Patents

Literature

39results about How to "Reduce cause" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

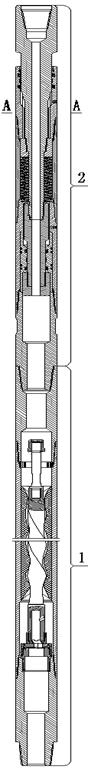

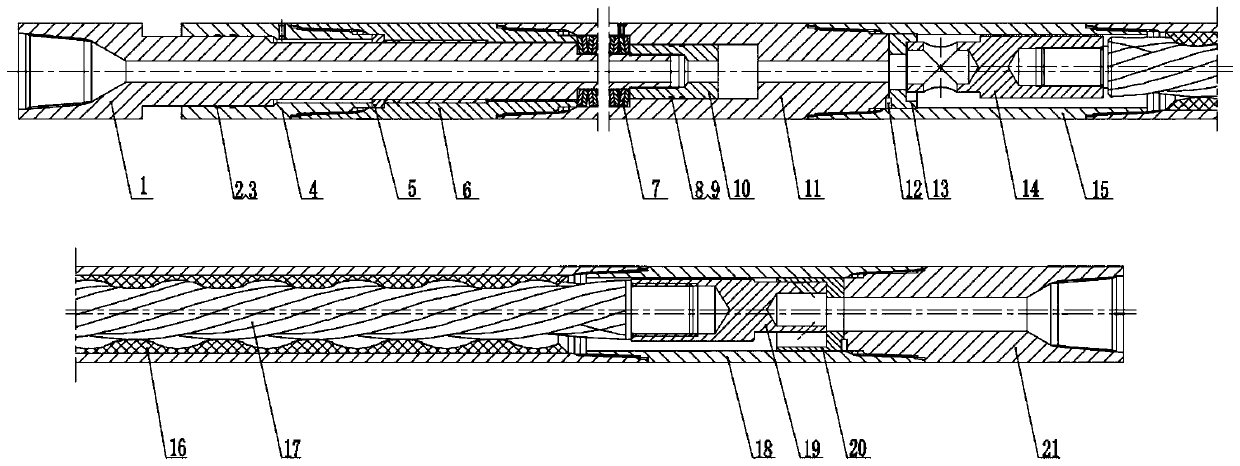

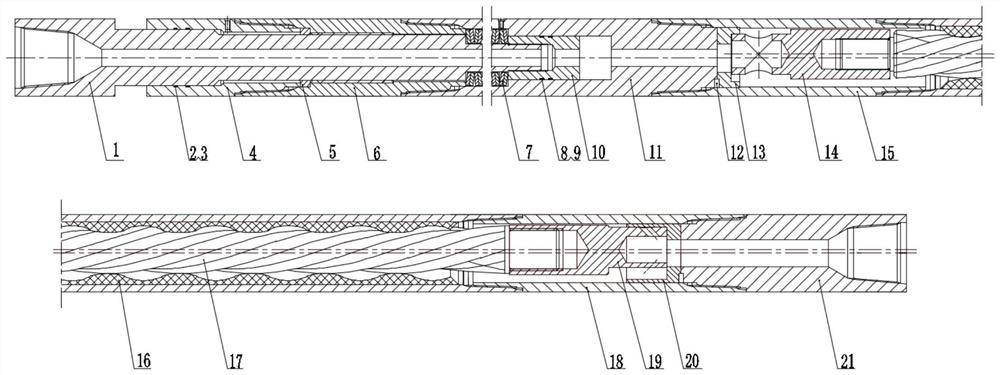

Pressure resistant tool for reducing frictional resistance of horizontal well section

ActiveCN102587832AStrong axial vibration capabilityEffective destructionDirectional drillingBorehole drivesUpper jointDrive shaft

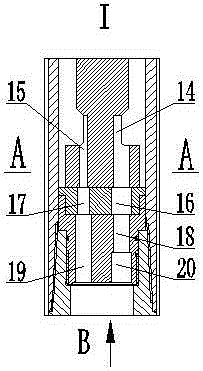

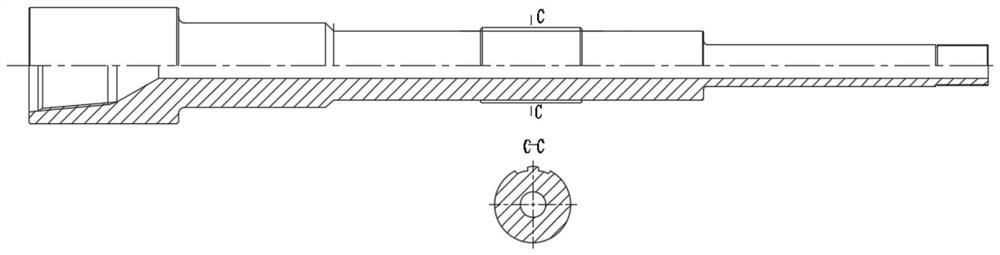

The invention relates to a pressure resistant tool for reducing frictional resistance of a horizontal well section, which is used for reducing the frictional resistance of the horizontal well section and improving horizontal section extending and drilling capacity. The technical scheme includes: the pressure resistant tool for reducing the frictional resistance of a whole well consists of a pulse part and a vibration part. The pulse part mainly comprises an upper joint, a power part, an upper abrasion-resistant block, an upper fixing sleeve, a lower abrasion-resistant block, a lower fixing sleeve, a lower valve and a lower joint. The vibration part mainly comprises a spline transmission shaft, a spline righting tube, a locking nut, a disk spring, a supporting shell, a piston rod, a piston bush, a piston nut and a pulse pup joint. The vibration part is in threaded connection with the upper end of the pulse part. The overall overflowing area of a valve part driven by a motor rotor is gradually reduced, and fluid energy is converted into a series of pulse pressure to be transmitted to the vibration part. The pressure resistant tool has the advantages of high axial vibration capacity and simple structure, the frictional resistance between a drill stem and the well wall can be reduced, and the horizontal well and large-displacement well horizontal section extending and drilling capacity is improved.

Owner:SOUTHWEST PETROLEUM UNIV

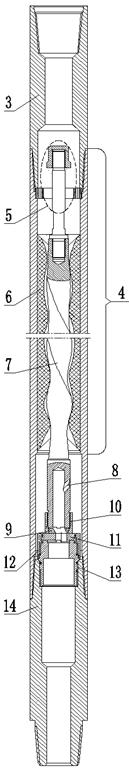

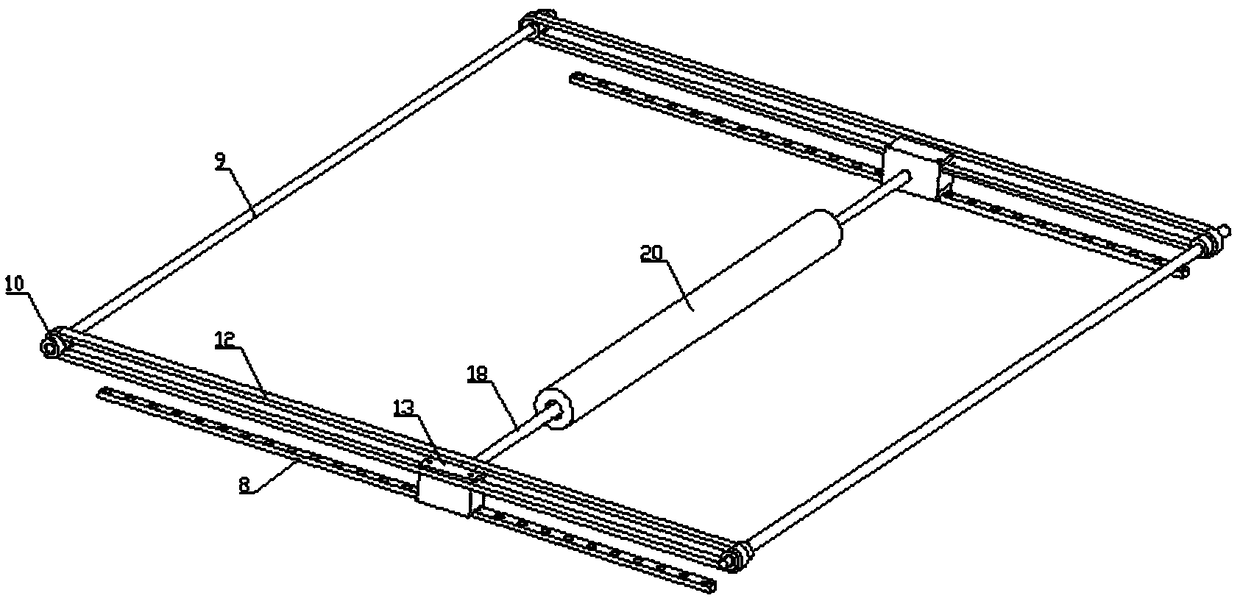

Water hammer pulse vibration pressurizing tool for long-horizontal-section horizontal well

InactiveCN105221073AStrong axial vibration capabilityIncreased axial compressionVibration drillingWear resistantAxial pressure

The invention relates to a water hammer pulse vibration pressurizing tool used for increasing axial pressure in a long-horizontal-section horizontal well. The technical scheme includes that the water hammer pulse vibration pressurizing tool mainly comprises a transmission shaft, a transmission shaft shell, a pressurizing assembly shell, a pressurizing assembly, a piston sleeve, a power assembly, a dynamic valve part, a wear-resistant valve, a static valve part and a lower joint, the transmission shaft shell, the pressurizing assembly shell, the power assembly and the lower joint are sequentially in threaded connection from top to bottom, the transmission shaft is matched with an inner hole of the transmission shaft shell, the upper end of the transmission shaft is connected with the piston sleeve through a thread, the pressurizing assembly is mounted between an isolating sleeve and the piston sleeve, the dynamic valve part is connected with the lower end of the power assembly through a thread, the static valve part is mounted in an inner hole in the upper end of the lower joint, and the wear-resistant valve is mounted in an inner hole in the upper end of the static valve part. The water hammer pulse vibration pressurizing tool has the advantages of good axial pressurizing effect, high vibration ability and simple structure, and extending and drilling ability of the long-horizontal-section horizontal well can be improved.

Owner:SOUTHWEST PETROLEUM UNIV

Natural plant whitening cream and preparation method thereof

InactiveCN105310938AReduce contentReduce causeCosmetic preparationsToilet preparationsLicorice root extractHorticulture

The invention provides a natural plant whitening cream, which consists of the following components in percentage by weight: 3-10% of corn propylene glycol, 0.2-1% of xanthan gum, 5-10% of glycerol, 1-3% of cetearyl glucoside, 1-5% of cetostearyl alcohol, 5-8% of olive-pomace oil, 5-8% of prunus amygdalus dulcis oil, 5-8% of avocado oil, 0.1-0.5% of a magnolia bark extract, 0.1-0.5% of an emblic leafflower fruit extract, 0.1-0.5% of a daisy flower extract, 0.1-0.5% of a glycyrrhiza glabra root extract, 0.1-0.5% of a mulberry bark extract and the balance of distilled water, wherein a whitening active composition is constituted by the emblic leafflower fruit extract, the daisy flower extract, the glycyrrhiza glabra root extract and the mulberry bark extract. The natural plant whitening cream disclosed by the invention has a comprehensive conditioning and whitening effect; and the natural plant whitening cream is significant in whitening effect, non-allergic, non-irritant, free from toxic and side effects, harmless to human bodies and high in safety.

Owner:中山市艾丽意素生物科技有限公司

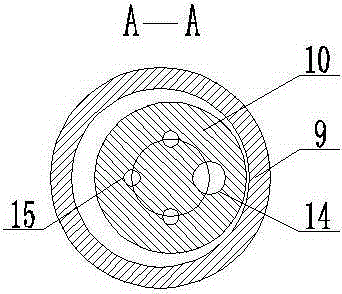

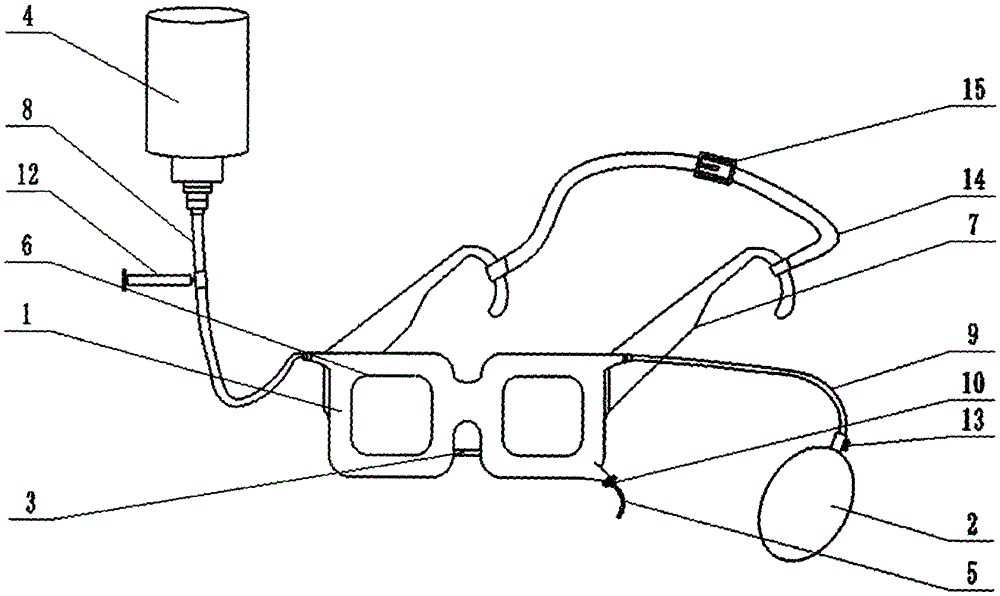

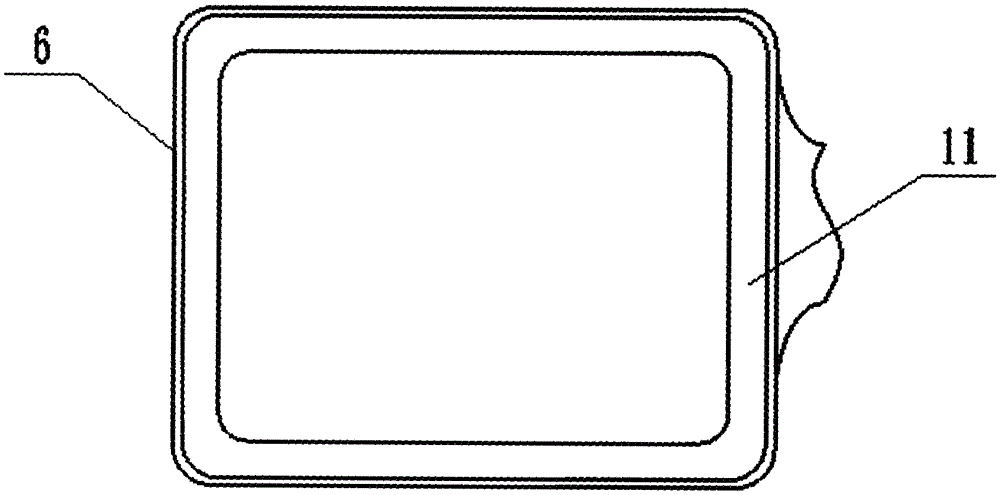

Household portable eye-washing conjunctival sac irrigator and usage

The invention discloses a household portable eye-washing conjunctival sac irrigator and usage. The irrigator comprises an eye-washing cover, an inflating balloon, a liquid discharge line, an eye wash storage bottle and a liquid discharge guide tube. The eye-washing cover is made by fixedly connecting two light-permeable three-dimensional seal covers, and fasteners are arranged outside the seal covers. The eye-washing cover is connected with the eye wash storage bottle through a liquid incoming tube and is connected with the inflating balloon through an air intake tube, and the bottom of the eye-washing cover is provided with the liquid discharge guide tube. The cooperative use of the eye-washing cover, the inflating balloon, the liquid discharge line, the eye wash storage bottle and the liquid discharge guide tube replaces a hospital eye-washing instrument, such as an eye-washing kettle, an eye speculum, a syringe and a water receiver, and these eye-washing instruments are integrated. The complex operating process in a hospital is omitted, eye washing is made simple and easy, and complex medical equipment is turned into a daily eye-care necessary instrument.

