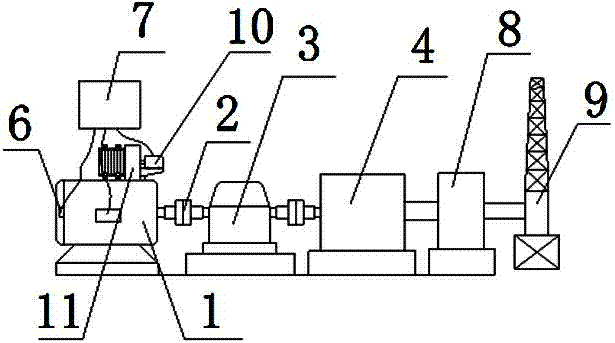

Drilling machine using motors as main power

InactiveCN102953677AReduce the number of drilling stopsAvoid stuck drillConstructionsRotary drillingElectric machineryStandby power

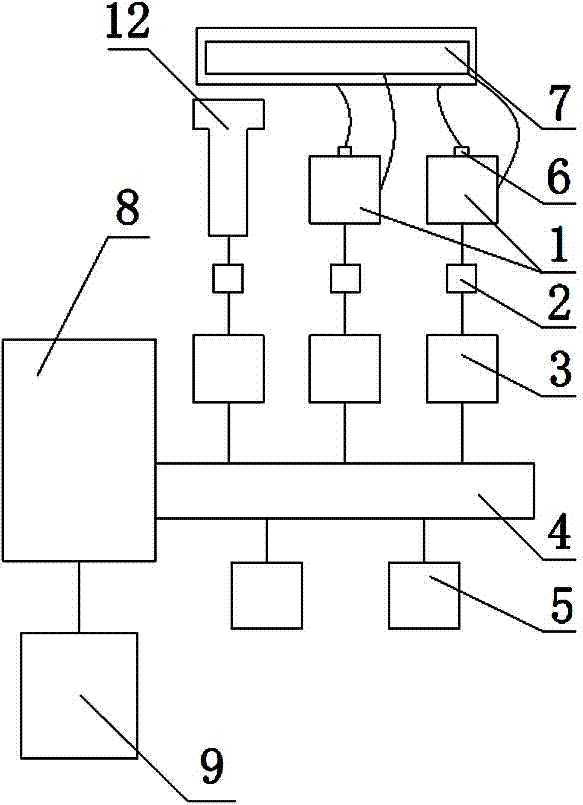

The invention relates to a drilling machine using motors as a main power. The drilling machine comprises at least two motors (1), fans (11), hydraulic couplers (3), a compounding transmission (4), a winch (8), a drilling machine body (9) and a diesel engine (12), wherein each motor (1) is provided with one fan (11), the output end of each motor (1) is connected with each hydraulic coupler (3), each hydraulic coupler (3) is connected with the input end of the compounding transmission (4), the output end of the winch (8) is connected with the drilling machine body (9), the diesel engine (12) is connected with each motor (1) in parallel, the output end of the compounding transmission (4) is connected with the winch (8), the output end of the winch (8) is connected with the drilling machine body (9), each motor (1) is an HTB02C frequency-variable and speed-adjustable asynchronous motor, and the compounding transmission (4) is connected with two sludge pumps (5). The drilling machine has the advantage that the motors is are used as the main power, and the diesel engine is used as a standby power, so the adaptability is high, the energy consumption is low, the maintenance cost is low, the environment-friendly effect is realized, and the control is accurate.

Owner:SICHUAN HONGHUA ELECTRIC

Well killing method used for eliminating gravity displacement of horizontal well

InactiveCN109098683ASolve a major technical difficultyEliminate kill methodFlushingSealing/packingWell killFormation fluid

The invention discloses a well killing method used for eliminating the gravity displacement of a horizontal well. The method includes: determining the closing pressure of an annular preventer; openinga ram preventer; hoisting a drilling tool at the speed of 0.3m / s, closing a semi-sealing ram preventer consistent with the drilling tool in the well in size when the length of the hoisted drilling tool reaches the length of a horizontal section in a well bottom, and then opening the annular preventer; starting a drilling fluid pump and opening a throttle valve, regulating the throttle valve to allow casing pressure to be equal to well closing casing pressure before the overflow discharge of the drilling fluid pump, regulating the pump speed of the drilling fluid pump to well killing pump speed, keeping the pump speed unchanged, and reading standpipe pressure at the moment; keeping the pressure of a circulating standpipe unchanged until formation fluid is discharged out of the ground; measuring the well closing casing pressure and the well closing standpipe pressure during pump shutdown and well closing, and judging the well closing casing pressure and the well closing standpipe pressure. The method has the advantages that gravity displacement is eliminated, and one large technical difficulty of the well killing of the horizontal well is solved.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preventing blockage through vibration in directional drilling process of horizontal well

