Anvil with good antirust performance for iron picture processing

A technology of anti-rust performance and iron painting, applied in special decorative structures, decorative arts, etc., can solve the problems of increasing board replacement time, cumbersome iron painting production, and increasing production costs, so as to improve work efficiency, reduce defective iron paintings, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

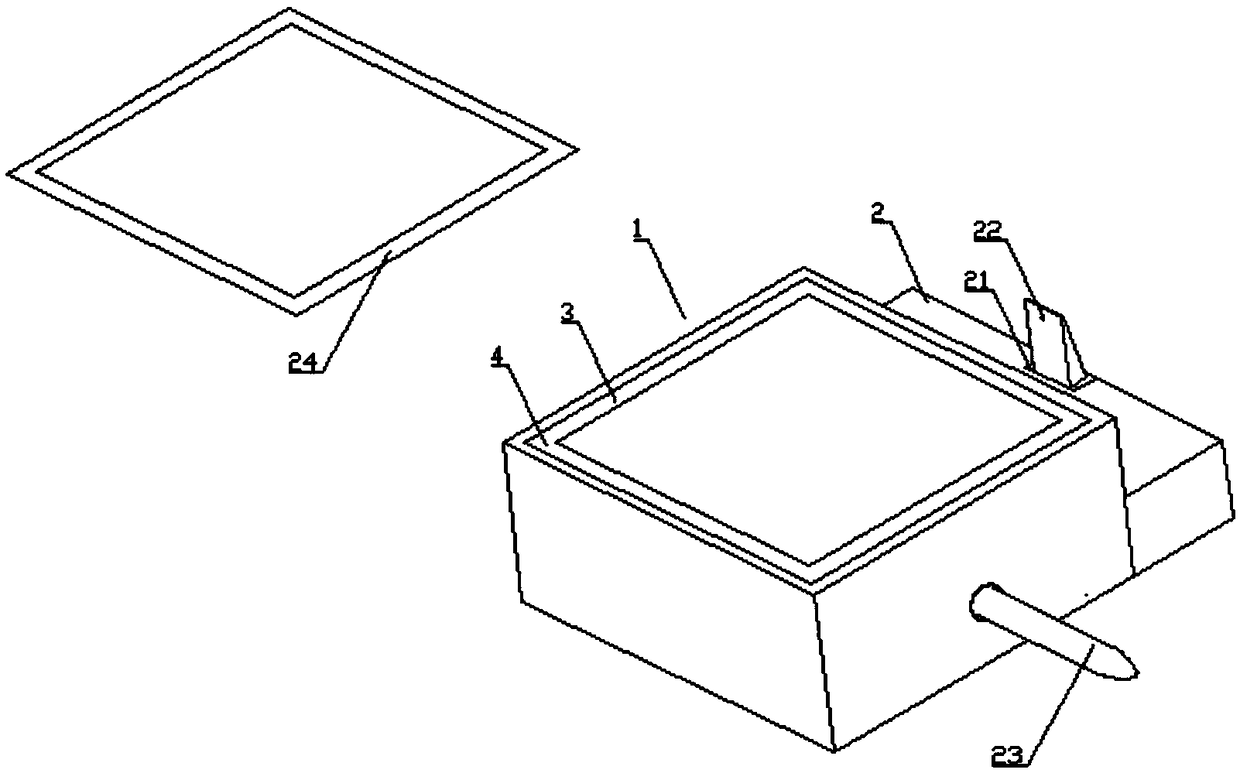

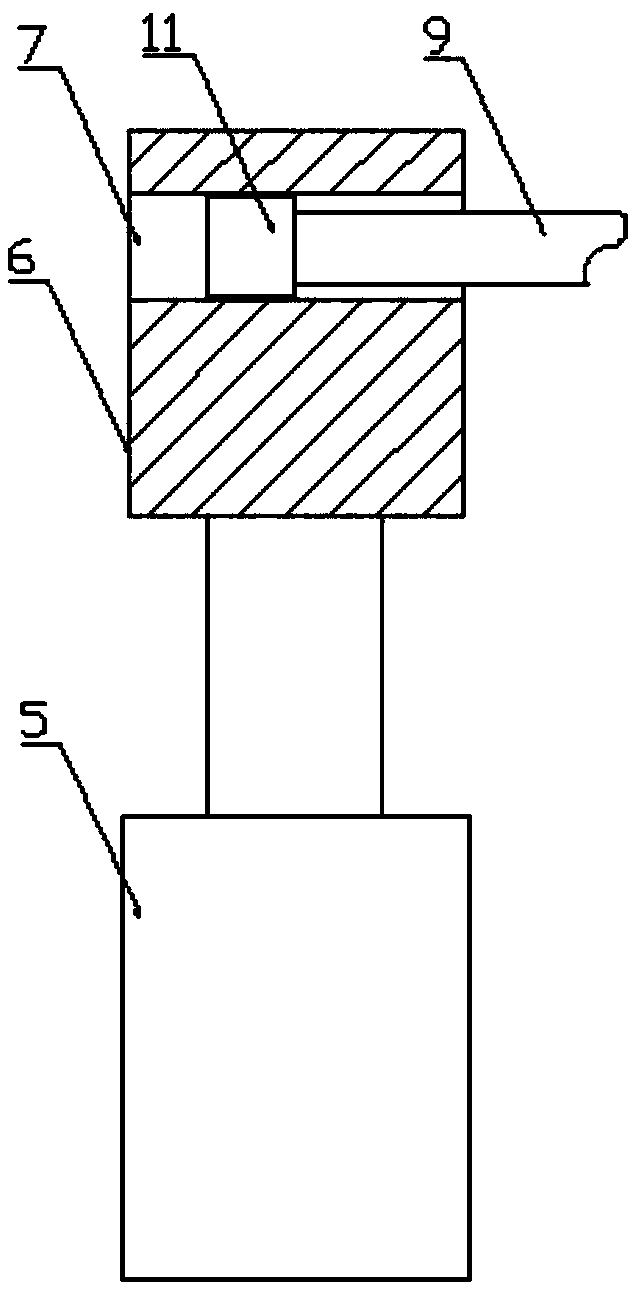

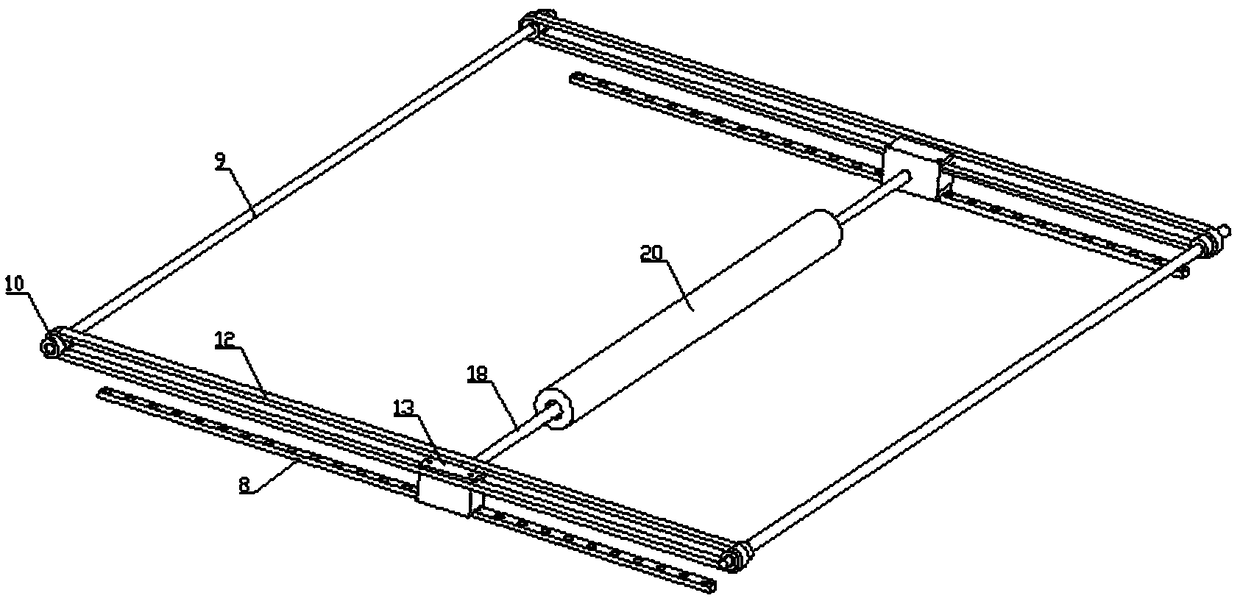

[0019] Such as Figure 1 to Figure 4 As shown, an anvil for iron painting processing with good antirust performance includes an anvil 1 and a step 2. The anvil 1 is provided with a "mouth" shaped groove 3, and the "mouth" shaped groove 3 is fixedly connected Grinding device 4, said grinding device 4 includes hydraulic rod 5 fixed on the bottom end of "mouth" shaped groove 3, said hydraulic rod 5 is fixedly connected to support base 6, said support base 6 has a circular groove 7 on the side and the bottom end The sliding rail 8 is fixedly connected, and the rotating shaft 9 is socketed between every two round grooves 7. There are two rotating shafts 9 and both ends of which are socketed outside the drum 10, and one end of one rotating shaft 9 is connected to a motor 11. The rotary drum 10 is covered with crawler belts 12, and the crawler belts 12 are arranged vertically to the rotating shaft 9. The composite slider 13 is slidably connected to the slide rail 8, and the lower end...

Embodiment 2

[0022] Such as Figure 1 to Figure 4 As shown, an anvil for iron painting processing with good antirust performance includes an anvil 1 and a step 2. The anvil 1 is provided with a "mouth" shaped groove 3, and the "mouth" shaped groove 3 is fixedly connected Grinding device 4, said grinding device 4 includes hydraulic rod 5 fixed on the bottom end of "mouth" shaped groove 3, said hydraulic rod 5 is fixedly connected to support base 6, said support base 6 has a circular groove 7 on the side and the bottom end The sliding rail 8 is fixedly connected, and the rotating shaft 9 is socketed between every two round grooves 7. There are two rotating shafts 9 and both ends of which are socketed outside the drum 10, and one end of one rotating shaft 9 is connected to a motor 11. The rotary drum 10 is covered with crawler belts 12, and the crawler belts 12 are arranged vertically to the rotating shaft 9. The composite slider 13 is slidably connected to the slide rail 8, and the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com