Device for reducing friction between drilling tool and well wall and method thereof

A wellbore and drilling tool technology, which is applied to the device and its field for reducing the friction between the drilling tool and the wellbore, can solve the problems that the drilling tool cannot be lifted or the drill is broken, the coiled tubing is reached, and the softness is hit. Improve the uniform contact time, strong axial vibration ability, and improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

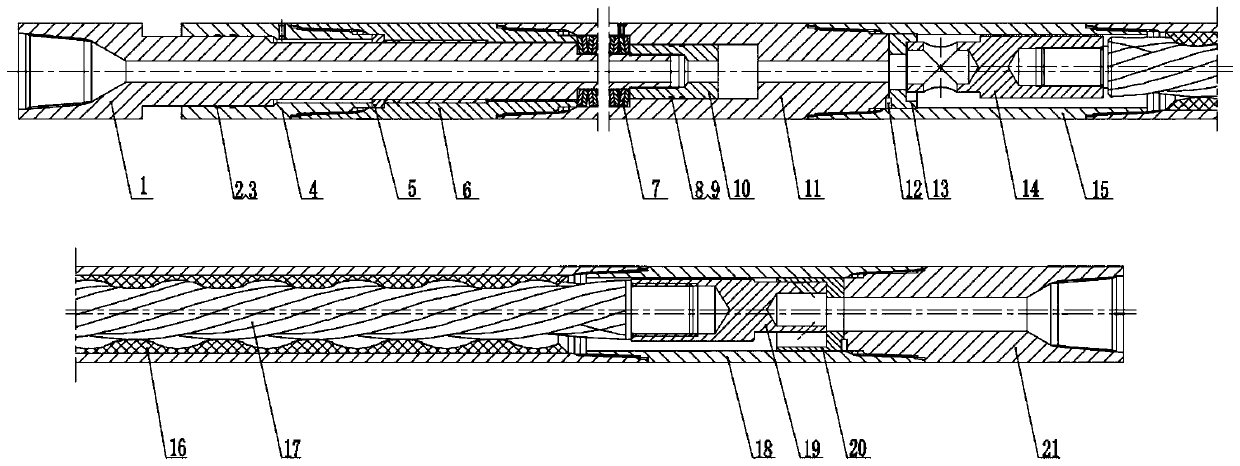

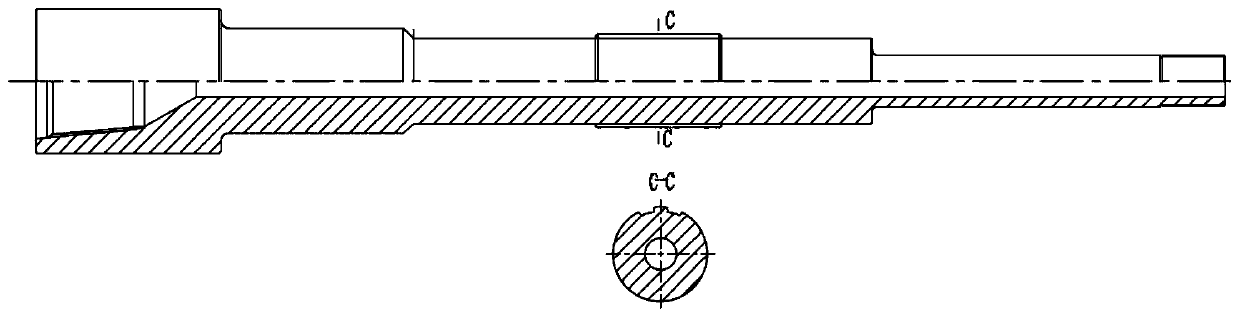

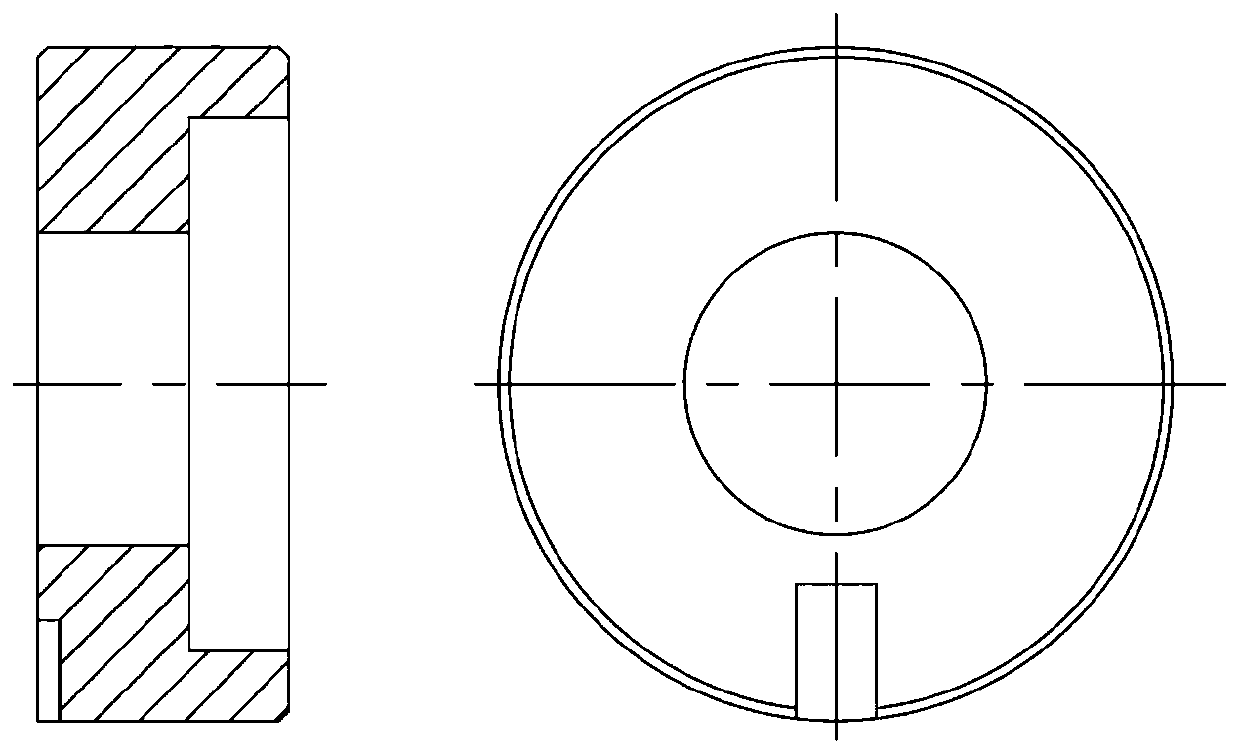

[0016] like Figure 1-Figure 6 As shown, a tool for reducing the friction between the drilling tool and the well wall, its structure mainly includes: a slide rod 1, a sealing ring 2, a retaining ring 3, a first upper casing 4, a limiting semi-circular ring 5, Second upper case 6, disc spring 7, sealing ring 8, retaining ring 9, piston 10, third upper case 11, ordinary flat key 12, upper fixed valve 13, upper moving valve 14, fourth upper case 15 , stator 16, rotor 17, lower casing 18, lower moving valve 19, lower fixed valve 20, lower interface 21; its technical features are: first upper casing 4, second upper casing 6, third upper casing 11 , the fourth upper casing 15, the stator 16, the lower casing 18, and the lower interface 21 are threaded sequentially from top to bottom; there is a round hole-shaped flow channel inside the slide rod 1, and the lower end of the slide rod 1 is installed on the first upper casing 4. In the inner hole of the second upper case 6, there is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com