Patents

Literature

65 results about "Wrought iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wrought iron is an iron alloy with a very low carbon (less than 0.08%) content in contrast to cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which gives it a "grain" resembling wood that is visible when it is etched or bent to the point of failure. Wrought iron is tough, malleable, ductile, corrosion-resistant and easily welded. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name wrought because it was hammered, rolled or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is mild or low carbon steel. Neither wrought iron nor mild steel contain enough carbon to be hardenable by heating and quenching.

Nitrogen alloyed stainless steel and process

InactiveUS20120082586A1Improved kineticsIncrease resistanceSolid state diffusion coatingMetal layered productsMartensitic stainless steelSS - Stainless steel

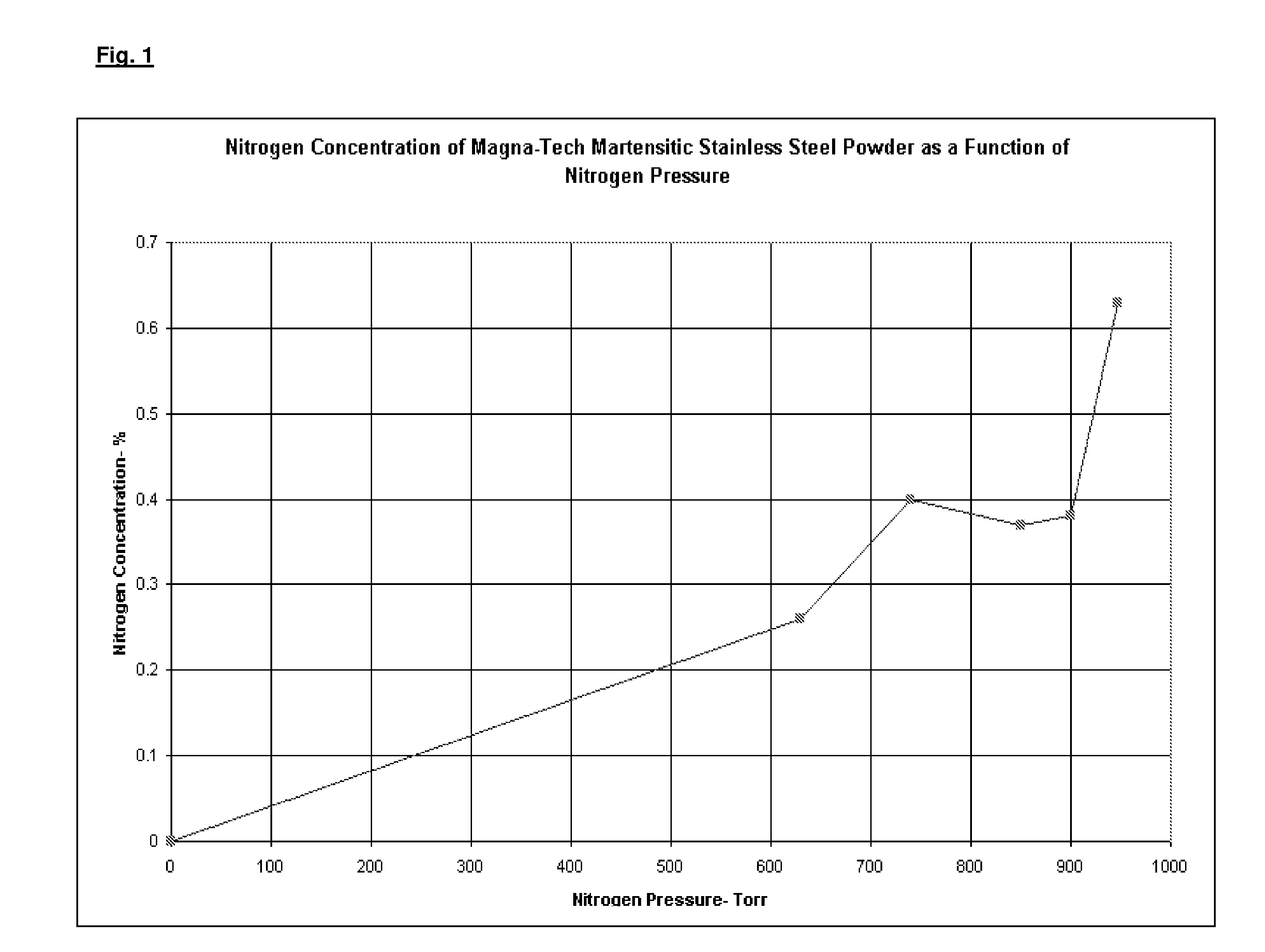

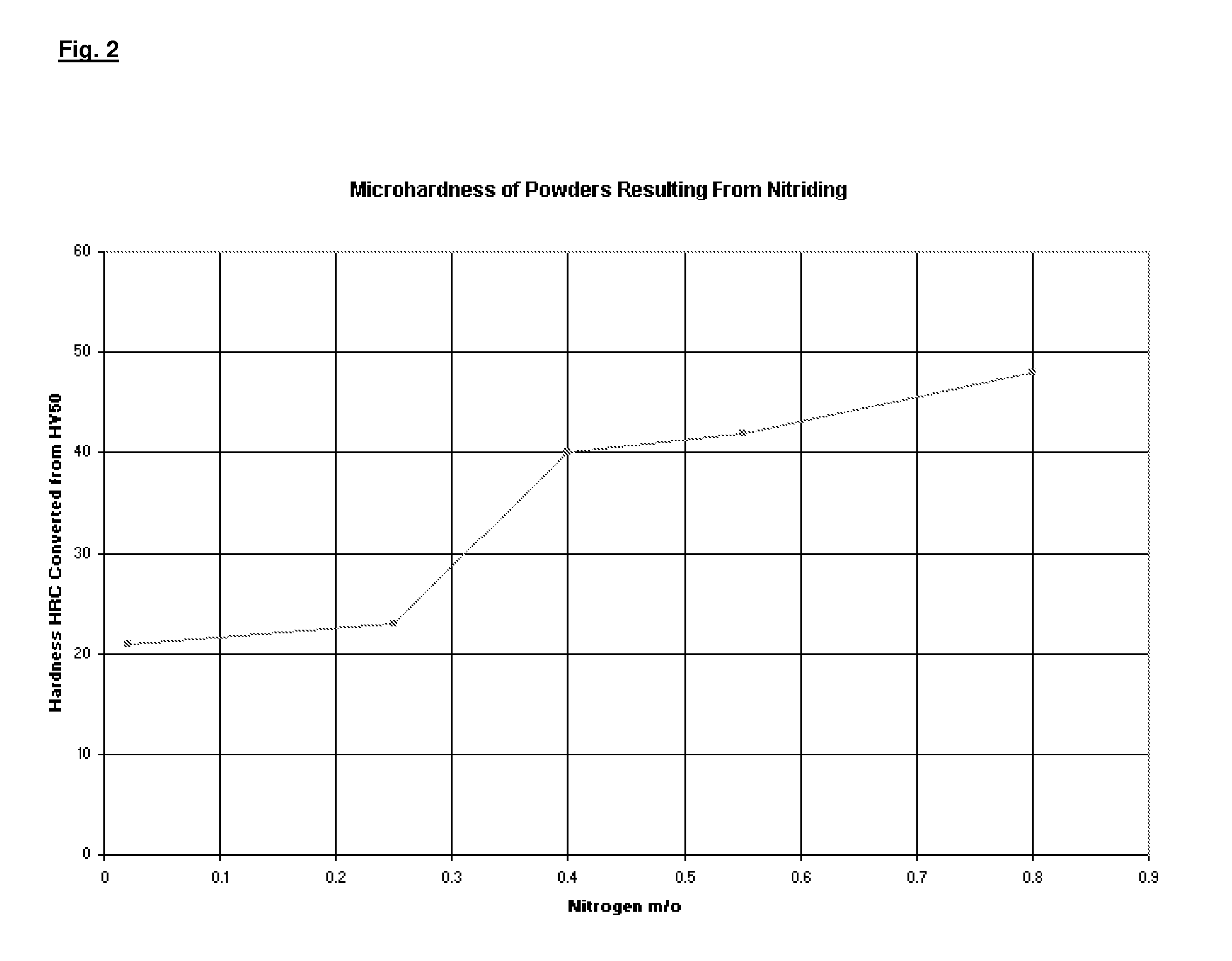

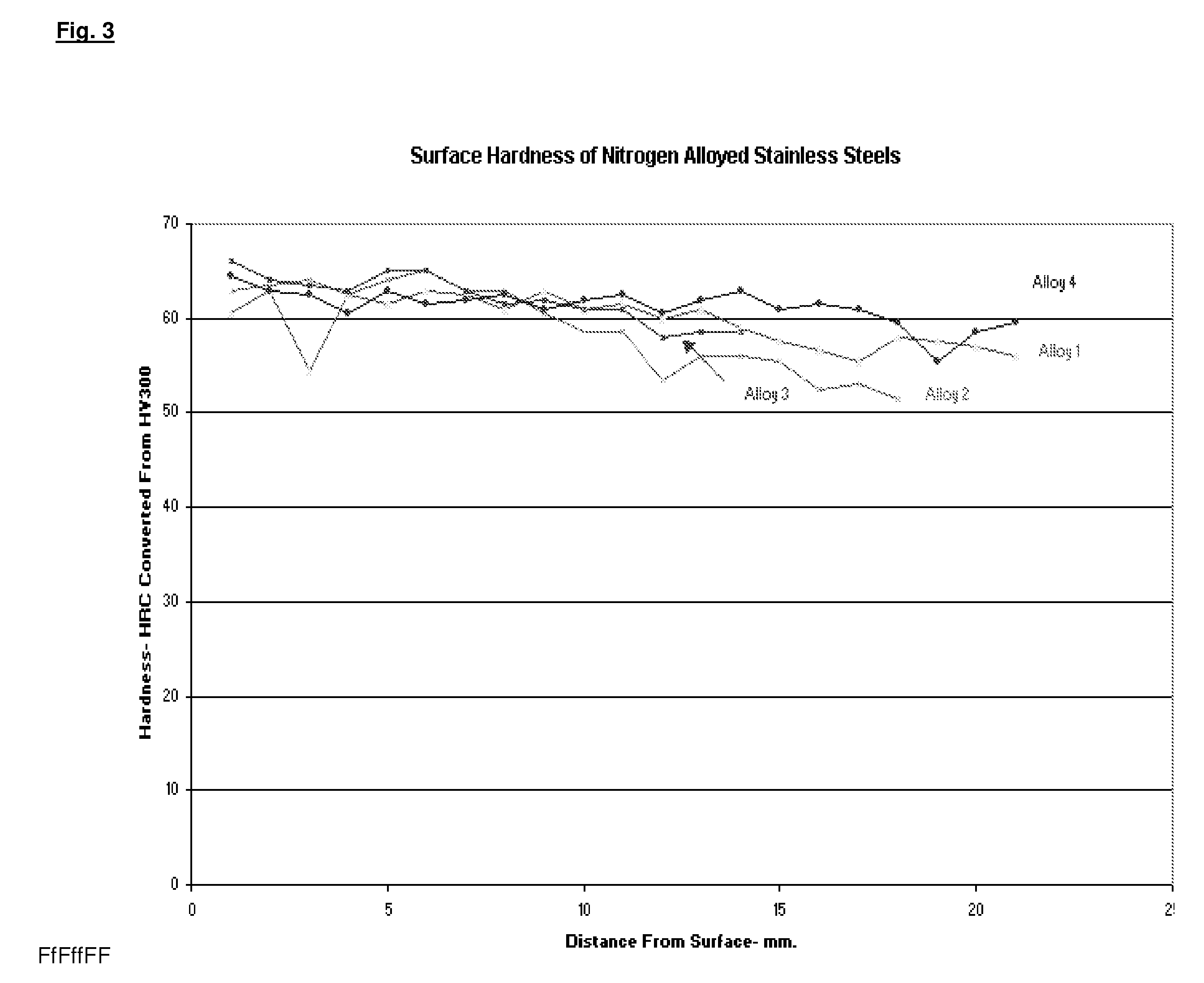

The present invention comprises the nitridization of stainless steel with a gaseous nitrogen compound such as nitrogen gas (N2), or ammonia (NH3) at high temperature wherein the reaction pressure is lowered. A base powder with properties similar to those of a martensitic stainless steel is prepared from a molten metal with the subsequent incorporation of selective additives such as cobalt, chromium, boron, copper, vanadium, niobium and mixtures thereof to improve high temperature resistance to scuffing and adhesive wear. The molten mixture is then atomized by water- or air-atomization to yield a base powder which is mixed with nitrogen or ammonia gas at various pressures in a static or fluidized bed to provide a nitrogen alloyed particulate, i.e., a nitrided particulate alloy. The powder is heated in a hot isostatic press under vacuum with argon gas at reduced pressure and later cooled to ambient (room) temperature. A second embodiment of the invention also comprises the use of a wrought iron-based stainless steel or casting as the starting material to be nitrided.