Owner:高付林

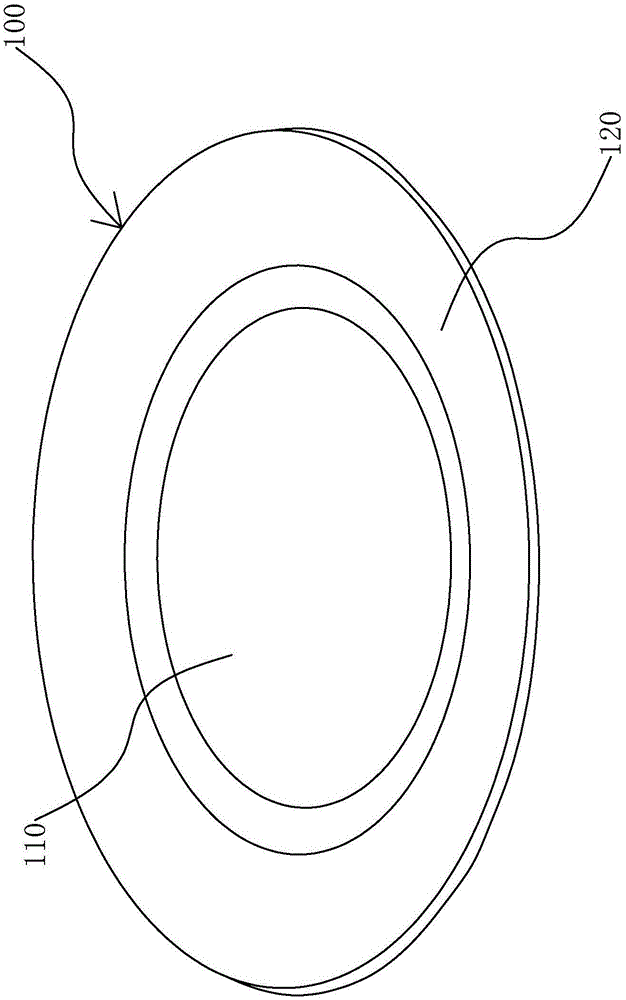

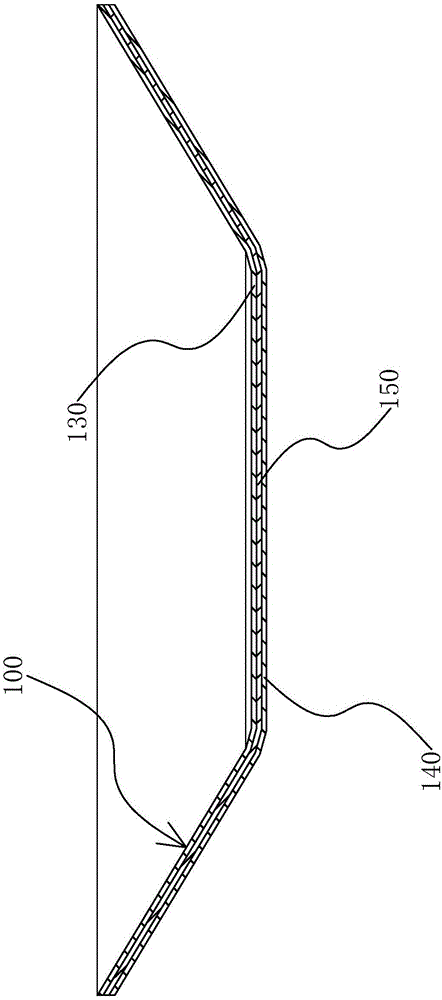

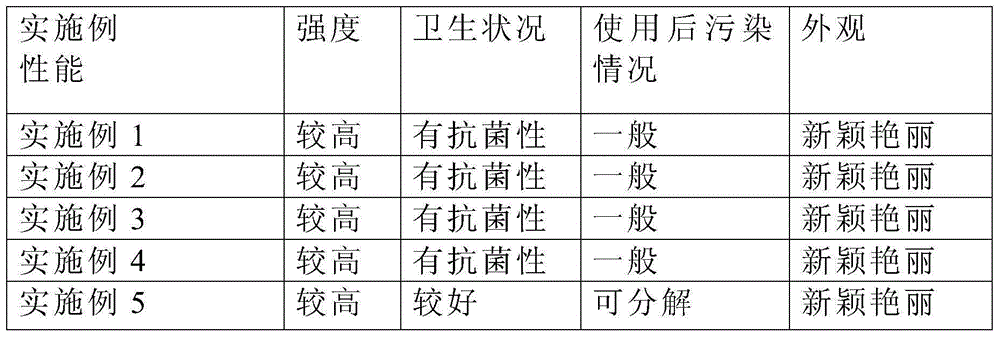

Double-color thin-wall plastic tableware and processing method thereof

ActiveCN105029984AImprove antibacterial propertiesStable anti-mildew effectSynthetic resin layered productsPlatesSurface layerPolystyrene

The invention relates to double-color thin-wall plastic tableware and a processing method thereof, and belongs to the technical field of tableware. The tableware comprises a body. The body comprises a round bottom in the middle and a conical flange extending to the periphery of the round bottom. The body is formed by multiple layers of sheets in a laminated mode and comprises an upper surface layer and a lower surface layer, the sheets are tightly attached to one another, the thickness of the sheets ranges from 0.2 mm to 0.7 mm, the sheets forming the upper surface layer and the lower surface layer have different colors, and the sheets are made of plastic, including polypropylene plastic (PP) and polystyrene plastic. Because the tableware is formed by the multiple layers of sheets of different colors in a combined mode, the tableware has high strength without becoming sunk easily, and is convenient to use and more novel and bright-colored in appearance; because the tableware is made of the polypropylene plastic (PP) or the polystyrene plastic with reasonable compatibility, on one hand, the long-lasting antibacterial and antifungal property and other properties of the cup are effectively guaranteed, and on the other hand, environmental pollution caused by disposable tableware can be reduced; because the tableware is processed through a plastic sucking moulding process with special parameters, the final properties of the tableware are improved.

Owner:宁波市森佰工贸有限公司

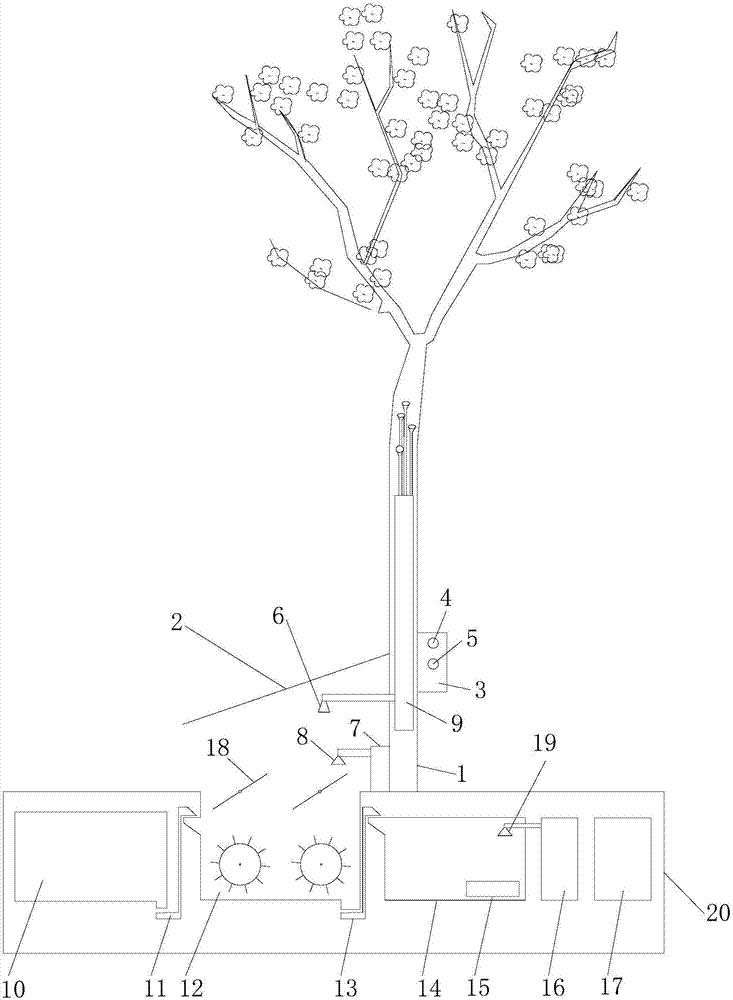

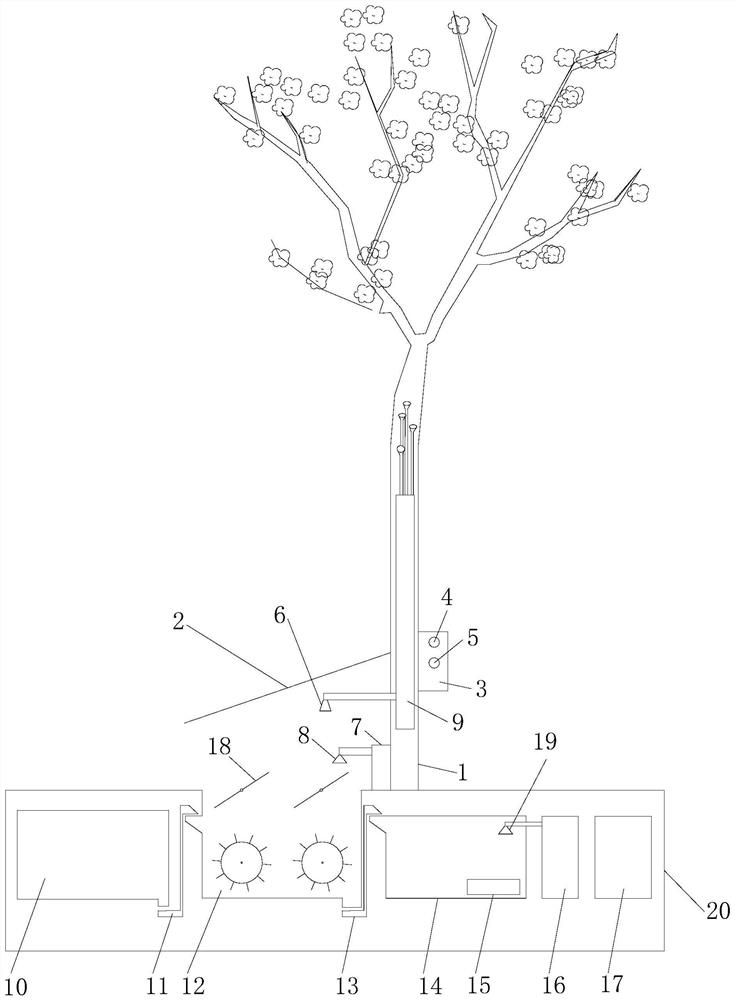

Ecological type garden-landscape public toilet for pet dogs

The invention discloses an ecological type garden-landscape public toilet for pet dogs, relates to public toilets for pet dogs, and solves the problems that odor and excrement of pet dog excretion pollute and affect the environment in a residential district, the excrement of the pet dogs is hard to process, existing public toilets for the pet dogs are poor in convenience and are short of a landscape effect, and the existing public toilets for the pet dogs are high in investment and large in engineering quantity due to the fact that the toilets need water supply and drainage pipeline projects. The ecological type garden-landscape public toilet comprises a landscape tree trunk, a solar panel, a storage box, a cleaning water nozzle, an inducer storage tank, an inducer nozzle, a water storage tank, a soil storage tank, a first lifting machine, a bedroom stirring machine, a second lifting machine, a fermentation box, a heater, an organic material decomposition agent storage tank, a storage battery, a turnable cover plate and an organic material decomposition nozzle. The ecological type garden-landscape public toilet has the advantages that the problems of odor and environment pollution caused by the excrement of the pet dogs are solved, and the public toilet is low in manufacturing cost, has landscape and lighting functions and can prepare organic fertilizer.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Chenopodium quinoa willd potato chips and preparation method thereof

InactiveCN105410779AColor, fragrance and taste are improvedStay brittleFood ingredient functionsFood additiveChipped potatoes

The present invention belongs to the technical field of potato chip food, and particularly relates to a preparation method for Chenopodium quinoa willd potato chips. Object of the present invention is to solve the problems that the existing compound processed potato chips are single in nutritional value and relatively high in market price, contains a variety of chemical component food additives, and are easy to be broken. A technical scheme adopted in the present invention is that: the Chenopodium quinoa willd potato chips comprises the following raw materials in parts by weight: 70-100 parts of potato flour, 20-30 parts of Chenopodium quinoa willd flour, 10-15 parts of corn flour, 1-3 parts of table salt, 1-2 parts of seed powder of Chinese prickly ash, 1-2 parts of tea polyphenols and 0.21-0.3 part of baking soda. Advantages of the Chenopodium quinoa willd potato chips are that the Chenopodium quinoa willd potato chips are good in mouthfeel, rich in nutrition and not easy to be broken.