InactiveCN105443062AAvoid stuck drillAvoid downhole accidents such as drill stickingVibration devicesOccurrence probabilityDrill pipe

The invention relates to the technical field of drilling and completion of a horizontal well and an extended reach well, in particular to a method for preventing blockage through vibration in a directional drilling process of the horizontal well. The method comprises the steps of installing a group or a plurality of groups of vibration tools on the upper portion of a drill collar and drill pipe in a horizontal well kick-off assembly and installing an anti-blocking centering device on the upper portion of the vibration tools. The method reduces the occurrence probability of sticking and blocking accidents in the drilling process, the vibration tools can generate vibration under the effect of fluid power, the vibration can be effectively transferred to nearby drilling tools, and the static friction force between the drilling tools and a lower well wall can be transformed to kinetic friction force in the sliding drilling process. The problem that the drilling tools are statically located on the lower well wall for a long time, so that drilling accidents such as drill blockage occur is solved. The shortcomings that if the drilling tools are in a static state for a long time, the adhesive force caused by the drilling tools and the lower well wall is bigger and bigger, so that the drilling tools are hard to be lifted, and even the sticking and blocking accidents occur are overcome.

Owner:CNPC GREATWALL DRILLING ENG

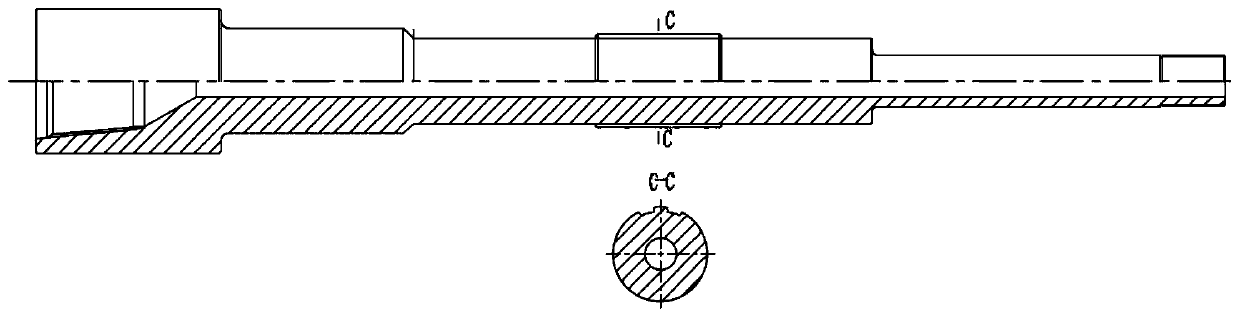

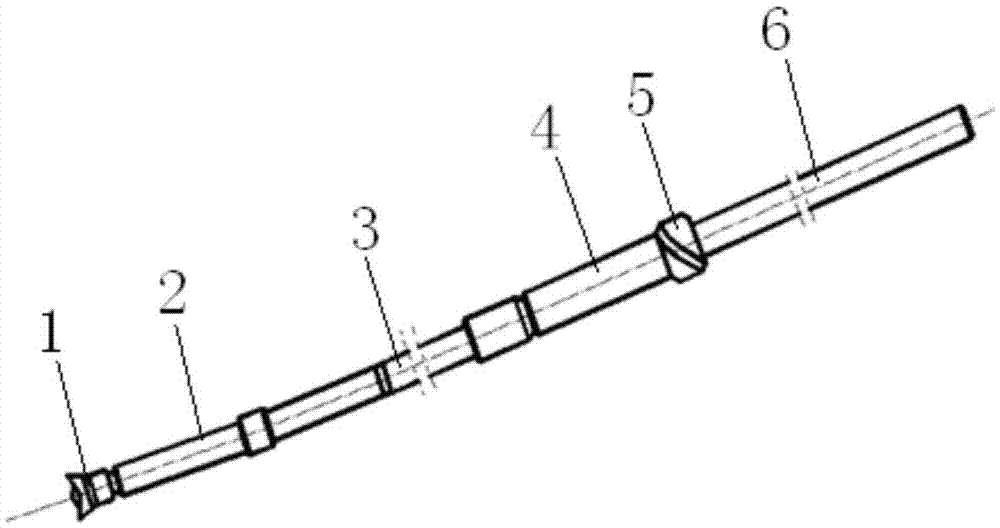

Self-locking drill rod capable of rotating forwards and backwards

ActiveCN112576203AContinuous disassemblySimple structureDrilling rodsGeothermal energy generationForward slidingEngineering

