Well drilling vibrator of horizontal well

A technology of horizontal wells and vibrators, which is applied in vibratory drilling, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of limited drilling footage in the horizontal section, poor ability to transmit drilling pressure, and difficulty in running coiled tubing. It achieves the effect of increasing the ROP, strong axial vibration ability and increasing the uniform contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

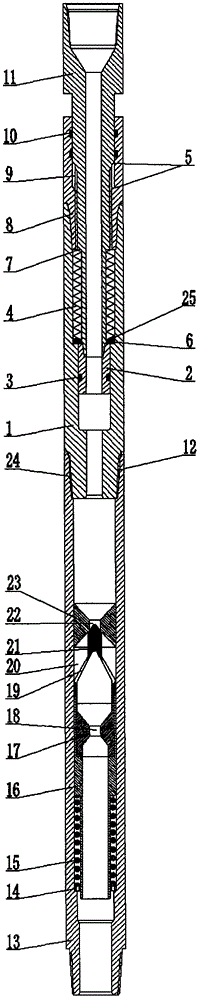

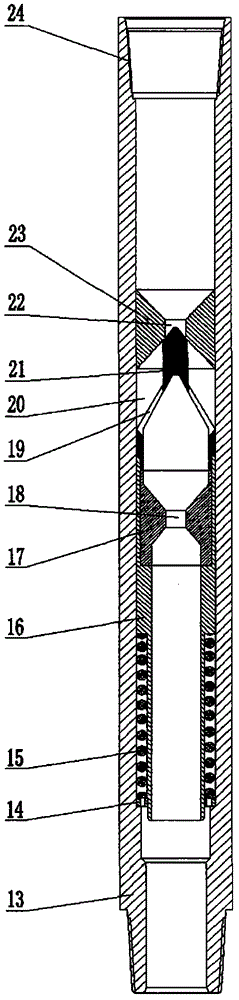

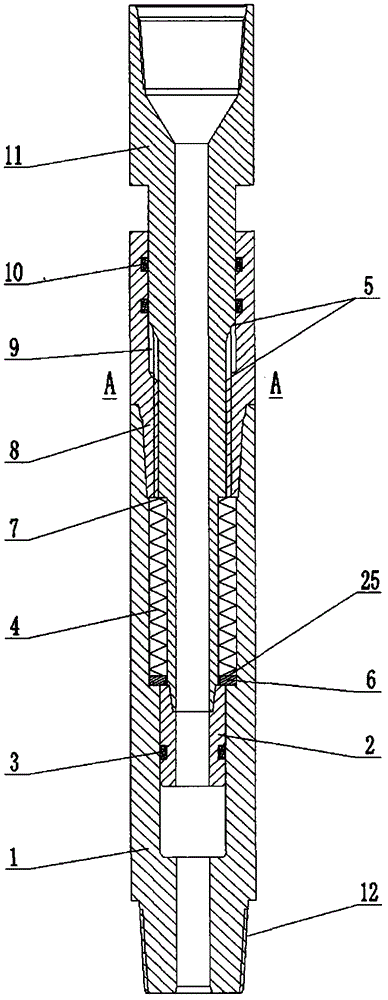

[0015] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 1-Figure 6 Shown; a horizontal well drilling vibrator, its structure is made up of an oscillating part and a valve part; the oscillating part is mainly composed of a housing (1), a piston head (2), a lower sealing ring (3), a disc spring (4) , support end face (5), spacer (6), upper shoulder (7), static sleeve (8), sliding cavity (9), upper sealing ring (10), sliding shaft (11), housing male thread ( 12) and lower shoulder (25) form. The valve parts are mainly composed of valve housing (13), retaining ring (14), spring (15), center pipe (16), sliding valve body (17), nozzle (18), water eye (19), second flow channel (20), valve plug (21), first flow passage (22), fixed valve seat (23) and housing female screw thread (24). The housing (1) of the oscillating part is connected with the static sleeve (8) by threads, and the sliding shaft (11) is installed in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com