Owner:XINZHOU TEACHERS UNIV

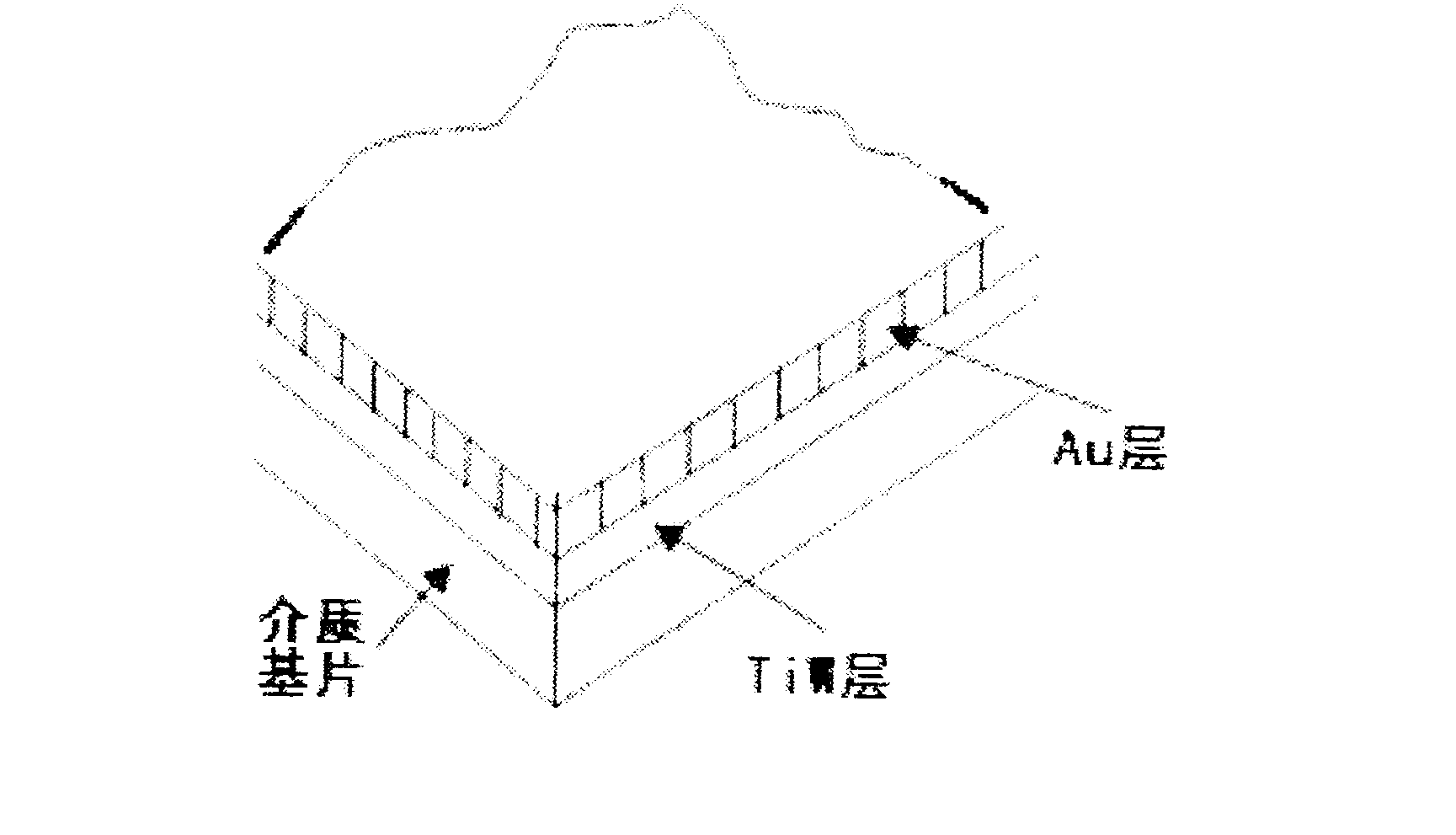

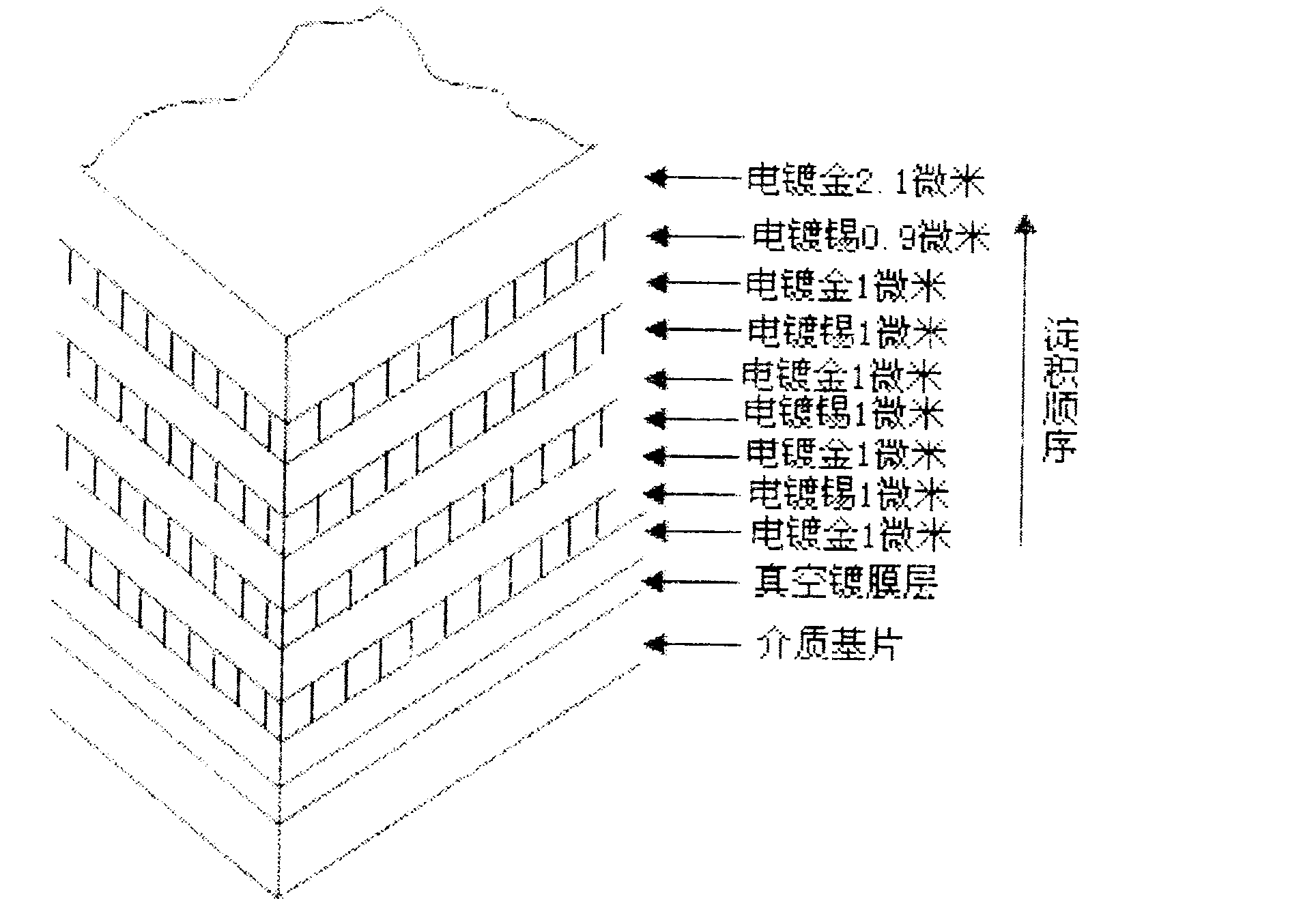

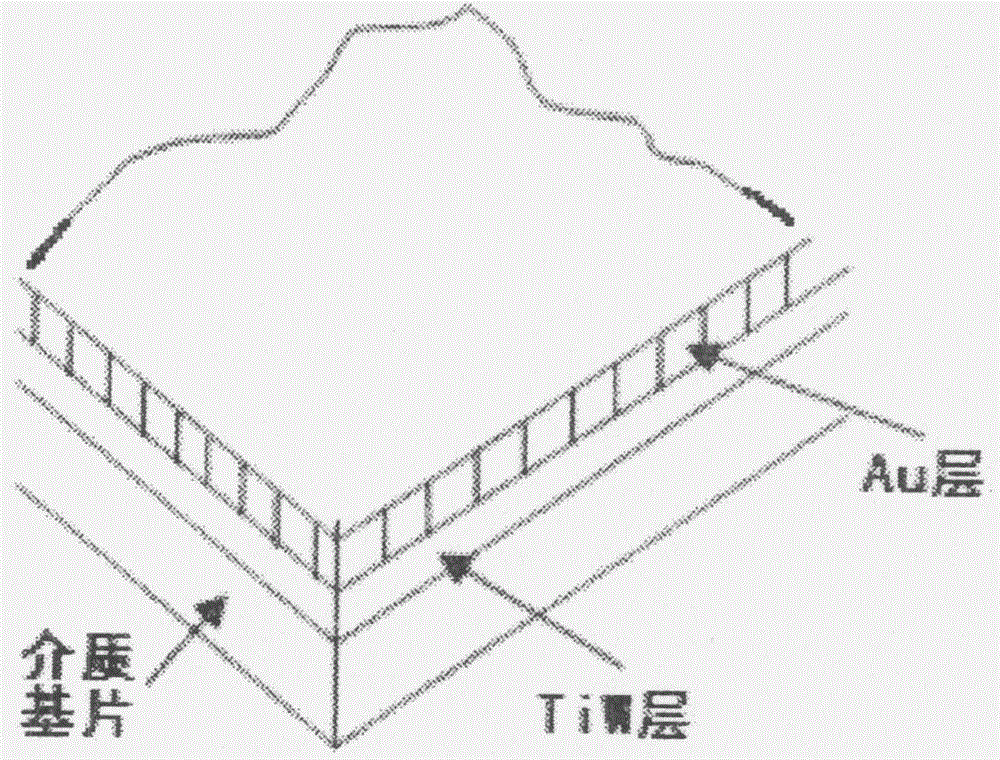

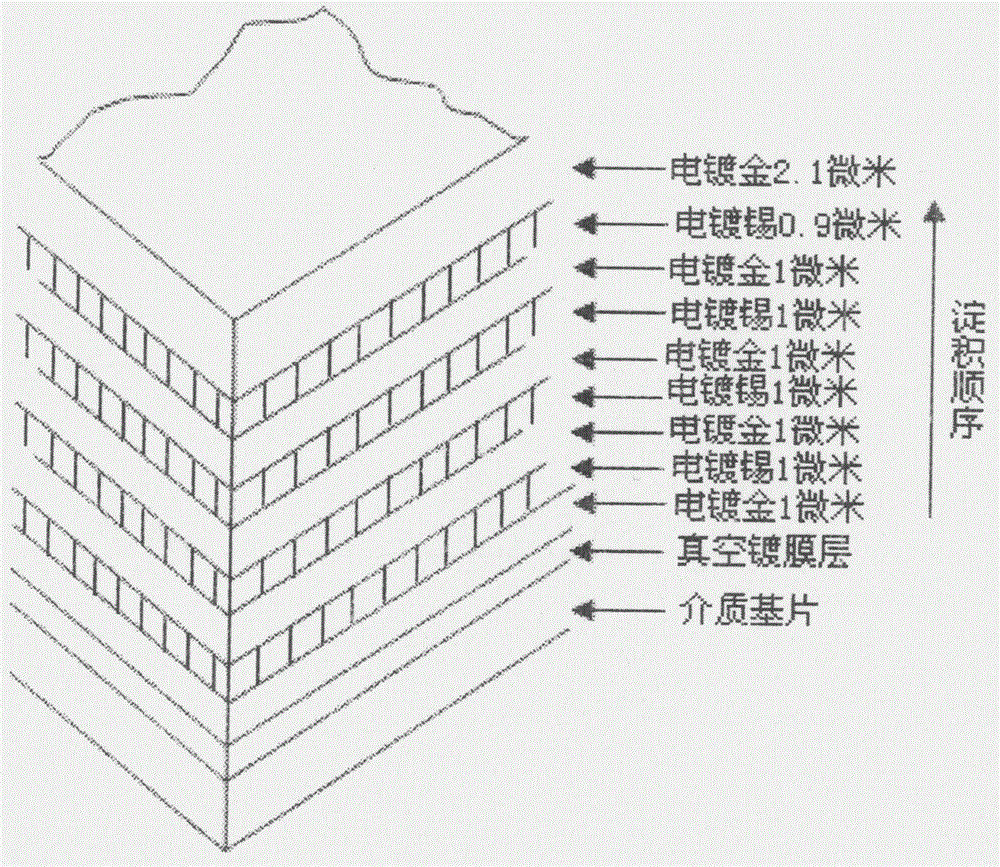

Brazed layer predeposition method

ActiveCN103264202AReduce processing workloadImprove thickness uniformitySoldering apparatusSemiconductor/solid-state device manufacturingHybrid integrated circuitSolder paste

The invention provides a brazed layer predeposition method, which comprises the following steps: A: vacuum sputtering coating a seed layer, and B: depositing each layer through a manner of sequentially alternating a gold layer and a tin layer. Through the scheme, the brazed layer predeposition method not only solves the problems existed in the prior art, and has the obvious advantages that aiming at a hybrid integrated circuit adopting braze, a process method by adopting soldering paste or soldering flux pieces in traditional soldering is improved, a layer of soldering flux layer with each component weight ratio being equivalent to components of the soldering flux pieces is deposited on a circuit soldering face (generally refers to a back face), the circuit can be directly placed on a soldering position when soldering is carried out, and soldering is realized through heating. Due to the technology, the processing workload for forming the soldering flux pieces can be reduced, and wastes caused by position offset among soldering positions, the soldering flux pieces, and the circuit to be soldered when soldering is carried out can be reduced.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