Owner:MAGNA TECH PM LABS

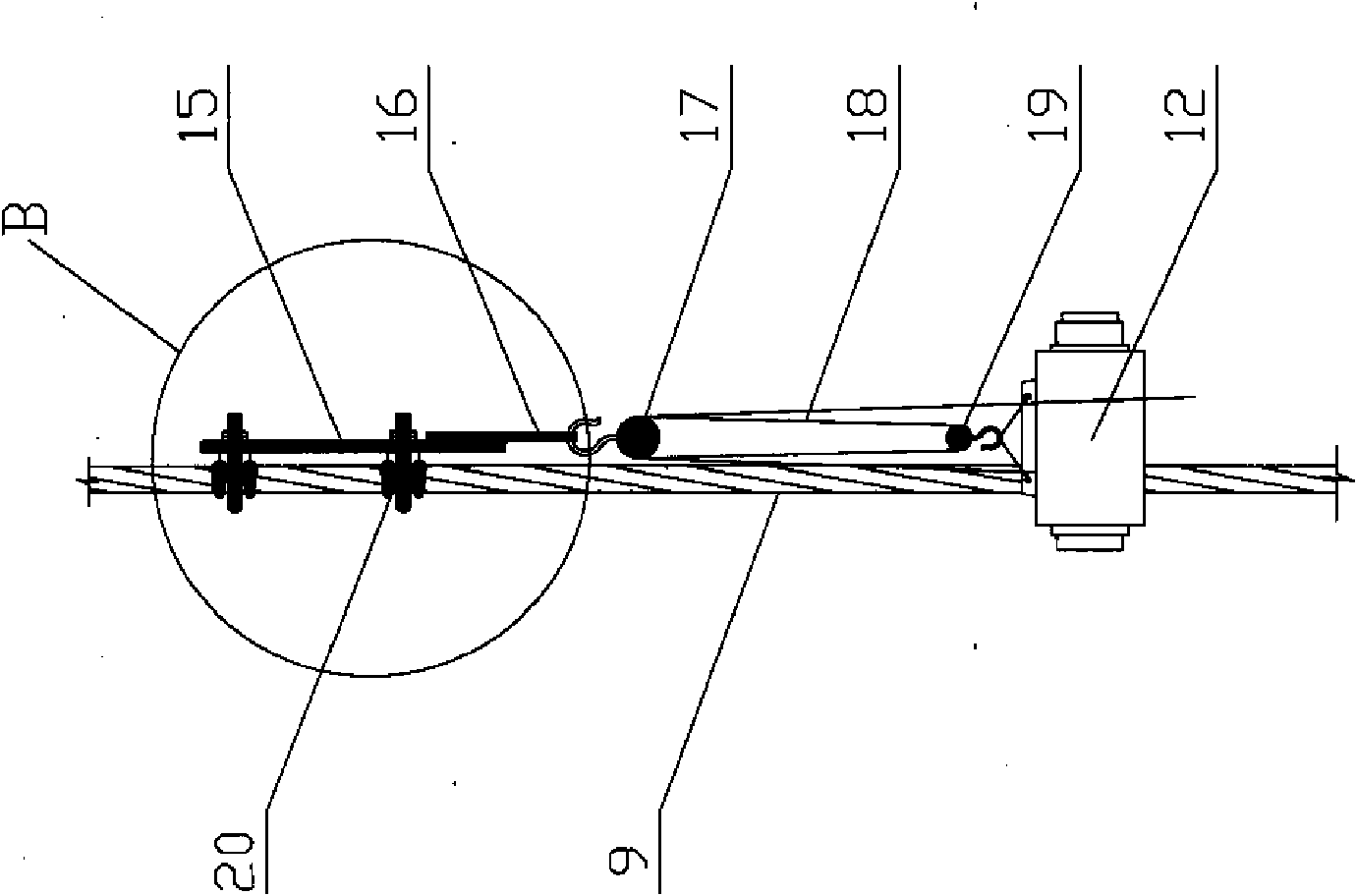

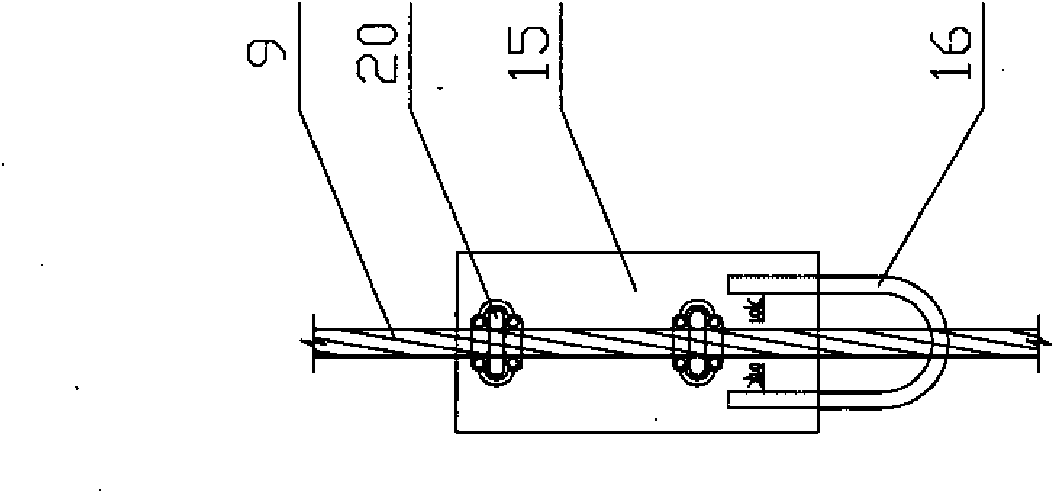

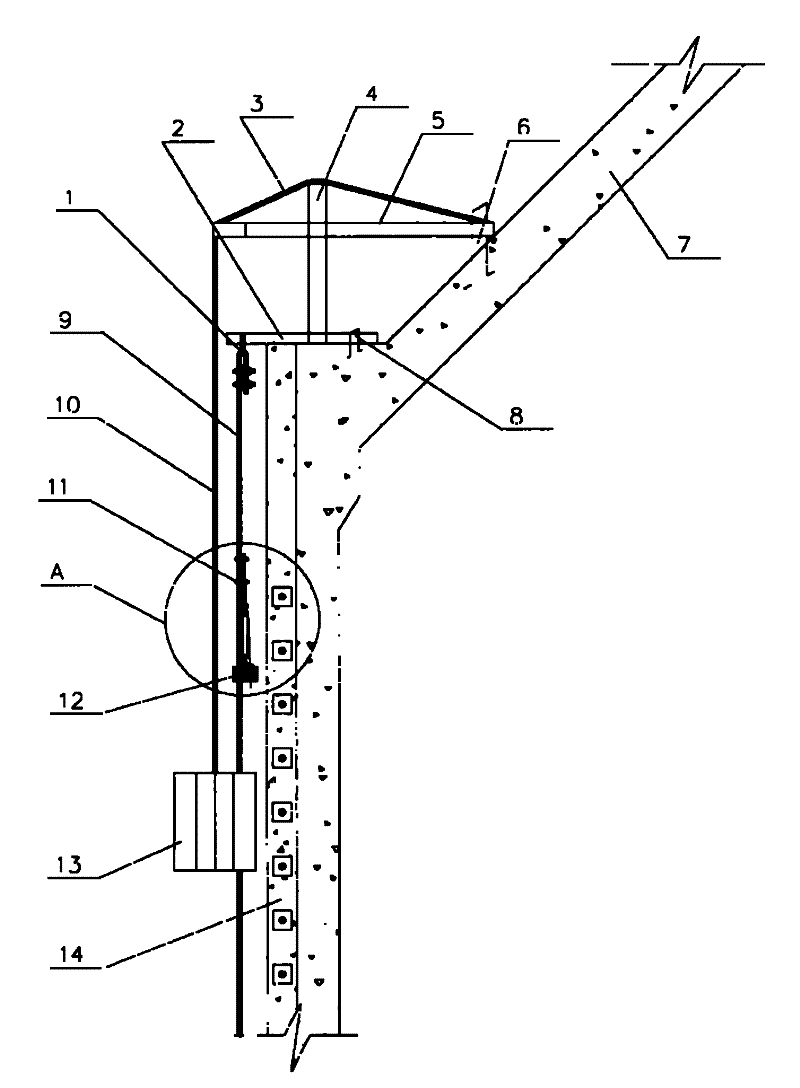

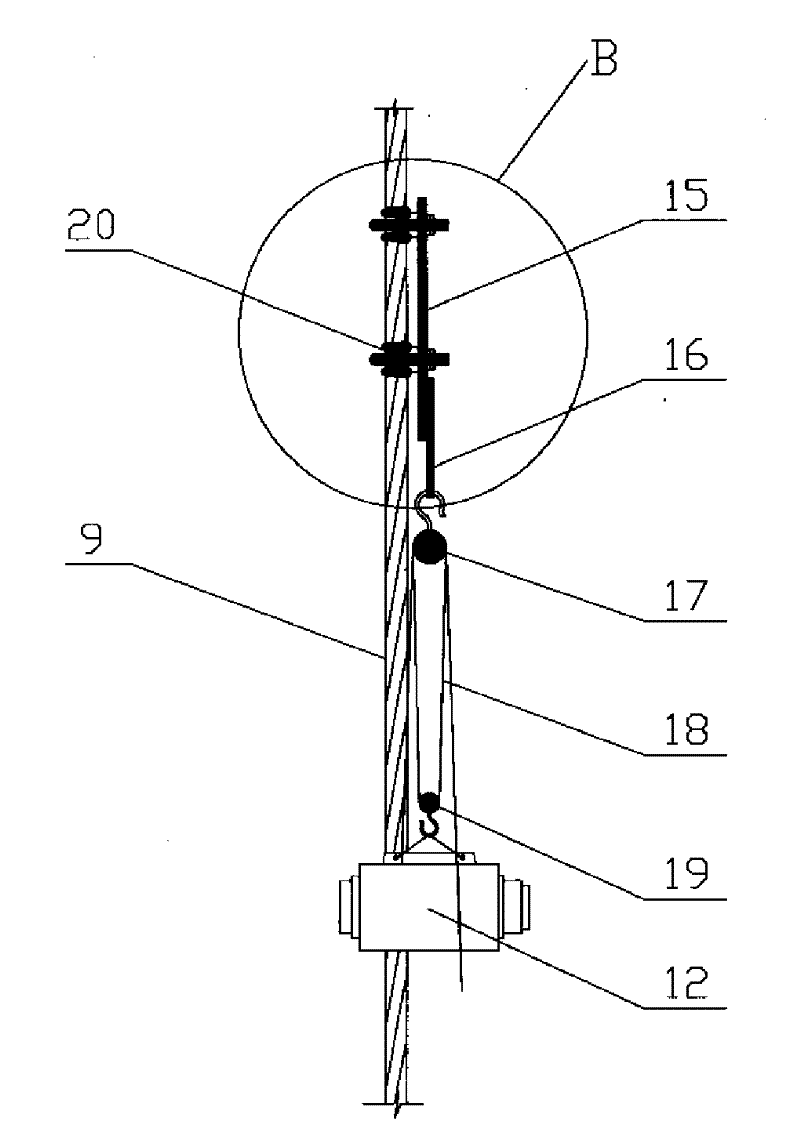

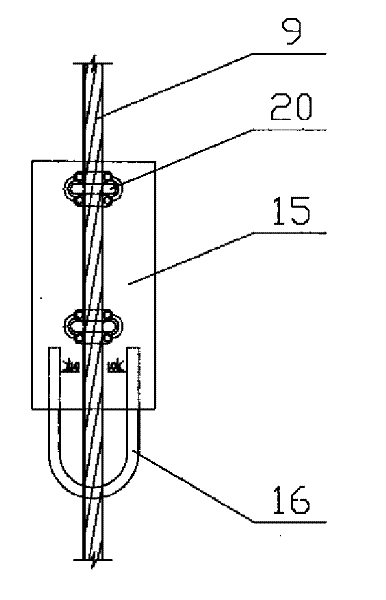

Large-tonnage jack tension construction technology for non-bonded prestressed silo

ActiveCN101597960AEven by forcePrevent rustBuilding material handlingBulk storage containerButtressNacelle

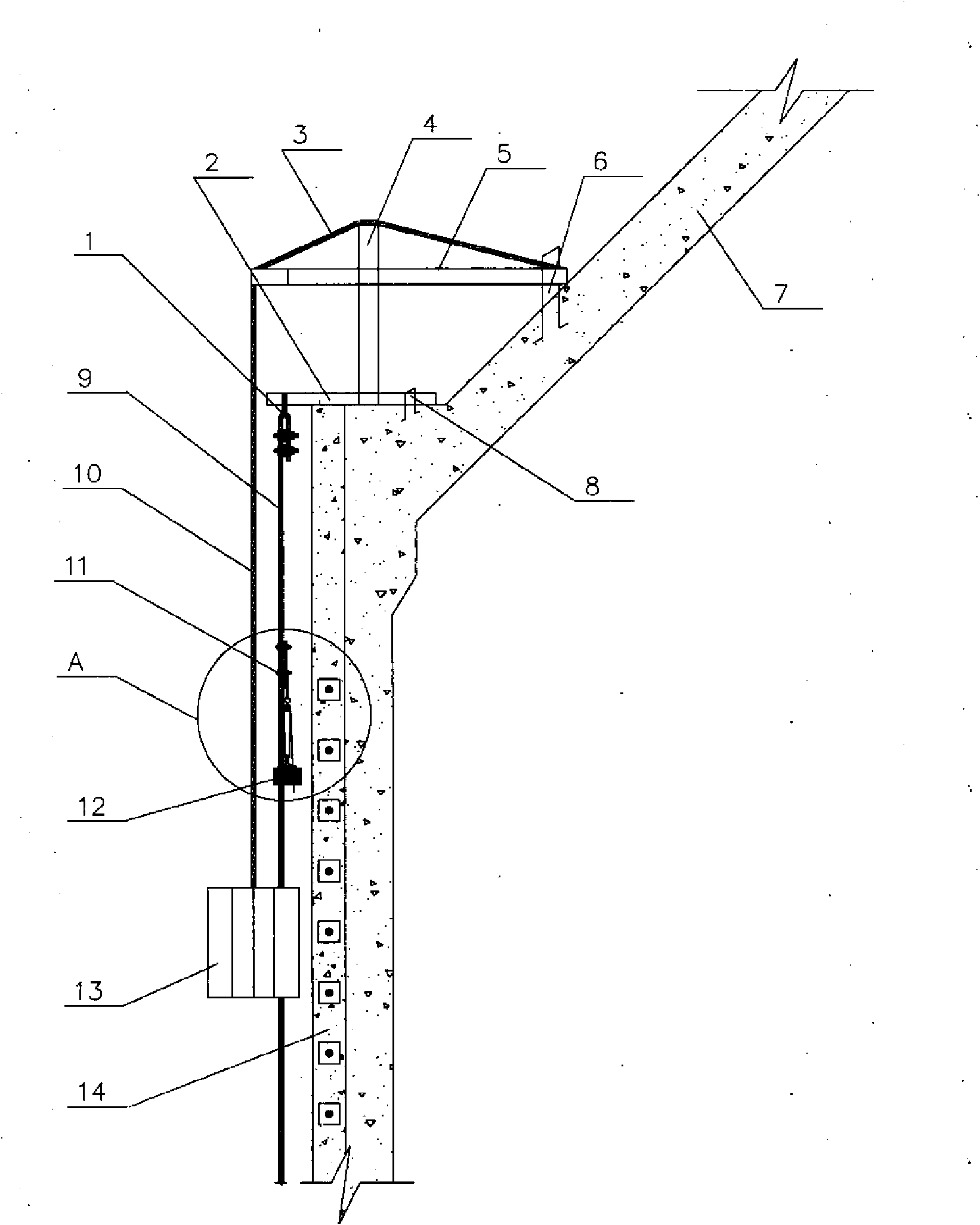

The invention discloses large-tonnage jack tension construction technology for a non-bonded prestressed silo. The invention aims to provide construction technology which uses a flat wrought iron anchor backing plate matched with an anchor device, takes a nacelle as an operation platform for tension construction, and uses a large-tonnage jack to perform cluster beam tension on prestressing tendons to improve construction quality, reduce construction cost and shorten construction period, wherein the anchor backing plate comprises a square wrought iron anchor backing plate body; and the square wrought iron anchor backing plate body is provided with an anchor eye and a mounting hole which correspond to the anchor device. A suspension mode of the nacelle is that a conical roof is provided with a nacelle suspension embedded part, which ensures that the conical roof of the silo becomes the balance weight of the nacelle; and a suspension mode of the jack is that the top of a buttress is provided with a jack hanger embedded part; the hanger embedded part is fixedly connected with a supporting beam; the outer end part of the supporting beam is welded with a lifting ring; one end of a steel wire rope is fixedly connected with the lifting ring; while the other end hangs down to the bottom of the silo; a connecting plate is connected with the steel wire rope; and the connecting plate is connected with a jack hanger.

Owner:李延春 +2

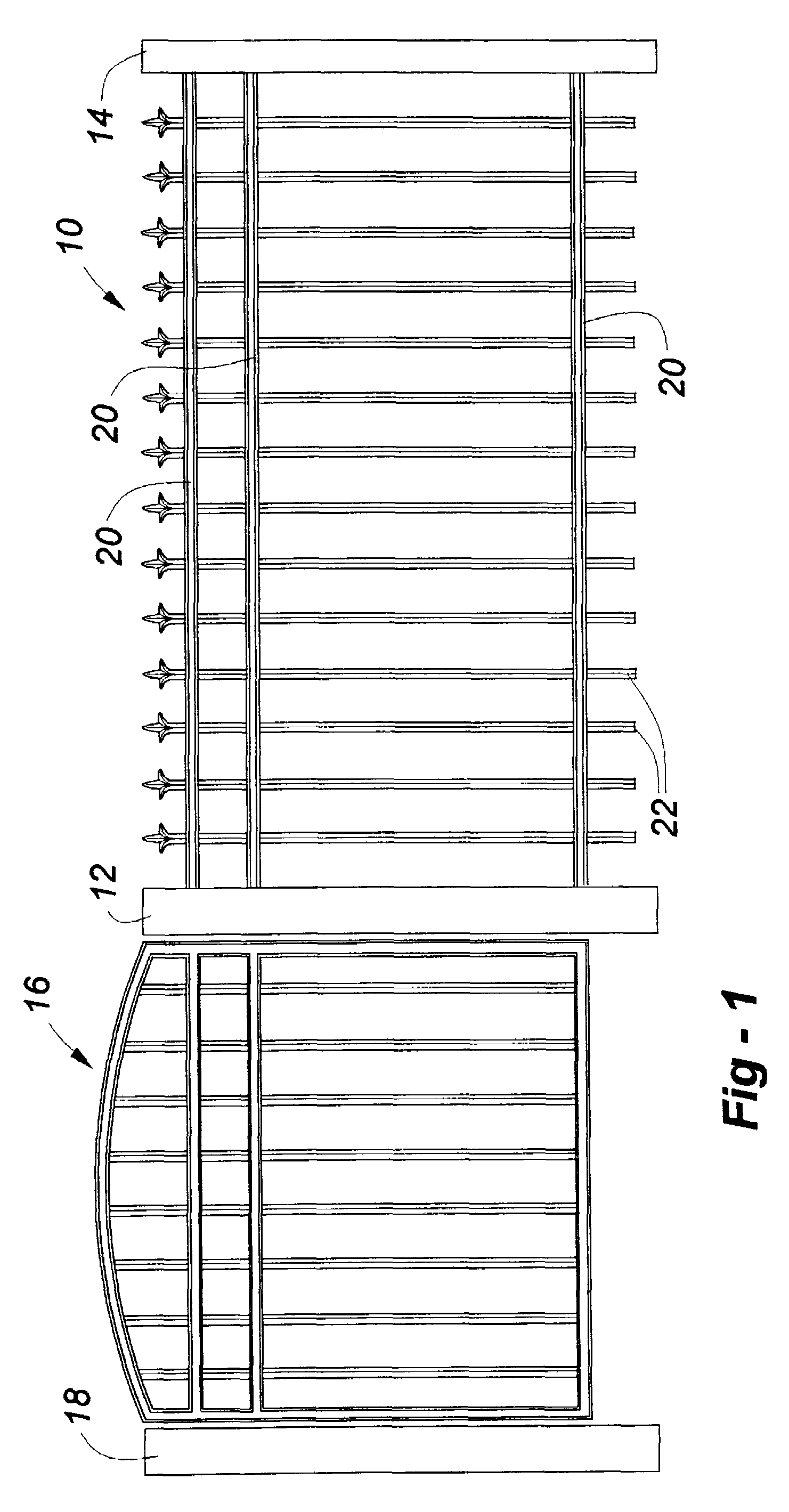

Plastic fencing simulative of wrought iron

Owner:DECKORATORS

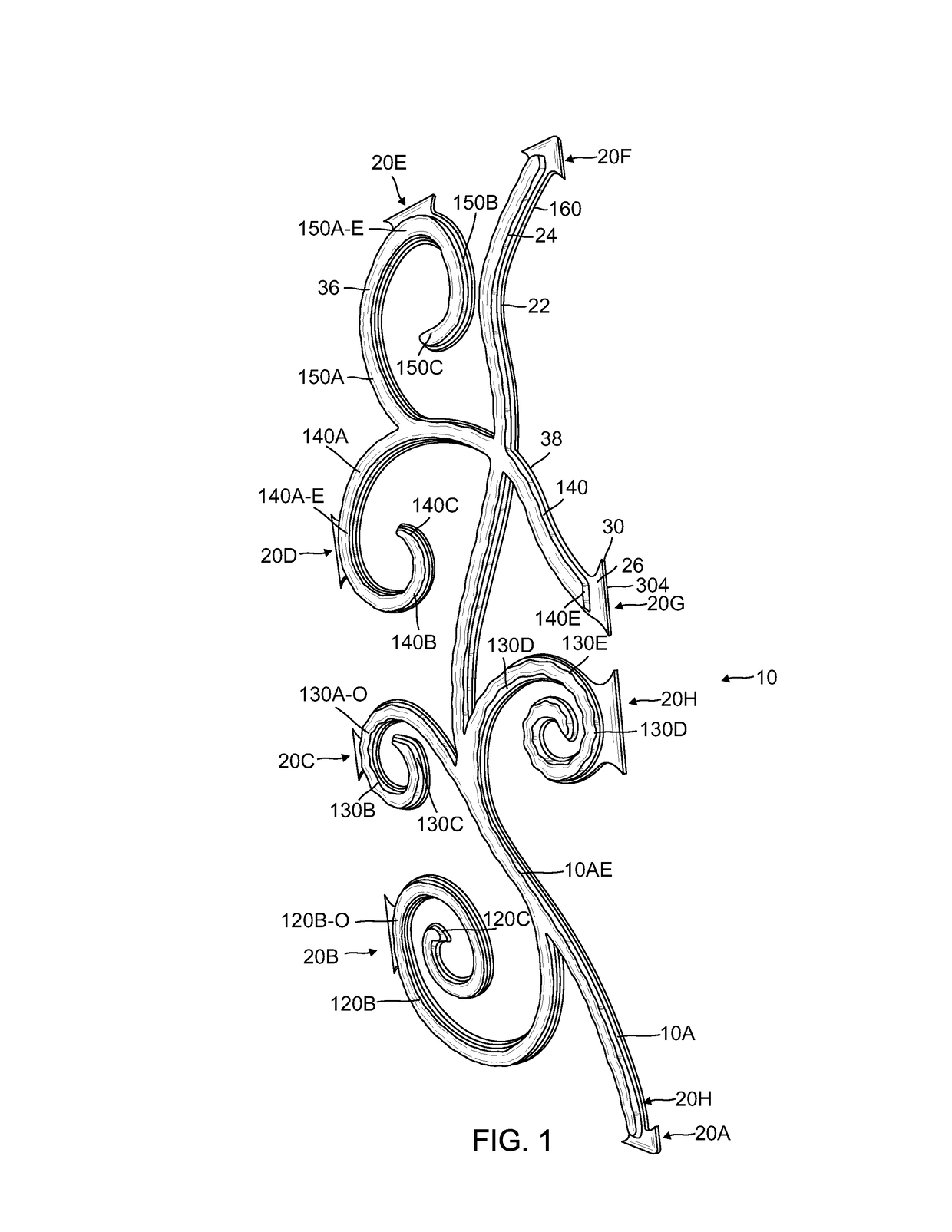

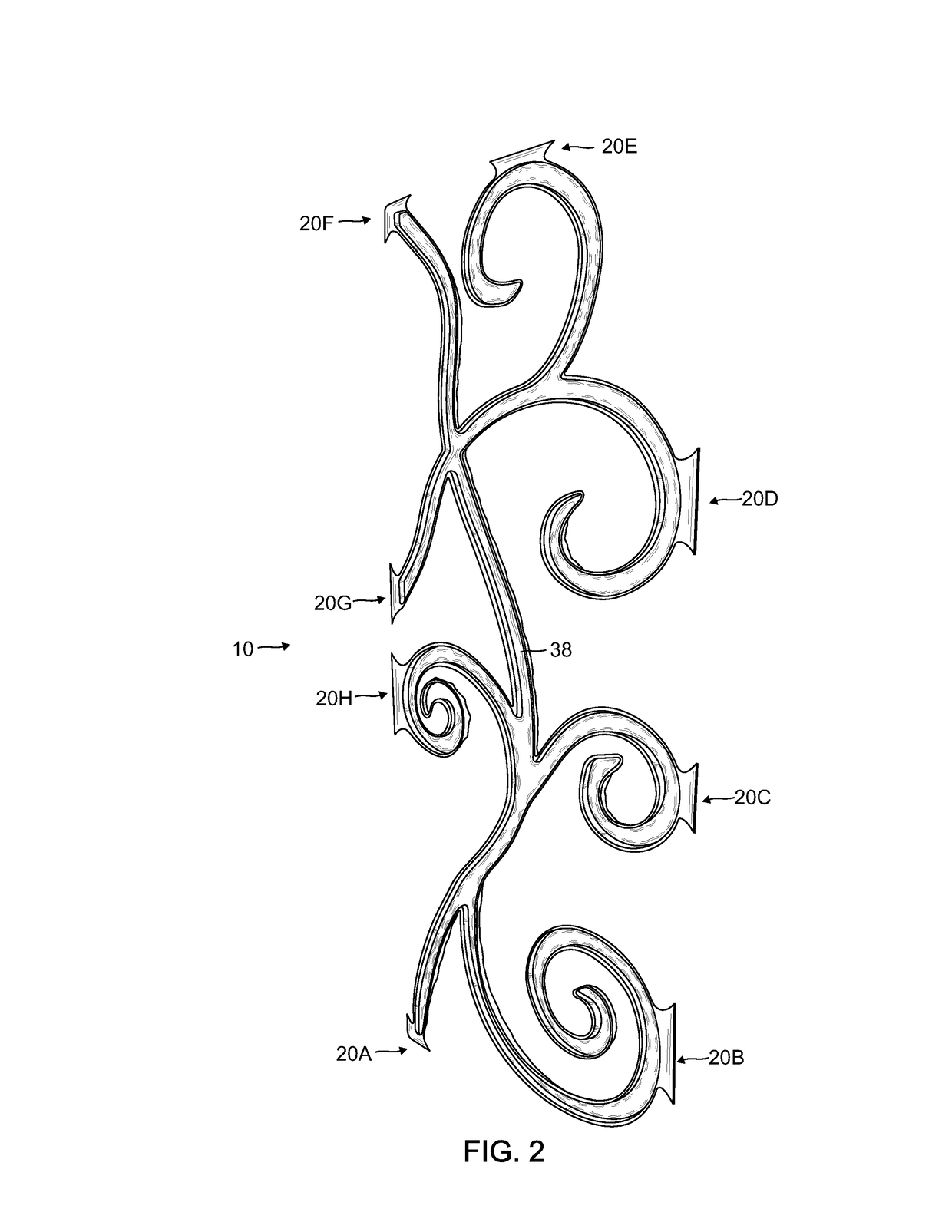

Method for manufacturing wrought iron picture

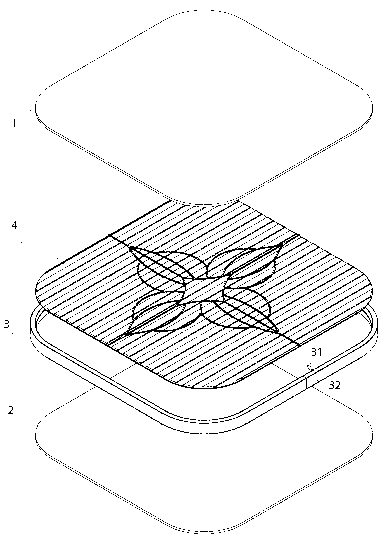

InactiveCN101791927AStrong three-dimensional senseEasy to storeSpecial ornamental structuresSpecial artistic techniquesPattern weldingMetallic materials

The invention relates to a method for manufacturing a wrought iron picture which has the characteristics of readily available materials, simple manufacturing process, understandability and easy learning, and strong three-dimensional sense, takes a metal as a raw material, and takes a manual tool as a main drawing tool. The method comprises the following steps: drawing, namely drawing a pattern ofthe wrought iron picture to be manufactured on a piece of paper; tracing-off, namely magnifying the pattern and copying the pattern on a metal material by using a piece of carbon paper; cutting, namely cutting an iron material according to the pattern on the metal material; knocking, namely knocking the picture by using the manual tool according to the characteristic of the pattern to be created so that the surface of a metal sheet has the three-dimensional sense; folding, namely folding the edges of the picture by using vises so as to flatten hems and realize the three-dimension sense; finely jointing, namely performing finish machining on fine parts of the folded metal picture draft by using a tool; welding, namely welding the patterns of each part of the metal picture draft into an overall pattern; baking vanish, namely baking the vanish and spraying the vanish on the front surface and the back surface of metal picture; assembling, namely drilling holes on an aluminum plastic boardin a picture frame, and fixing the metal picture by using metal wires; and mounting, namely covering the back surface of the picture frame by using a multilayer board or fixing the back surface of the picture frame with the multilayer board.