The invention discloses a self-locking drill rod capable of rotating forwards and backwards. The drill rod comprises a rod body, a male connector, a female connector, a mandrel and a sliding sleeve, wherein the mandrel is sleeved in the rod body and has driving force for sliding backwards in the axial direction, the sliding sleeve is slidably arranged outside the male connector in an axial sealingand sleeving mode and is in transmission fit with the male connector, meshing teeth are arranged at the front end of a sliding sleeve and the rear end of the female connector, and when a male connector of a rear drill rod is in threaded connection with a female connector of a middle drill rod, the male connector of the rear drill rod axially pushes a mandrel in the middle drill rod to axially slide forwards together with a sliding sleeve, so that the sliding sleeve of the middle drill rod is meshed with the meshing teeth of a female connector of the front drill rod. According to the self-locking drill rod capable of rotating forwards and backwards, by means of the matching relation between the adjacent drill rods, automatic locking during upward drilling and automatic unlocking during downward drilling can be achieved, forward and reverse alternate rotation and reciprocating hole sweeping can be achieved so as to enhance deslagging, jam releasing and pressure relieving, and thereforedrill jamming and drill holding are avoided; and the link of manual auxiliary disassembling and assembling is omitted, so that mechanical automatic drill rod assembling and disassembling are achieved,and the automatic construction efficiency of a drilling machine can be greatly improved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