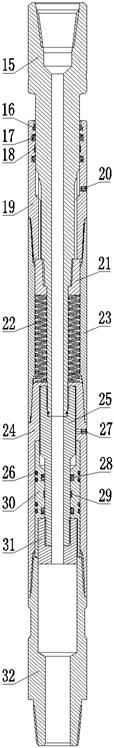

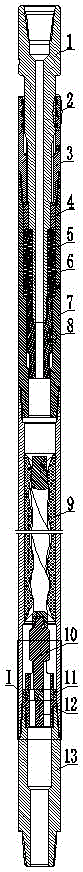

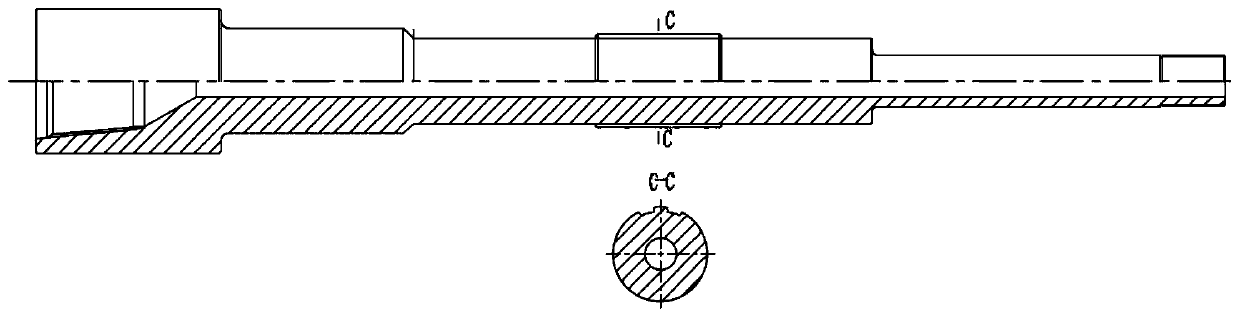

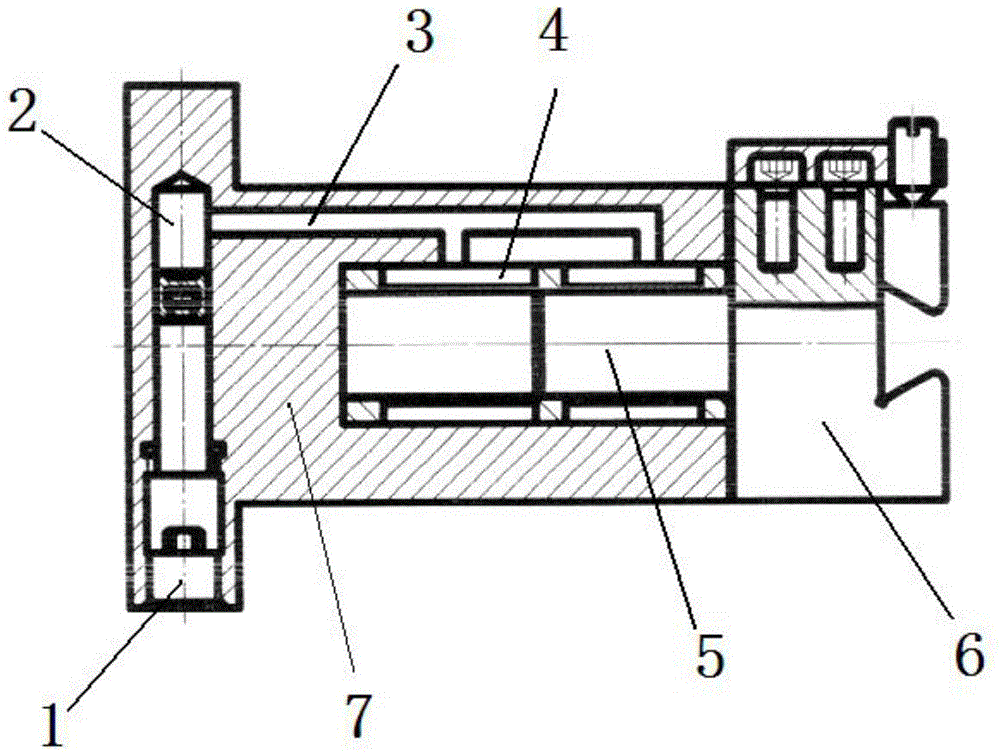

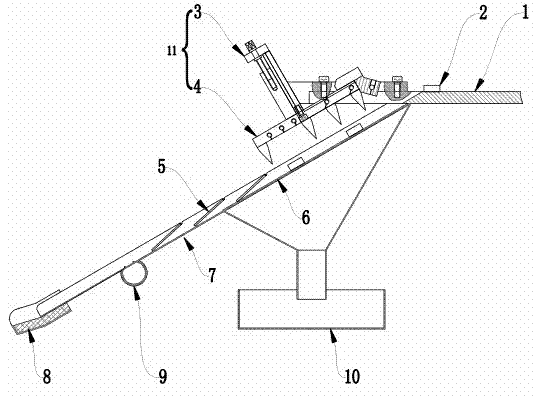

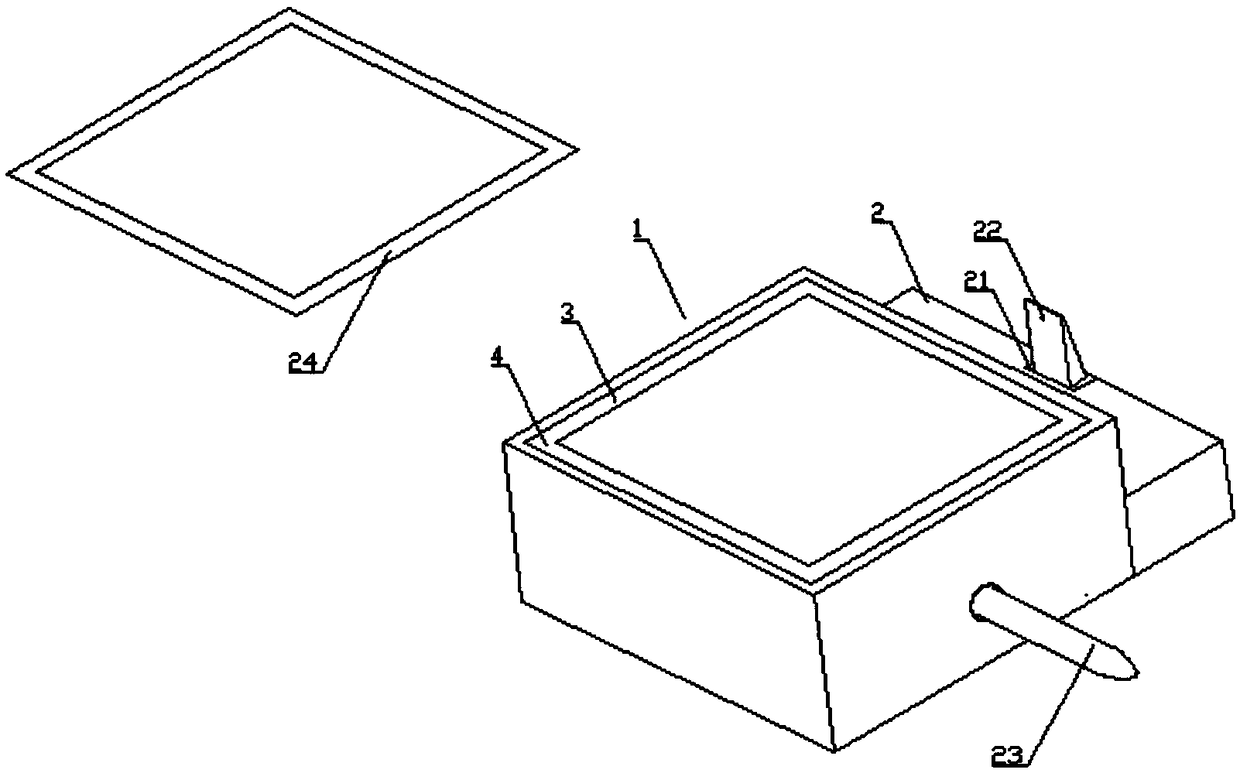

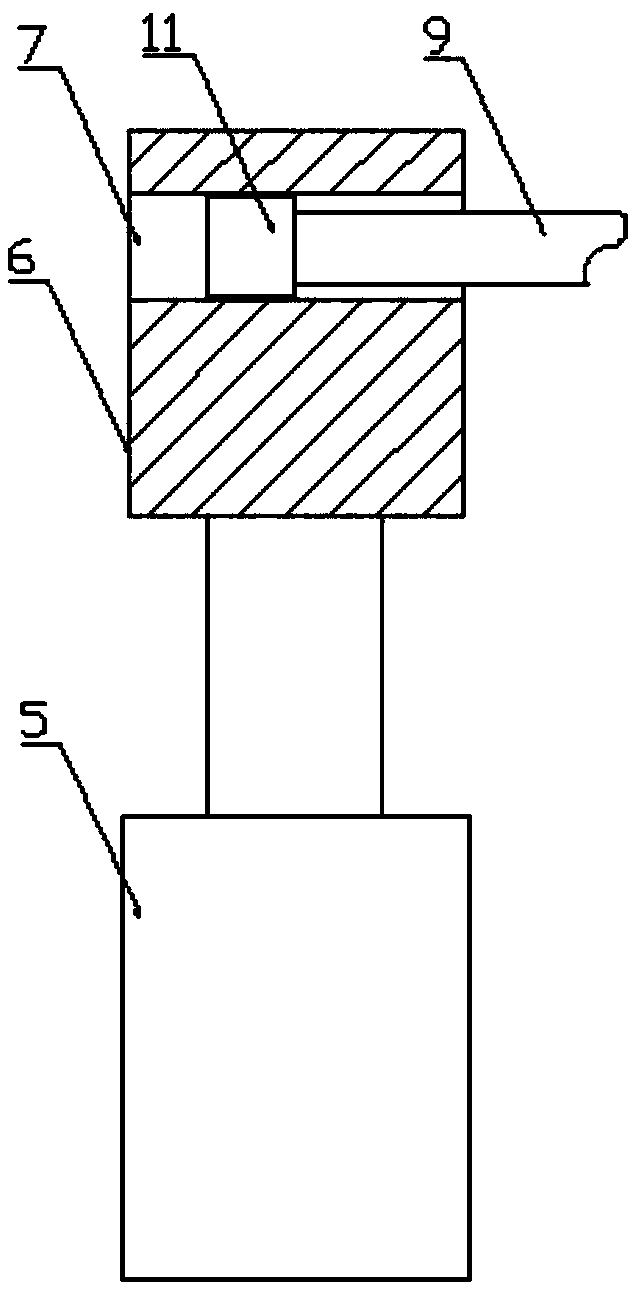

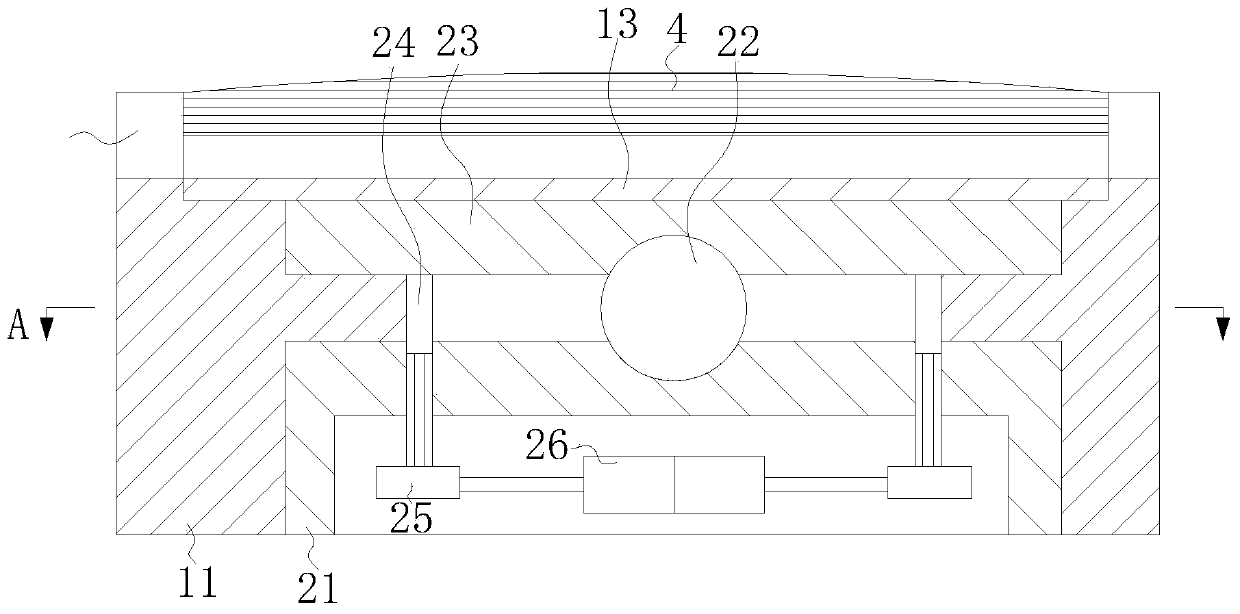

Device for reducing friction between drilling tool and well wall and method thereof

ActiveCN110748297AStrong axial vibration capabilityReduce frictional resistanceDrilling rodsVibration drillingWell drillingStructural engineering

The invention relates to a tool for reducing friction between a drilling tool and a well wall, improving well drilling efficiency and shortening a well drilling cycle and a method thereof. According to the technical scheme, the tool for reducing the friction between the drilling tool and the well wall mainly comprises a sliding rod, a sealing ring, a check ring, a first upper shell, a limiting semi-circular ring, a second upper shell, a disc spring, a sealing ring, a check ring, a piston, a third upper shell, a common flat key, an upper fixed valve, an upper moving valve, a fourth upper shell,a stator, a rotor, a lower shell, a lower moving valve, a lower fixed valve and a lower interface, wherein the first upper shell, the second upper shell, the third upper shell, the fourth upper shell, the stator, the lower shell and the lower interface are in threaded connection in sequence, under the driving of the rotor, an inclined hole runner of the lower moving valve is periodically opened and closed, the energy of fluid is converted into a series of pulse pressures, and static friction between the drilling tool and the well wall is broken, so that the purpose of reducing the friction and improving the drilling capacity of a horizontal section is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

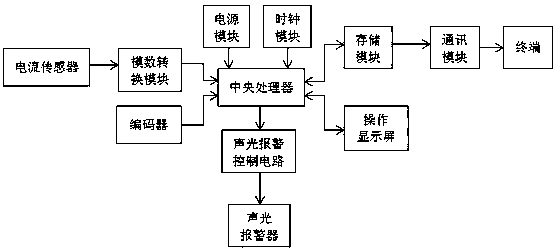

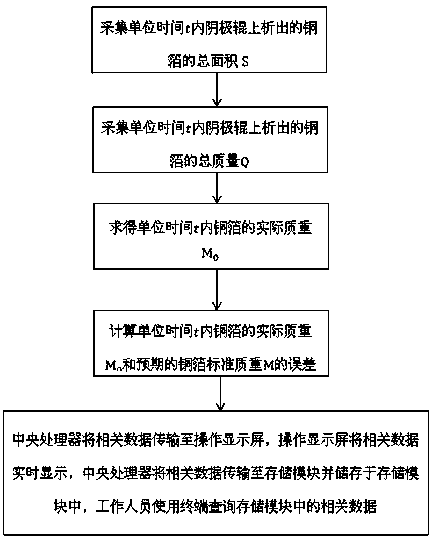

Device and method for real-time calculation and display of weight of copper foil

PendingCN107761137AQuality assuranceReduce causeCellsElectroforming processesCurrent transducerCopper foil

The invention discloses a device and a method for real-time calculation and display of weight of a copper foil. The device includes a central processor, a clock module, a current sensor for collectingthe output current of a rectifier, an analog-to-digital conversion module, a coder for collecting the rotation speed of a cathode roller, a storage module, a communication module, an operation display screen, a terminal and a power supply; the coder is connected with a rotating shaft of the cathode roller; the current sensor is connected with the current output end of the rectifier; the current sensor is connected with the central processor through the analog-to-digital conversion module; the operation display screen and the central processor are connected; the central processor is respectively connected with the analog-to-digital conversion module and the coder, the central processor is connected with the storage module, and the storage module is connected with the terminal through the communication module. The device in real time calculates the actual weight and error of the copper foil, by comparison with the expected standard weight of the copper foil, the problem of the actual weight of the copper foil is promptly found out, and the scrap rate of the copper foil is reduced.