Owner:杭州余杭区柏海铁艺工作室

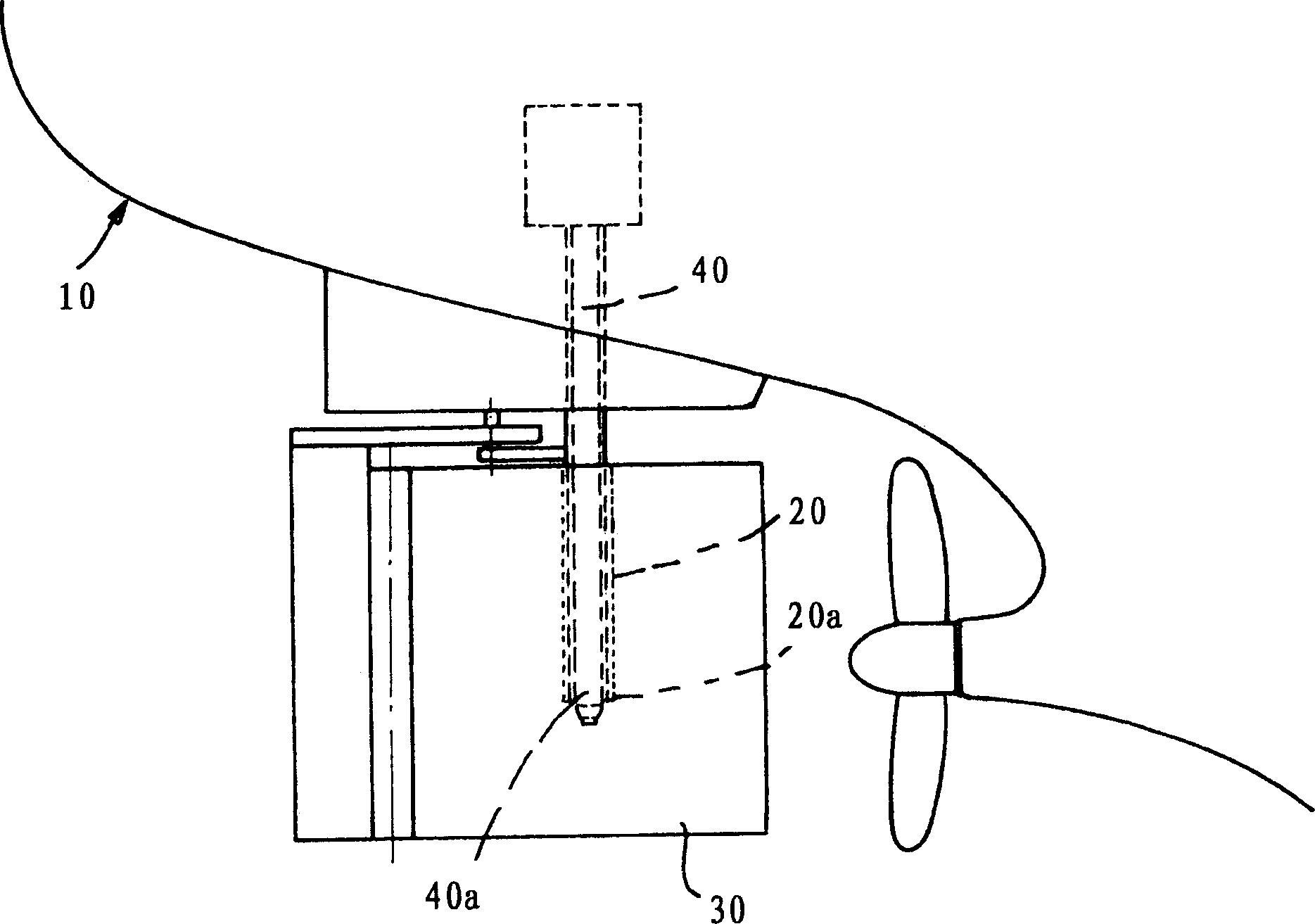

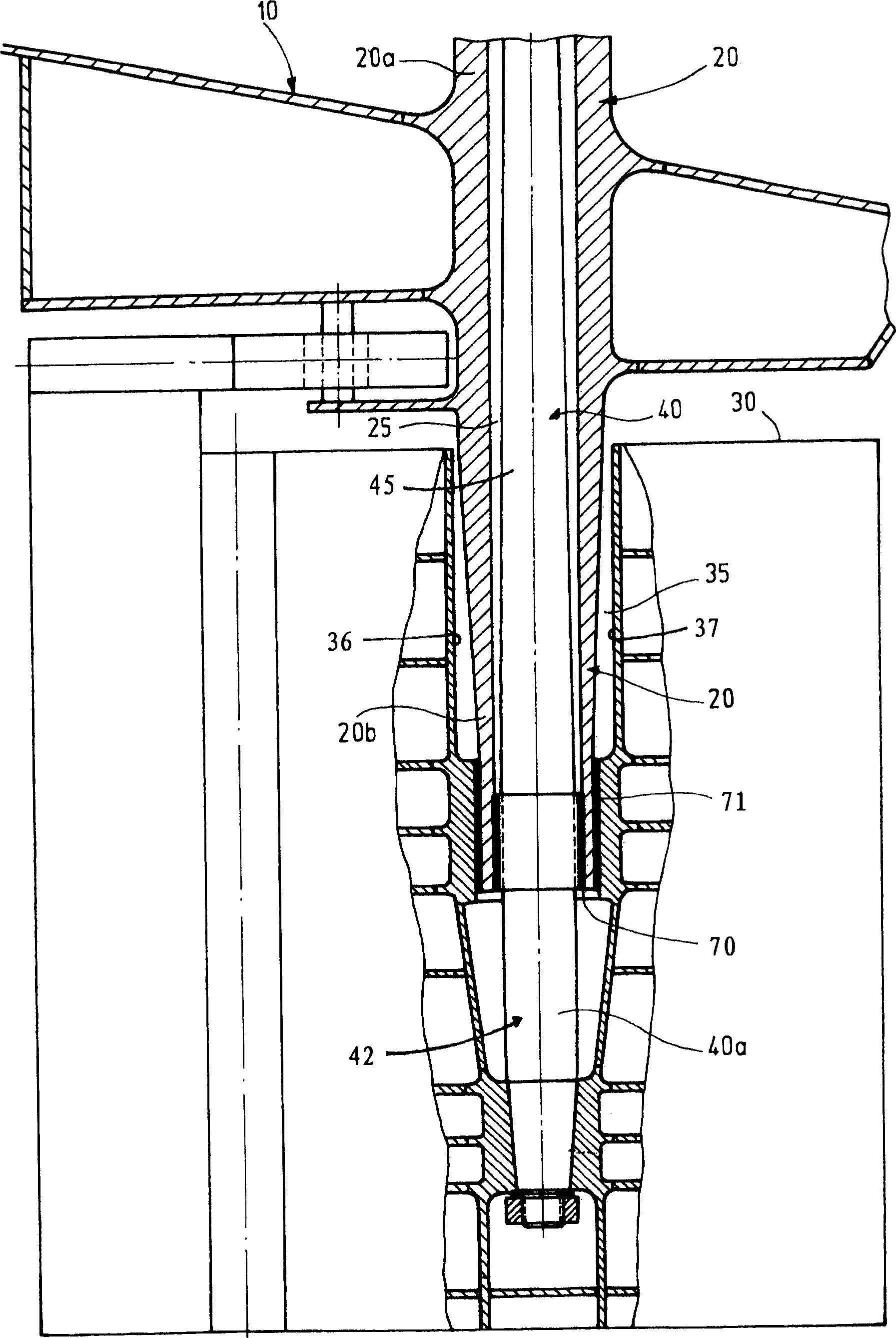

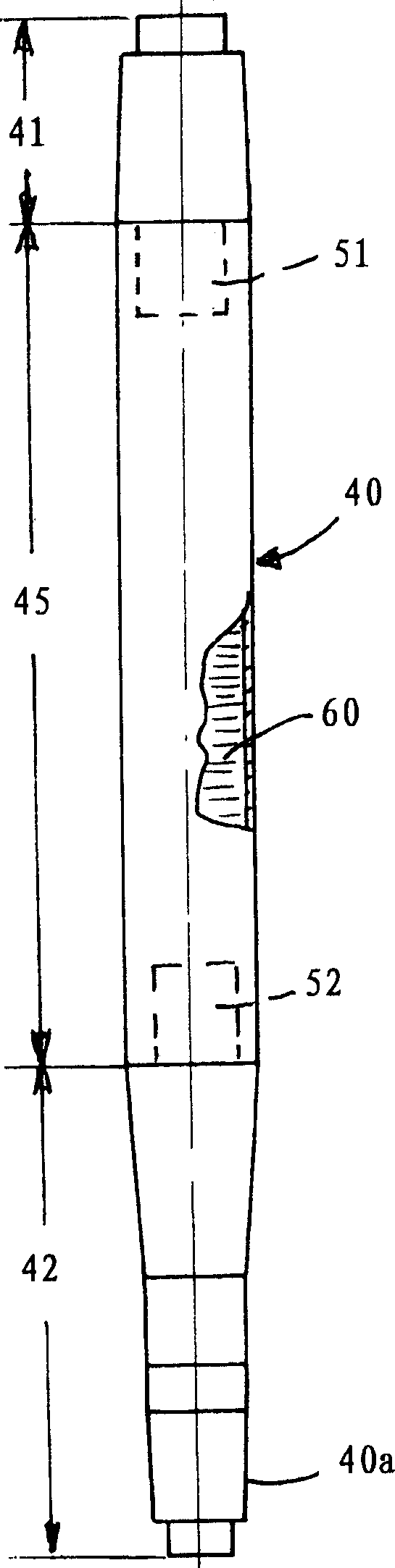

Rudder post for rudders for water vehicles

InactiveCN1891571AIncrease the lengthLarge diameterSteering ruddersShaftsMetallic materialsEngineering

The stock has end sections (41, 42) made of a wrought iron, and a middle stock section (45) connected with the end sections. The middle stock section is made of a carbon fibrous composite or graphite fibers, which form the section (45) in the form of windings. The windings extend into the opposite ends of the end section of the stock and are firmly connected with the end section. -

