External gear shaft sleeve machining technology and milling-clearing-integration equipment thereof

A gear bushing and processing technology, which is applied in metal processing equipment, metal material coating technology, wheels, etc., can solve the problem of gear processing quality and uneven surface unevenness of workpieces, improve processing quality, and reduce surface unevenness. possibility, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: It is a kind of external gear sleeve processing technology disclosed by the present invention, including the following processing steps:

[0040] Blank material cutting: choose 42CrMo as the blank material, and cut the ingredients into segments according to the specifications and sizes of the external gear bushing through a sawing machine to obtain the first processed product;

[0041] Preheating: Put the first processed product into a heating furnace and heat it at 300°C for 1 hour until the first processed product is heated to 1150°C, and then take it out of the heating furnace to obtain the second processed product;

[0042] Forging forming: the second processed product is hot-forged at a temperature of 850°C by a forging press, and then cooled, so that the second processed product is processed with a shaft sleeve through hole along the axial direction to obtain the third processed product;

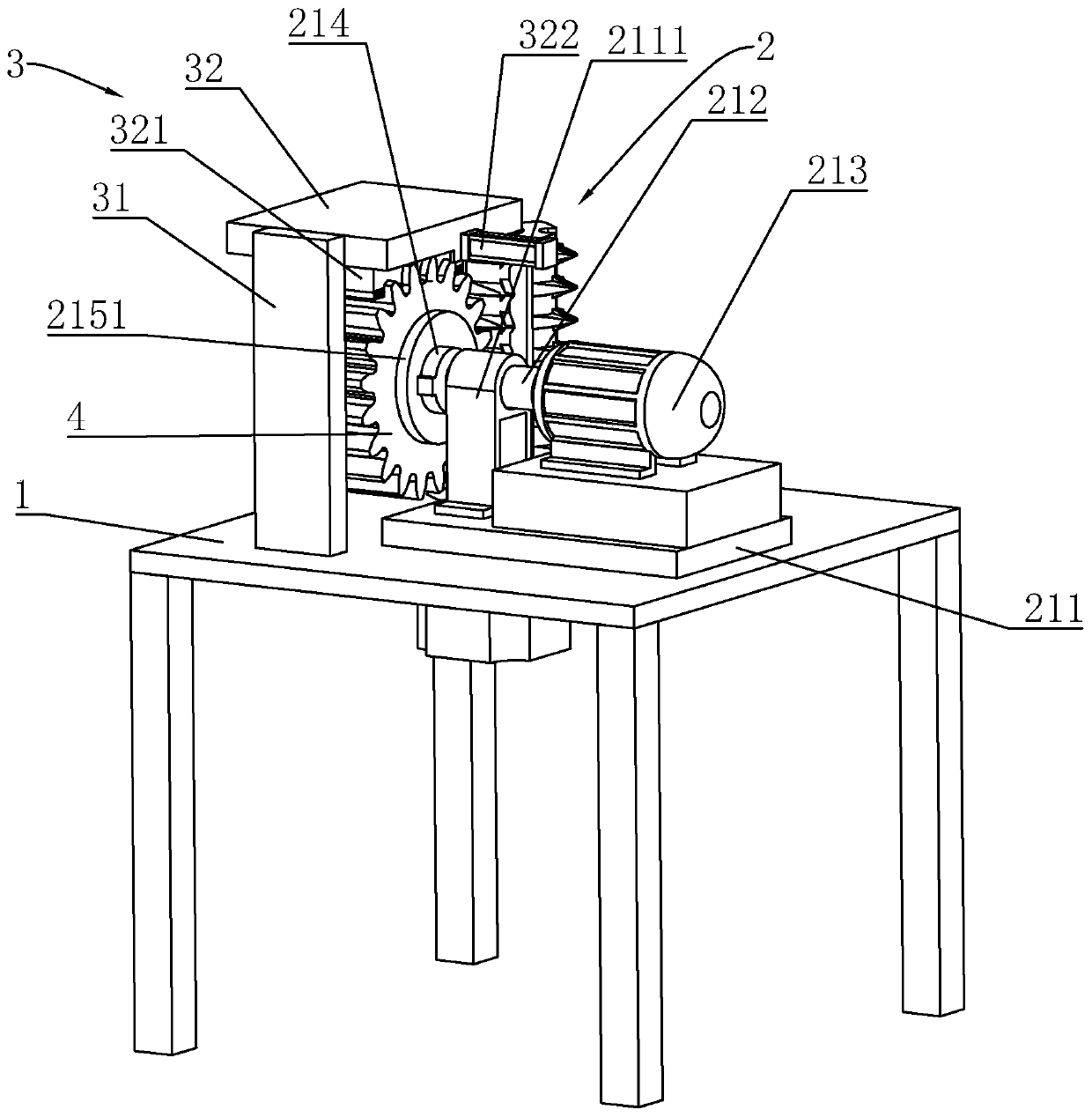

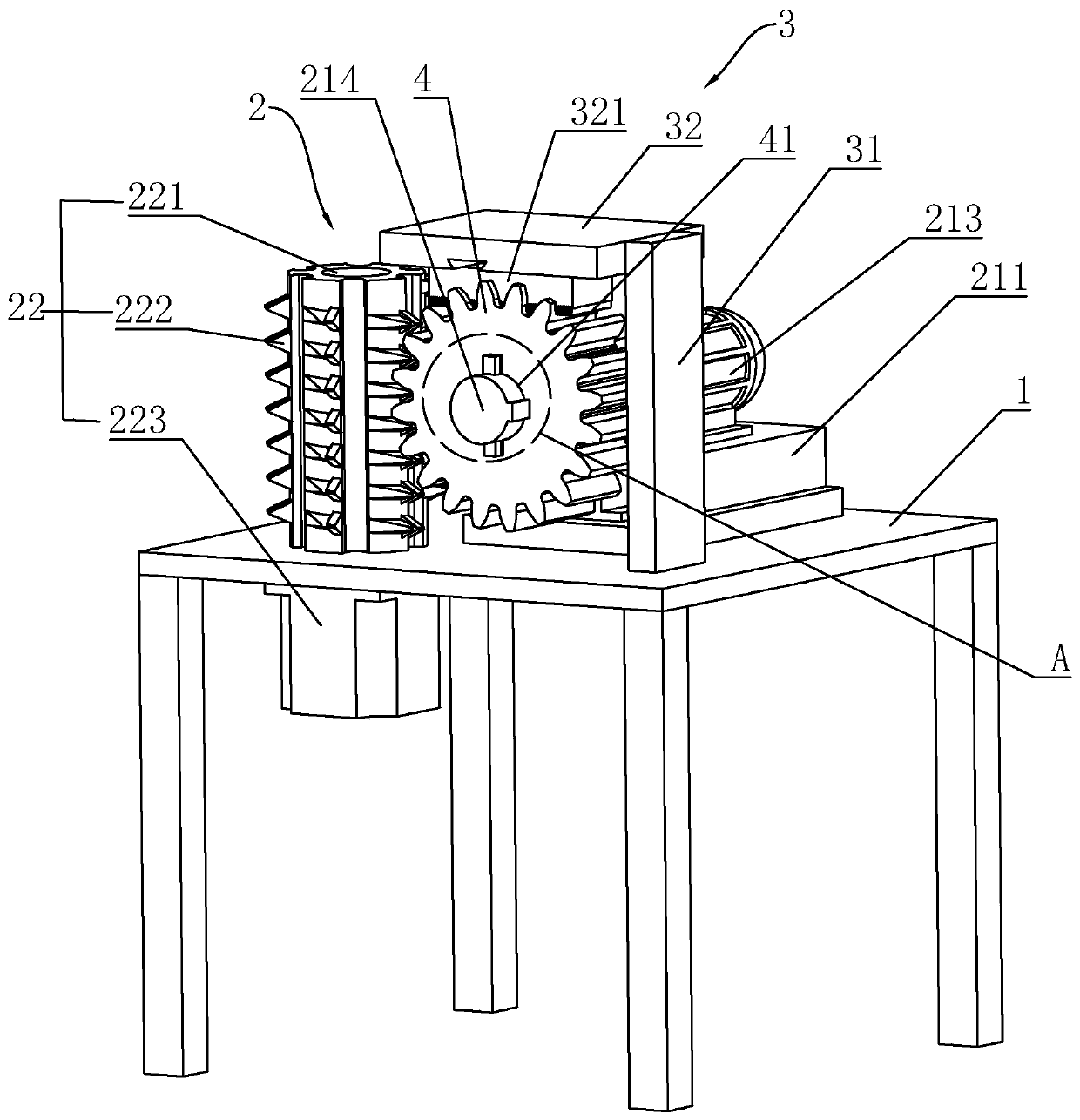

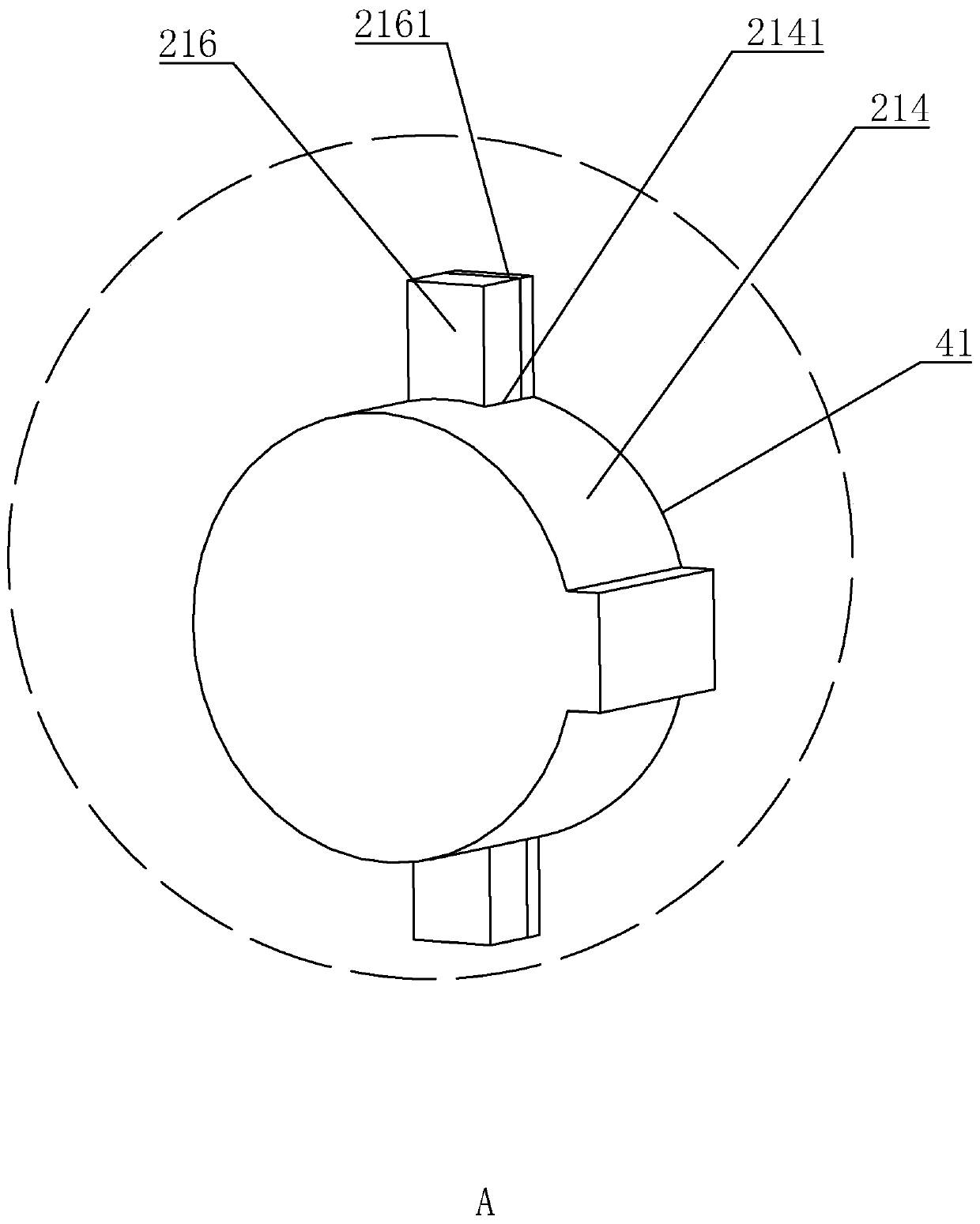

[0043] Milling treatment: use milling-cleaning integrated equ...

Embodiment 2

[0048] Embodiment 2: Different from Embodiment 1, it is a kind of external gear sleeve processing technology disclosed by the present invention, which includes the following processing steps:

[0049] Blank material cutting: choose 42CrMo as the blank material, and cut the ingredients into segments according to the specifications and sizes of the external gear bushing through a sawing machine to obtain the first processed product;

[0050] Preheating: Put the first processed product into the heating furnace and heat it at 300°C for 1.25 hours until the first processed product is heated to 1150°C, and then take it out of the heating furnace to obtain the second processed product;

[0051] Forging forming: the second processed product is hot-forged at a temperature of 1000°C by a forging press, and then cooled, so that the second processed product is processed with a shaft sleeve through hole along the axial direction to obtain the third processed product;

[0052] Milling treat...

Embodiment 3

[0057] Embodiment 3: The difference from Embodiment 1 is that it is a kind of external gear sleeve processing technology disclosed by the present invention, which includes the following processing steps:

[0058] Blank material cutting: choose 42CrMo as the blank material, and cut the ingredients into segments according to the specifications and sizes of the external gear bushing through a sawing machine to obtain the first processed product;

[0059] Preheating: Put the first processed product into the heating furnace and heat it at 300°C for 1.5 hours until the first processed product is heated to 1150°C, and then take it out of the heating furnace to obtain the second processed product;

[0060] Forging forming: the second processed product is hot-forged at a temperature of 1150°C by a forging press, and then cooled, so that the second processed product is processed with a shaft sleeve through hole along the axial direction to obtain the third processed product;

[0061] Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com