Owner:LINGBAO WASON COPPER FOIL

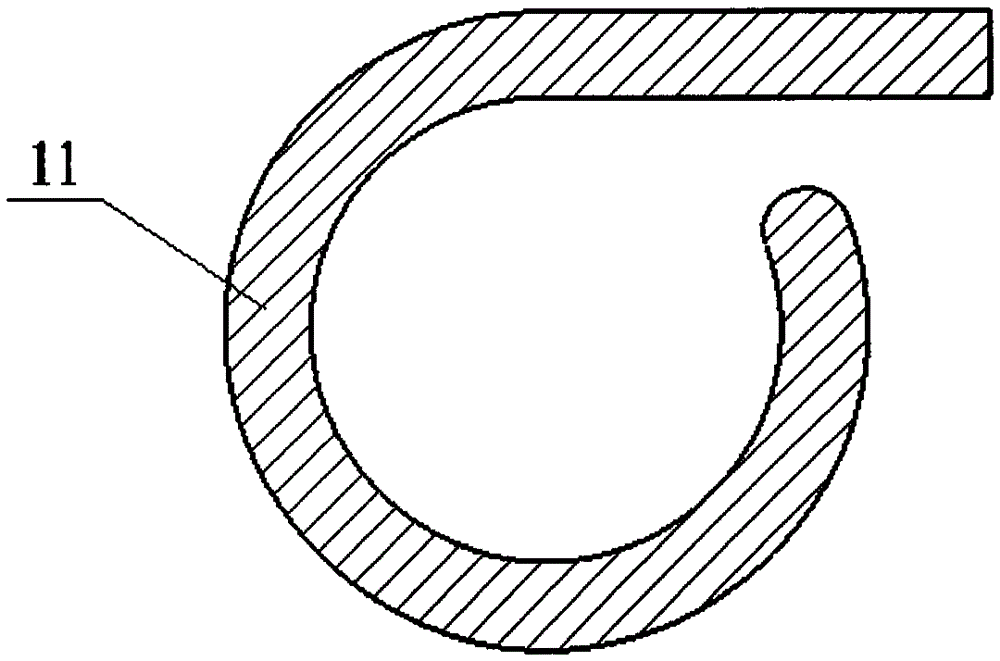

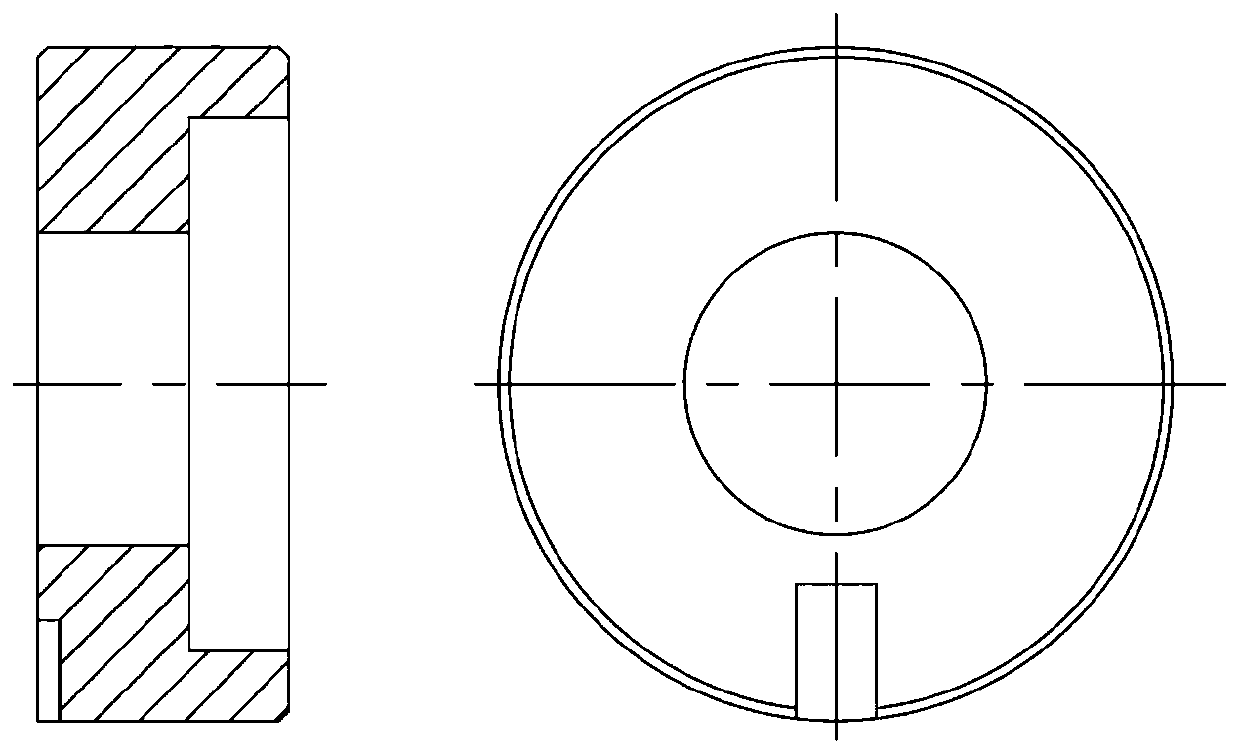

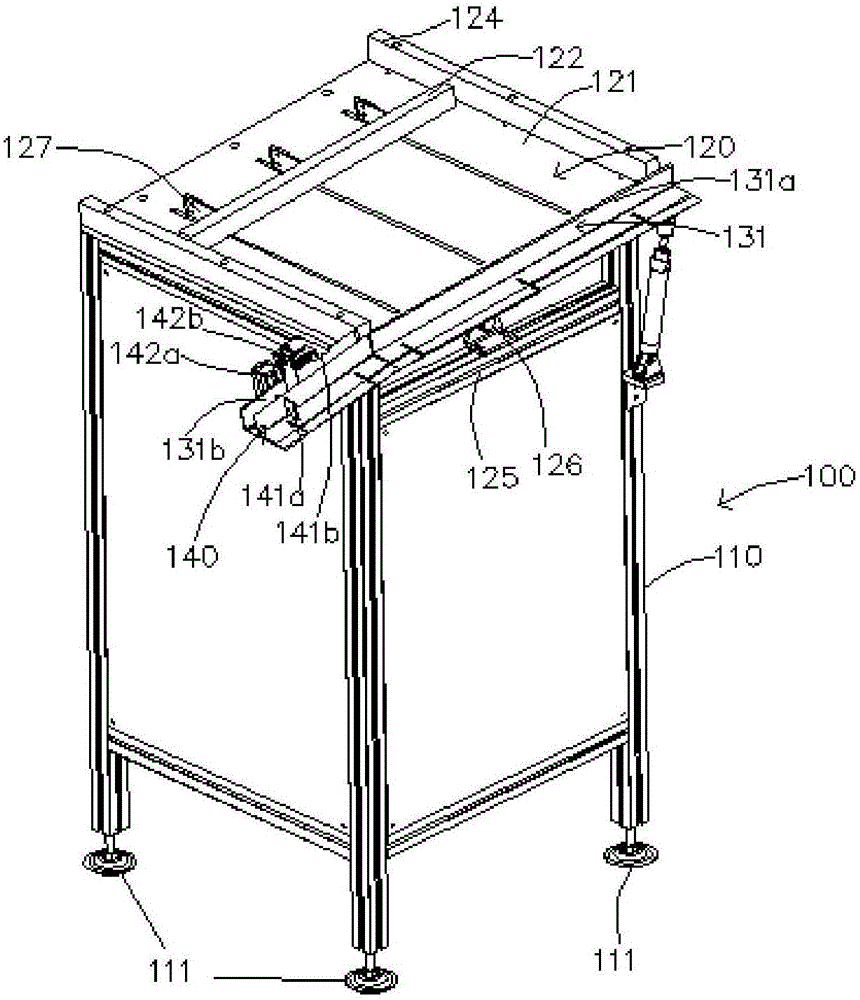

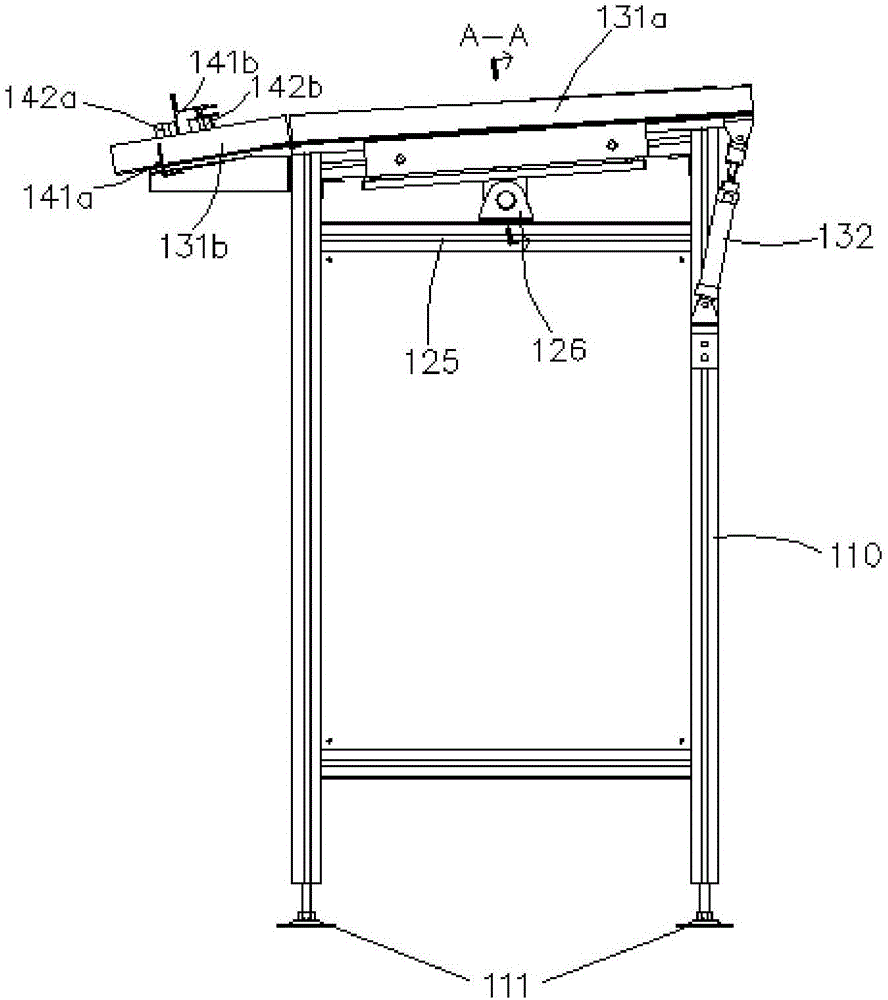

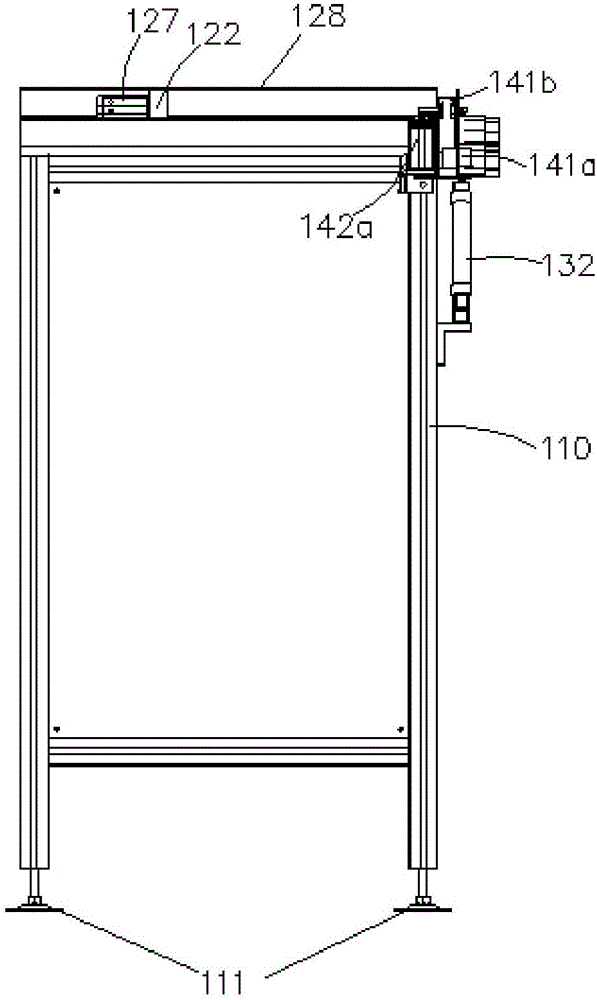

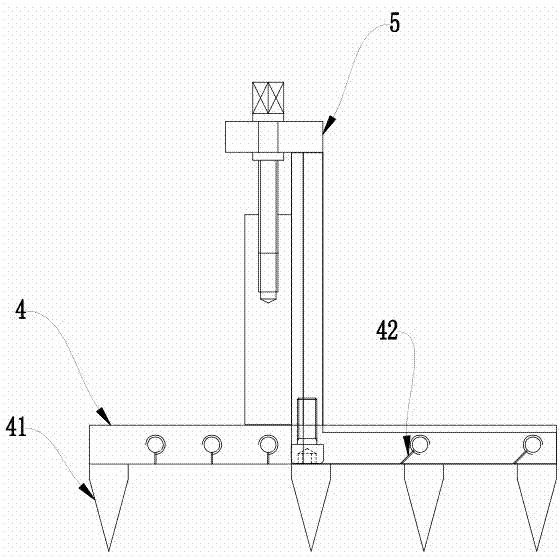

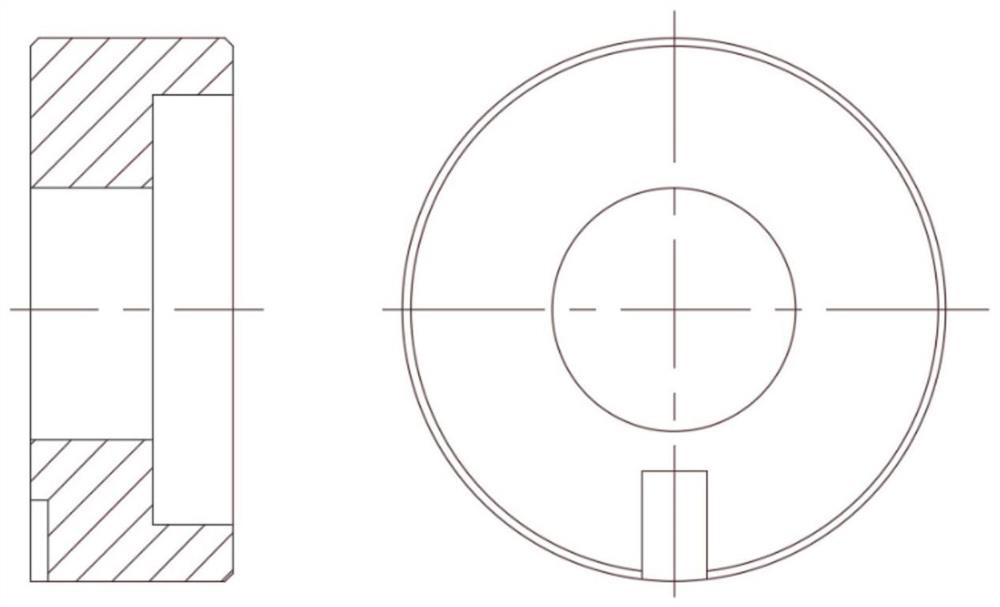

Bearing ring feeder

ActiveCN106743512AImprove work efficiencyAvoid colliding with each otherConveyor partsEngineeringOblique angle

The invention discloses a bearing ring feeder which comprises a framework and an oblique storage table. The storage table is arranged on the framework, an oblique discharge channel is arranged on a side of the storage table, the lowest end of the discharge channel is hinged onto the framework, and a driving device for changing oblique angles of the discharge channel is arranged at the highest end of the discharge channel; a push device for pushing bearing rings to the discharge channel is arranged on the storage table; a ring separating device for discharging the bearing rings one by one is arranged at a discharge outlet of the discharge channel. The bearing ring feeder has the advantages that the storage table has appropriate oblique angles, so that the bearing rings can be neatly arrayed, can be separately fed and can be prevented from being collided with one another, accordingly, defective products due to collision can be reduced, and the production cost can be lowered; the distance between a pair of discharge barriers of the discharge channel can be appropriately adjusted, and accordingly the discharge channel is applicable to discharging the diversified bearing rings.

Owner:NINGBO CIXING BEARING

Method and clamp for eliminating deformation of blade caused by machining stress

InactiveCN104440161AEliminate deformationReduce causePositioning apparatusMetal-working holdersWaste productEngineering

The invention discloses a clamping method and clamp for eliminating deformation of blade caused by machining stress. A clamping tool of a locating shaft of the clamp is designed into a hydraulic centering clamp, the critical torque at which the blade deforms is measured according to the characteristic that the clamping force of the hydraulic clamp is adjustable, the torque of the clamping force of the hydraulic centering clamp is adjusted to be lower than the critical torque value at which the blade deforms, when the deformation torque generated by an element is larger than critical torque value, the clamp is not subjected to rigid restrained deformation, instead, the locating part of the clamp twists or extends slightly in the deforming direction of the element due to the fact that the clamping torque is smaller than the deformation torque, after the element releases stress, the hydraulic centering clamp clamps the clamping locating part again for continuous machining, and therefore the problem that the blade deforms due to the machining stress is solved. The clamping method and clamp have the advantages that by means of the clamping method and clamp, deformation generated by the element of the blade in machining can be eliminated; the clamping method and clamp can be used for machining various types of blades, reduce waste products caused by stress deformation in machining of the blades and improve machining efficiency by over 300%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

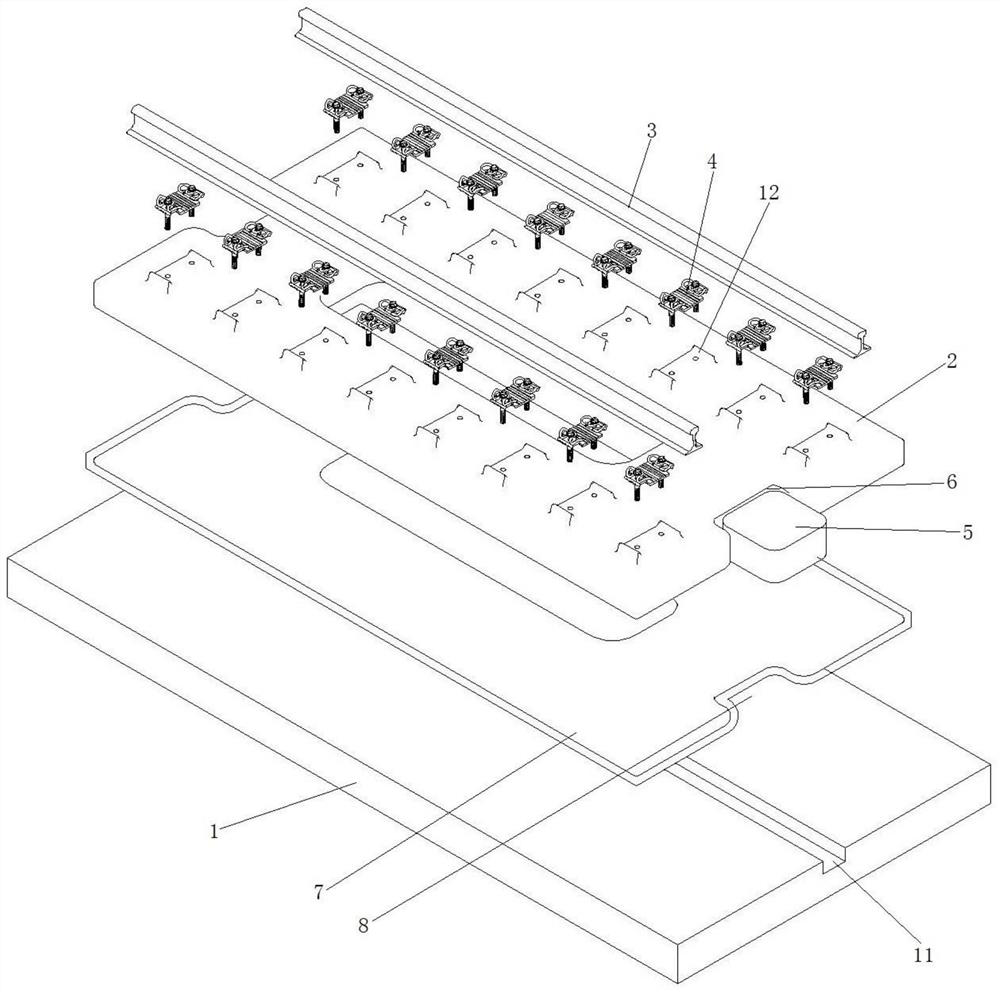

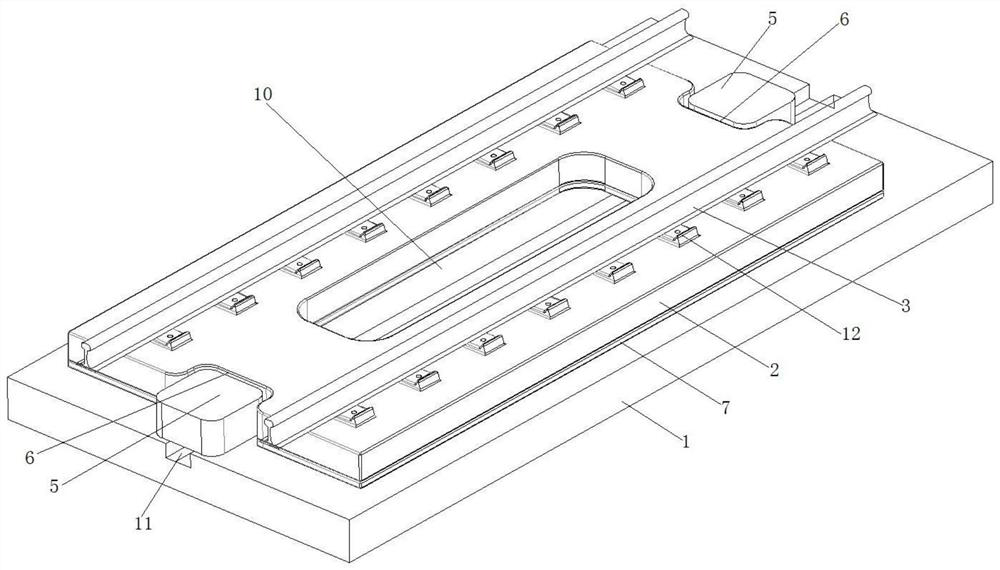

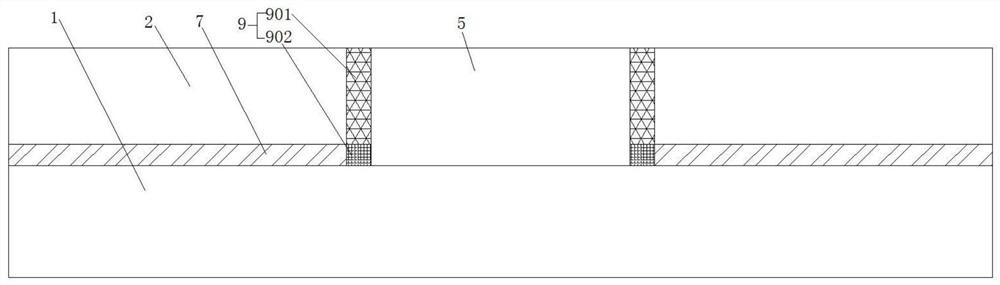

Novel assembly type ballastless track structure and mounting method thereof

PendingCN111996842AEasy height adjustmentHigh curveBallastwayRailway track constructionTrackwayClassical mechanics