Owner:BECKER MARINE SYST

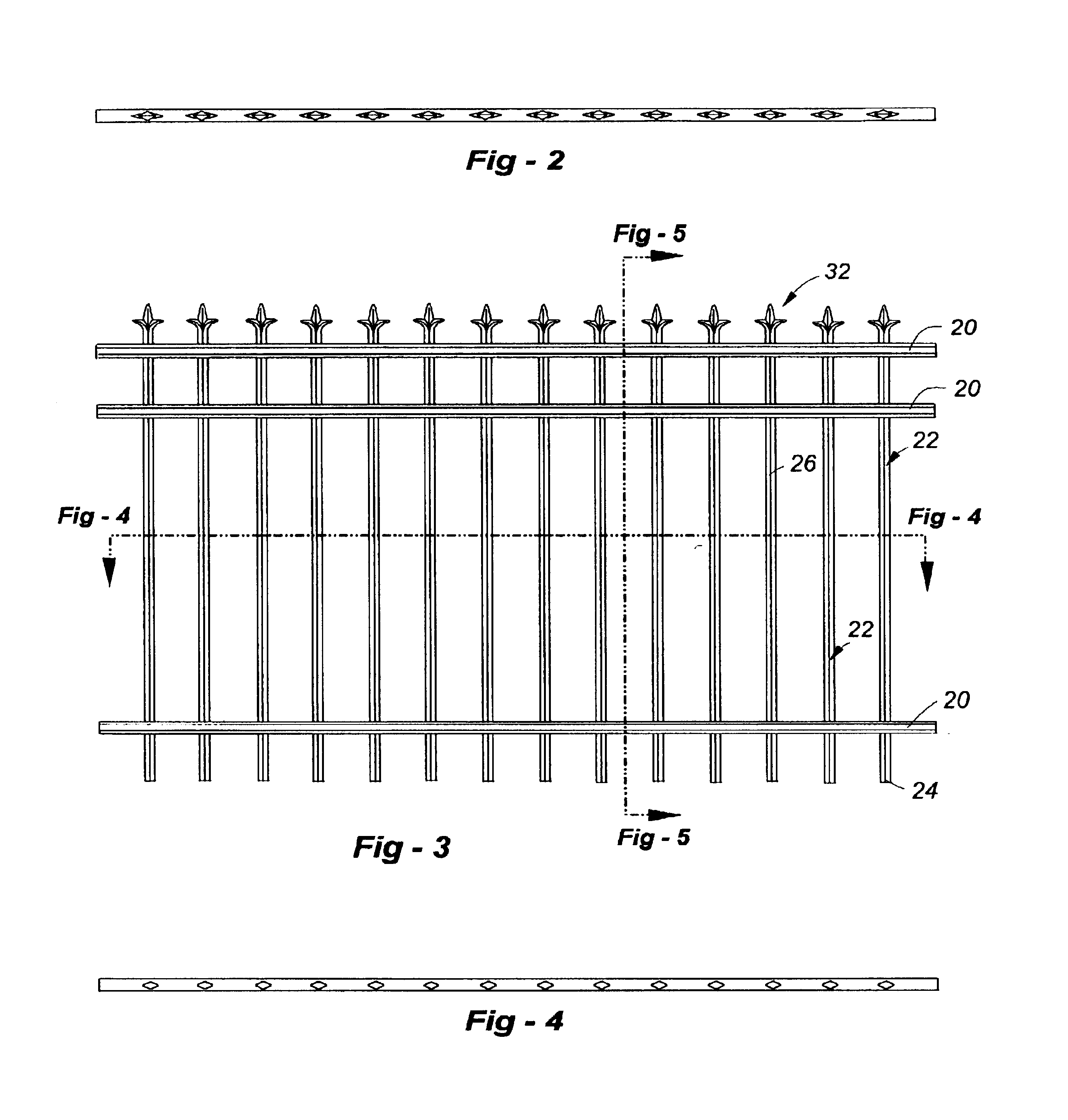

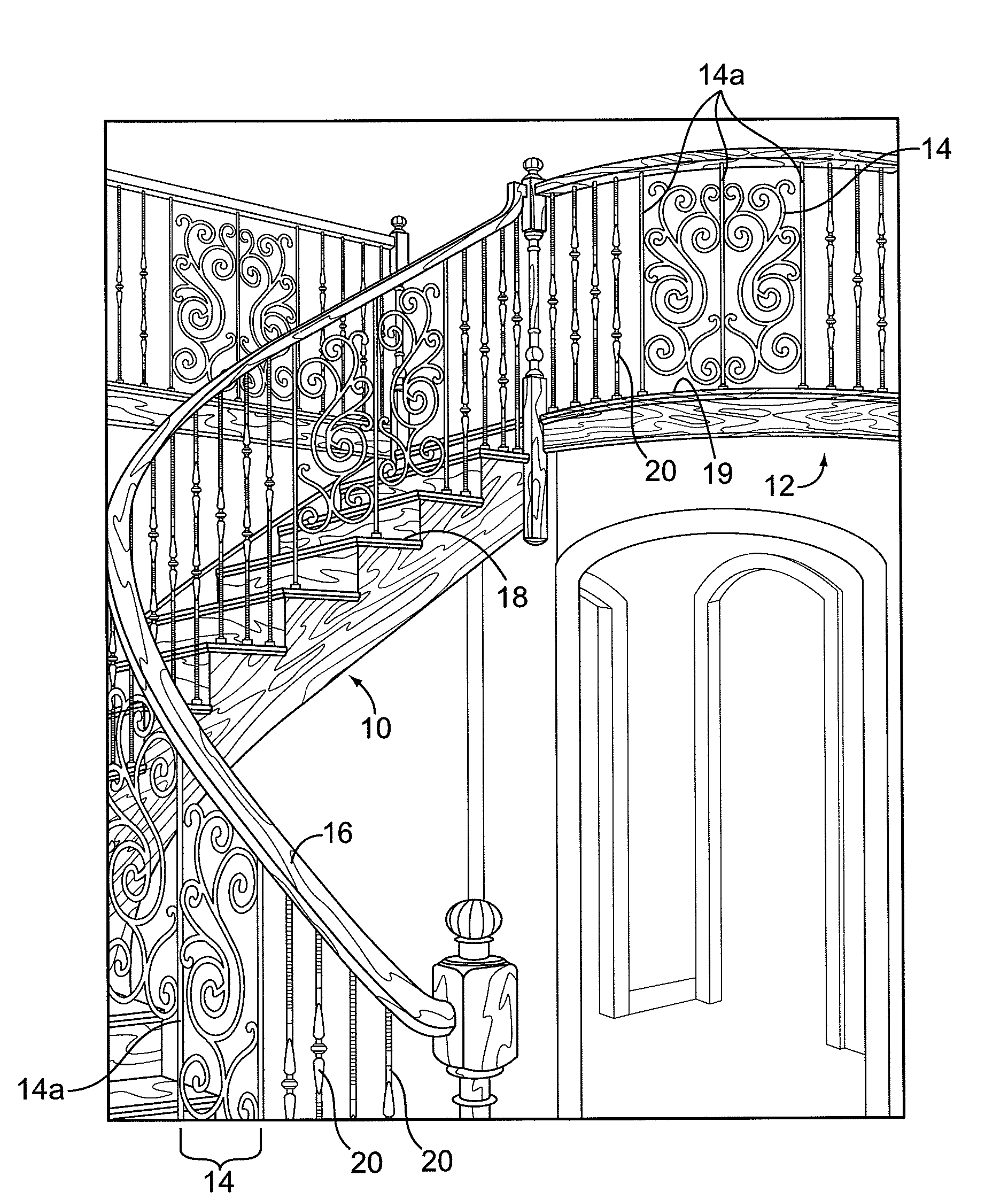

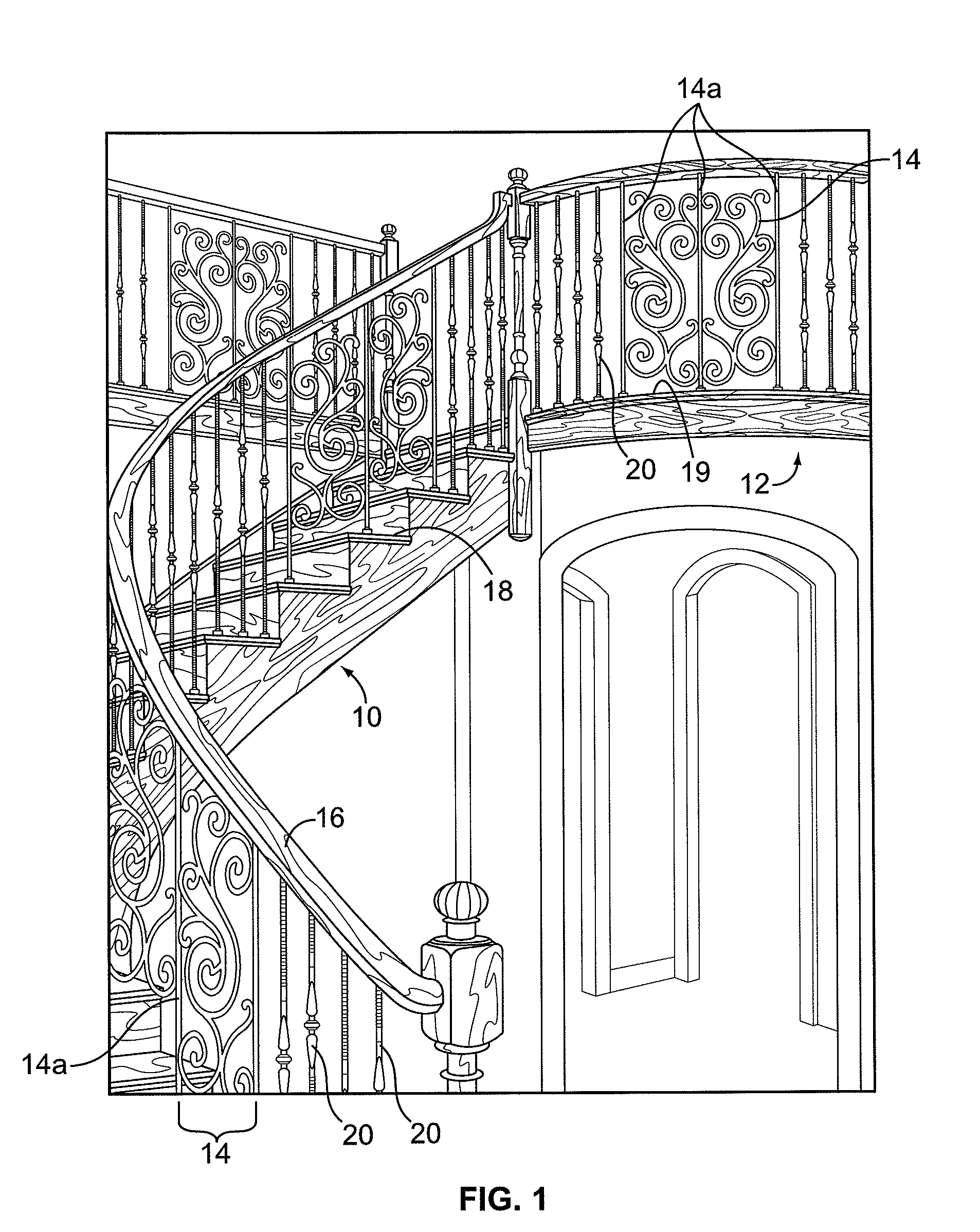

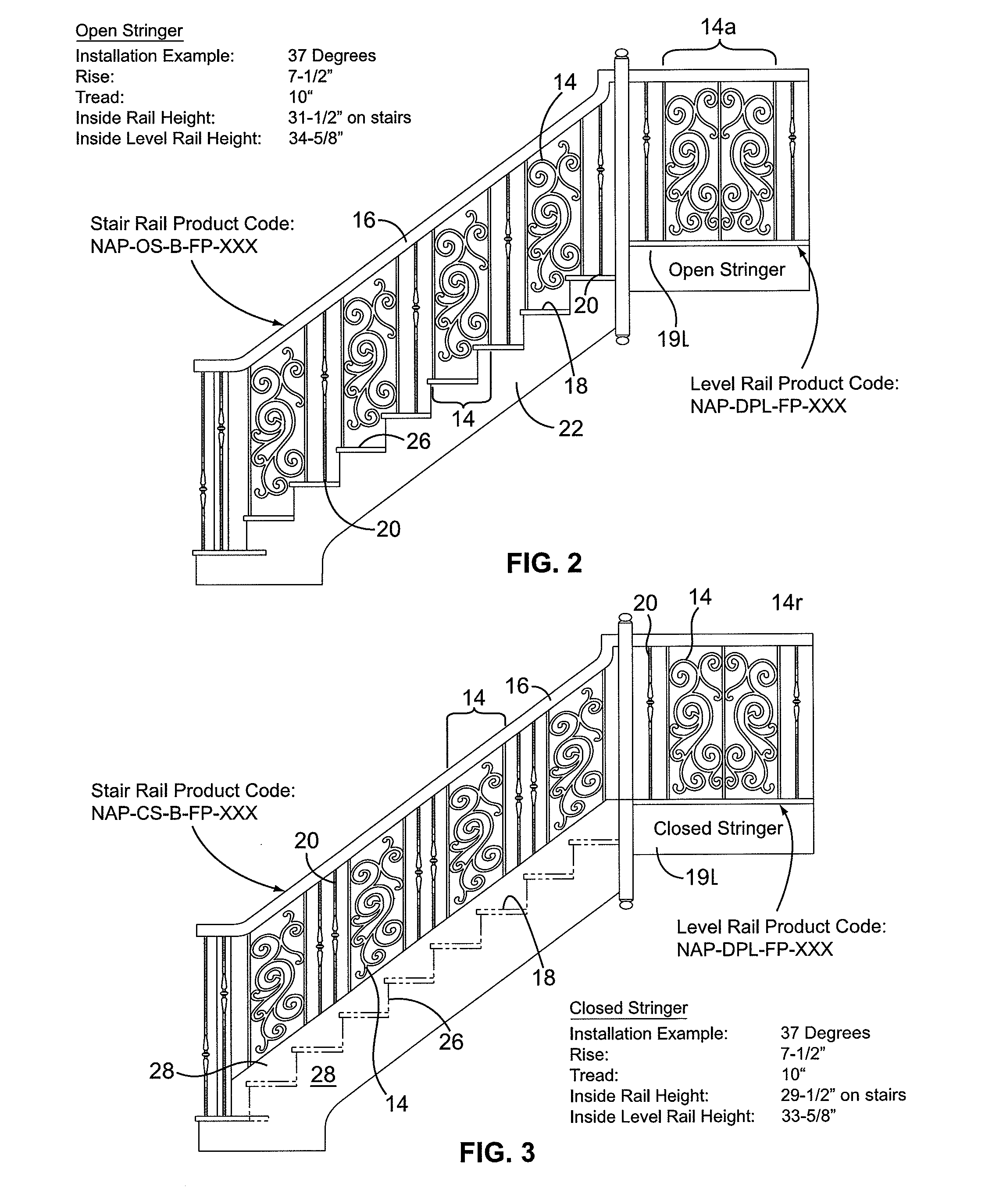

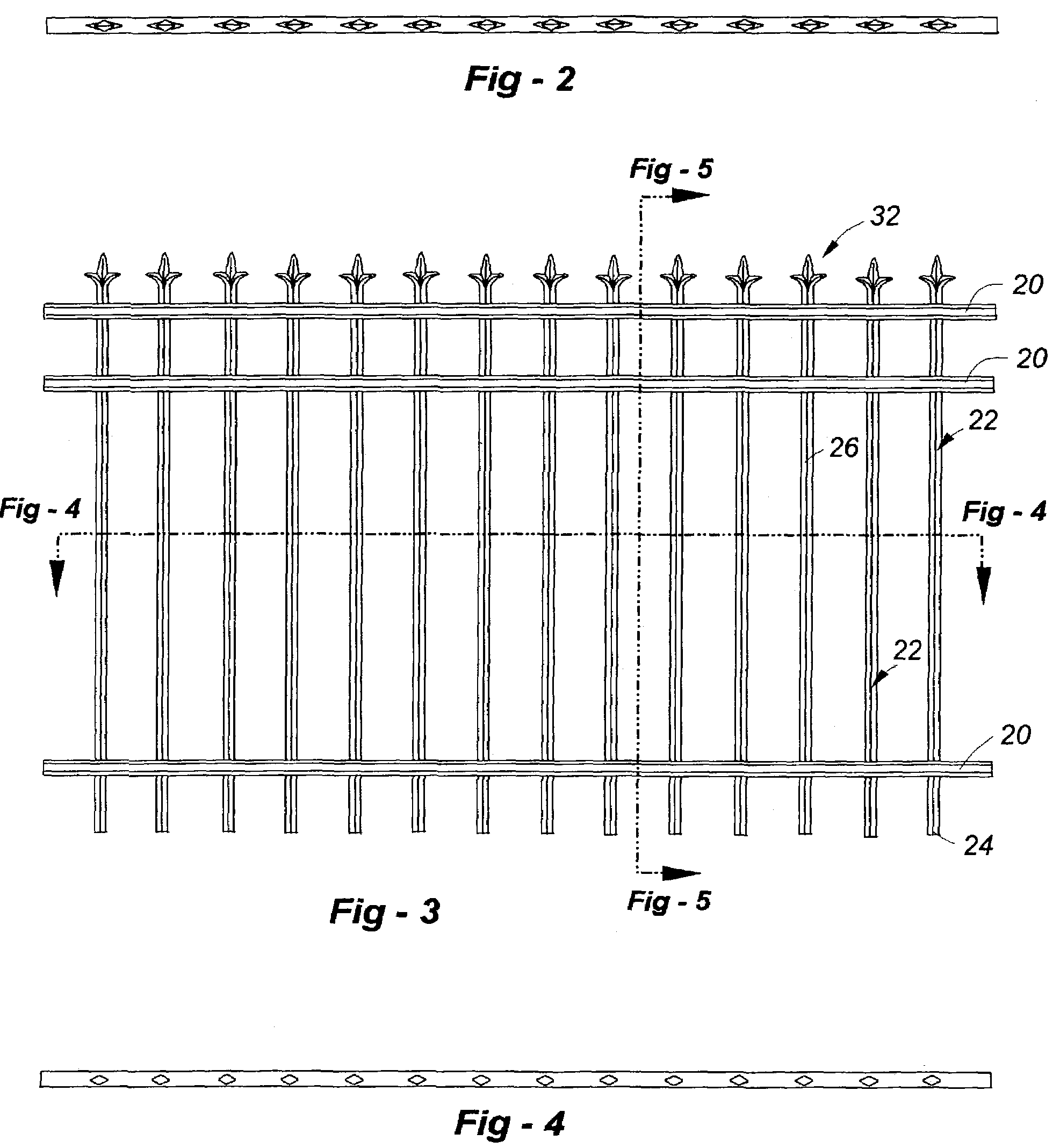

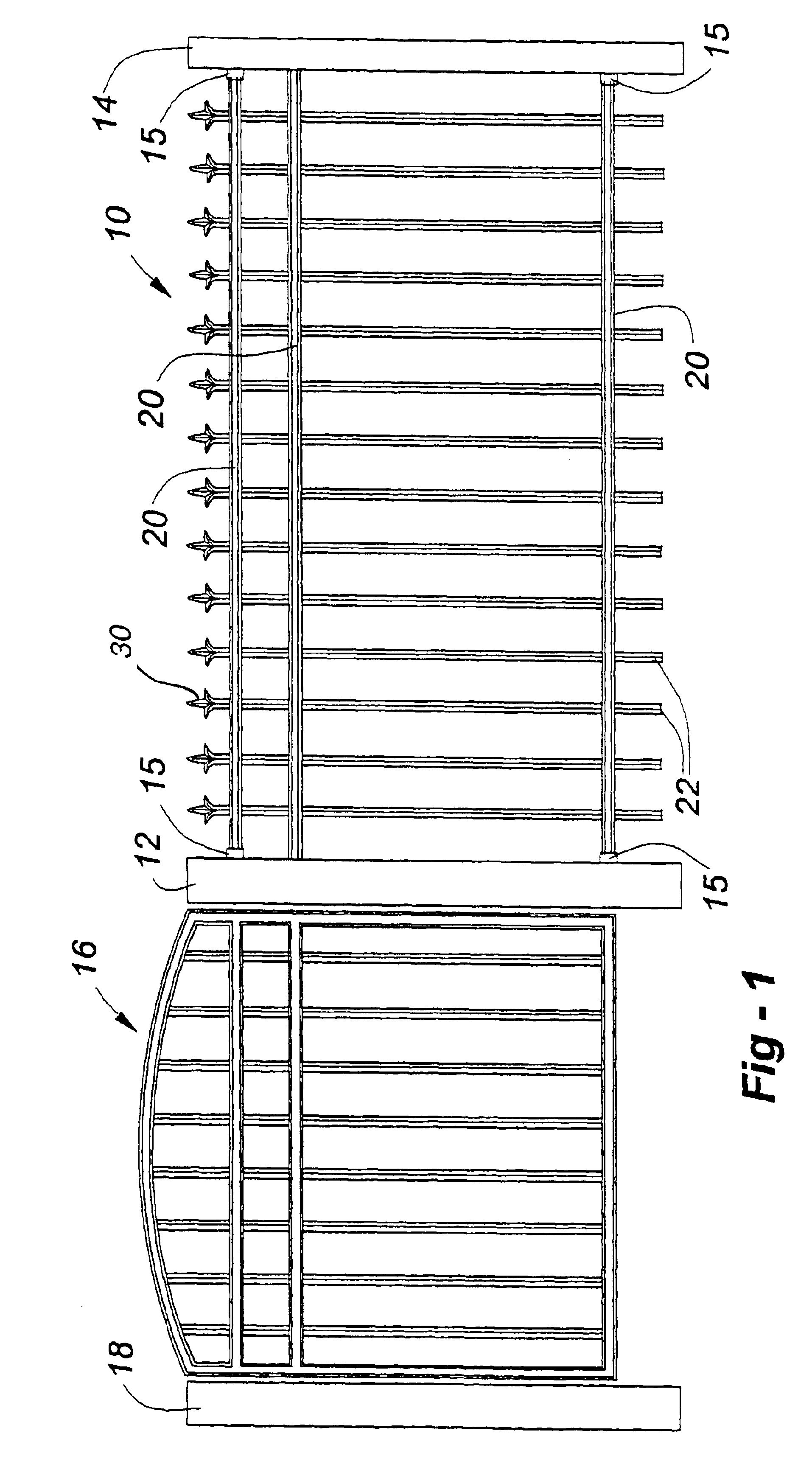

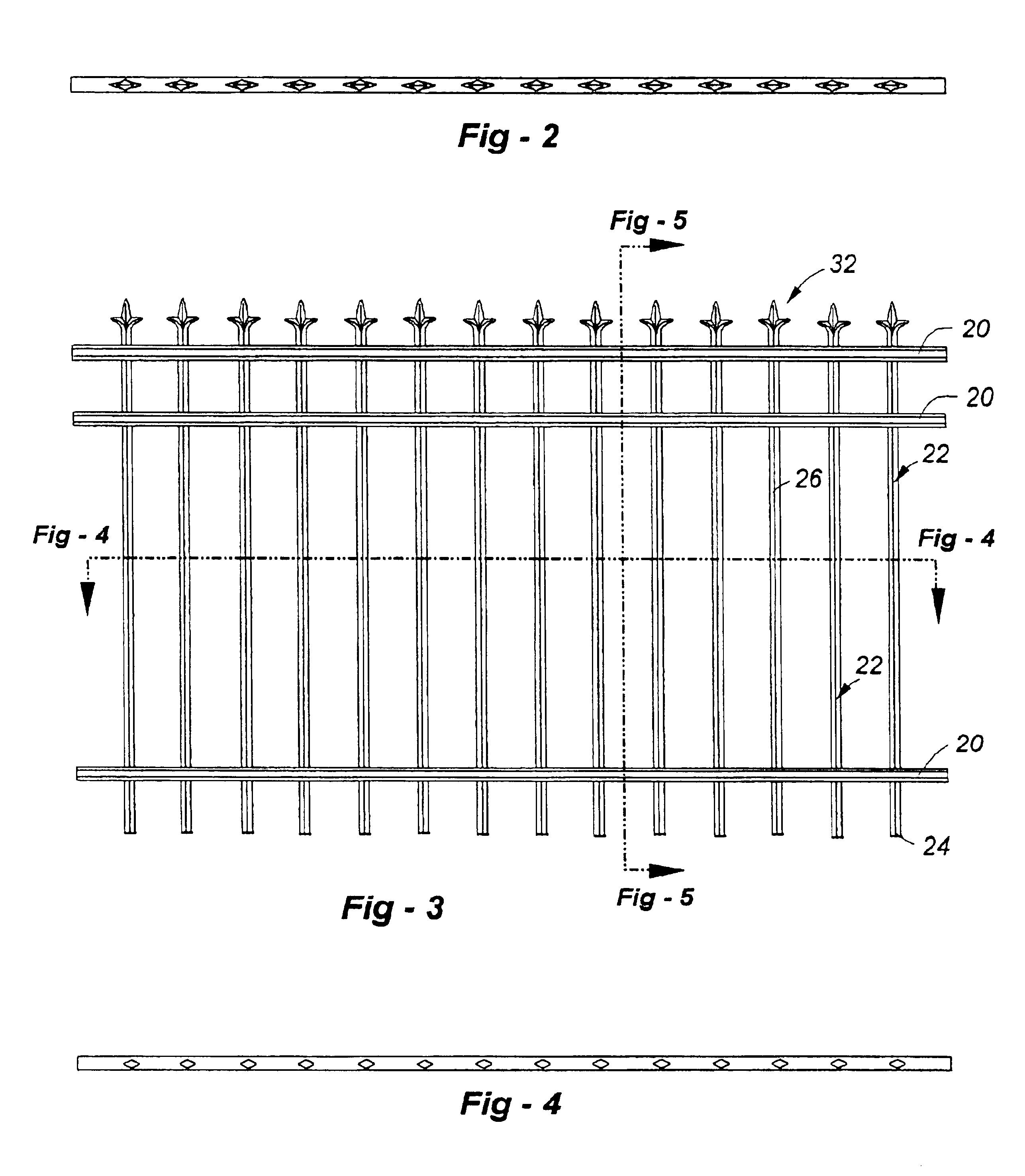

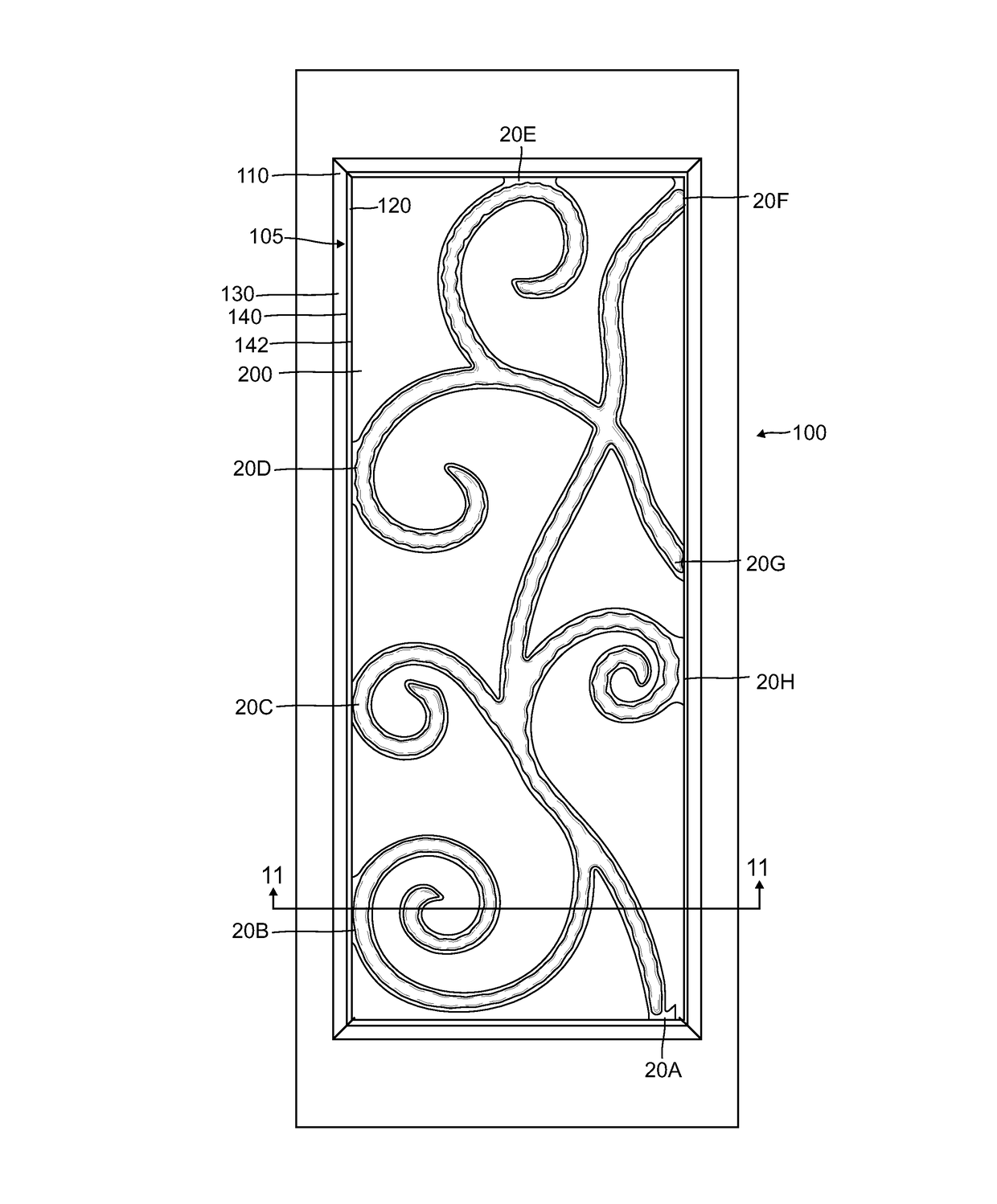

Panels for use in staircases, gates, fences and balconies and the method of making panels therefore

A method of making a barrier portion of ornamental staircases, balconies and fences is disclosed including the use of a cutting device to create a design panel from a sheet of material. The panels are cut from materials including steel, bronze, aluminum and other metals, alloys, plastics and wood by using cutting devices such as high energy lasers, water jets and routers guided by computer. The panels are cut to emulate wrought iron panels used in prior art staircase and balcony decorative elements without the problems of requiring a skilled installer to forge the elements and weld them together and then install the elements. The panels are pre-finished in factory and are easily assembled; useable in staircases having open and closed stringers such that they can be installed by the homeowner, meet required codes and have long lasting rust free characteristics at a low cost.