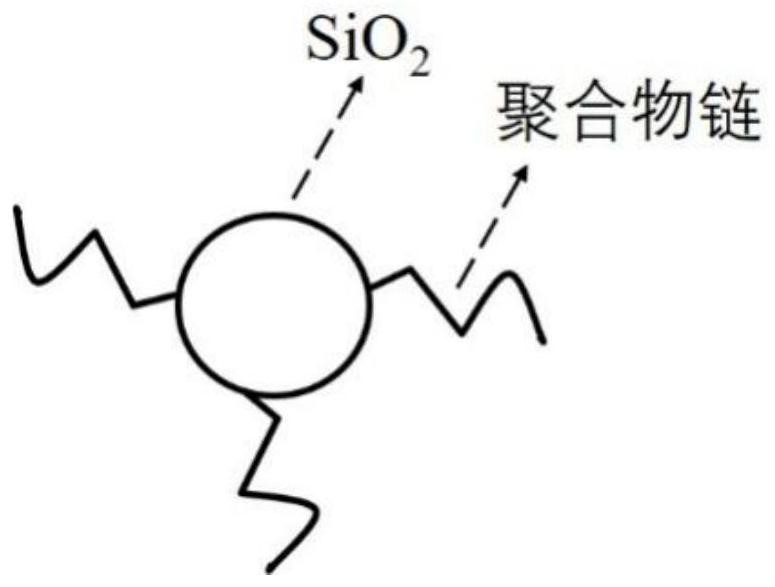

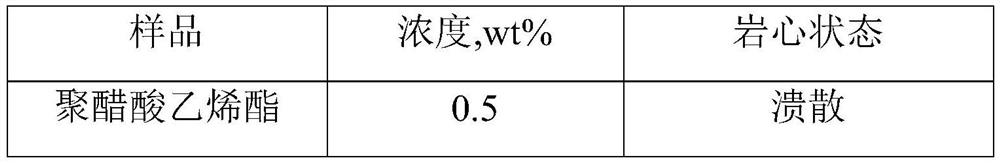

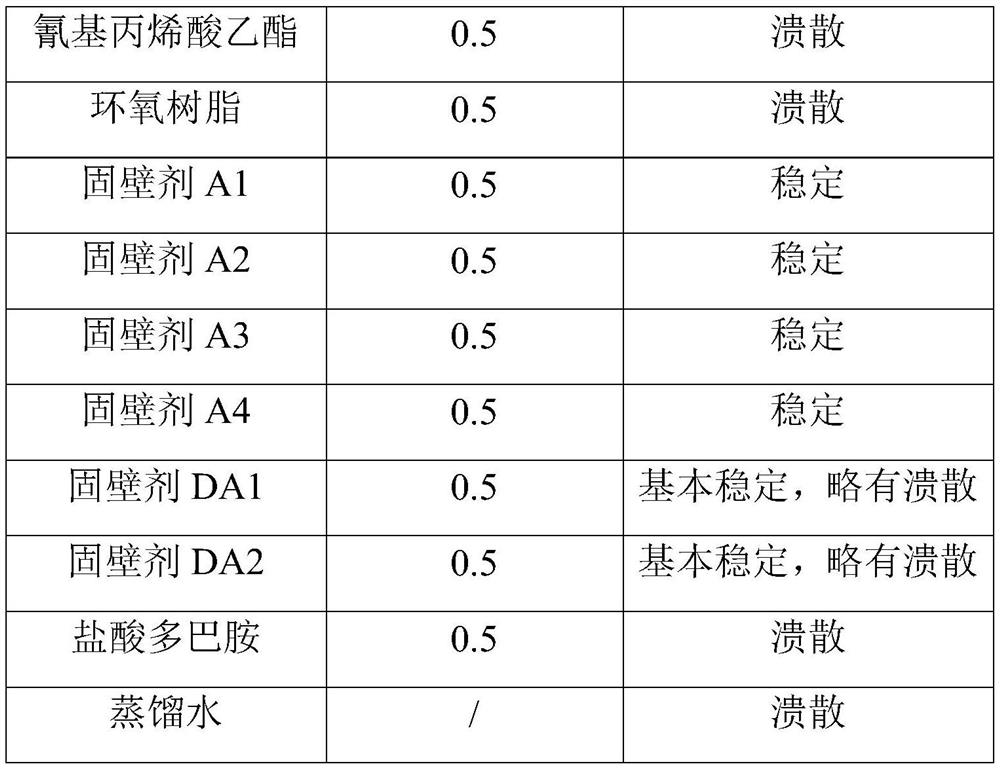

Cementing and blocking type wall fixing agent for water-based drilling fluid as well as preparation method and application of cementing and blocking type wall fixing agent

ActiveCN114716984AGood sealingStrong cementing functionOther chemical processesDrilling compositionMeth-Ethyl group

The invention relates to the technical field of well drilling, and discloses a cementing plugging type wall fixing agent as well as a preparation method and application thereof. The method comprises the following steps: (1) preparing a dispersion system A from nano silicon dioxide, preparing a dispersion system B from gamma-(methacryloyloxy) propyltrimethoxysilane, mixing the dispersion system A and the dispersion system B, adjusting the pH value to 8-9, adding phenothiazine for reaction, filtering after the reaction is finished, and washing and drying a product; (2) mixing the modified silicon dioxide prepared in the step (1), acrylamide, acrylic acid, sodium p-styrenesulfonate, dimethyl diallyl ammonium chloride, 1-ethyl-(3-dimethylaminopropyl) carbodiimide, dopamine hydrochloride and water, introducing protective gas to remove oxygen, and adding an initiator to react; and (3) washing, drying and crushing the product obtained in the step (2) to obtain the wall fixing agent. The wall fixing agent disclosed by the invention is beneficial to maintaining and even enhancing rock strength, so that an effect of stabilizing a fractured formation well wall is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Multifunctional accessory ingredient of drilling fluid

InactiveCN103396770AAchieve regulationFiltration filter is goodDrilling compositionCellulosePolymer science

The invention discloses a multifunctional accessory ingredient of a drilling fluid. The multifunctional accessory ingredient is composed of anionic cellulose sodium salt, graphite powder, potassium humate, potassium chloride, small cations, polyacrylonitrile salt, a middle-molecular polymer and a synergist, wherein the production process of the middle-molecular polymer comprises the following steps of: firstly, mixing acrylic acid and acrylic amide according to the weight ratio of 55:45, and distilling and dehydrating to form a mixture for later use; and respectively adding sodium sulfate and maleic anhydride into the mixture, and then, carrying out polymerization reaction and grafting to obtain the middle-molecular polymer, wherein the sodium sulfate accounts for 40% of the weight of the mixture and the maleic anhydride accounts for 60% of the weight of the mixture. The synergist is composed of the following raw materials in weight ratio: 20% of ethanediamine, 30% of hydrogen peroxide, 40% of vinyl monomers and 10% of plasticizer, and is obtained through mixing the raw materials and reacting at the temperature of 80 DEG C for 4h.

Owner:蔡修枝

Quick-drill pneumatic hard rock drill

ActiveCN102900355AHigh shear forceIncrease propulsionConstructionsReciprocating drilling machinesAtmospheric pressureCylinder block

The invention discloses a quick-drill pneumatic hard rock drill which comprises a host machine, an operating valve and a propulsion unit, which are independent of one another and are connected with one another. An air suction nozzle communicated with an air distribution valve is arranged on a base of the host machine; the air distribution valve is in a fin type structure and consists of a valve body, a valve block and a valve rod; a valve cavity is arranged inside the valve body and is respectively communicated with a front chamber and a back chamber of a cylinder body through left and right air passages; the seesaw-like valve block is installed in the valve cavity through the valve rod; under the action of air pressure, the two ends of the valve block can respectively close or open the left and right air passages to enable a piston rod to move with high frequency; and a rotating device is arranged on a machine head. According to the invention, a new fin type air distribution valve which is flexible in change-over is adopted, so the impact frequency is greatly improved. The rotating device realizes primary transmission by adopting worm-and-gear principle, the transmission ratio is big, and the transmission efficiency is high. The quick-drill pneumatic hard rock drill is small in size, light in weight and convenient to operate, and is applicable for various propulsion modes.

Owner:青岛达邦钻机有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com