The invention discloses a novel assembly type ballastless track structure and a mounting method thereof. The novel assembly type ballastless track structure comprises a concrete base, track plates andsteel rails, convex blocking tables which are distributed in parallel at equal intervals are prefabricated on the upper surface of the concrete base. The track plates are arranged between the adjacent convex blocking tables in a clamped mode, and clamping grooves are formed in the outer walls of the two longitudinal ends of each track plate respectively. Every two adjacent track plates are independently arranged, a gap distance is kept between every two adjacent track plates, an independent detachable adjusting layer is arranged between each track plate and the concrete base, receding groovesare formed in the positions, corresponding to the clamping grooves, of the two longitudinal ends of each adjusting layer respectively, and the receding grooves clamp the convex blocking tables. Elastic assemblies are further arranged between the inner sides of the clamping grooves and the convex blocking tables and between the inner sides of the receding grooves and the convex blocking tables. According to the ballastless track structure, the superrelation on curve can be achieved, the construction is easy and convenient, the height of the track plates is easy to adjust, the adjusting layerscan be replaced and maintained, and the later maintenance cost is low.

Owner:WUHAN BILLION TECH DEV CO LTD +1

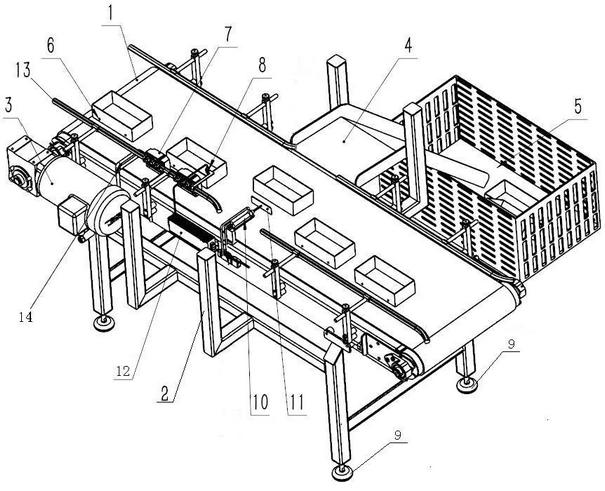

Device and method for detecting neglected loading of magnet buckle of food packaging box

PendingCN113253352AReduce causeSortingElectric/magnetic detectionStructural engineeringMotor controller

The invention discloses a device and method for detecting neglected loading of a magnet buckle of a food packaging box. The device comprises a belt support and a conveying belt installed on the belt support, a servo conveying motor driving the conveying belt to work is further installed at the front end of the belt support, and a motor controller is arranged adjacent to the servo conveying motor; a magnet detection sensor, a gift box positioning detection sensor and an air cylinder telescopic arm are sequentially arranged on one side of the belt support in the longitudinal direction, a control module is installed on the belt support, the gift box positioning detection sensor is connected with the control module through an electric wire, and an unqualified product collecting channel is formed in the position, right opposite to the air cylinder telescopic arm, of the belt support. The belt support is further provided with an electromagnetic valve for controlling the telescopic arm of the air cylinder to work, and the control module is connected with the motor controller, the electromagnetic valve and the magnet detection sensor through wires. According to the invention, it can be effectively guaranteed that all the bottom boxes entering the assembling machine are qualified and normal, and waste products caused by the absence of magnet buckles are reduced.

Owner:GUIZHOU XINIUWANG PRINTING

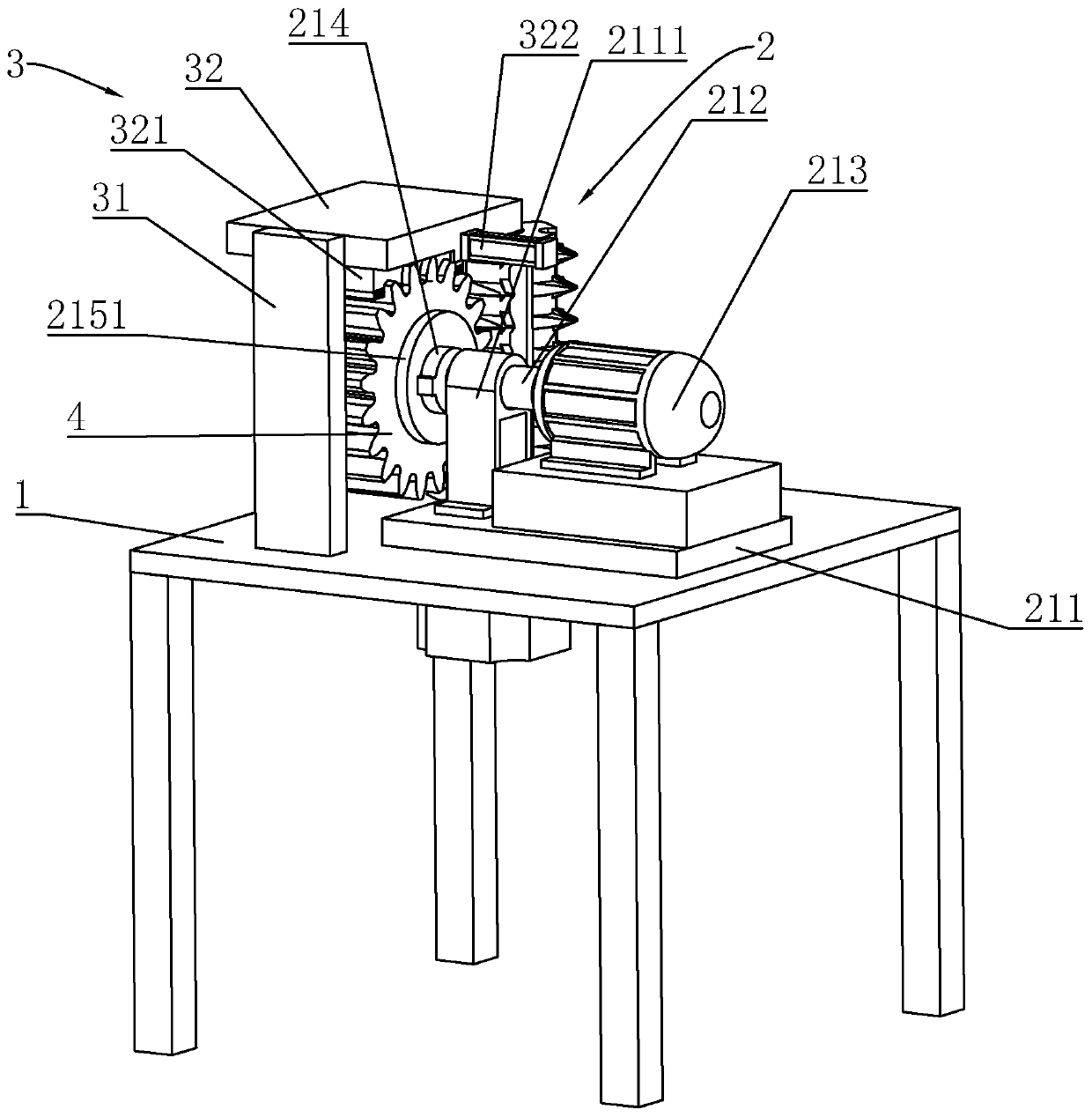

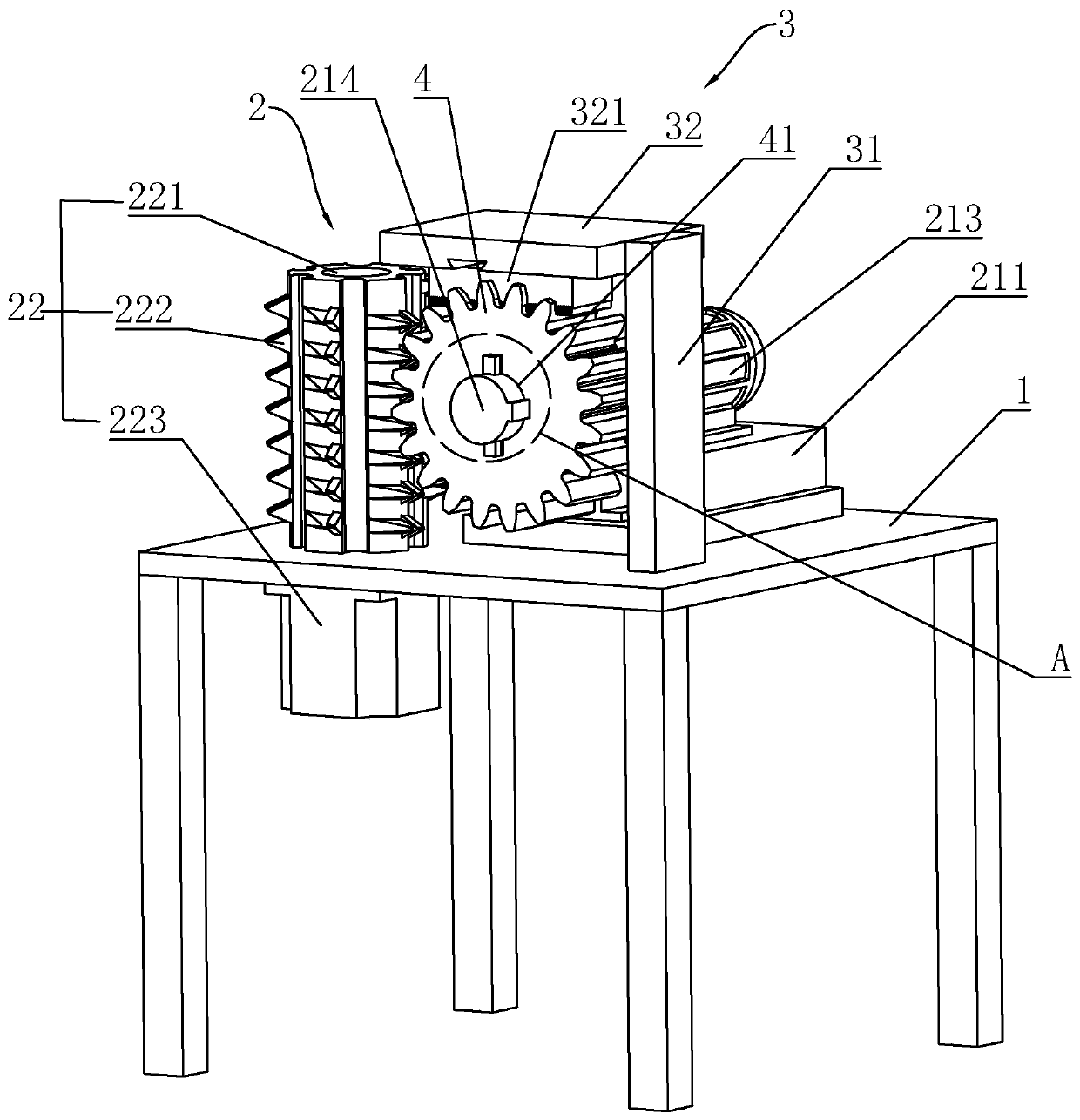

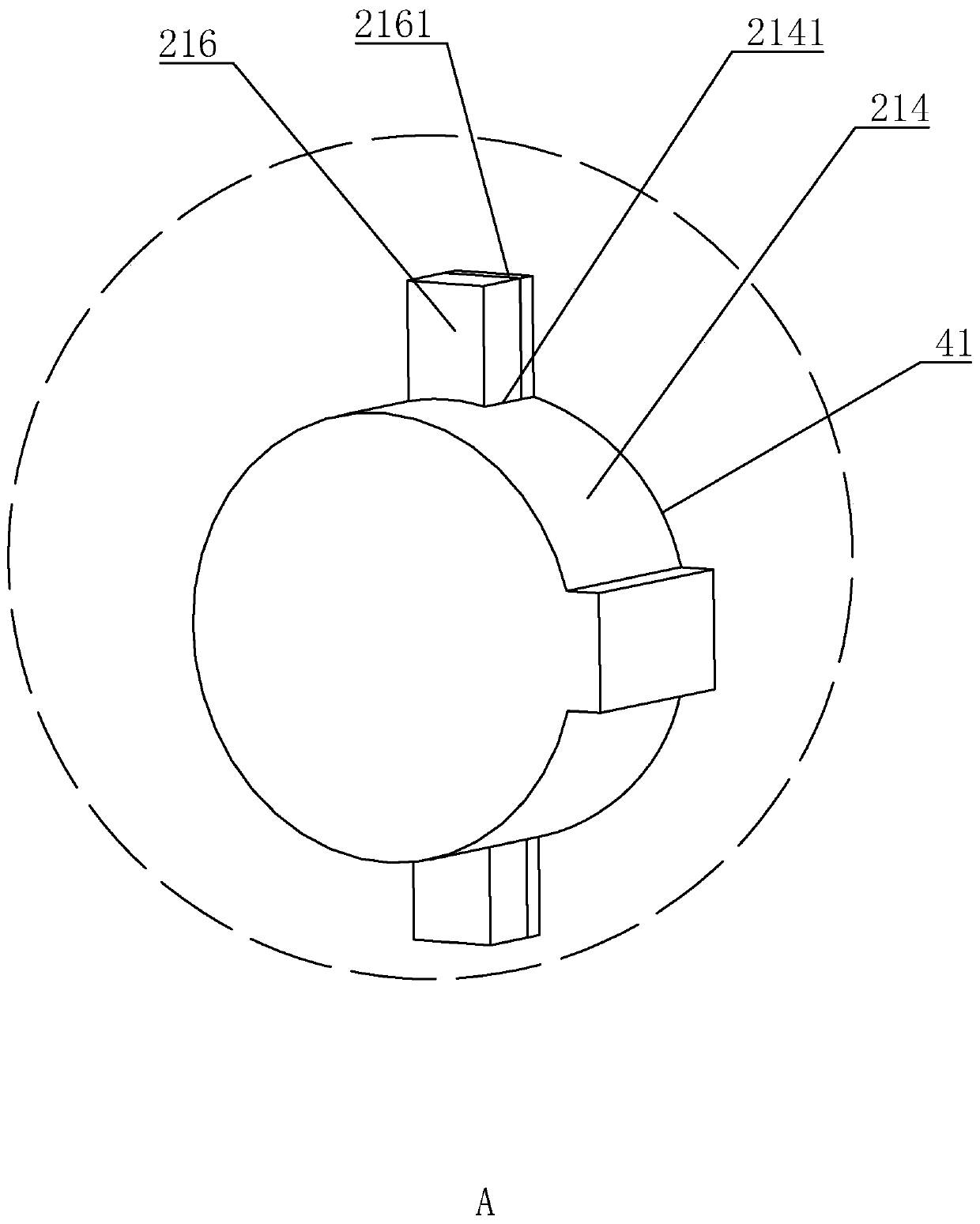

External gear shaft sleeve machining technology and milling-clearing-integration equipment thereof

InactiveCN111331065AImprove cleanlinessImprove processing qualitySolid state diffusion coatingWheelsCarburizingMachining process

The invention discloses an external gear shaft sleeve machining technology and milling-clearing-integration equipment thereof. The technology mainly comprises seven machining procedures of blank cutting, preheating, forge piece forming, milling treatment, carburizing treatment, furnace discharging and cooling, and detection warehouse-out, wherein in the milling treatment machining procedure, scrapiron bonded to the outer side of an external gear shaft sleeve is cleared away through the milling-clearing-integration equipment, so that the possibility that the surface of the external gear shaftsleeve is uneven due to the fact that the scrap iron is bonded to the outer side of the external gear shaft sleeve is reduced, and the effect of improving the machining quality of external gear shaftsleeve products is achieved.