Owner:IANNOTTA ANTONIO

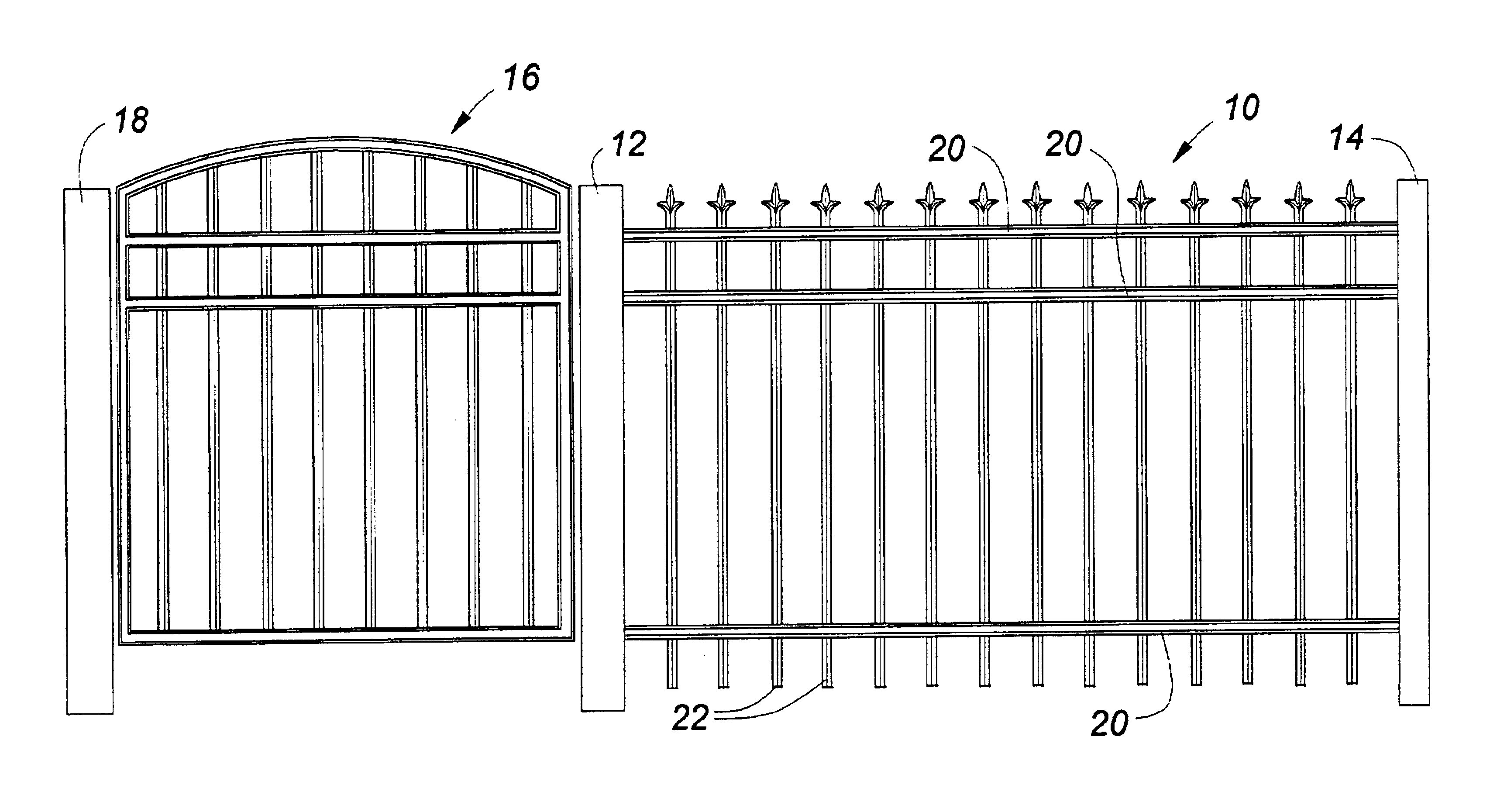

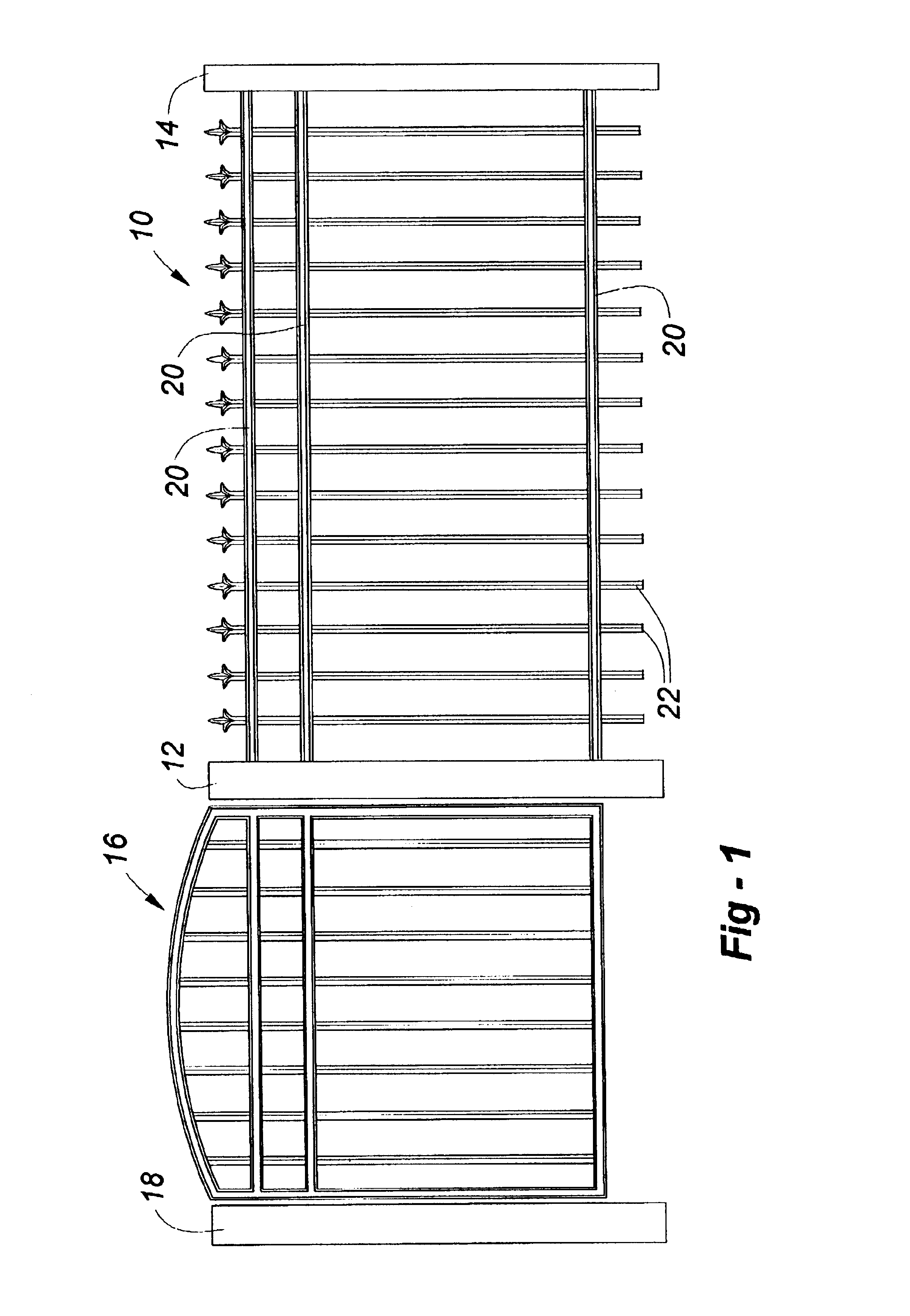

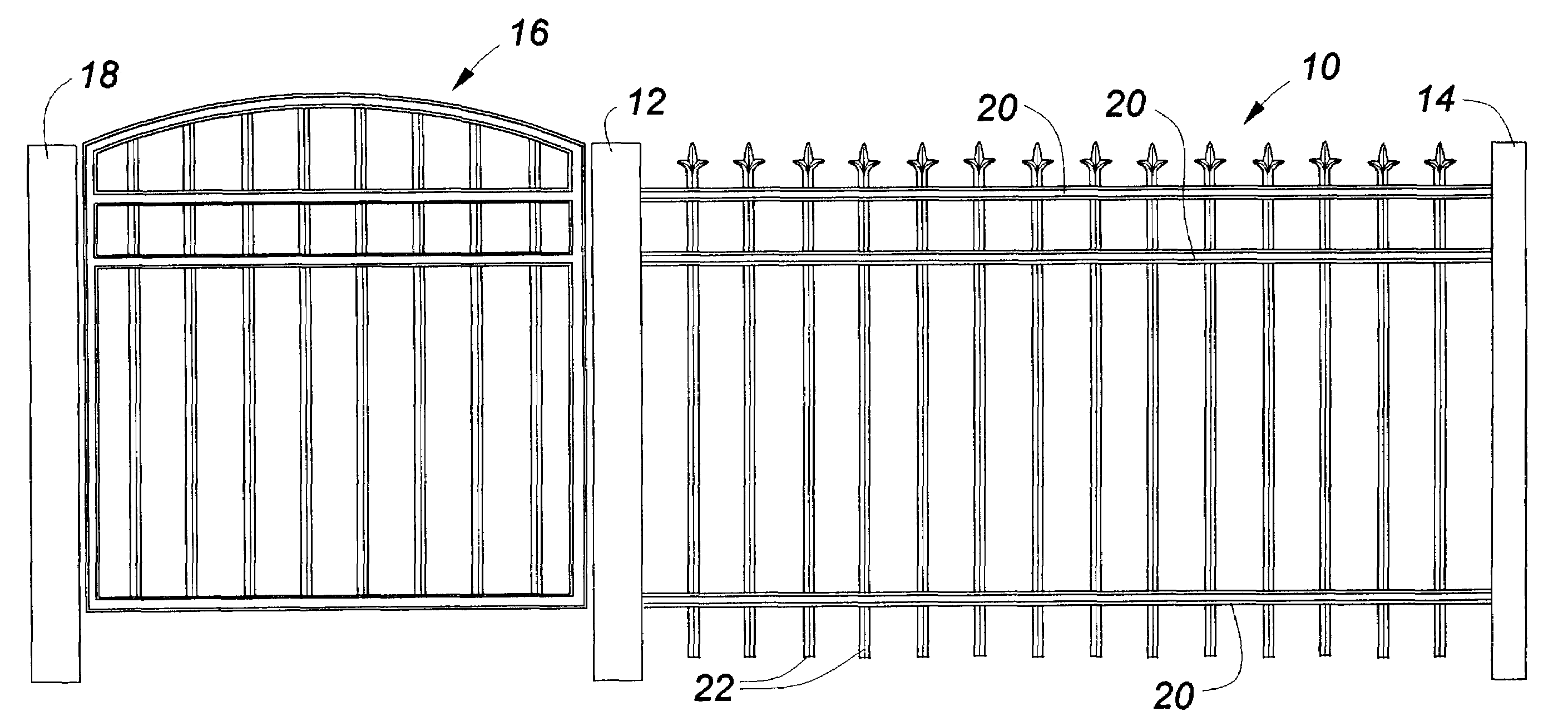

Plastic fencing simulative of wrought iron

An injection molded plastic fence panel that includes an upper horizontal rail and a lower horizontal rail. The panel also includes multiple spaced-apart vertical members extending between and interconnecting the upper and lower horizontal rails. The vertical members each have a diamond-shaped cross-section with a front-to-back depth and a side-to-side width. The depth of the vertical members is less than the width of the vertical members.

Owner:UNIVERSAL CONSUMER PROD

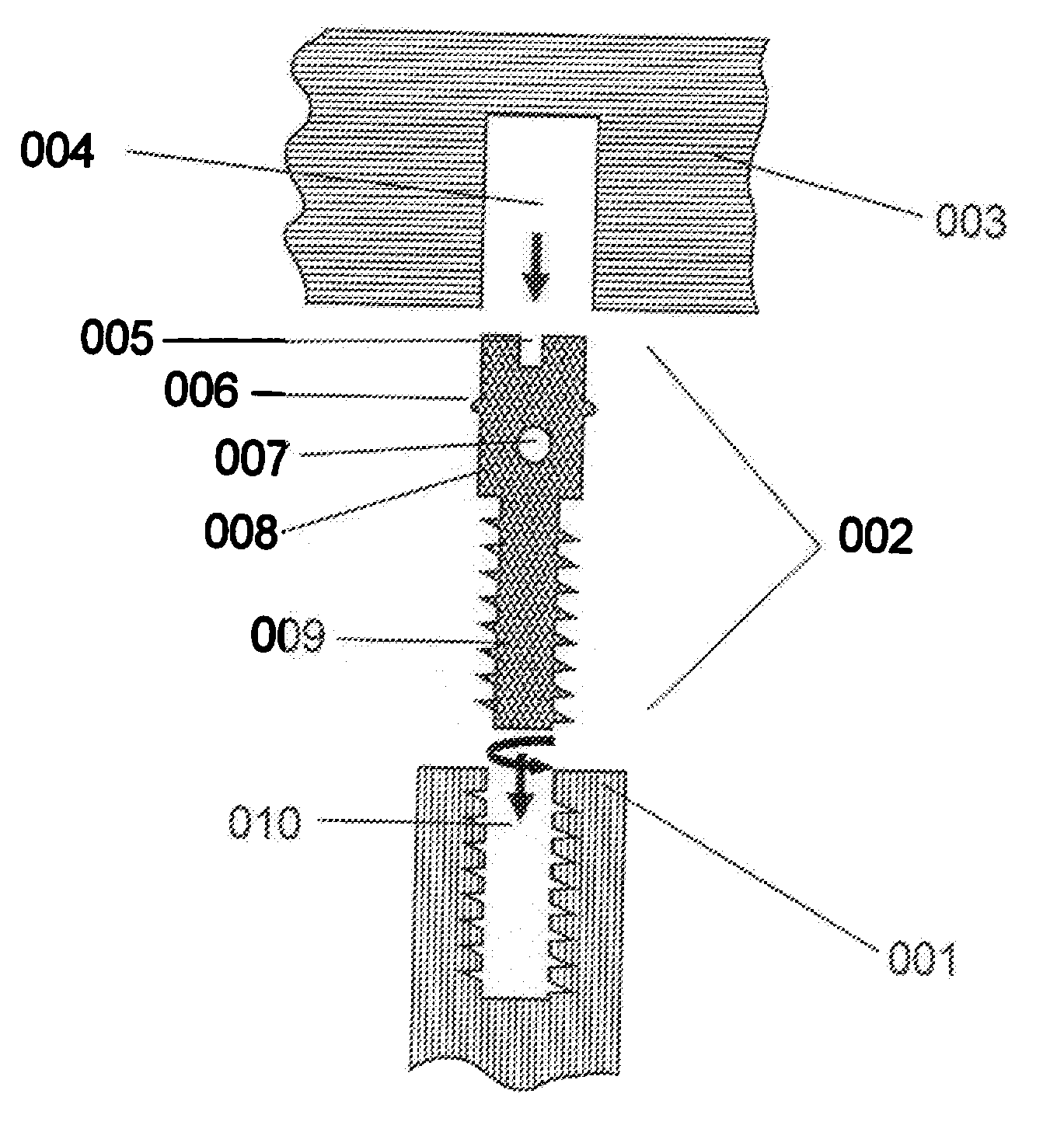

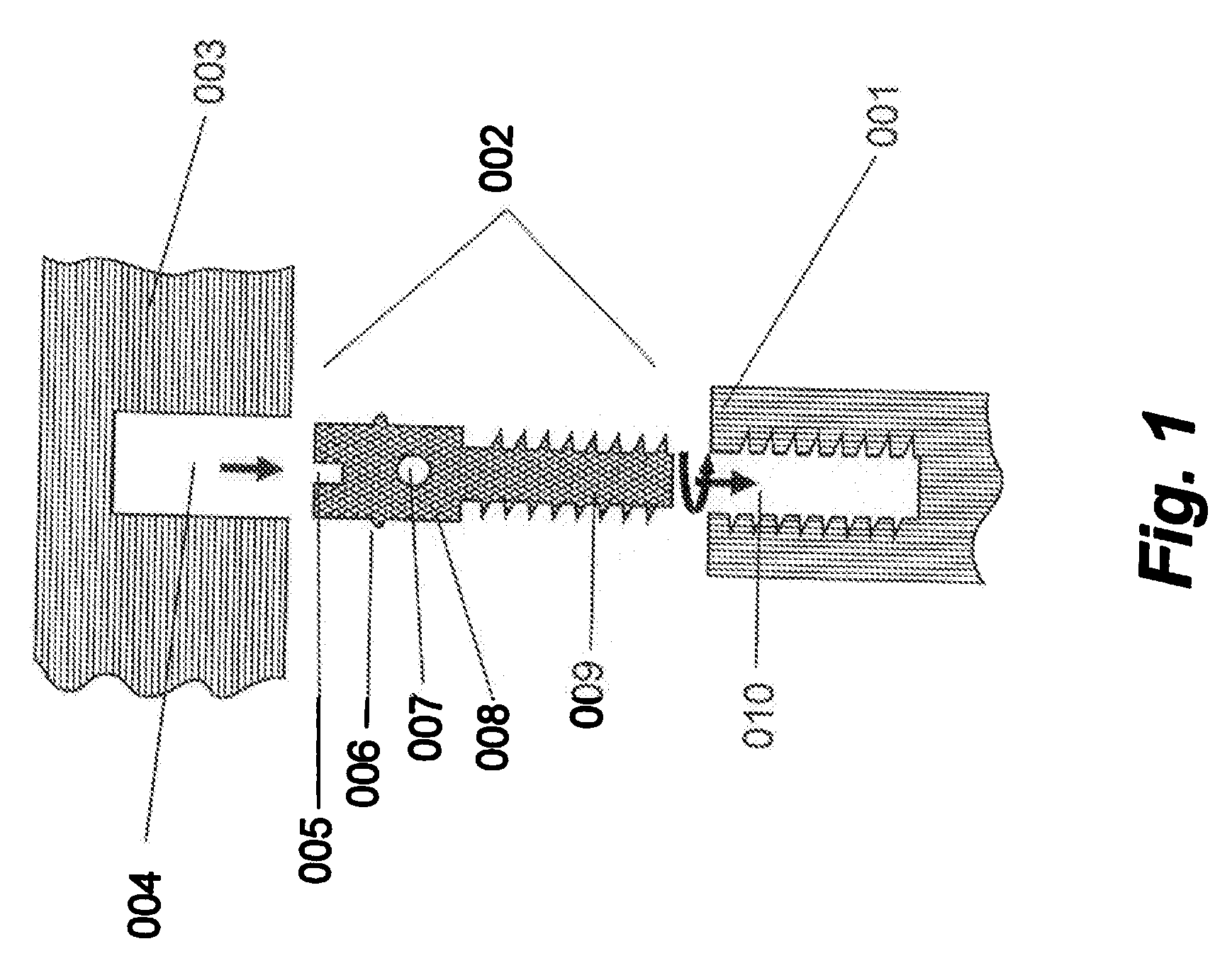

Picket assembly

The present invention provides embodiments of wrought iron picket assemblies having fasteners for mounting wooden hand rails for use in constructing railings, said fasteners also serving a fixing function during surface treatment of a picket.

