A processing method of high-precision titanium capillary parts and a grinding tube assembly used in the method

A processing method and capillary technology, which are applied in the processing of titanium capillary parts and the field of grinding tube components, can solve the problems of difficult production, small size, high requirements on surface finish and verticality of dimensional tolerance, etc. The effect of optimizing the quality of the tube blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

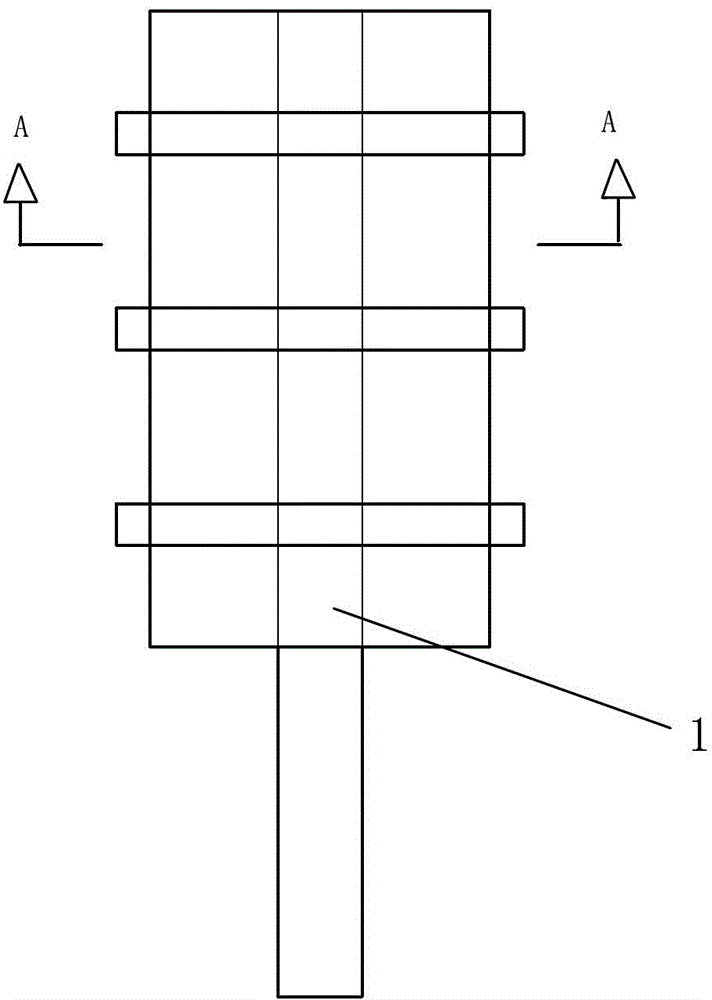

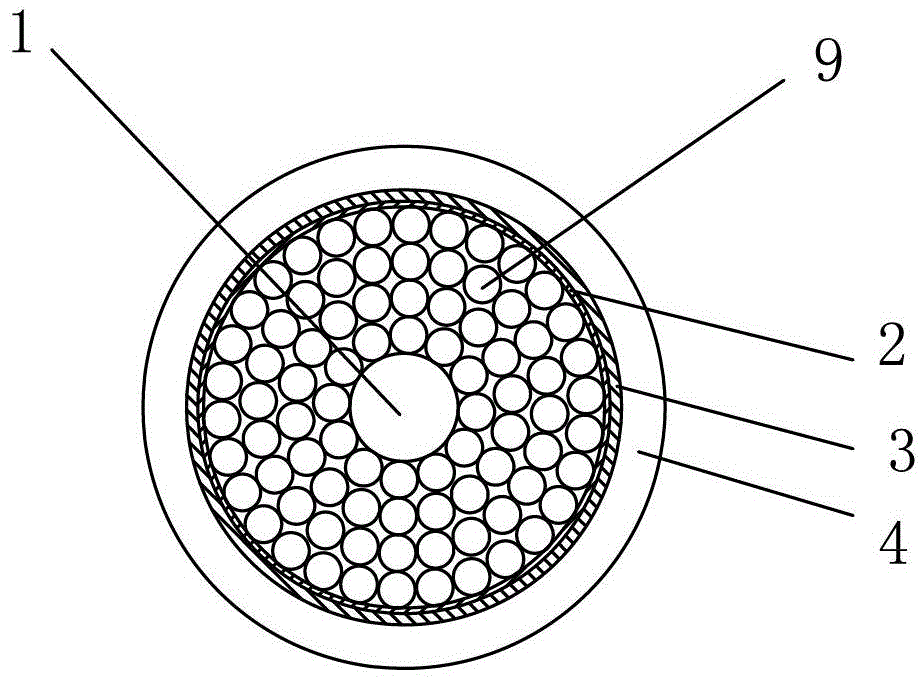

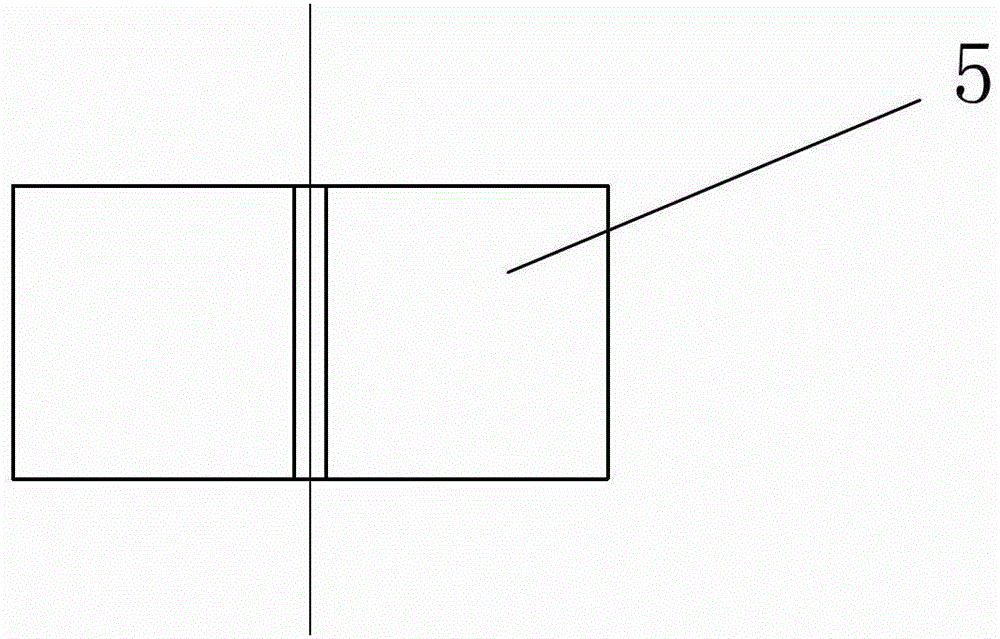

[0040] Such as Figure 1-6 As shown, the grinding tube assembly of the present invention includes a clamp ring 5 and a short tube assembly 6, wherein the short tube assembly is a strip-shaped titanium capillary tube cut into a φ0.8×0.05mm titanium capillary tube with a length of about 140mm-150mm, and every 1000 A titanium capillary 9 is packed into a strip-shaped bundle, and a φ10mm×250mm iron mandrel 1 is clamped in the center of the strip-shaped bundle. One end of the iron mandrel is aligned with one end of the bar-shaped titanium capillary, and the other end of the iron mandrel extends out of the The outside of the bundle; the outside of the strip bundle is bound tightly with wrapping paper 2, adhesive tape 3 and rubber strip 4 in sequence; the strip bundle is cut into short tube assemblies with a length of 7 mm.

[0041] Cut the φ25×2mm steel pipe or ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com