Owner:南京德长锻造有限公司

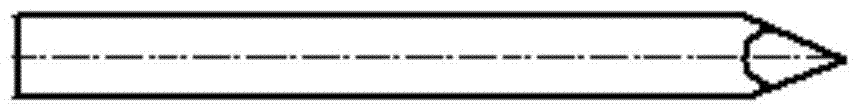

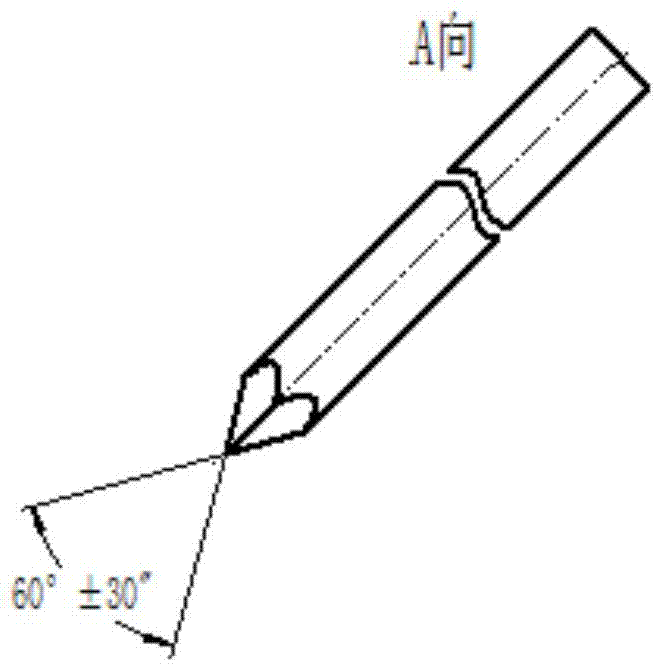

Center hole benchmark correcting method reducing cutting torque

The invention relate to a center hole benchmark correcting method reducing cutting torque. The center hole benchmark correcting method includes the following steps that a center hole benchmark correcting process of a journal type typical blade part machining technology is selected; equipment for machining in the center hole benchmark correcting process is selected; the positioning benchmark of a clamp and the equipment is selected, and the positioning benchmark of the clamp and a part is selected; a center hole benchmark correcting tool for reducing cutting torque is designed; the coaxiality tolerance actual values of the benchmark of a center hole are detected before heat treatment and semifinishing in a journal type blade in the machining process, and an average value is calculated; the center hole benchmark correcting tool is used for machining and correcting the center hole of the part, and whether the coaxiality tolerance value of the journal of the part subjected to external grinding conforms to the tolerance or not is judged; machining parameters are set; and the differences of the coaxiality tolerance actual values of the benchmark of the center hole of the part are compared. According to the center hole benchmark correcting method reducing cutting torque, the qualification rate of the machining process with the center hole of the journal type blade as the benchmark is increased, waste products caused by profile deformation when the coaxiality of the center hole is not qualified are reduced, the machining efficiency is improved to be more than 200%, and the qualification rate is more than 90%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

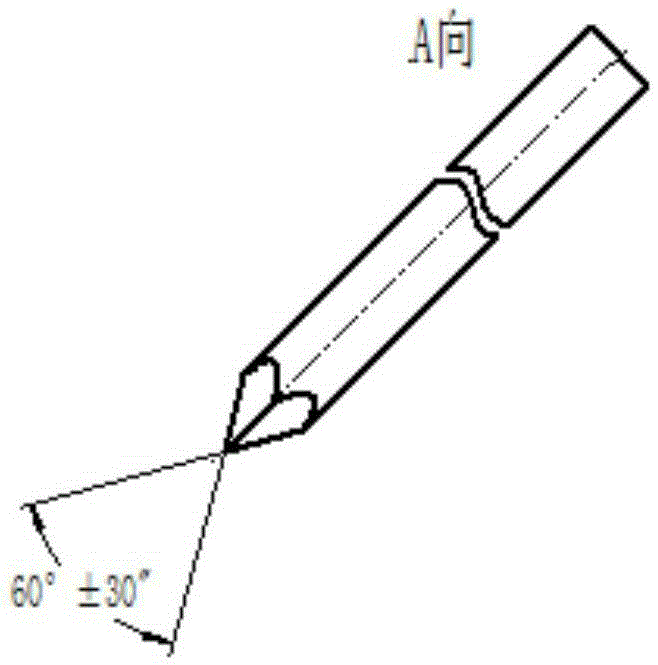

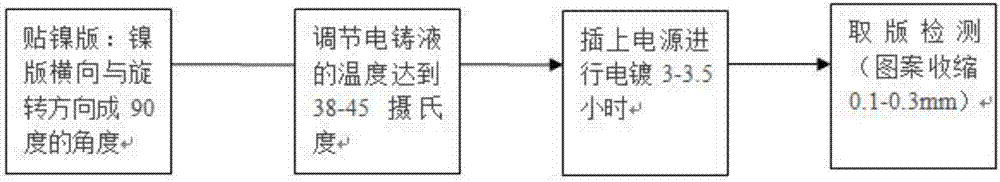

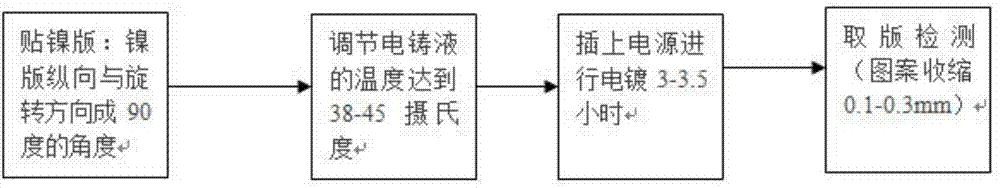

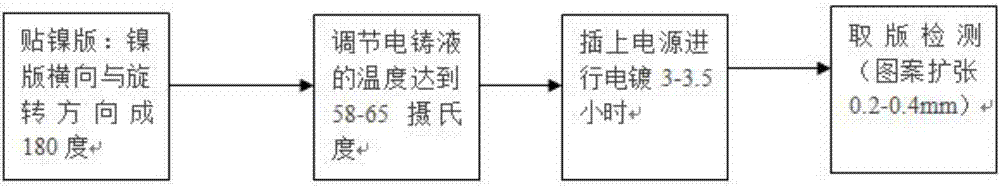

Position alignment control technology of laser locating nickel plate

ActiveCN107245730AHigh precisionPrecise positioningCellsElectroforming processesEngineeringDesign pattern

The invention discloses a position alignment control technology of a laser locating nickel plate. The position alignment control technology employs the temperature and speed direction matching correspondence rule, and carries out contraction or expansion correction with the combination of the deviation of design pattern, thus the perfect position alignment effect is achieved. The position alignment control technology has the following advantages that one, the position alignment control precision is improved, the alignment to a pattern is easy during printing, and directional printing is realized; and two, the design cost is saved, and rejects of membranes and paper and rejects caused by the fact that the position alignment in printing is not precise in a production process are reduced substantially.

Owner:中丰田光电科技(珠海)有限公司

A sliding feeding device

A sliding feeder comprises a slideway, a burr-removing mechanism and a dust-collecting system, the slideway is provided with a slideway mesh plate and sliding buffer mechanisms, the burr-removing mechanism comprises a burr-removing stand and a burr-removing disk, the burr-removing disk is provided with burr brushes and high-pressure air curtain mechanisms, and the dust-collecting system comprises three dust-collecting components. The sliding feeder can automatically convey workpieces pressed by a press to the next process, decreases labor intensity, reduces labor cost, and can automatically remove burrs and dust on workpieces to increase the cleanliness of the surfaces of workpieces, thus reducing defective workpieces.

Owner:河源富马硬质合金股份有限公司

Non-twisting double-layer printing towel quilt gray fabric bleaching and dyeing pretreatment method

The invention discloses a non-twisting double-layer printing towel quilt gray fabric bleaching and dyeing pretreatment method, which comprises the steps of desizing, removing of untwisted yarns, refining and bleaching, drying and cutting, wherein singeing treatment is further carried out after drying and before cutting. By adopting the non-twisting double-layer printing towel quilt gray fabric bleaching and dyeing pretreatment method, speckled flocks and flock balls of the gray fabric generated in a pretreatment processing process of bleaching and dyeing can be greatly reduced and alleviated, and printing inferior-quality products caused by too much speckled flocks and flock balls are reduced.

Owner:NANTONG DADONG

A kind of brazing layer pre-deposition method

ActiveCN103264202BReduce processing workloadReduce causeSoldering apparatusSemiconductor/solid-state device manufacturingSputteringWorkload

The invention provides a brazed layer predeposition method, which comprises the following steps: A: vacuum sputtering coating a seed layer, and B: depositing each layer through a manner of sequentially alternating a gold layer and a tin layer. Through the scheme, the brazed layer predeposition method not only solves the problems existed in the prior art, and has the obvious advantages that aiming at a hybrid integrated circuit adopting braze, a process method by adopting soldering paste or soldering flux pieces in traditional soldering is improved, a layer of soldering flux layer with each component weight ratio being equivalent to components of the soldering flux pieces is deposited on a circuit soldering face (generally refers to a back face), the circuit can be directly placed on a soldering position when soldering is carried out, and soldering is realized through heating. Due to the technology, the processing workload for forming the soldering flux pieces can be reduced, and wastes caused by position offset among soldering positions, the soldering flux pieces, and the circuit to be soldered when soldering is carried out can be reduced.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Automatic calling method for shot blasting speed process of shot blasting machine

PendingCN113146484AGuarantee the quality of shot blastingEliminate wear and tearAbrasive machine appurtenancesStructural engineeringMechanical engineering

The invention discloses an automatic calling method for a shot blasting speed process of a shot blasting machine, and relates to the technical field of steel production. The automatic calling method comprises the following steps that the shot blasting quality of steel plates is tracked for a long time to form a shot blasting speed process requirement; and after shot blasting steel plate information is transmitted into a secondary stage through an identification system, the secondary stage searches the shot blasting process according to the identification information and transmits the shot blasting process to a primary stage for executing the shot blasting speed. Through surface quality verification of the steel plates of different steel types and thicknesses after shot blasting, the optimal shot blasting speed is set, the production quantity of the shot blasting steel plates is improved, steel shot consumption is reduced, and buckling and the like of thin steel plates caused by long shot blasting striking time is reduced.

Owner:NANJING IRON & STEEL CO LTD

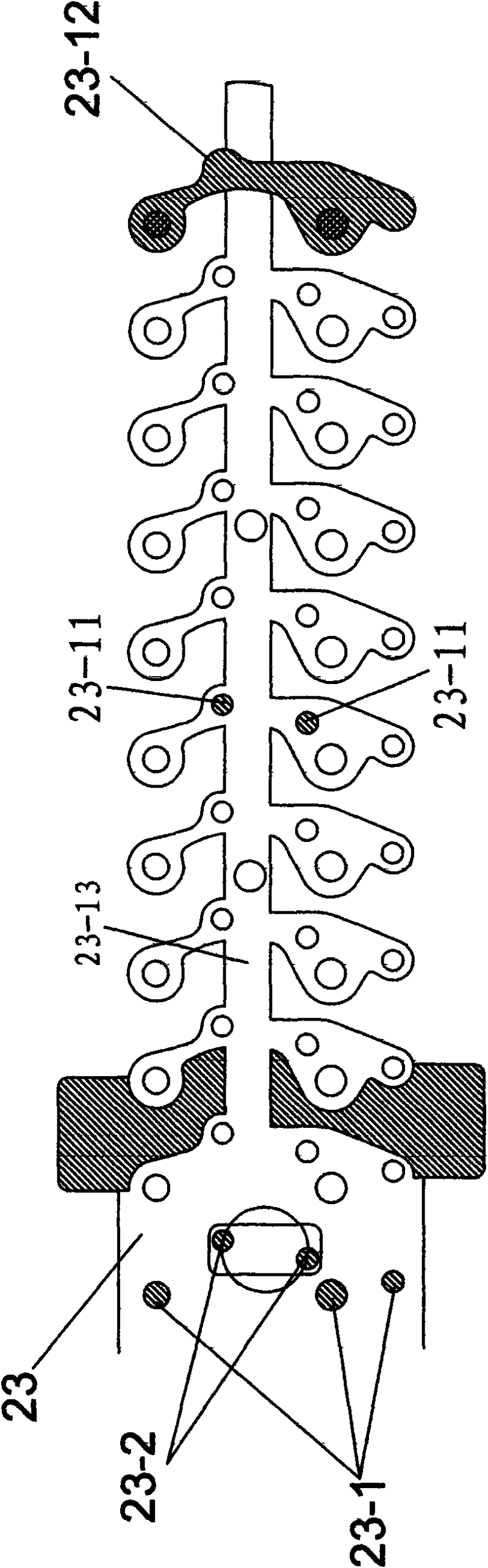

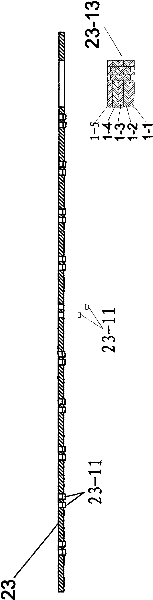

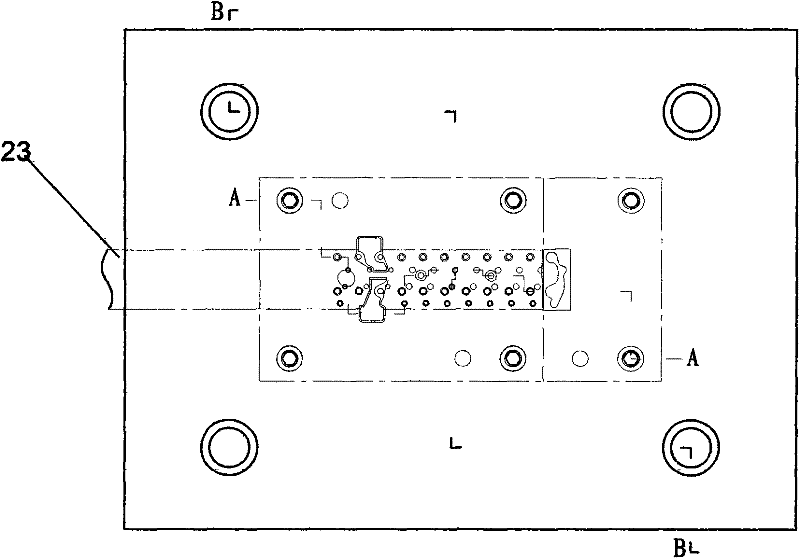

Punching and riveting mould of combined hinge connecting sheet

The invention relates to a punching and riveting device of a combined connecting movable sheet used on a hinge. The device comprises a fixing mold base, an upper mold and a lower mold. Three punching needles, two riveting hole punch needles and a pair of shear type punches are respectively arranged at the front end of the upper mold. A perforation is arranged in the middle of the upper mold, a slider is arranged on the perforation, and two separation punch needles with elastic elements are mounted below the slider. A forming punch is arranged at the back end of the upper mold. A control system is arranged on the upper mold and is connected with a connection power rod. The lower mold is provided with perforations corresponding to the upper mold punching needles, the riveting hole punch needles, the shear type punches, the separation punch needles and the forming punch. Two or more than two movable ejector pins with the elastic elements are distributed on the lower mold plate. The perforation corresponding to the forming punch is arranged on the lower mold. A returned material device is arranged above the lower mold. The invention integrates the punch processing and the riveting processing for the connecting movable sheet on the hinge, greatly reduces the processing time, and greatly improves the processing efficiency and saves the production cost.