Owner:GOODE GARVIN +1

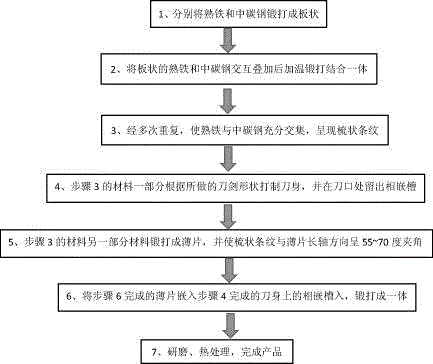

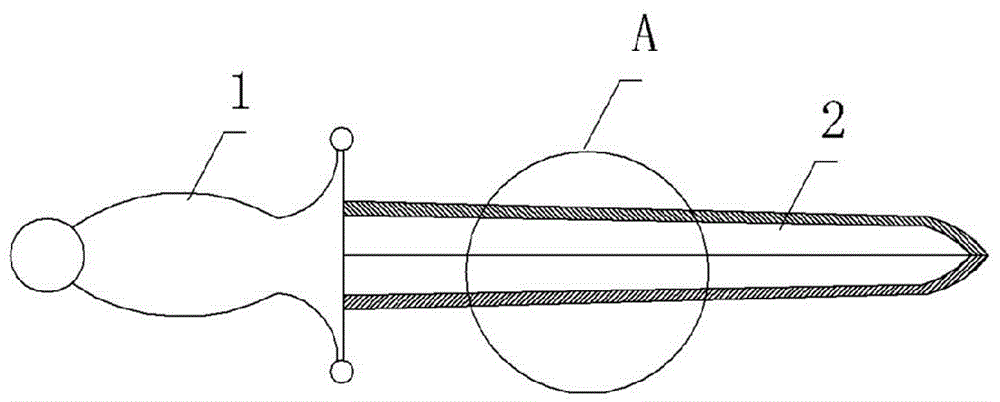

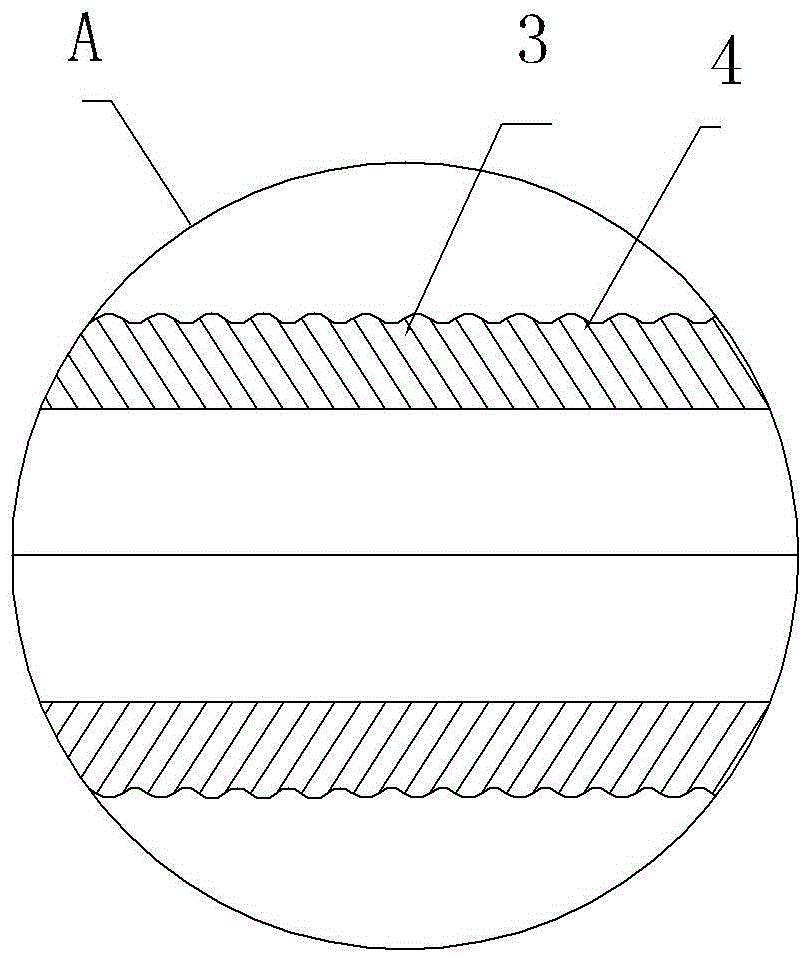

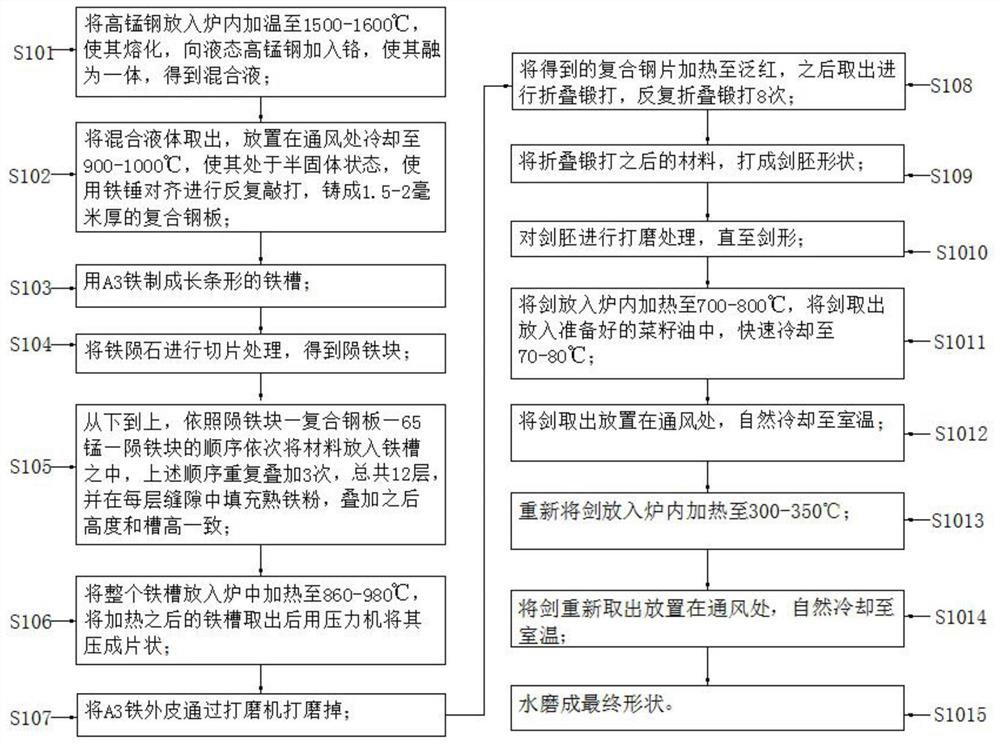

Knife manufacturing method

The invention discloses a knife manufacturing method. The knife manufacturing method comprises the manufacturing process of forming of a rough blank of a knife, and grooves are reserved in the knife edge of the knife. The knife manufacturing method is characterized by comprising the steps that parallel inlaying and folded forging are conducted on ordinary wrought iron and a medium carbon steel bar according to the ratio of 1:1, so that a mixture with the internal structure being in a railing shape is formed; then the mixture is forged into a sheet, and strips are formed in the sheet, wherein the included angles between the strips and the long axis direction of the sheet are 55-70 degrees; and the sheet with the oblique strips is inlaid in the grooves in a knife body, heat treatment and grinding are conducted on the knife body after the sheet with the strips and the knife body are completely melted into a whole, and thus manufacturing of the knife is completed. According to the knife manufacturing method, alternate forging of steel and iron is conducted on the knife edge of the knife, and hidden sawtooth-shaped structures are formed during grinding by means of the hardness difference between steel and iron, so that a pressure sectioning process and a sawing process are achieved at the same time when the knife is used for cutting an object, and accordingly the knife edge of the knife is made extremely sharp.

Owner:季长强

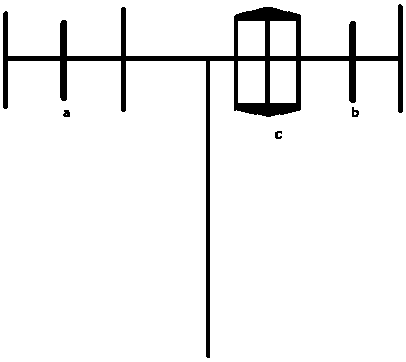

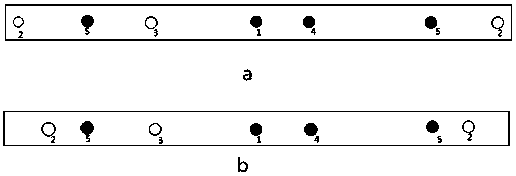

Row marker used for various fields, guaranteeing straight movement, and having convenience in fertilization and carriage

The invention provides a row marker used for various fields, guaranteeing straight movement, and having convenience in fertilization and carriage, belongs to the technical field of row markers for marking positions of rows for paving a mulching film before cultivation on fields. The invention solves the following technical problems: in the prior art, a track drawn by a row marker is liable to bend, and the row marker is inconvenience and unscientific when being used for adjusting distances between rows, and cannot help fertilization and is inconvenient to carry. According to the technical scheme, positions of square tubes are controlled through different designs of round holes in two surfaces of a horizontal square tube, so that the row marker can fit row marking in two specifications. A triangle iron and a hexagonal wrought iron plate in the middle part of a mulching film can mark shallow rows and deep rows, which are beneficial to fertilization. Distance between wheels, which have flat and wide rims, and the horizontal square tube is increased under connection of an octa-hole square tube and a wrought iron plate and is regulated by the octa-hole square tube. The wheels are contacted with ground so as to guarantee straight movement of the row marker, and the row marker is convenient to push and carry; rubber sleeves with grooves are arranged at a handle top end and a position at 60-70 cm down from the top end of a long tube, so that the row marker is convenient to hold. The end portion of the long tube is rectangular in shape. A middle drill hole is fixed on the horizontal square tube. A red outer ring is additionally arranged on the head of a bolt.

Owner:秦明杰

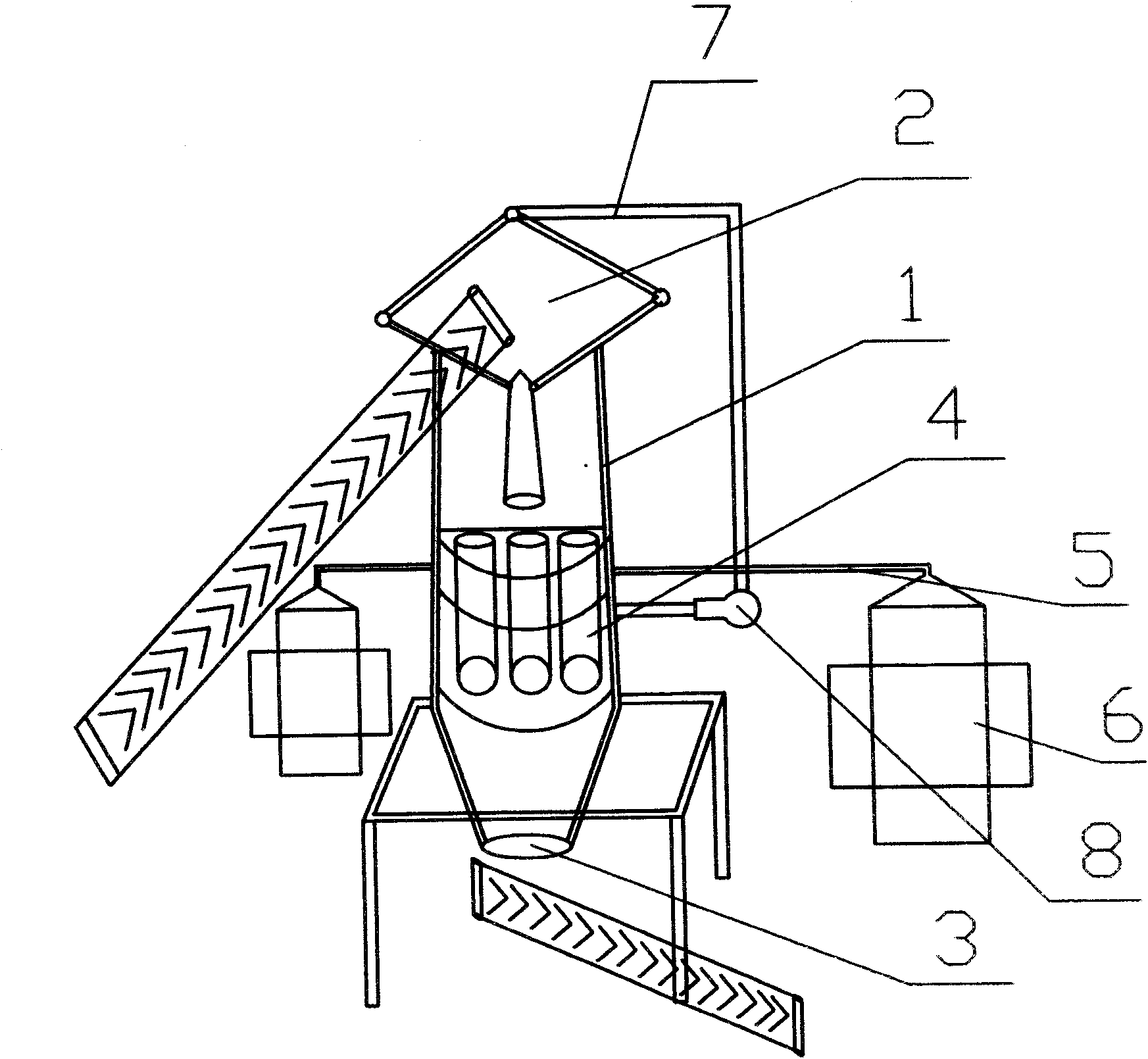

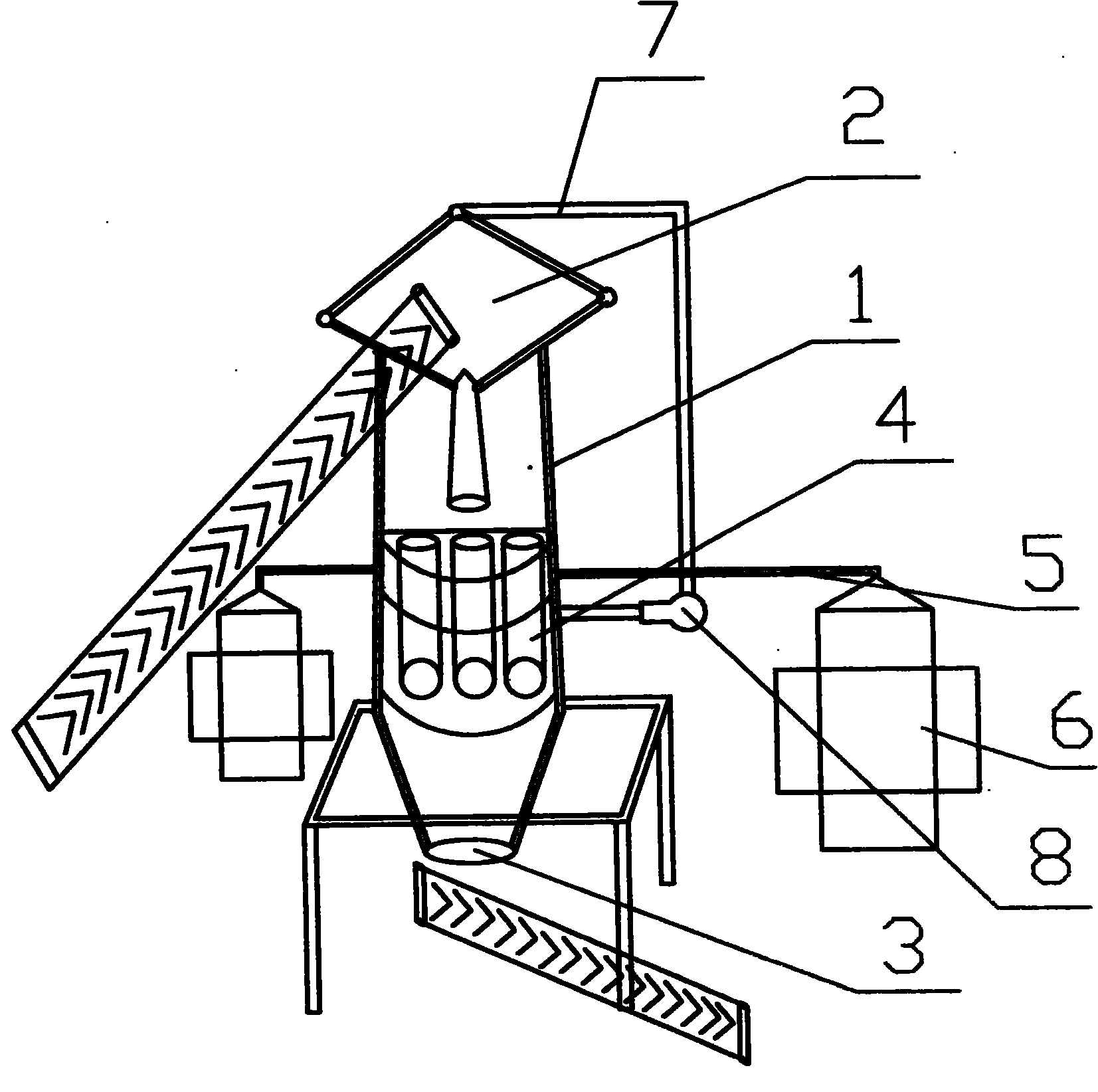

Method and device using coal to directly reduce iron

The invention discloses a method and a device using coal to directly reduce iron. The method comprises the following steps: mixing iron-making materials, chemical alloy materials and high-strength binder by the weight ratio of 100:(0.5-1):(6-8); kneading and stirring; then, pressing the materials into pelletized bodies by a double-roller ball-pressing machine; directly calcining the pelletized bodies at 1,200 to 1,250 DEG C by using coal-based gas by a vertical tube furnace; and dry-distilling and reducing into crystalline iron in the absence of oxygen; and crushing and separating to obtain wrought iron materials. The device of the invention comprises a furnace body, wherein a feeding hole constitutes the top end of the furnace body, and a discharging hole constitutes the bottom end of the furnace body; a plurality of standby combustion tubes are arranged in the furnace body; gas inlet pipes are respectively connected to two lateral surfaces of the furnace body; gas outlet pipes are connected with a gas generator; and a circulating air pipe equipped with an air blower is arranged on the furnace. The weight percentage of iron in the produced product reaches 90% to 94%; and the cylindrical iron pressed by a high-strength pressure forming machine is a high-grade steel-making material having low contents of sulfur, phosphorus and silicon.

Owner:姜文平

Environmental-friendly counterweight block for reuse of recycled materials

The invention discloses an environmental-friendly counterweight block for reuse of recycled materials. The environmental-friendly counterweight block comprises, by weight, 25-45% of steel slag, 1-4% of particle steel, 0.5-3.5% of cast iron scrap, 2-7% of raw iron filings, 1-3% of wrought iron filings, 1.5-4% of slag, 0.3-1% of slag powder, 0.5-5% of sponge iron, 1-3% of iron concentrate powder, 1.5-3.5% of iron powder, 2-5% of waste color steel tiles, 5-9% of a sawing machine material, 4-8% of a punch material, 8-12% of pure steel scrap, 0.8-5% of a grinder material, 0.1-1.5% of iron mud, 3-6%of oiled steel scrap, 1-4% of a steel scrap crushing material and 0.5-3% of other matter. The environmental-friendly counterweight block for reuse of the recycled materials has the reasonable designand low production cost and can recycle waste materials generated in the steel processing process, the pollutant emission is reduced, and the energy-saving and environmental-friendly effects are achieved.

Owner:XUANCHENG VALIN PRECISION TECH

Manufacture method of efficient graphite fry pot

InactiveCN104739210AExtended service lifeHigh thermal conductivityCooking-vessel materialsCorrosionWrought iron

The invention relates to the manufacture and processing field of fry pots, in particular to a manufacture method of an efficient graphite fry pot. The manufacture method of the efficient graphite fry pot includes the step of preparing materials of 60-70 parts of graphite, 30-40 parts of aluminum oxide, 10-20 parts of wrought iron, 15 parts of glass wool and 10 parts of PVC (polyvinyl chloride) material. The manufacture method of the efficient graphite fry pot has the advantages of manufacturing the efficient graphite fry pot high in work efficiency, low in manufacture cost, and long in use life, using a mixing technique of the graphite, the aluminum oxide and the wrought iron to manufacture the efficient graphite fry pot having good high temperature oxidation resistance, corrosion resistance and electrical insulation performance, prolonging use life of the efficient graphite fry pot, improving heat conducting performance of the efficient graphite fry pot by adding the graphite, and obtaining the efficient graphite fry pot which can perform stir frying and fries delicious vegetables.

Owner:QINGDAO TIANDI CARBON

Bearing block smelting process

The invention discloses a bearing block smelting process. The bearing block smelting process includes steps of preparing hearth furnace burden comprising fire clay, quartz sand and water; filing the hearth furnace burden into a cupola furnace to produce a hearth furnace and then reserving a tuyere on the hearth furnace; increasing the internal temperature of the cupola furnace to dry the hearth furnace; making a fire in the cupola furnace and increasing the internal temperature of the cupola furnace to be 900 DEG C; charging the furnace with materials including coke, pig iron, wrought iron, scrap steel, silicon, manganese and iron; increasing the internal temperature of the cupola furnace to be 900-1200 DEG C and then smelting the materials in the cupola furnace; opening the cupola furnace to discharge molten iron at the temperature ranging from 1400 DEG C to 1450 DEG C while adding 0.6%-0.75% of copper, 0.5%-0.6% of chromium and 0.4%-0.5% of molybdenum into the molten iron; and finally pouring the molten iron into a mold cavity by a bull ladle so as to realize casting. The bearing block smelting process used for casting has the advantages of simplicity, short smelting cycle and wide applicable range.

Owner:陆宝庆

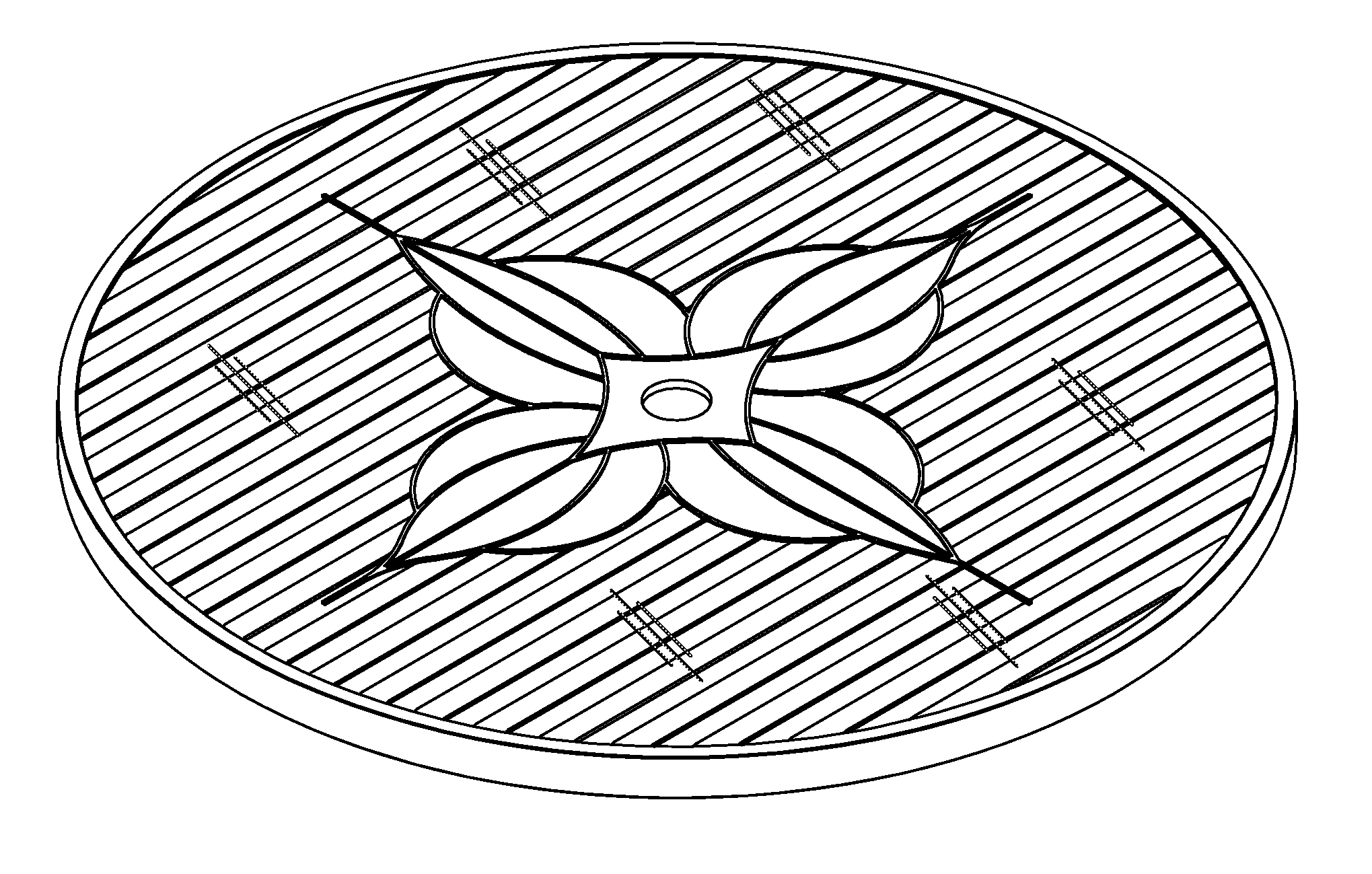

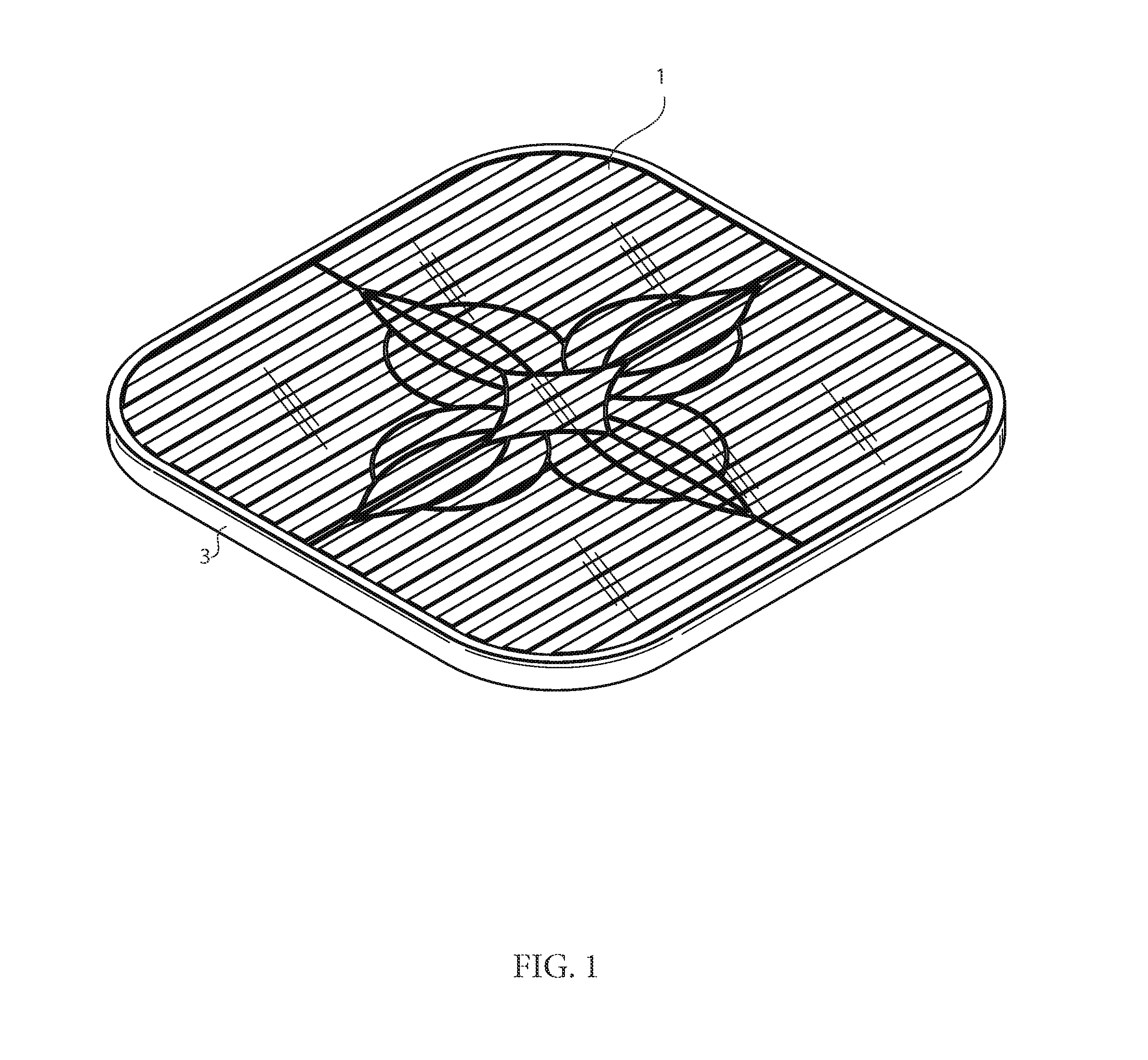

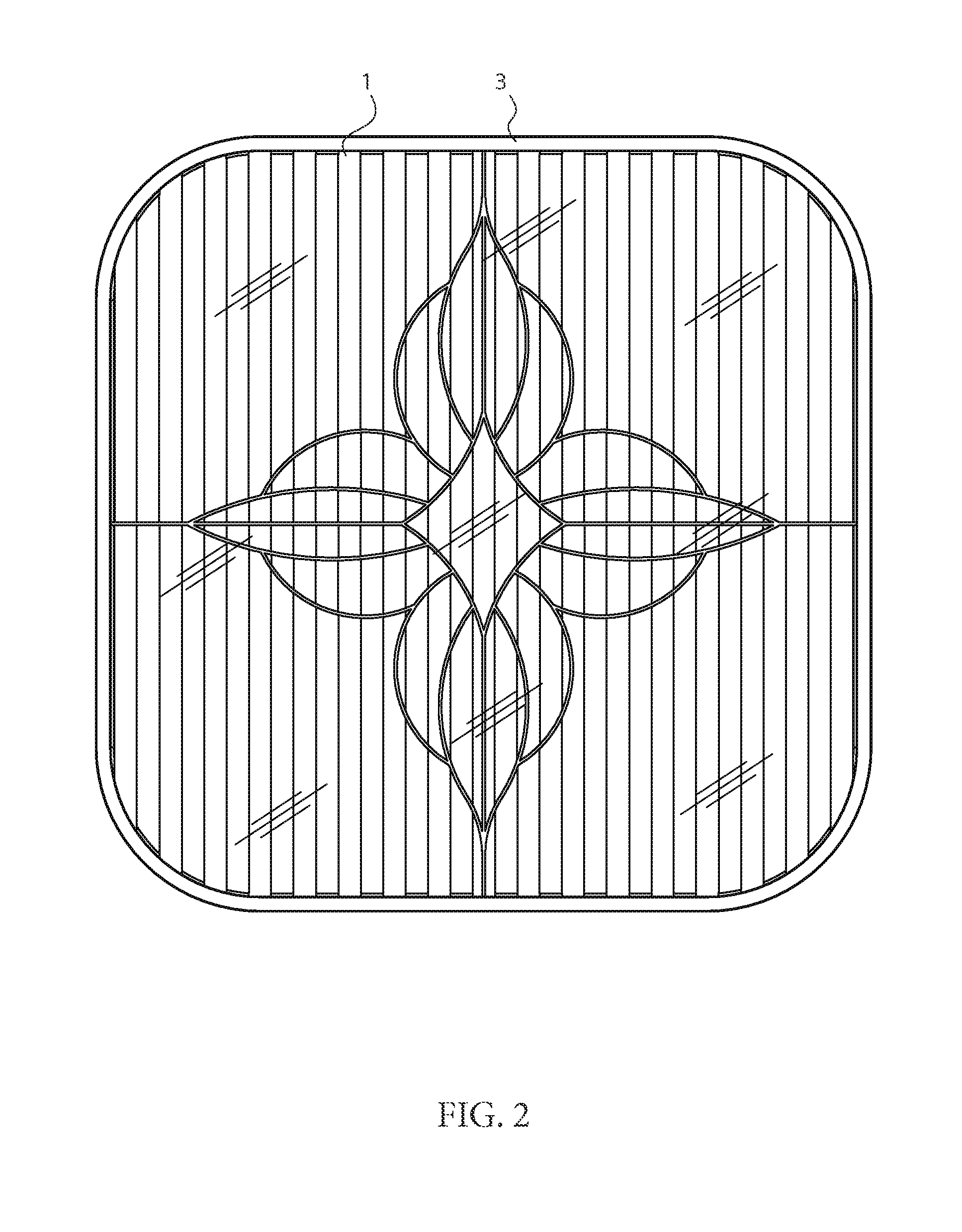

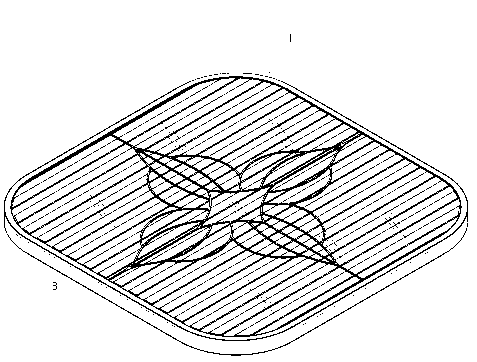

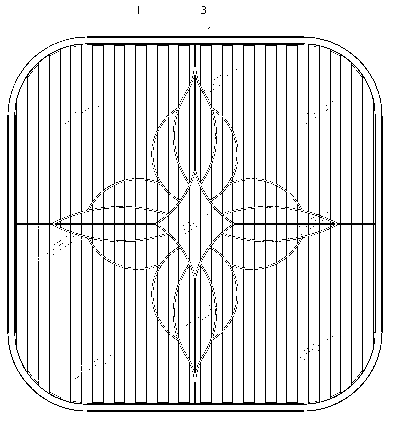

Method to Construct Masterpiece Custom Triple Pane Tabletops

A method of constructing a triple pane unit for encapsulating a decorative center piece. The center piece being a pane of leaded glass or wrought iron is encapsulated by two panes of glass. An adhesive is applied to the perimeter of the leaded glass / wrought iron for the alignment and adhering of the two panes of glass.

Owner:DEBUS JOEL P

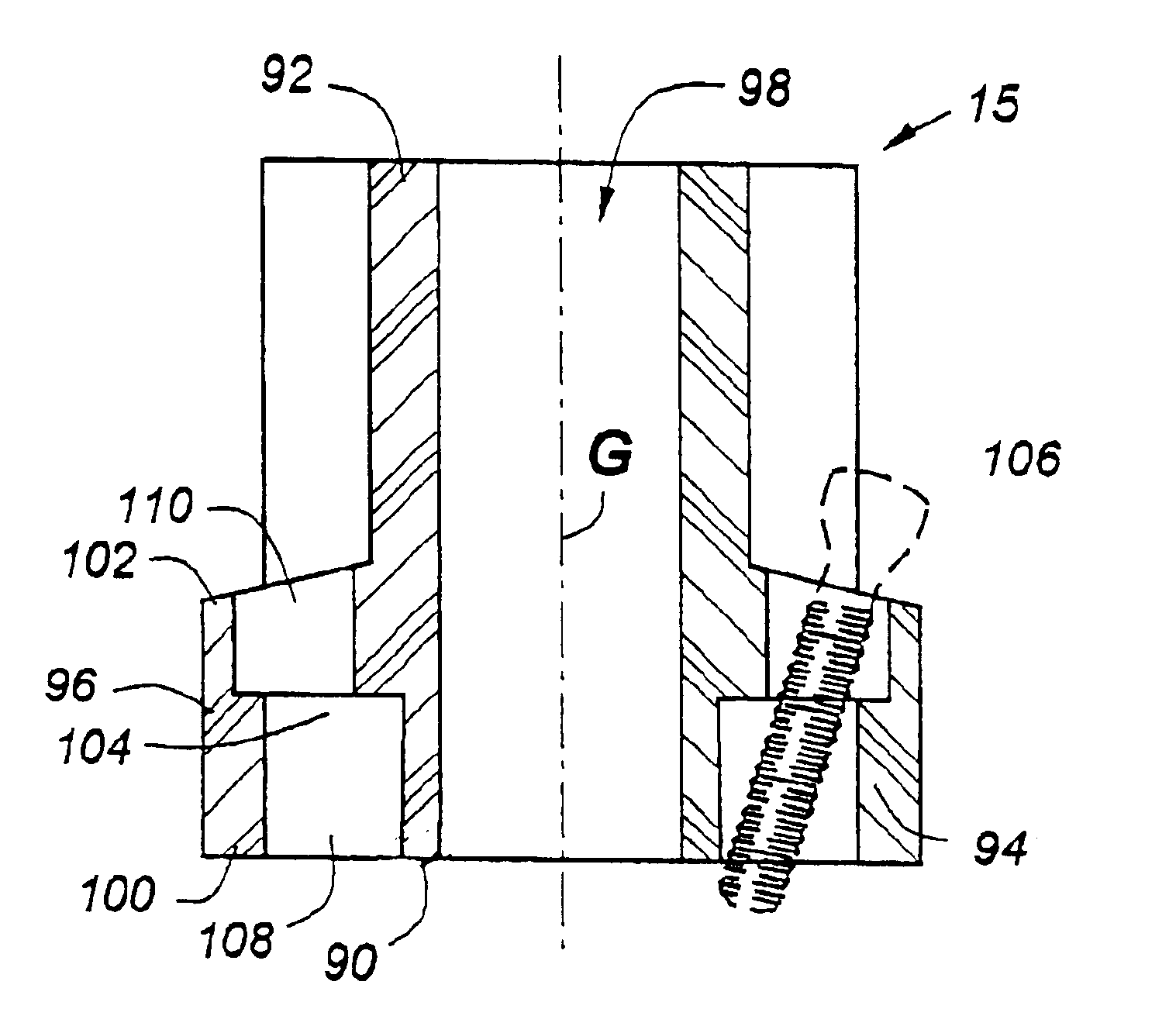

Plastic fencing simulative of wrought iron

A bracket for supporting an elongated rail with respect to a post includes a bracket body with a rail supporting portion and an attachment portion. The rail supporting portion has an opening defined therein for receiving the end of the rail when the bracket body is installed. The opening has a central axis. The attachment portion has a first surface and a second surface spaced therefrom. A fastener receiving passage is defined from the first surface to the second surface. The passage is formed by a first bore extending from the first surface part way to the second surface and a second bore extending part way from the second surface to the first surface. The first and second bores interconnect to find the passage. The central axis of the first and second bores are each generally parallel to the central axis in the opening. The axis of the first and second bores are offset with respect to one another by a distance greater than half the difference in their widths.

Owner:UNIVERSAL CONSUMER PROD

Large-tonnage jack tension construction technology for non-bonded prestressed silo

ActiveCN101597960BEven by forcePrevent rustBuilding material handlingBulk storage containerButtressNacelle

The invention discloses large-tonnage jack tension construction technology for a non-bonded prestressed silo. The invention aims to provide construction technology which uses a flat wrought iron anchor backing plate matched with an anchor device, takes a nacelle as an operation platform for tension construction, and uses a large-tonnage jack to perform cluster beam tension on prestressing tendonsto improve construction quality, reduce construction cost and shorten construction period, wherein the anchor backing plate comprises a square wrought iron anchor backing plate body; and the square wrought iron anchor backing plate body is provided with an anchor eye and a mounting hole which correspond to the anchor device. A suspension mode of the nacelle is that a conical roof is provided witha nacelle suspension embedded part, which ensures that the conical roof of the silo becomes the balance weight of the nacelle; and a suspension mode of the jack is that the top of a buttress is provided with a jack hanger embedded part; the hanger embedded part is fixedly connected with a supporting beam; the outer end part of the supporting beam is welded with a lifting ring; one end of a steel wire rope is fixedly connected with the lifting ring; while the other end hangs down to the bottom of the silo; a connecting plate is connected with the steel wire rope; and the connecting plate is connected with a jack hanger.

Owner:李延春 +2

Hand-making method for angelica keiskei health-care tea

The invention relates to a hand-making method for angelica keiskei health-care tea, which mainly comprises the following steps: (1) picking fresh angelica keiskei leaves, and washing; (2) spreading the angelica keiskei leaves on a clean bamboo dust pan, and putting at a sunshade and ventilation place for 3-5h; (3) putting into a hot cast iron pan, repeatedly turning with a tea handle, and gathering the angelica keiskei leaves with the tip of the tea handle; (4) transferring the angelica keiskei leaves into a wrought iron pan which is preheated, kneading tea leaves, and driving into strips; (5) transferring from the wrought iron pan, and primarily baking; (6) rebaking; (7) drying the angelica keiskei leaves until the moisture content is 6% below, and carrying out sterilization treatment, thus obtaining the angelica keiskei health-care tea. the made angelica keiskei tea is good in mouth feeling, has certain anti-cancer effect, antibacterial effect, the effects of inhibiting gastric acid secretion and being anti-ulcer, as well as the effects of reducing blood pressure, blood sugar, blood fat, and the like.

Owner:重庆钲铮科技有限公司

Method for manufacturing wrought iron picture

InactiveCN101791927BStrong three-dimensional senseEasy to storeSpecial ornamental structuresSpecial artistic techniquesMetallic materialsMetal sheet

The invention relates to a method for manufacturing a wrought iron picture which has the characteristics of readily available materials, simple manufacturing process, understandability and easy learning, and strong three-dimensional sense, takes a metal as a raw material, and takes a manual tool as a main drawing tool. The method comprises the following steps: drawing, namely drawing a pattern of the wrought iron picture to be manufactured on a piece of paper; tracing-off, namely magnifying the pattern and copying the pattern on a metal material by using a piece of carbon paper; cutting, namely cutting an iron material according to the pattern on the metal material; knocking, namely knocking the picture by using the manual tool according to the characteristic of the pattern to be created so that the surface of a metal sheet has the three-dimensional sense; folding, namely folding the edges of the picture by using vises so as to flatten hems and realize the three-dimension sense; finely jointing, namely performing finish machining on fine parts of the folded metal picture draft by using a tool; welding, namely welding the patterns of each part of the metal picture draft into an overall pattern; baking vanish, namely baking the vanish and spraying the vanish on the front surface and the back surface of metal picture; assembling, namely drilling holes on an aluminum plastic board in a picture frame, and fixing the metal picture by using metal wires; and mounting, namely covering the back surface of the picture frame by using a multilayer board or fixing the back surface of the picture frame with the multilayer board.

Owner:杭州余杭区柏海铁艺工作室

Grain-yellow glaze for ceramics and preparation method thereof

The invention discloses a valley yellow glaze for ceramics, which is composed of 44-47 parts of feldspar, 15-18 parts of quartz, 14-16 parts of calcite, 4-5 parts of material soil and 3-4 parts of manganese carbonate according to weight parts. 1.5-2.0 parts of wrought iron, 3-4 parts of barium carbonate, and 8-10 parts of frit. The specific method is a. Accurately weigh the above components by weight, and mix them uniformly to form a mixed solid raw material, which is calculated into the ball mill according to the ratio of ball stone: mixed solid raw material: water=2:1-1.1:0.8-0.85 Mix and ball mill to form a slurry; b. Ball mill for 11-13 hours. After the ball-milled glaze passes through a 160-mesh sieve, put it in a crucible and burn it at a temperature of 1000-1150°C. Put the burnt glaze frit into crushed machine pulverization; c, the pulverized glaze: ball stone: water = 1: 1.5: 0.5, wet ball milling for 7-9 hours, after testing the fineness of the glaze, the finished product of Guhuang glaze is obtained. The preparation and operation of the invention are simple, and the glaze surface of the prepared glutinous yellow glaze ceramic handicraft is moist and bright, and has the advantages of easy dispersion, strong tinting power, bright color, high brightness, uniform color and luster, and the like.