Owner:张仕浪

An ecological garden landscape pet dog public toilet

ActiveCN107439388BSolve the problem of pollution affecting the environmentEasy to handleAnimal housingWater storage tankTree trunk

An ecological garden landscape pet dog public toilet relates to a pet dog public toilet. The present invention aims to solve the environmental impact caused by pet dog excretion caused by peculiar smell and excrement pollution in the existing residential areas, the excrement of pet dogs is difficult to handle, and the existing pet toilets for pet dogs excrete are poor in convenience and require water pipeline engineering The connection causes the problems of high investment, large engineering volume and lack of landscape effect. Pet dog public toilet includes landscape tree trunk, solar panel, storage box, cleaning water nozzle, inducer storage tank, inducer nozzle and water storage tank, soil storage tank, first lifter, bedroom mixer, second lifter, fermentation Box, heater, organic material decomposing agent storage tank, storage battery, rotating cover plate and organic material decomposing agent nozzle. The pet dog public toilet solves the problems of peculiar smell and environmental pollution caused by pet dog excretion, has low manufacturing cost, has the functions of landscape and lighting, and can also prepare organic fertilizers.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

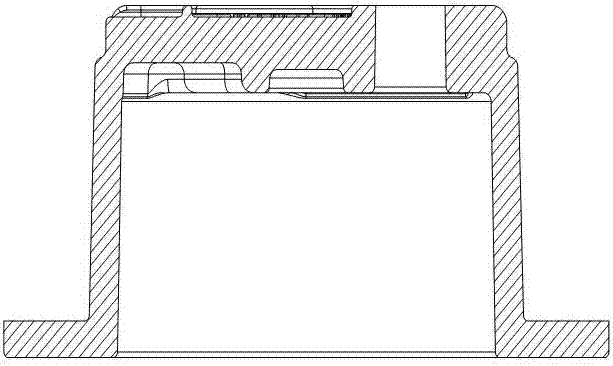

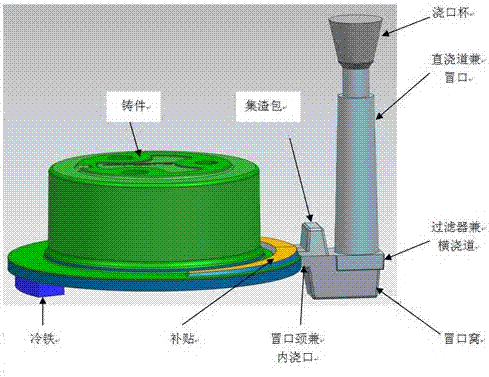

"Point" pouring process system for ductile iron castings

The invention relates to a point-type pouring process system for a nodular iron casting. According to the invention, a sprue, a horizontal runner, an ingate, a riser and riser neck are integrated into a functional body through optimization and concentration, and the functional body exerts multiple effects; i.e., the functional body can be used as the sprue for pouring and exerts buffering, filtering, pouring guiding, slag collecting and feeding effects and other effects, thereby realizing multiple purposes of the functional body. Moreover, through combined design of a chiller and a pad, a progressively-solidifying feeding channel is formed. Thus, the point-type pouring process system is constructed.

Owner:山东汇金股份有限公司

Method for adjusting matching degree of forming parameters of coal ash autoclaved standard brick

Owner:太原钢铁(集团)有限公司

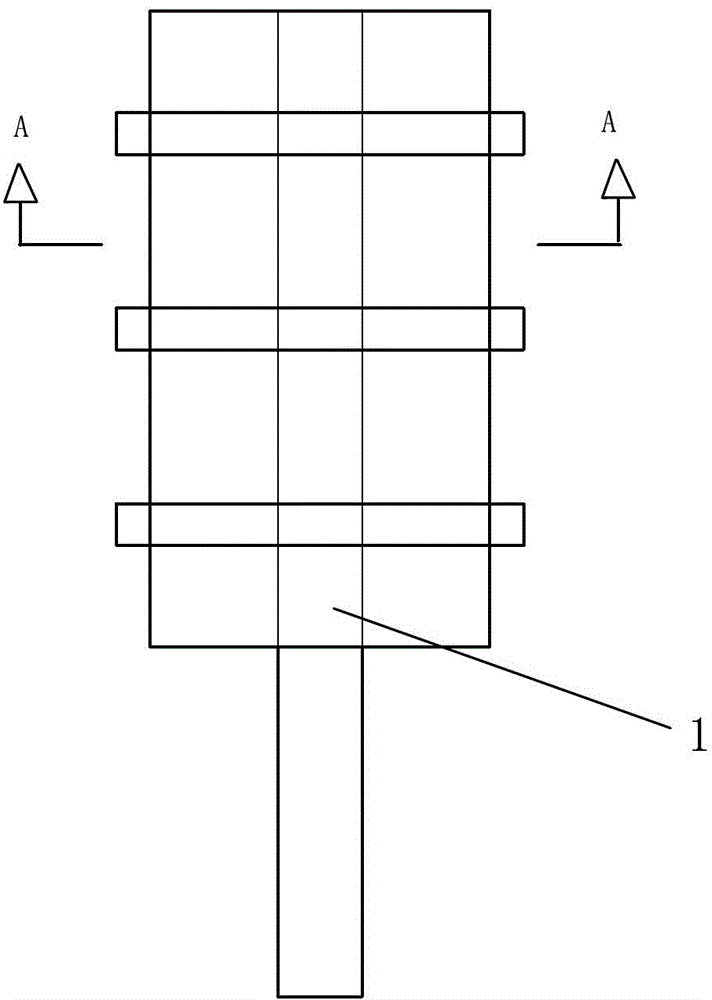

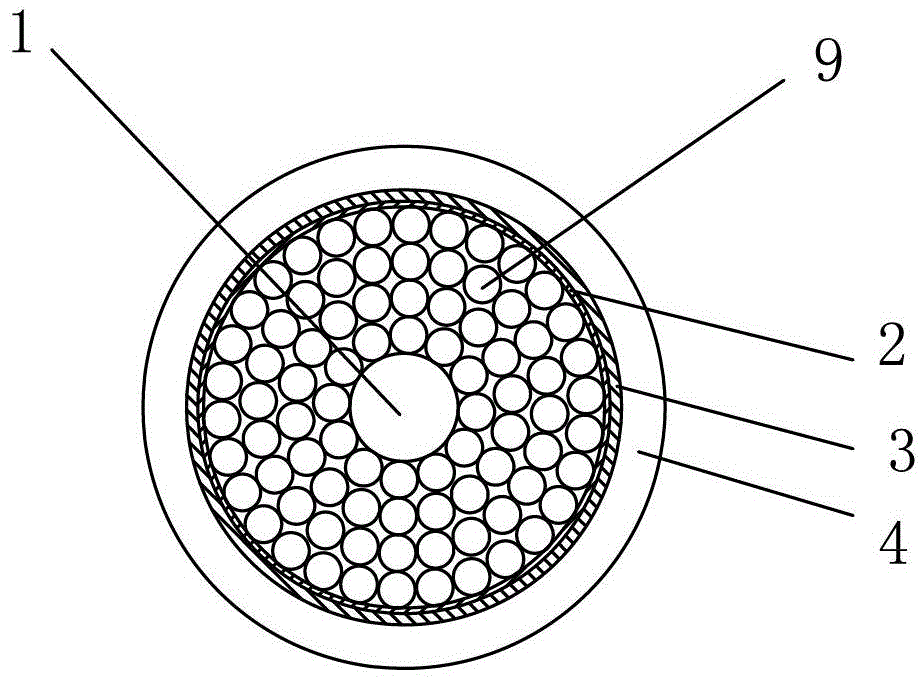

A processing method of high-precision titanium capillary parts and a grinding tube assembly used in the method

ActiveCN103386612BReduce causeOptimize tube blank qualityOther manufacturing equipments/toolsPlane surface grinding machinesMeasuring instrumentPipe fitting

The invention provides a processing method for a high-precision Ti capillary pipe fitting and a pipe grinding assembly used in the processing method. The precise Ti capillary pipe fitting is produced by the steps of adopting a laser diameter measuring instrument and an eddy current flaw detector for optimally selecting pipe blanks, adopting a specific process to draw Ti capillary pipes, adopting ultrasonic waves to clean the capillary pipes, blanking the bundled capillary pipes by adopting a specific fastening clamp, and preparing the pipe grinding assembly, and finely grinding the end faces of the capillary pipes on a grinding machine. The method has the technological characteristics of good product quality, high finished rate, higher production efficiency, less equipment investment and suitability for production in batch.

Owner:宝鸡力兴钛业科技有限公司

A Center Hole Datum Correction Method for Reducing Cutting Torque

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Anvil with good antirust performance for iron picture processing

PendingCN108749461ARealize the function of cleaning and rust removalQuality improvementSpecial ornamental structuresEngineeringImage processing

The invention discloses an anvil with good antirust performance for iron picture processing and relates to the technical field of iron pictures. The anvil comprises an anvil body and a step, wherein asquare-shaped groove is formed in the anvil body, a polishing device is fixedly connected in the square-shaped groove, and the polishing device comprises a hydraulic rod fixed to the bottom end of the square-shaped groove. The anvil disclosed by the invention is good in antirust performance. By arranging the anvil, the step and a cone-shaped anvil, beating, cutting off, fine beating and angle shaping of the iron picture are achieved, so that the iron picture manufacturing environment is cleaner and tidier, and convenient to manage, and the work efficiency is improved. As the polishing deviceis arranged in the anvil body, cleaning and derusting functions can be achieved after the iron pictures are manufactured, so that the quality of the manufactured iron picture is improved, and defective goods of the iron pictures as a result of rust of the anvil are reduced. Meanwhile, the polishing device is stored in the square-shaped groove when the polishing function is not used, and the anvilis small in occupied space and convenient to maintain.

Owner:芜湖储铁艺铁画设计有限公司

A device and method for reducing friction between drilling tool and well wall

ActiveCN110748297BStrong axial vibration capabilityReduce frictional resistanceDrilling rodsVibration drillingWell drillingStructural engineering

The invention relates to a tool for reducing friction between a drilling tool and a well wall, improving well drilling efficiency and shortening a well drilling cycle and a method thereof. According to the technical scheme, the tool for reducing the friction between the drilling tool and the well wall mainly comprises a sliding rod, a sealing ring, a check ring, a first upper shell, a limiting semi-circular ring, a second upper shell, a disc spring, a sealing ring, a check ring, a piston, a third upper shell, a common flat key, an upper fixed valve, an upper moving valve, a fourth upper shell,a stator, a rotor, a lower shell, a lower moving valve, a lower fixed valve and a lower interface, wherein the first upper shell, the second upper shell, the third upper shell, the fourth upper shell, the stator, the lower shell and the lower interface are in threaded connection in sequence, under the driving of the rotor, an inclined hole runner of the lower moving valve is periodically opened and closed, the energy of fluid is converted into a series of pulse pressures, and static friction between the drilling tool and the well wall is broken, so that the purpose of reducing the friction and improving the drilling capacity of a horizontal section is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

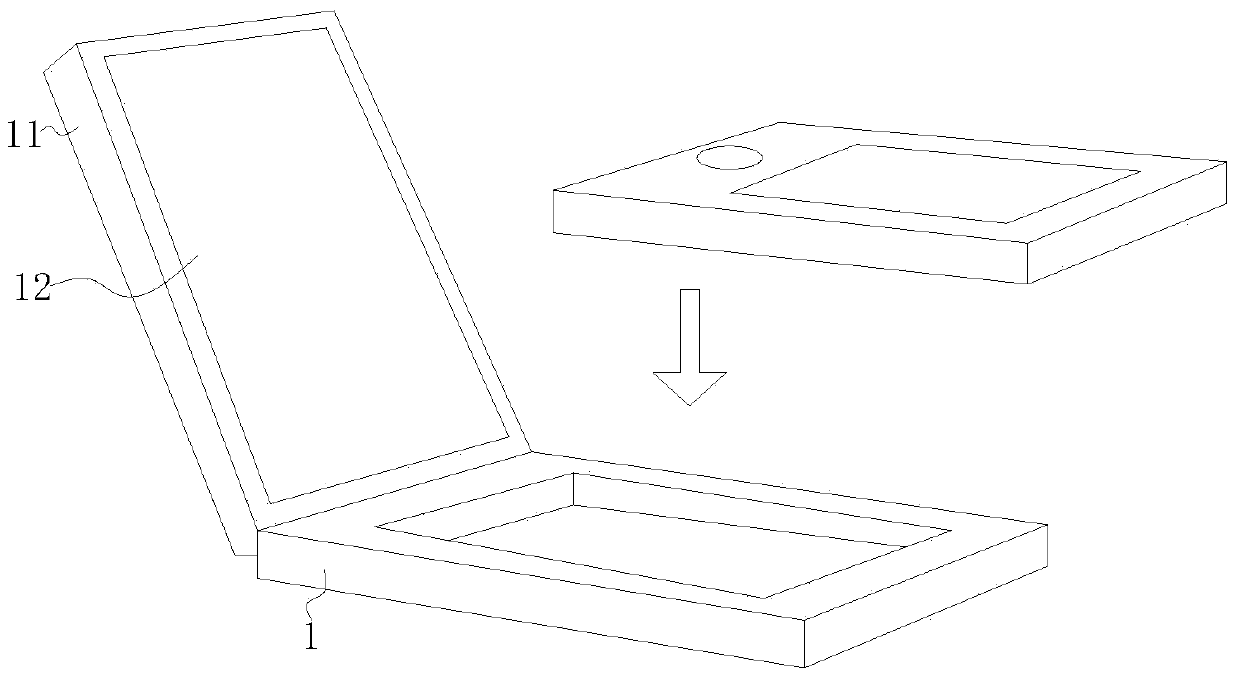

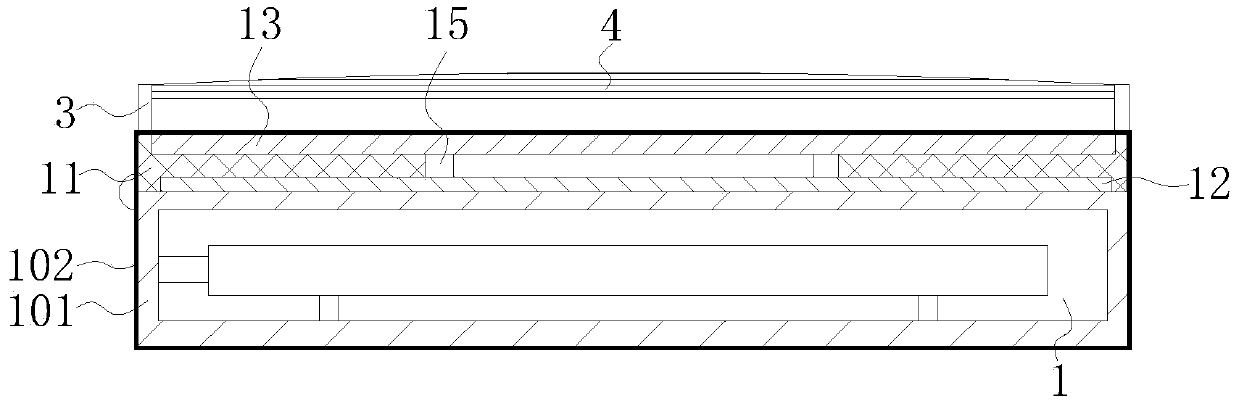

A mobile phone protective case capable of enlarging the display area

ActiveCN107295122BSave replacement costIncrease the display areaTelephone set constructionsComputer hardwareLiquid-crystal display

The invention relates to a mobile phone protective case capable of enlarging the display area, and aims to provide a mobile phone protective case capable of enlarging the display area which is easy to carry, reliable in structure and excellent in display effect. The mobile phone protective case includes a clamping sleeve. A reversible display is arranged on the top of the clamping sleeve. A display bracket capable of making a liquid crystal display screen rotate relative to the display is arranged on the display. A lens support is arranged outside the liquid crystal display screen. A detachable liquid zoom lens is arranged on the lens support. The display area of a mobile phone can be enlarged quickly without the need for a user to replace the mobile phone, and the phone replacement cost is saved for users. The liquid crystal display screen can be adjusted according to the angle and distance between the liquid crystal display screen and an eye lens in order to make the eyes always in a best viewing position and to protect the eyes. The clamping sleeve is made of a novel aluminum alloy material and a novel resin material, and is thus of higher structural strength.

Owner:上海博梦通讯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com