Owner:长沙市望城区铜官官山陶瓷有限公司

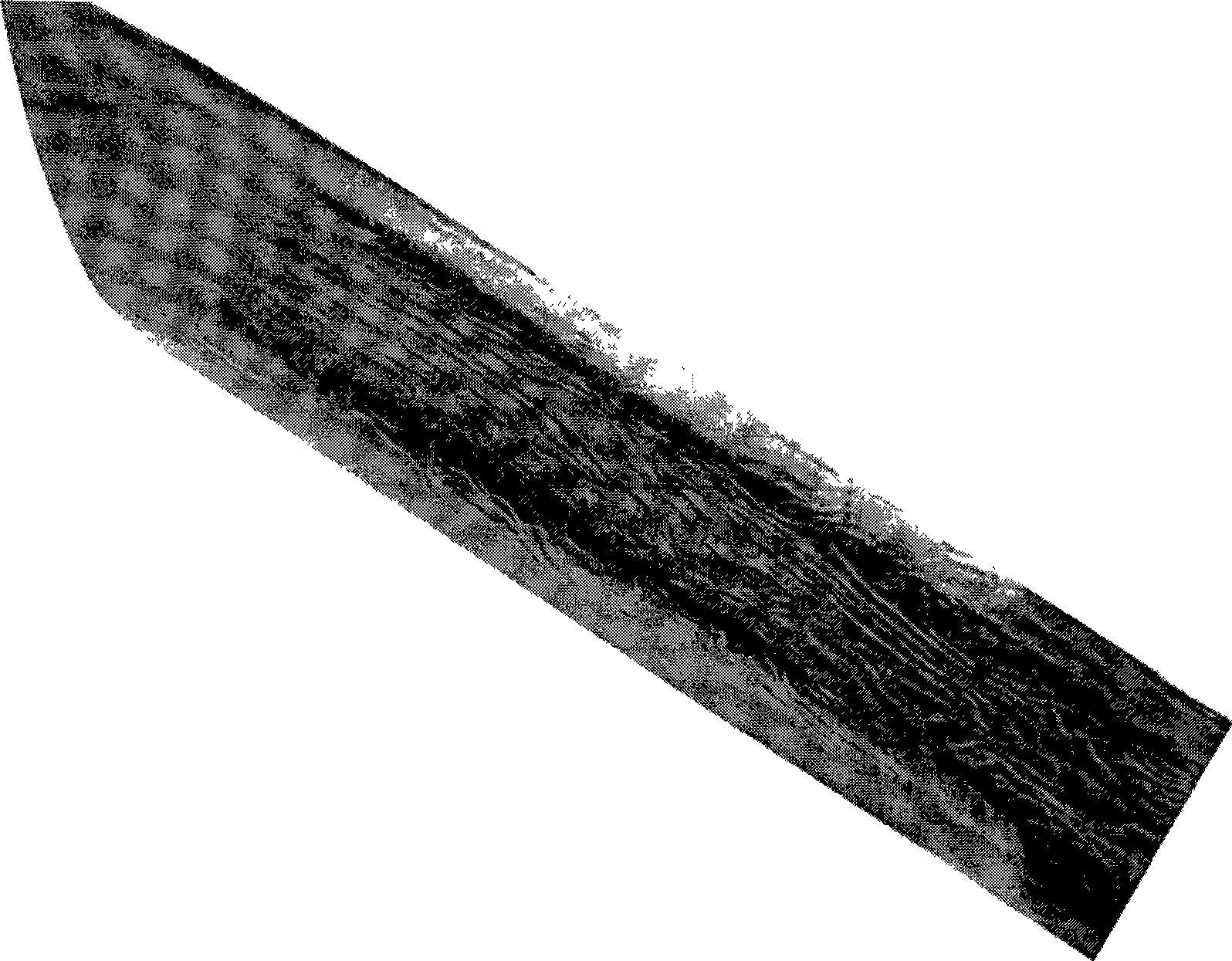

Method for casting sword from meteoric iron composite steel

The invention discloses a method for casting a sword from meteoric iron composite steel. The method includes the following steps that high-manganese steel is placed into a furnace to be heated to be melted, chromium is added to the liquid high-manganese steel, and the chromium and the liquid high-manganese steel are integrated; the mixture is taken out and placed in the ventilated place to be cooled; a long-strip-shaped iron trough is prepared from A3 iron; slicing treatment is performed on iron meteorite; materials are sequentially placed into the iron trough in the sequence from a meteoric iron block, a composite steel plate, 65 manganese to a meteoric iron block from bottom to top, and each layer of the gap is filled with wrought iron powder; the whole iron trough is placed into the furnace to be heated, and the heated iron trough is taken out and then is pressed into the sheet shape by a press machine; the skin of the A3 iron is polished away by a polishing machine; an obtained composite steel sheet is heated to go red and is taken out for folding forging; the material after folding forging is forged into the sword embryo shape; polishing treatment is performed on the sword embryo until the sword shape is formed; the sword is placed into the furnace to be heated and is taken out to be placed into rapeseed oil to be quickly cooled; the sword is taken out and placed in the ventilated place to be naturally cooled to the room temperature; and the sword is subjected to water milling until the final shape is formed.

Owner:查长伟

Slide pedestal smelting process

The invention discloses a slide pedestal smelting process. The slide pedestal smelting process includes steps of preparing hearth furnace burden comprising fire clay, quartz sand, titanium alloy and water; filling the hearth furnace burden into a medium-frequency quick smelting furnace to produce a hearth furnace and reserving a tuyere on the hearth furnace; regulating the internal temperature of the medium-frequency quick smelting furnace to be 750-800 DEG C so as to dry the hearth furnace; making a fire in the medium-frequency quick smelting furnace to enable the internal temperature of the medium-frequency quick smelting furnace to be 950-1000 DEG C; charging the hearth furnace with materials including coke, pig iron, wrought iron, high-manganese steel, silicon and iron; increasing the internal temperature of the medium-frequency quick smelting furnace to be 1800-2200 DEG C and then smelting the materials in the medium-frequency quick smelting furnace; opening the medium-frequency quick smelting furnace to discharge molten iron under the temperature ranging from 1800 DEG C to 2200 DEG C; and finally pouring the molten iron into a mold cavity by a bull ladle so as to realize casting. The slide pedestal smelting process is simple, is high in production efficiency, has no affection to alloy compositions, and can be used for smelting alloy with high smelting point.

Owner:陆宝庆

Method for manufacturing handwork flower folding knife

InactiveCN101367167ANot easy to wearSave moneyCutting toolsMetallic material coating processesPattern generationMaterials science

The invention discloses a method for producing a manual pattern knife, which relates to the decoration field. Members of minority nationality like to wear a broadsword to show the agile and brave spirit, particularly wish to imprint patterns on the surface of the broadsword. The invention is a method for carving natural patterns on the surface of the broadsword by means of a method of pressure processing and chemical action; the method comprises the following steps: a plurality of steel sheets and wrought iron sheets are overlapped at intervals and are smelted by fire at the temperature between 1, 400 and 1, 500 DEG C and glow at the temperature between 850 and 950 DEG C in a furnace, and steps of beating, folding, twisting and the like are interweaved; after the needed broadsword type is processed, the surface of the broadsword is ground, and then the pattern generation is performed in pattern generation liquid to obtain a finished product. The method has the advantages of primitive and simple patterns, difficult abrasion, local supply of raw materials, small investment, simple process, easy grasp, suitability for folk hand-making and the like.

Owner:马自正

Decorative garage door insert simulating wrought iron but made of specially coated plastic

Owner:KELLEY ROBERT A

Bargaining counter chip

InactiveCN101234253AImprove performanceReduce manufacturing costRoulette gamesIron powderAdditive ingredient

The invention provides a counter chip, which is made of materials composed of main ingredients, auxiliary materials and adhesive, the main ingredients are pig iron powders, wrought iron powders, iron ore powders or steel waste powders, the auxiliary materials are calcium carbonate, barium sulfate or barite, the adhesive is resin or glue. The counter chip can also be made of materials composed of main ingredients and adhesive or materials composed of main ingredients, auxiliary materials and pottery clay or materials composed of main ingredients, auxiliary materials, cement and wire mesh, or materials composed of main ingredients, auxiliary materials, glass powders and wire mesh. The counter chip has the good performance, and is able to save metal plate and reduce producing cost, if steel waste is used to be materials, the invention is also good for the environmental protection, the adoption of the counter chips in counters can improve the hand feeling effect when using counters and solidness of the counters.

Owner:孙旭东

Method to construct masterpiece custom triple pane tabletops

InactiveCN103120477AEasy to understand technical contentGlass/slag layered productsTablesAdhesiveEngineering

A method of constructing a triple pane unit for encapsulating a decorative center piece. The center piece being a pane of leaded glass or wrought iron is encapsulated by two panes of glass. An adhesive is applied to the perimeter of the leaded glass / wrought iron for the alignment and adhering of the two panes of glass.

Owner:乔尔 P 德布斯

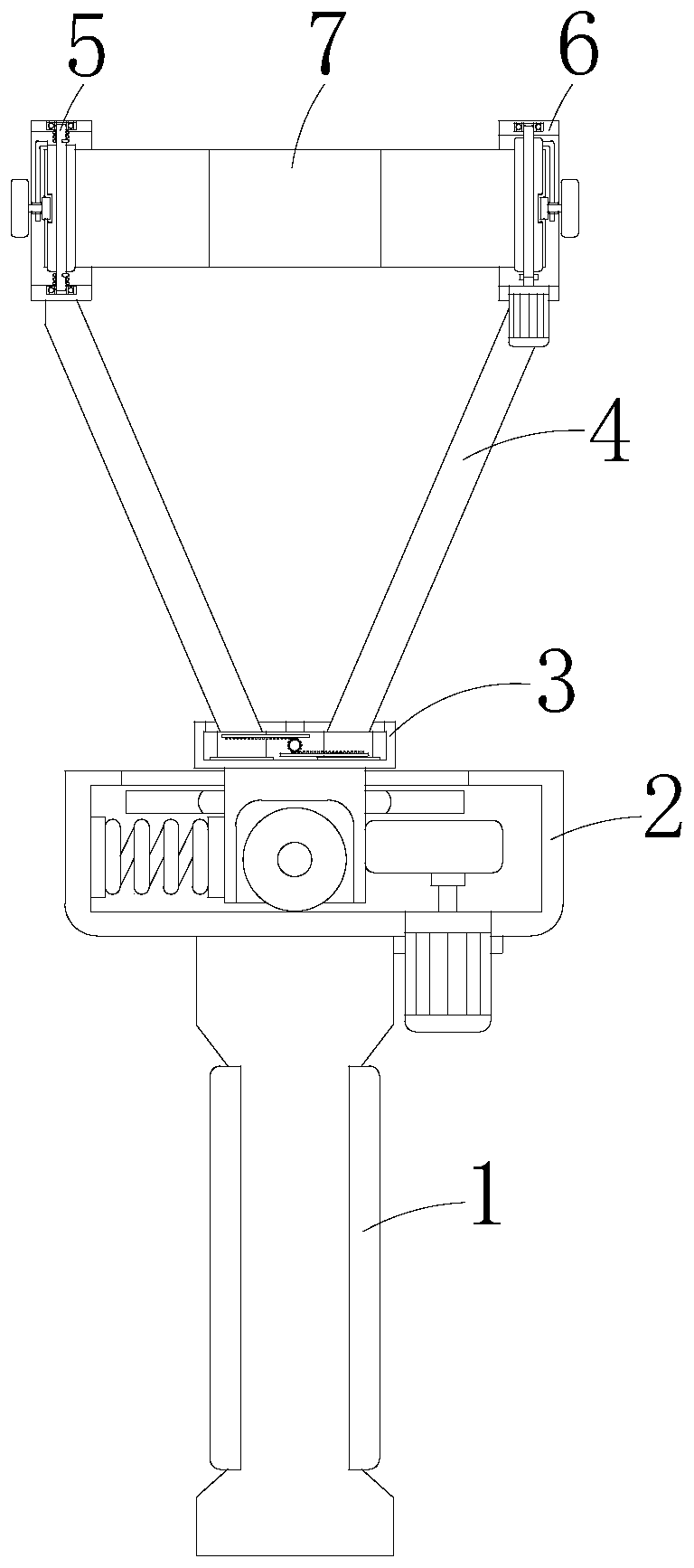

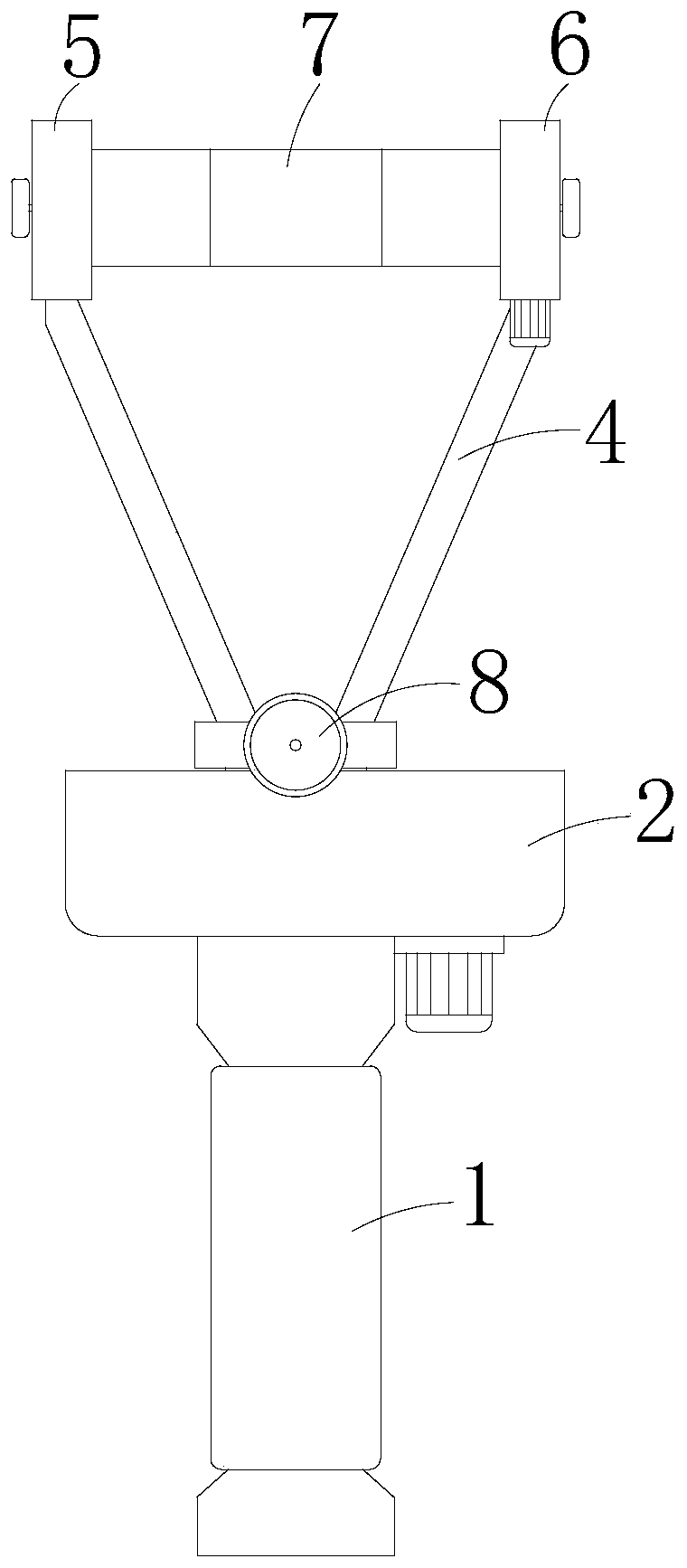

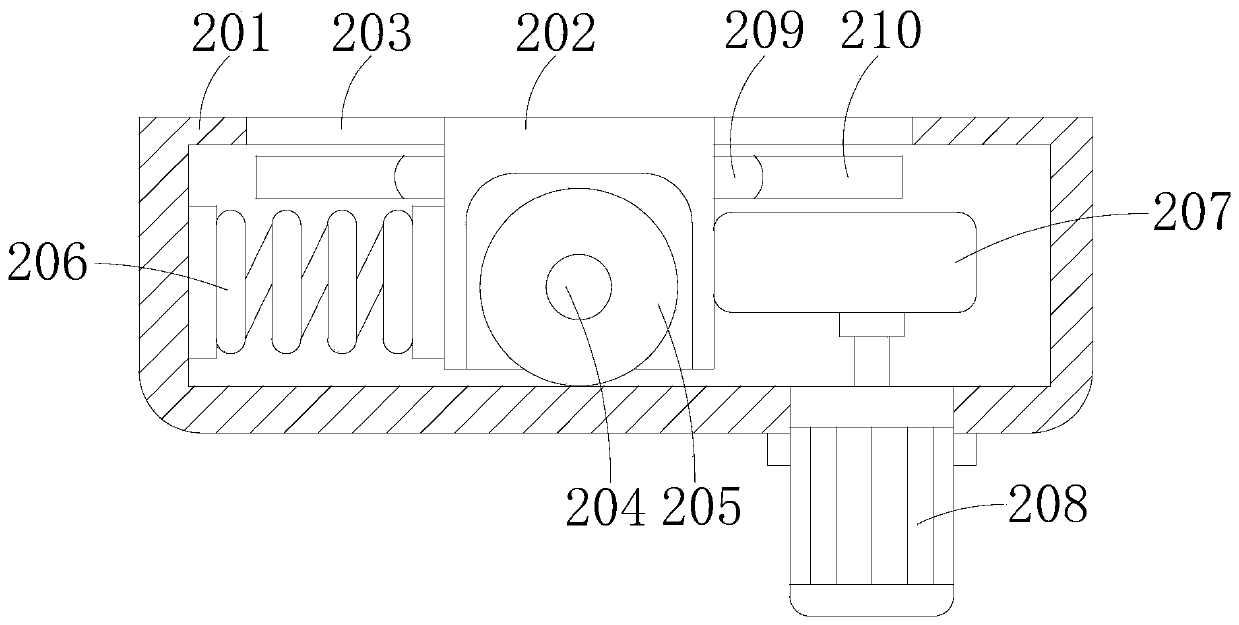

A full-angle iron anti-theft window frosting derusting device

ActiveCN110394720BEasy to holdEasy to controlGrinding machine componentsPortable grinding machinesSpecial designStructural engineering

The invention discloses a full-angle iron anti-theft window frosting and derusting device, and relates to the technical field of derusting. The full-angle iron anti-theft window frosting and derustingdevice comprises a grip, a shaking mechanism, an adjusting mechanism, two inclined rods, a first fixing mechanism, a second fixing mechanism, abrasive paper and a rotary knob. The top end of the gripis fixedly connected to the middle of the bottom of the shaking mechanism. The bottom of the adjusting mechanism is fixedly installed to the middle of the top of the shaking mechanism, the two inclined rods are symmetrically and fixedly installed inside the top of the adjusting mechanism. According to the full-angle iron anti-theft window frosting and derusting device, by arranging the first fixing mechanism and the second fixing mechanism, due to the special design of the shape of the abrasive paper, the abrasive paper can be driven to reciprocate when the second fixing mechanism is operatedfor frosting and derusting an anti-theft window, and meanwhile, due to the shape of the abrasive paper, the 180-degree part at the outer side of the anti-theft window rod body can be completely wrapped and frosted.

Owner:杭州余杭弘创物业有限公司

wok

ActiveCN109044082BReduce manufacturing costGood high temperature oxidation resistanceCooking-vessel materialsCooking vessel constructionsAl powderHigh heat

The invention relates to a cooking utensil, in particular to a frying pan. The pot body of the wok is made of graphite composite material, and the graphite composite material includes the following materials in parts by weight: 2-5 parts of glass fiber, 10-20 parts of aluminum oxide, 5-10 parts of aluminum powder, cooked 10-15 parts of iron, 3-8 parts of titanium powder, 1-5 parts of magnesium oxide, 1-5 parts of calcium carbonate, 50-80 parts of graphite. In the wok of the present invention, graphite, glass fiber, alumina, aluminum powder, titanium powder, wrought iron, magnesium oxide, calcium carbonate, etc. are mixed to make the wok, which has low preparation cost, safety and environmental protection, and has good high temperature oxidation resistance Non-toxicity, corrosion resistance and electrical insulation, which improves the service life of the wok.

Owner:NINGBO BEEFIT KITCHENWARE

High-strength lithium battery, and preparation method thereof

InactiveCN108346759AHigh strengthEasy to useFinal product manufactureJackets/cases materialsManganeseMaterials science

The invention belongs to the technical field of lithium battery, and discloses a high-strength lithium battery. The high-strength lithium battery comprises, by weight, 20 to 50 parts of carbon, 30 to50 parts of silicon, 10 to 30 parts of manganese, 10 to 15 parts of phosphorus, 20 to 30 parts of sulfur, 10 to 20 parts of chromium, 5 to 10 parts of vanadium, 5 to 15 parts of nitrogen, 3 to 5 partsof titanium, 50 to 70 parts of aluminium, and 100 to 150 parts of iron. According to the preparation method, wrought iron, aluminium, manganese, chromium, and vanadium are introduced into a melting container, and a die is adopted to prepare a lithium battery case higher in strength; the surface of the lithium battery case is sprayed with carbon powder, silicon powder, and phosphorus powder successively, so that the lithium battery electricity conductive effect is better, the strength is higher, under external force impact, lithium battery case deformation is not caused, lithium battery usingeffect is better, the obtained lithium battery is safer to use, heating or blasting is not caused, lithium battery water penetration and electric leakage are prevented effectively, the lithium batteryservice life is prolonged, and the using effect is better.

Owner:JIANGSU HAIDESEN ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com